1

/

von

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

SH/T 0305-1993 English PDF (SHT0305-1993)

SH/T 0305-1993 English PDF (SHT0305-1993)

Normaler Preis

$70.00 USD

Normaler Preis

Verkaufspreis

$70.00 USD

Grundpreis

/

pro

Versand wird beim Checkout berechnet

Verfügbarkeit für Abholungen konnte nicht geladen werden

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click SH/T 0305-1993

Historical versions: SH/T 0305-1993

Preview True-PDF (Reload/Scroll if blank)

SH/T 0305-1993: Determination method for the seal compatibility index of petroleum products

SH/T 0305-93

SH

Petrochemical Industry Standard

of the People’s Republic of China

Replacing SH/T 0305-92

Determination method for the seal compatibility index

of petroleum products

APPROVED ON. JUNE 11, 1993

IMPLEMENTED ON. MAY 1, 1994

Approved by. China Petrochemical Corporation (Sinopec Group).

Table of Contents

1 Subject content and application scope ... 3

2 Reference standard ... 3

3 Definition ... 3

4 Method summary ... 3

5 Apparatuses and material... 3

6 Reagent ... 5

7 Test procedures ... 5

8 Calculation ... 6

9 Precision... 8

10 Report ... 9

Additional information... 9

Determination method for the seal compatibility

index of petroleum products

1 Subject content and application scope

This Standard specifies the determination method for the seal compatibility

index of petroleum products.

This Standard applies to petroleum products, excluding the ones containing

water.

2 Reference standard

GB/T 528 Determination of the tensile properties of vulcanized rubber

GB/T 531 Rubber – Determination of Shore A hardness

3 Definition

Seal compatibility index (SCI). It refers to the percentage of volume expansion

that is converted from the diameter expansion of the standard nitrile rubber ring

in the test sample, under the specified test conditions.

4 Method summary

USE a taper gauge to measure the inner diameter of the rubber ring. SOAK the

rubber ring in the test sample at 100°C for 24h. TAKE it out for cooling. USE a

taper gauge to measure the inner diameter change rate of the rubber ring in

unit of the percentage of volume expansion.

5 Apparatuses and material

5.1 Apparatuses

5.1.1 Rubber ring. The rubber rings refer to the square cross-section rings made

from processed nitrile rubber. The inner diameter is 25 ± 0.25mm. The side

length of the square cross section is 1.5 ± 0.15mm.

7.3 PUT a rubber ring in the cooling oil at room temperature. SOAK for 15min.

7.4 USE a bamboo tweezer to take out the soaked rubber ring. PUT it on the

filter paper, so as to drain the oil slick on the surface of the rubber ring. AVOID

stretching or twisting the rubber ring.

7.5 Gently PUT the rubber ring on the taper gauge, so as to measure the inner

diameter of the rubber ring. PLACE the side with less burrs face down on the

taper gauge. During the measurement, USE one hand to gently touch the

rubber ring. USE the other hand to rotate the taper gauge, so as to keep the

rubber ring on the horizon. PAY special attention to avoid stretching the rubber

ring. Furthermore, MAKE sure that there is no visible gap between the rubber

ring and the taper gauge by observation. OBSERVE the lower edge of the

rubber ring. READ out the dimension of inner diameter D1, accurate to 0.025mm

(1/4 scale).

7.6 PUT the rubber ring into the test oil after the measurement. It is only

allowable to put one rubber ring into each wide-mouth bottle. SHAKE the wide-

mouth bottle, so as to totally soak the rubber ring into the test oil. COVER the

lid. PUT the wide-mouth bottle in the drying oven preheated to 100 ± 2°C

immediately. KEEP the drying oven at constant temperature for 24h.

7.7 After keeping at constant temperature for 24h, TAKE out the wide-mouth

bottle from the drying oven. USE the bamboo tweezer cleaned with petroleum

ether to take out the rubber ring. PUT the rubber ring into the cooling oil

immediately. COVER the lid. COOL for 45 ± 15min.

7.8 MEASURE according to the steps specified in the Articles 7.4 and 7.5.

READ out the inner diameter dimension of the expanded rubber ring D2,

accurate to 0.025mm (1/4 scale). The expanded rubber ring is extremely easy

to deform. PAY special attention to avoid stretching or twisting the rubber ring

during the measurement.

Note. The overall test procedures must be conducted by the same person.

