1

/

από

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 662-2013 English PDF (QCT662-2013)

QC/T 662-2013 English PDF (QCT662-2013)

Κανονική τιμή

$105.00 USD

Κανονική τιμή

Τιμή έκπτωσης

$105.00 USD

Τιμή μονάδας

/

ανά

Τα έξοδα αποστολής υπολογίζονται κατά την ολοκλήρωση της αγοράς.

Δεν ήταν δυνατή η φόρτωση της διαθεσιμότητας παραλαβής

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 662-2013

Historical versions: QC/T 662-2013

Preview True-PDF (Reload/Scroll if blank)

QC/T 662-2013: Vehicle air conditioner (HFC-134a) receiver dryer

QC/T 662-2013

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.60

T 26

Replacing QC/T 662-2000

Vehicle air conditioner (HFC-134a) receiver dryer

ISSUED ON: OCTOBER 17, 2013

IMPLEMENTED ON: MARCH 01, 2014

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 8

2 Normative references ... 8

3 Terms and definitions ... 8

4 Technical requirements ... 9

5 Test method ... 11

6 Inspection rules ... 15

7 Marking, packaging, transportation and storage ... 16

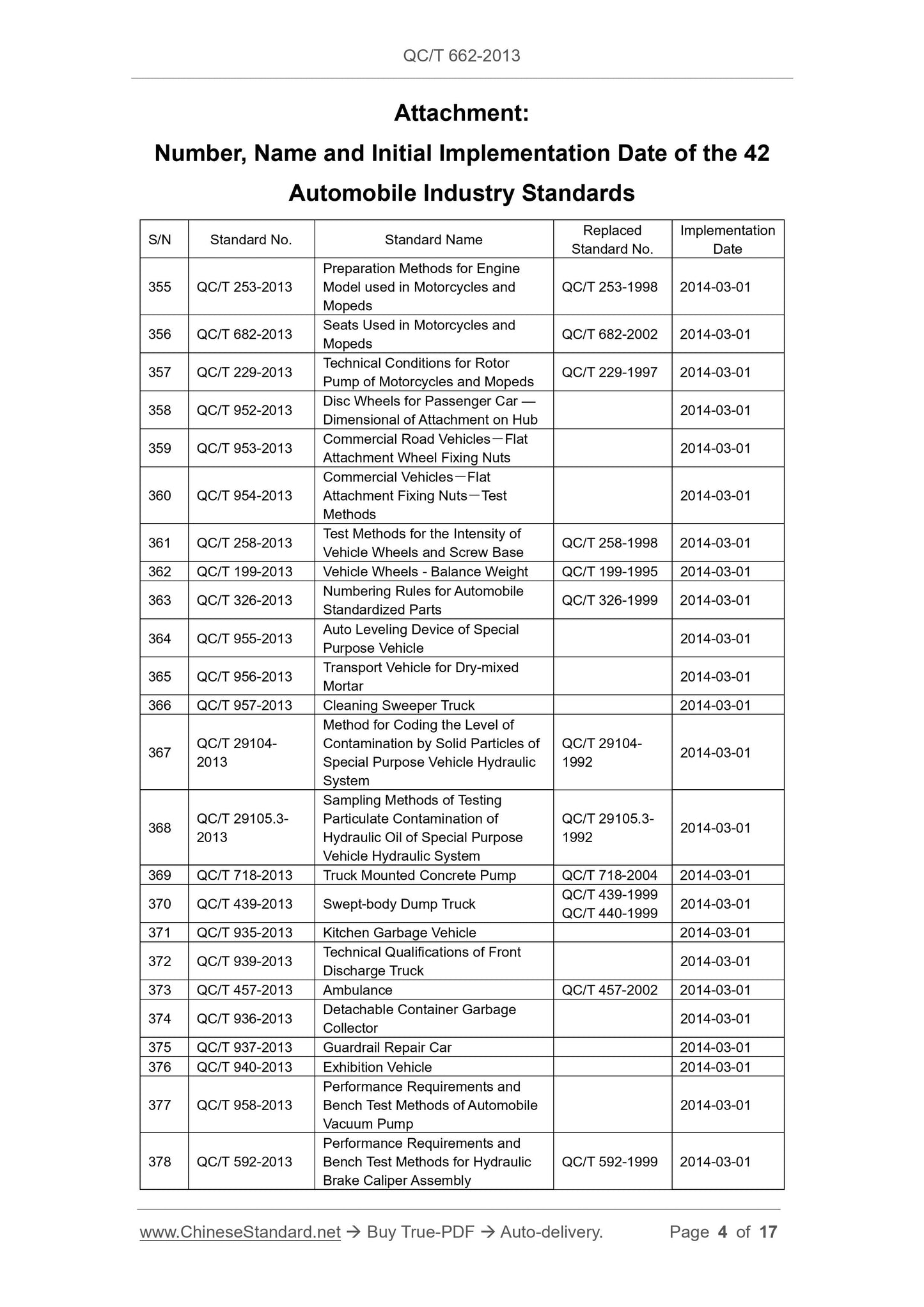

Attachment:

Number, Name and Initial Implementation Date of the 42

Automobile Industry Standards

S/N Standard No. Standard Name Replaced Standard No.

Implementation

Date

355 QC/T 253-2013

Preparation Methods for Engine

Model used in Motorcycles and

Mopeds

QC/T 253-1998 2014-03-01

356 QC/T 682-2013 Seats Used in Motorcycles and Mopeds QC/T 682-2002 2014-03-01

357 QC/T 229-2013 Technical Conditions for Rotor Pump of Motorcycles and Mopeds QC/T 229-1997 2014-03-01

358 QC/T 952-2013 Disc Wheels for Passenger Car — Dimensional of Attachment on Hub 2014-03-01

359 QC/T 953-2013 Commercial Road Vehicles-Flat Attachment Wheel Fixing Nuts 2014-03-01

360 QC/T 954-2013

Commercial Vehicles-Flat

Attachment Fixing Nuts-Test

Methods

2014-03-01

