1

/

/

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

SN/T 2697-2010 English PDF (SNT2697-2010)

SN/T 2697-2010 English PDF (SNT2697-2010)

Normaalihinta

$250.00 USD

Normaalihinta

Alennushinta

$250.00 USD

Yksikköhinta

/

kohti

Toimituskulut lasketaan kassalla.

Noudon saatavuutta ei voitu ladata

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click SN/T 2697-2010

Historical versions: SN/T 2697-2010

Preview True-PDF (Reload/Scroll if blank)

SN/T 2697-2010: Determination of sulfur, phosphorus, arsenic and chloride in coal for import and export. X-ray fluorescence spectrometric method

SN/T 2697-2010

SN

ENTRY-EXIT INSPECTION AND QUARANTINE INDUSTRY

STANDARD OF THE PEOPLE’S REPUBLIC OF CHINA

Determination of Sulfur, Phosphorus, Arsenic and Chloride

in Coal for Import and Export – X-Ray Fluorescence

Spectrometric Method

ISSUED ON: NOVEMBER 1, 2010

IMPLEMENTED ON: MAY 1, 2011

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Method Summary ... 5

4 Reagents and Materials ... 5

5 Apparatus ... 5

6 Sampling and Sample Preparation ... 5

7 Preparation of Specimen ... 6

8 Analytical Procedures ... 6

9 Measurement ... 7

10 Calculation of Results... 7

11 Precision ... 7

Appendix A (Informative) Preparation of Standard Sample ... 8

Appendix B (Informative) Measurement Conditions of X-Ray Fluorescence

Spectrometer ... 10

Determination of Sulfur, Phosphorus, Arsenic and Chloride

in Coal for Import and Export – X-Ray Fluorescence

Spectrometric Method

1 Scope

This Standard specifies the X-ray fluorescence spectrometric method for determination of

sulfur, phosphorus, arsenic and chloride in coal.