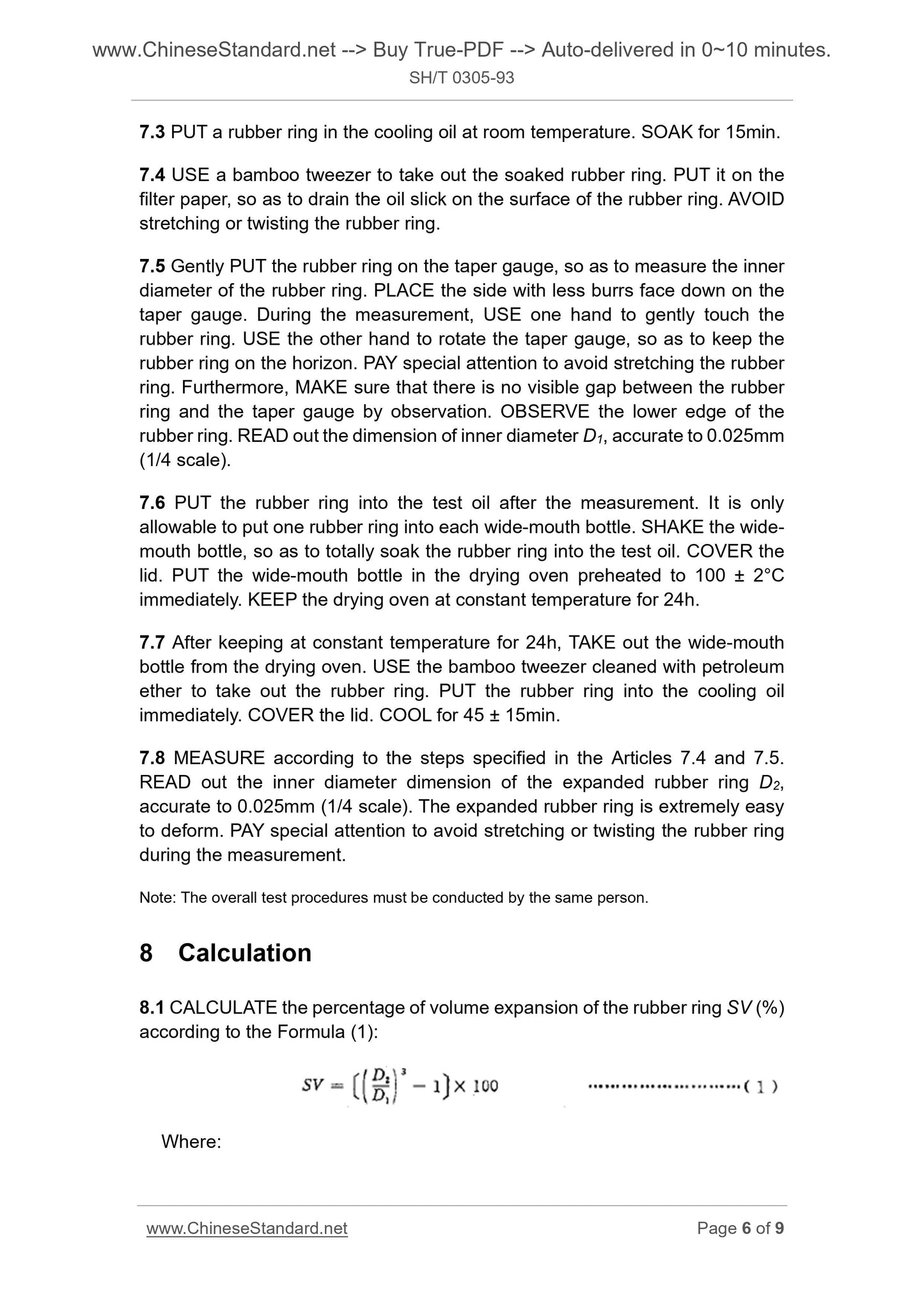

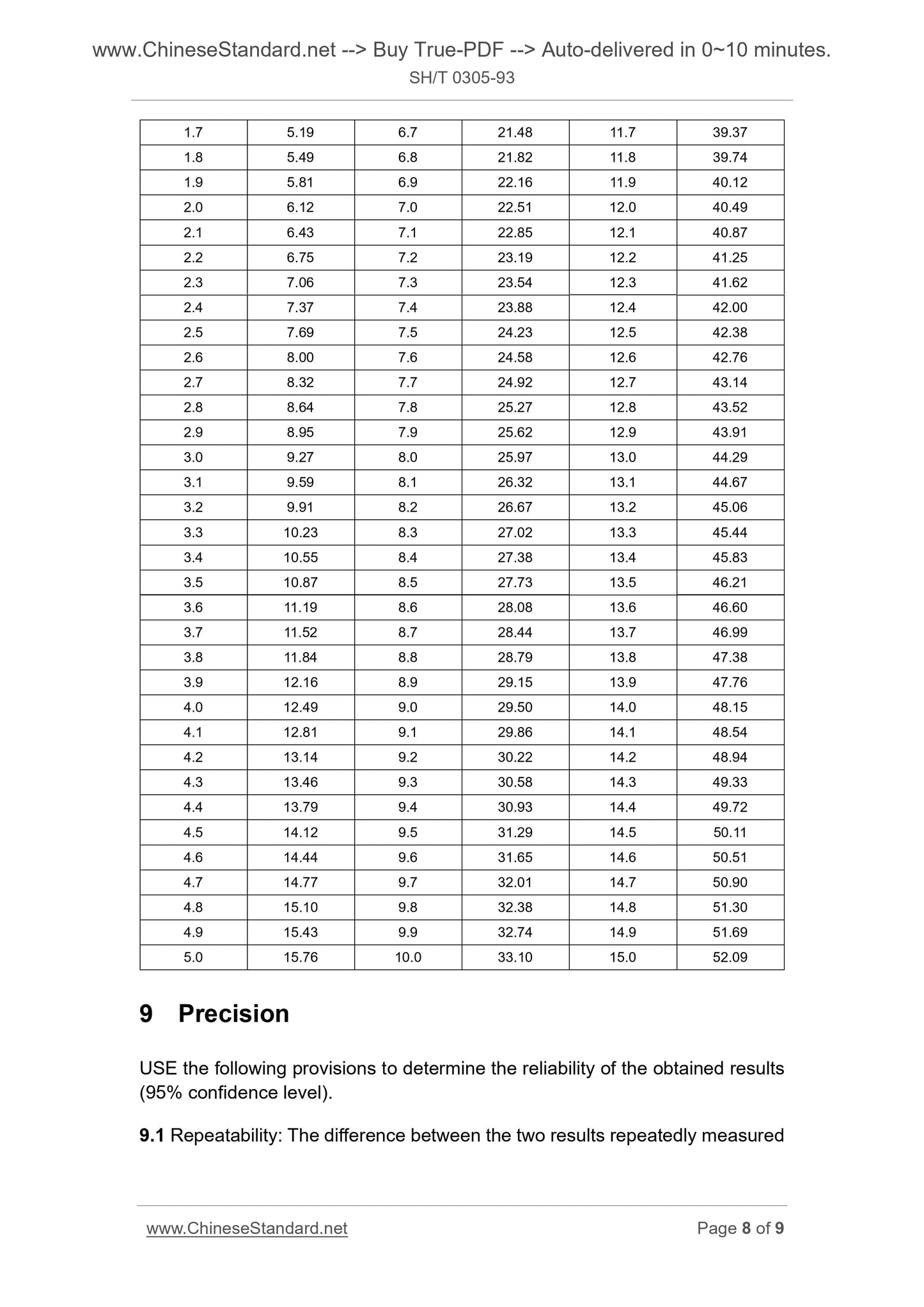

8 Calculation

8.1 CALCULATE the percentage of volume expansion of the rubber ring SV (%)

according to the Formula (1).

Where.