361 QC/T 258-2013 Test Methods for the Intensity of Vehicle Wheels and Screw Base QC/T 258-1998 2014-03-01

362 QC/T 199-2013 Vehicle Wheels - Balance Weight QC/T 199-1995 2014-03-01

363 QC/T 326-2013 Numbering Rules for Automobile Standardized Parts QC/T 326-1999 2014-03-01

364 QC/T 955-2013 Auto Leveling Device of Special Purpose Vehicle 2014-03-01

365 QC/T 956-2013 Transport Vehicle for Dry-mixed Mortar 2014-03-01

366 QC/T 957-2013 Cleaning Sweeper Truck 2014-03-01

367 QC/T 29104-2013

Method for Coding the Level of

Contamination by Solid Particles of

Special Purpose Vehicle Hydraulic

System

QC/T 29104-

1992 2014-03-01

368 QC/T 29105.3-2013

Sampling Methods of Testing

Particulate Contamination of

Hydraulic Oil of Special Purpose

Vehicle Hydraulic System

QC/T 29105.3-

1992 2014-03-01

369 QC/T 718-2013 Truck Mounted Concrete Pump QC/T 718-2004 2014-03-01

370 QC/T 439-2013 Swept-body Dump Truck QC/T 439-1999 QC/T 440-1999 2014-03-01

371 QC/T 935-2013 Kitchen Garbage Vehicle 2014-03-01

372 QC/T 939-2013 Technical Qualifications of Front Discharge Truck 2014-03-01

373 QC/T 457-2013 Ambulance QC/T 457-2002 2014-03-01

374 QC/T 936-2013 Detachable Container Garbage Collector 2014-03-01

375 QC/T 937-2013 Guardrail Repair Car 2014-03-01

376 QC/T 940-2013 Exhibition Vehicle 2014-03-01

377 QC/T 958-2013

Performance Requirements and

Bench Test Methods of Automobile

Vacuum Pump

2014-03-01

378 QC/T 592-2013

Performance Requirements and

Bench Test Methods for Hydraulic

Brake Caliper Assembly

QC/T 592-1999 2014-03-01

Vehicle air conditioner (HFC-134a) receiver dryer

1 Scope

This standard specifies the technical requirements, test methods, inspection

rules, markings, packaging, transportation and storage of vehicle air conditioner

(HFC-134a) receiver dryer (hereinafter referred to as receiver dryers).