1.7 5.19 6.7 21.48 11.7 39.37

1.8 5.49 6.8 21.82 11.8 39.74

1.9 5.81 6.9 22.16 11.9 40.12

2.0 6.12 7.0 22.51 12.0 40.49

2.1 6.43 7.1 22.85 12.1 40.87

2.2 6.75 7.2 23.19 12.2 41.25

2.3 7.06 7.3 23.54 12.3 41.62

2.4 7.37 7.4 23.88 12.4 42.00

2.5 7.69 7.5 24.23 12.5 42.38

2.6 8.00 7.6 24.58 12.6 42.76

2.7 8.32 7.7 24.92 12.7 43.14

2.8 8.64 7.8 25.27 12.8 43.52

2.9 8.95 7.9 25.62 12.9 43.91

3.0 9.27 8.0 25.97 13.0 44.29

3.1 9.59 8.1 26.32 13.1 44.67

3.2 9.91 8.2 26.67 13.2 45.06

3.3 10.23 8.3 27.02 13.3 45.44

3.4 10.55 8.4 27.38 13.4 45.83

3.5 10.87 8.5 27.73 13.5 46.21

3.6 11.19 8.6 28.08 13.6 46.60

3.7 11.52 8.7 28.44 13.7 46.99

3.8 11.84 8.8 28.79 13.8 47.38

3.9 12.16 8.9 29.15 13.9 47.76

4.0 12.49 9.0 29.50 14.0 48.15

4.1 12.81 9.1 29.86 14.1 48.54

4.2 13.14 9.2 30.22 14.2 48.94

4.3 13.46 9.3 30.58 14.3 49.33

4.4 13.79 9.4 30.93 14.4 49.72

4.5 14.12 9.5 31.29 14.5 50.11

4.6 14.44 9.6 31.65 14.6 50.51

4.7 14.77 9.7 32.01 14.7 50.90

4.8 15.10 9.8 32.38 14.8 51.30

4.9 15.43 9.9 32.74 14.9 51.69

5.0 15.76 10.0 33.10 15.0 52.09

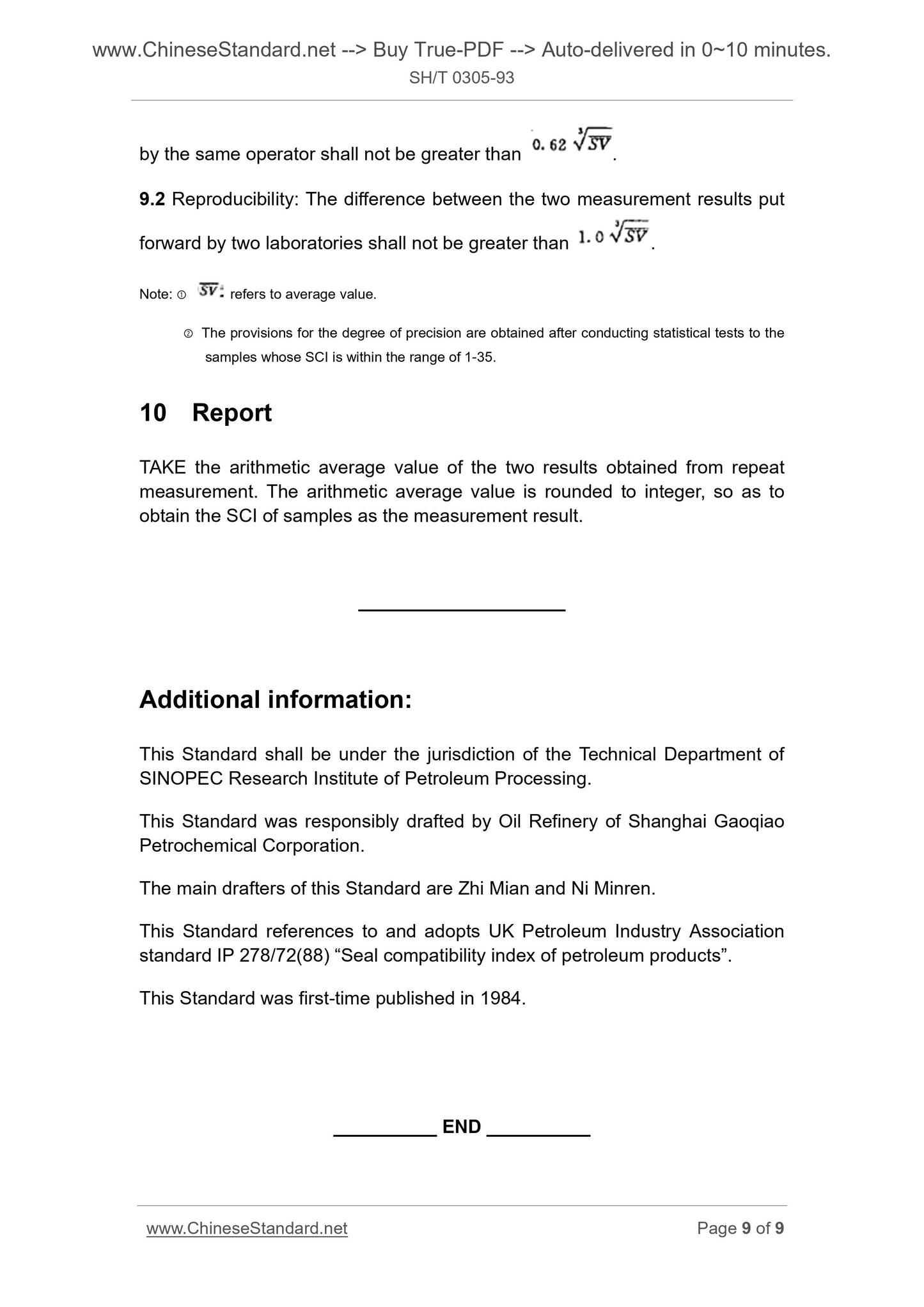

9 Precision

USE the following provisions to determine the reliability of the obtained results

(95% confidence level).