This standard is applicable to vehicle air conditioner receiver dryer with HFC-

134a as the refrigerant, working pressure at 0 ~ 2.5 MPa, effective internal

volume less than 1000 mL.

2 Normative references

The clauses contained in the following standards constitute the clauses of this

standard through quotation in this standard. When this standard is published,

all editions are valid. All standards will be revised, and all parties using this

standard shall explore the possibility of using the latest version of the following

standards.

GB/T 191-2008 Packaging - Pictorial marking for handling of goods

GB/T 6287-1986 Determination of static adsorbed water for molecular sieve

GB/T 10125-1997 Corrosion tests in artificial atmospheres-Salt spray tests

3 Terms and definitions

The terms and definitions apply to this standard.

3.1

Receiver dryer

The receiver dryer is a device with drying and filtering functions, used to

absorb residual moisture in the refrigeration system, filter residual impurities,

store high-pressure liquid refrigerant.

3.2

Desiccant

The solid adsorbent used to adsorb residual moisture. In the refrigeration

4.3 Pressure resistance

When tested according to 5.4 of this standard, after the receiver dryer is tested

under a pressure of 5.3 MPa, there shall be no leakage or obvious deformation,

meanwhile it shall not be broken under a pressure of 10.5 MPa.

4.4 Cleanliness

When tested according to 5.5 of this standard, the internal impurity content shall

not exceed 15 mg; the maximum solid impurity size shall not exceed 350 µm.

4.5 Drying performance

4.5.1 When tested according to 5.6.1 of this standard, the water capacity of the

desiccant is not less than 15%

4.5.2 When tested according to 5.6.2 of this standard, the residual moisture of

the desiccant is not more than 2.5%.

4.6 Pressure loss

When tested according to 5.7 of this standard, the pressure difference between

inlet and outlet shall meet the design requirements, generally not more than 20

kPa.

4.7 High temperature resistance

After the test in accordance with 5.8 of this standard, there shall be no abnormal

deformation or damage in appearance; it shall meet the requirements of 4.2;

the internal parts shall not be damaged.

4.8 Low temperature resistance

After testing in accordance with 5.9 of this standard, there shall be no abnormal

deformation or damage in appearance; it shall meet the requirements of 4.2;

the internal parts shall not be damaged.

4.9 Resistance to cyclic temperature change

After the test in accordance with 5.10 of this standard, there shall be no

abnormal deformation or damage in appearance; it shall meet the requirements

of 4.2; the internal parts shall not be damaged.

4.10 Vibration resistance

After the test in accordance with 5.11 of this standard, there shall be no

abnormal deformation or damage in appearance; it shall meet the requirements

of 4.2; the internal parts shall not be damaged.

5.1.6 The accuracy of the leak detector is not less than 0.5 g/a.

5.2 Appearance quality and external dimension inspection

Visual inspection of the appearance quality shall meet the requirements of 4.1

of this standard.

5.3 Air tightness test

Choose at least one of the following test methods.

5.3.1 Room temperature is 20 °C ~ 30 °C. Under the conditions of presence of

safety devices, fill the HFC-134a into the receiver dryer to make it be saturated.

Then charge the nitrogen to increase the pressure to 3.4 MPa ± 0.4 MPa. Use

the electronic refrigerant leak detector; the probe moving speed is 25 mm/s ~

50 mm/s; the distance between the leak detection probe and the inspected part

is not more than 10 mm.

5.3.2 At room temperature 20 °C ~ 30 °C, fill the receiver dryer with 1.0 MPa

dry nitrogen with a purity of not less than 75%; use a nitrogen leak detector to

detect it. It is equivalent to an annual leakage rate of HFC-134a under 3.4 MPa

conditions of not more than 5 g/a.