9.1 Repeatability. The difference between the two results repeatedly measured

by the same operator shall not be greater than .

9.2 Reproducibility. The difference between the two measurement results put

forward by two laboratories shall not be greater than .

①Note. refers to average value.

② The provisions for the degree of precision are obtained after conducting statistical tests to the

samples whose SCI is within the range of 1-35.

10 Report

TAKE the arithmetic average value of the two results obtained from repeat

measurement. The arithmetic average value is rounded to integer, so as to

obtain the SCI of samples as the measurement result.

Additional information.

This Standard shall be under the jurisdiction of the Technical Department of

SINOPEC Research Institute of Petroleum Processing.

This Standard was responsibly drafted by Oil Refinery of Shanghai Gaoqiao

Petrochemical Corporation.

The main drafters of this Standard are Zhi Mian and Ni Minren.

This Standard references to and adopts UK Petroleum Industry Association

standard IP 278/72(88) “Seal compatibility index of petroleum products”.

This Standard was first-time published in 1984.

Get QUOTATION in 1-minute: Click SH/T 0305-1993

Historical versions: SH/T 0305-1993

Preview True-PDF (Reload/Scroll if blank)

SH/T 0305-1993: Determination method for the seal compatibility index of petroleum products

SH/T 0305-93

SH

Petrochemical Industry Standard

of the People’s Republic of China

Replacing SH/T 0305-92

Determination method for the seal compatibility index

of petroleum products

APPROVED ON. JUNE 11, 1993

IMPLEMENTED ON. MAY 1, 1994

Approved by. China Petrochemical Corporation (Sinopec Group).

Table of Contents

1 Subject content and application scope ... 3

2 Reference standard ... 3

3 Definition ... 3

4 Method summary ... 3

5 Apparatuses and material... 3

6 Reagent ... 5

7 Test procedures ... 5

8 Calculation ... 6

9 Precision... 8

10 Report ... 9

Additional information... 9

Determination method for the seal compatibility

index of petroleum products

1 Subject content and application scope

This Standard specifies the determination method for the seal compatibility

index of petroleum products.

This Standard applies to petroleum products, excluding the ones containing

water.

2 Reference standard

GB/T 528 Determination of the tensile properties of vulcanized rubber

GB/T 531 Rubber – Determination of Shore A hardness

3 Definition

Seal compatibility index (SCI). It refers to the percentage of volume expansion

that is converted from the diameter expansion of the standard nitrile rubber ring

in the test sample, under the specified test conditions.

4 Method summary

USE a taper gauge to measure the inner diameter of the rubber ring. SOAK the

rubber ring in the test sample at 100°C for 24h. TAKE it out for cooling. USE a

taper gauge to measure the inner diameter change rate of the rubber ring in

unit of the percentage of volume expansion.

5 Apparatuses and material

5.1 Apparatuses

5.1.1 Rubber ring. The rubber rings refer to the square cross-section rings made

from processed nitrile rubber. The inner diameter is 25 ± 0.25mm. The side

length of the square cross section is 1.5 ± 0.15mm.

7.3 PUT a rubber ring in the cooling oil at room temperature. SOAK for 15min.

7.4 USE a bamboo tweezer to take out the soaked rubber ring. PUT it on the

filter paper, so as to drain the oil slick on the surface of the rubber ring. AVOID

stretching or twisting the rubber ring.

7.5 Gently PUT the rubber ring on the taper gauge, so as to measure the inner

diameter of the rubber ring. PLACE the side with less burrs face down on the

taper gauge. During the measurement, USE one hand to gently touch the

rubber ring. USE the other hand to rotate the taper gauge, so as to keep the

rubber ring on the horizon. PAY special attention to avoid stretching the rubber

ring. Furthermore, MAKE sure that there is no visible gap between the rubber

ring and the taper gauge by observation. OBSERVE the lower edge of the

rubber ring. READ out the dimension of inner diameter D1, accurate to 0.025mm

(1/4 scale).