5.3.3 Block the outlet end; fill the inner cavity with 3.5 MPa dry high-purity

nitrogen from the inlet end; immerse the entire dryer in clean water; keep it for

3 minutes; no bubbles shall escape .

5.4 Pressure...

Get QUOTATION in 1-minute: Click QC/T 662-2013

Historical versions: QC/T 662-2013

Preview True-PDF (Reload/Scroll if blank)

QC/T 662-2013: Vehicle air conditioner (HFC-134a) receiver dryer

QC/T 662-2013

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.60

T 26

Replacing QC/T 662-2000

Vehicle air conditioner (HFC-134a) receiver dryer

ISSUED ON: OCTOBER 17, 2013

IMPLEMENTED ON: MARCH 01, 2014

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 8

2 Normative references ... 8

3 Terms and definitions ... 8

4 Technical requirements ... 9

5 Test method ... 11

6 Inspection rules ... 15

7 Marking, packaging, transportation and storage ... 16

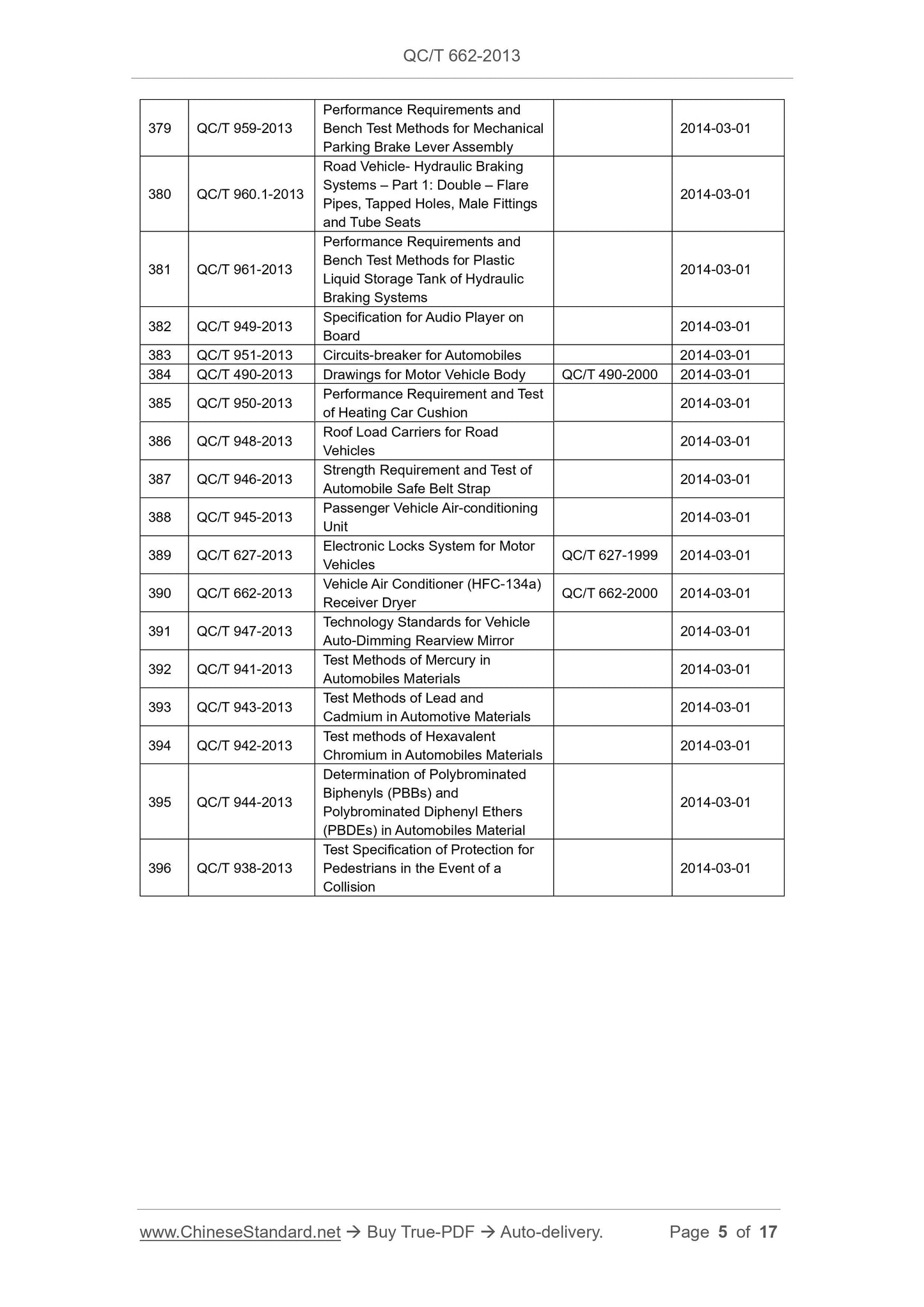

Attachment:

Number, Name and Initial Implementation Date of the 42

Automobile Industry Standards

S/N Standard No. Standard Name Replaced Standard No.

Implementation

Date

355 QC/T 253-2013

Preparation Methods for Engine

Model used in Motorcycles and

Mopeds

QC/T 253-1998 2014-03-01

356 QC/T 682-2013 Seats Used in Motorcycles and Mopeds QC/T 682-2002 2014-03-01

357 QC/T 229-2013 Technical Conditions for Rotor Pump of Motorcycles and Mopeds QC/T 229-1997 2014-03-01

358 QC/T 952-2013 Disc Wheels for Passenger Car — Dimensional of Attachment on Hub 2014-03-01

359 QC/T 953-2013 Commercial Road Vehicles-Flat Attachment Wheel Fixing Nuts 2014-03-01

360 QC/T 954-2013

Commercial Vehicles-Flat

Attachment Fixing Nuts-Test

Methods

2014-03-01

361 QC/T 258-2013 Test Methods for the Intensity of Vehicle Wheels and Screw Base QC/T 258-1998 2014-03-01

362 QC/T 199-2013 Vehicle Wheels - Balance Weight QC/T 199-1995 2014-03-01

363 QC/T 326-2013 Numbering Rules for Automobile Standardized Parts QC/T 326-1999 2014-03-01

364 QC/T 955-2013 Auto Leveling Device of Special Purpose Vehicle 2014-03-01

365 QC/T 956-2013 Transport Vehicle for Dry-mixed Mortar 2014-03-01

366 QC/T 957-2013 Cleaning Sweeper Truck 2014-03-01

367 QC/T 29104-2013

Method for Coding the Level of

Contamination by Solid Particles of

Special Purpose Vehicle Hydraulic

System

QC/T 29104-

1992 2014-03-01

368 QC/T 29105.3-2013

Sampling Methods of Testing

Particulate Contamination of

Hydraulic Oil of Special Purpose

Vehicle Hydraulic System

QC/T 29105.3-

1992 2014-03-01

369 QC/T 718-2013 Truck Mounted Concrete Pump QC/T 718-2004 2014-03-01

370 QC/T 439-2013 Swept-body Dump Truck QC/T 439-1999 QC/T 440-1999 2014-03-01

371 QC/T 935-2013 Kitchen Garbage Vehicle 2014-03-01

372 QC/T 939-2013 Technical Qualifications of Front Discharge Truck 2014-03-01

373 QC/T 457-2013 Ambulance QC/T 457-2002 2014-03-01

374 QC/T 936-2013 Detachable Container Garbage Collector 2014-03-01

375 QC/T 937-2013 Guardrail Repair Car 2014-03-01

376 QC/T 940-2013 Exhibition Vehicle 2014-03-01

377 QC/T 958-2013

Performance Requirements and

Bench Test Methods of Automobile

Vacuum Pump

2014-03-01

378 QC/T 592-2013

Performance Requirements and

Bench Test Methods for Hydraulic

Brake Caliper Assembly

QC/T 592-1999 2014-03-01

Vehicle air conditioner (HFC-134a) receiver dryer

1 Scope

This standard specifies the technical requirements, test methods, inspection

rules, markings, packaging, transportation and storage of vehicle air conditioner

(HFC-134a) receiver dryer (hereinafter referred to as receiver dryers).