7.6 PUT the rubber ring into the test oil after the measurement. It is only

allowable to put one rubber ring into each wide-mouth bottle. SHAKE the wide-

mouth bottle, so as to totally soak the rubber ring into the test oil. COVER the

lid. PUT the wide-mouth bottle in the drying oven preheated to 100 ± 2°C

immediately. KEEP the drying oven at constant temperature for 24h.

7.7 After keeping at constant temperature for 24h, TAKE out the wide-mouth

bottle from the drying oven. USE the bamboo tweezer cleaned with petroleum

ether to take out the rubber ring. PUT the rubber ring into the cooling oil

immediately. COVER the lid. COOL for 45 ± 15min.

7.8 MEASURE according to the steps specified in the Articles 7.4 and 7.5.

READ out the inner diameter dimension of the expanded rubber ring D2,

accurate to 0.025mm (1/4 scale). The expanded rubber ring is extremely easy

to deform. PAY special attention to avoid stretching or twisting the rubber ring

during the measurement.

Note. The overall test procedures must be conducted by the same person.

8 Calculation

8.1 CALCULATE the percentage of volume expansion of the rubber ring SV (%)

according to the Formula (1).

Where.

1.7 5.19 6.7 21.48 11.7 39.37

1.8 5.49 6.8 21.82 11.8 39.74

1.9 5.81 6.9 22.16 11.9 40.12

2.0 6.12 7.0 22.51 12.0 40.49

2.1 6.43 7.1 22.85 12.1 40.87

2.2 6.75 7.2 23.19 12.2 41.25

2.3 7.06 7.3 23.54 12.3 41.62

2.4 7.37 7.4 23.88 12.4 42.00

2.5 7.69 7.5 24.23 12.5 42.38

2.6 8.00 7.6 24.58 12.6 42.76

2.7 8.32 7.7 24.92 12.7 43.14

2.8 8.64 7.8 25.27 12.8 43.52

2.9 8.95 7.9 25.62 12.9 43.91

3.0 9.27 8.0 25.97 13.0 44.29

3.1 9.59 8.1 26.32 13.1 44.67

3.2 9.91 8.2 26.67 13.2 45.06

3.3 10.23 8.3 27.02 13.3 45.44

3.4 10.55 8.4 27.38 13.4 45.83

3.5 10.87 8.5 27.73 13.5 46.21

3.6 11.19 8.6 28.08 13.6 46.60

3.7 11.52 8.7 28.44 13.7 46.99

3.8 11.84 8.8 28.79 13.8 47.38

3.9 12.16 8.9 29.15 13.9 47.76

4.0 12.49 9.0 29.50 14.0 48.15

4.1 12.81 9.1 29.86 14.1 48.54

4.2 13.14 9.2 30.22 14.2 48.94

4.3 13.46 9.3 30.58 14.3 49.33

4.4 13.79 9.4 30.93 14.4 49.72

4.5 14.12 9.5 31.29 14.5 50.11

4.6 14.44 9.6 31.65 14.6 50.51

4.7 14.77 9.7 32.01 14.7 50.90

4.8 15.10 9.8 32.38 14.8 51.30

4.9 15.43 9.9 32.74 14.9 51.69

5.0 15.76 10.0 33.10 15.0 52.09

9 Precision

USE the following provisions to determine the reliability of the obtained results

(95% confidence level).

9.1 Repeatability. The difference between the two results repeatedly measured

by the same operator shall not be greater than .

9.2 Reproducibility. The difference between the two measurement results put

forward by two laboratories shall not be greater than .

①Note. refers to average value.

② The provisions for the degree of precision are obtained after conducting statistical tests to the

samples whose SCI is within the range of 1-35.

10 Report

TAKE the arithmetic average value of the two results obtained from repeat

measurement. The arithmetic average value is rounded to integer, so as to

obtain the SCI of samples as the measurement result.

Additional information.

This Standard shall be under the jurisdiction of the Technical Department of

SINOPEC Research Institute of Petroleum Processing.

This Standard was responsibly drafted by Oil Refinery of Shanghai Gaoqiao

Petrochemical Corporation.

The main drafters of this Standard are Zhi Mian and Ni Minren.

This Standard references to and adopts UK Petroleum Industry Association

standard IP 278/72(88) “Seal compatibility index of petroleum products”.

This Standard was first-time published in 1984.

Share