This standard is applicable to vehicle air conditioner receiver dryer with HFC-

134a as the refrigerant, working pressure at 0 ~ 2.5 MPa, effective internal

volume less than 1000 mL.

2 Normative references

The clauses contained in the following standards constitute the clauses of this

standard through quotation in this standard. When this standard is published,

all editions are valid. All standards will be revised, and all parties using this

standard shall explore the possibility of using the latest version of the following

standards.

GB/T 191-2008 Packaging - Pictorial marking for handling of goods

GB/T 6287-1986 Determination of static adsorbed water for molecular sieve

GB/T 10125-1997 Corrosion tests in artificial atmospheres-Salt spray tests

3 Terms and definitions

The terms and definitions apply to this standard.

3.1

Receiver dryer

The receiver dryer is a device with drying and filtering functions, used to

absorb residual moisture in the refrigeration system, filter residual impurities,

store high-pressure liquid refrigerant.

3.2

Desiccant

The solid adsorbent used to adsorb residual moisture. In the refrigeration

4.3 Pressure resistance

When tested according to 5.4 of this standard, after the receiver dryer is tested

under a pressure of 5.3 MPa, there shall be no leakage or obvious deformation,

meanwhile it shall not be broken under a pressure of 10.5 MPa.

4.4 Cleanliness

When tested according to 5.5 of this standard, the internal impurity content shall

not exceed 15 mg; the maximum solid impurity size shall not exceed 350 µm.

4.5 Drying performance

4.5.1 When tested according to 5.6.1 of this standard, the water capacity of the

desiccant is not less than 15%

4.5.2 When tested according to 5.6.2 of this standard, the residual moisture of

the desiccant is not more than 2.5%.

4.6 Pressure loss

When tested according to 5.7 of this standard, the pressure difference between

inlet and outlet shall meet the design requirements, generally not more than 20

kPa.

4.7 High temperature resistance

After the test in accordance with 5.8 of this standard, there shall be no abnormal

deformation or damage in appearance; it shall meet the requirements of 4.2;

the internal parts shall not be damaged.

4.8 Low temperature resistance

After testing in accordance with 5.9 of this standard, there shall be no abnormal

deformation or damage in appearance; it shall meet the requirements of 4.2;

the internal parts shall not be damaged.

4.9 Resistance to cyclic temperature change

After the test in accordance with 5.10 of this standard, there shall be no

abnormal deformation or damage in appearance; it shall meet the requirements

of 4.2; the internal parts shall not be damaged.

4.10 Vibration resistance

After the test in accordance with 5.11 of this standard, there shall be no

abnormal deformation or damage in appearance; it shall meet the requirements

of 4.2; the internal parts shall not be damaged.

5.1.6 The accuracy of the leak detector is not less than 0.5 g/a.

5.2 Appearance quality and external dimension inspection

Visual inspection of the appearance quality shall meet the requirements of 4.1

of this standard.

5.3 Air tightness test

Choose at least one of the following test methods.

5.3.1 Room temperature is 20 °C ~ 30 °C. Under the conditions of presence of

safety devices, fill the HFC-134a into the receiver dryer to make it be saturated.

Then charge the nitrogen to increase the pressure to 3.4 MPa ± 0.4 MPa. Use

the electronic refrigerant leak detector; the probe moving speed is 25 mm/s ~

50 mm/s; the distance between the leak detection probe and the inspected part

is not more than 10 mm.

5.3.2 At room temperature 20 °C ~ 30 °C, fill the receiver dryer with 1.0 MPa

dry nitrogen with a purity of not less than 75%; use a nitrogen leak detector to

detect it. It is equivalent to an annual leakage rate of HFC-134a under 3.4 MPa

conditions of not more than 5 g/a.

5.3.3 Block the outlet end; fill the inner cavity with 3.5 MPa dry high-purity

nitrogen from the inlet end; immerse the entire dryer in clean water; keep it for

3 minutes; no bubbles shall escape .

5.4 Pressure...

Share