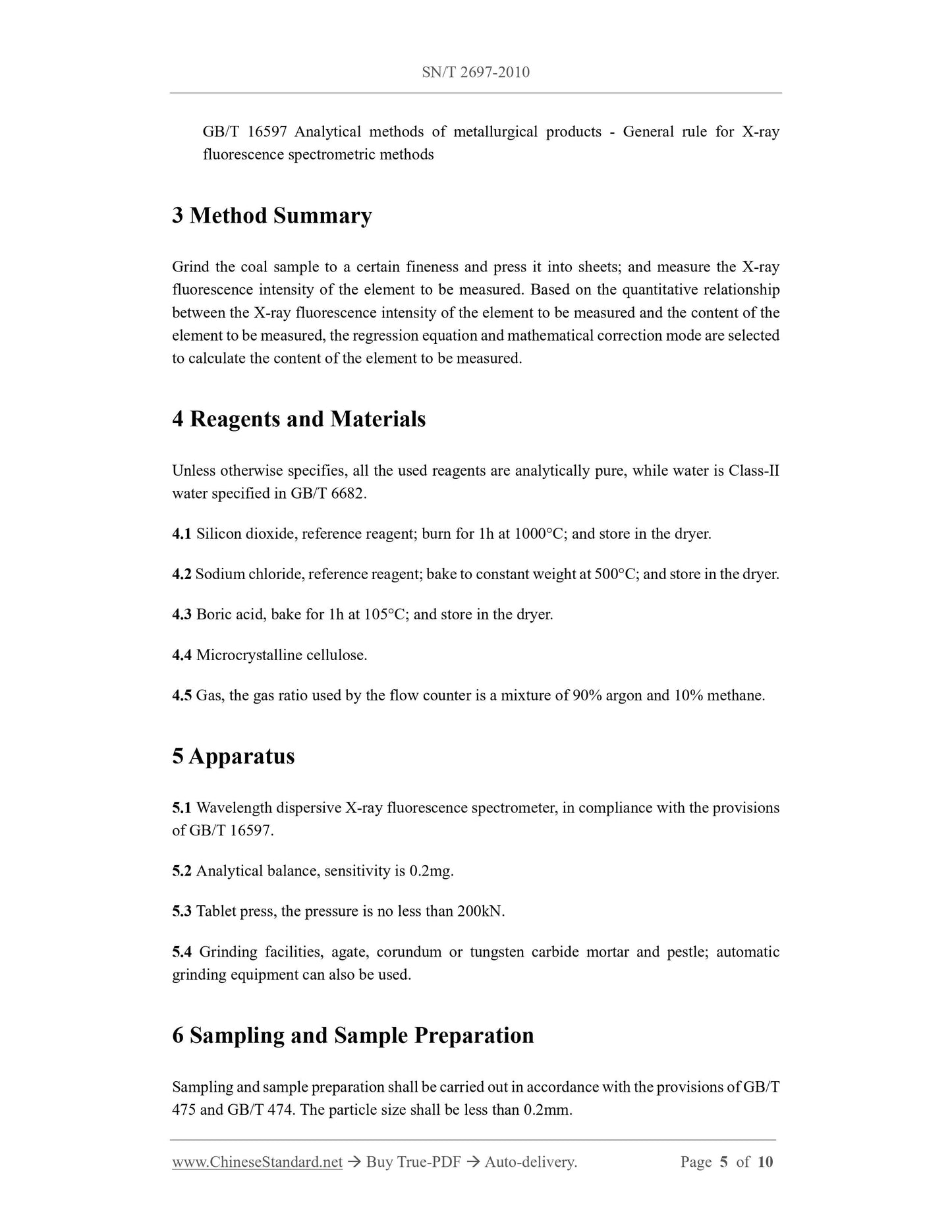

This Standard is applicable to the determination of sulfur, phosphorus, arsenic and chlorine

content in imported and exported bitumite, anthracite and lignite. The measurement range of

each element is shown in Table 1.

Table 1 – Measurement Range of Each Element

2 Normative References

The following documents are essential to the application of this Document. For the dated

documents, only the versions with the dates indicated are applicable to this Document; for the

undated documents, only the latest version (including all the amendments) is applicable to this

Document.

GB/T 212 Proximate analysis of coal

GB/T 474 Preparation method of coal sample

GB/T 475 Method for manual sampling of commercial coal

GB/T 483 General rules for analytical and testing methods of coal

GB/T 6682 Water for analytical laboratory use - Specification and test methods

Element Measurement range (mass fraction)

GB/T 16597 Analytical methods of metallurgical products - General rule for X-ray

fluorescence spectrometric methods

3 Method Summary

Grind the coal sample to a certain fineness and press it into sheets; and measure the X-ray

fluorescence intensity of the element to be measured. Based on the quantitative relationship

between the X-ray fluorescence intensity of the element to be measured and the content of the

element to be measured, the regression equation and mathematical correction mode are selected

to calculate the content of the element to be measured.

4 Reagents and Materials

Unless otherwise specifies, all the used reagents are analytically pure, while water is Class-II

water specified in GB/T 6682.

4.1 Silicon dioxide, reference reagent; burn for 1h at 1000°C; and store in the dryer.

4.2 Sodium chloride, reference reagent; bake to constant weight at 500°C; and store in the dryer.

4.3 Boric acid, bake for 1h at 105°C; and store in the dryer.

4.4 Microcrystalline cellulose.

4.5 Gas, the gas ratio used by the flow counter is a mixture of 90% argon and 10% methane.

5 Apparatus

5.1 Wavelength dispersive X-ray fluorescence spectrometer, in compliance with the provisions

of GB/T 16597.

5.2 Analytical balance, sensitivity is 0.2mg.

5.3 Tablet press, the pressure is no less than 200kN.

5.4 Grinding facilities, agate, corundum or tungsten carbide mortar and pestle; automatic

grinding equipment can also be used.

6 Sampling and Sample Preparation

Sampling and sample preparation shall be carried out in accordance with the provisions of GB/T

475 and GB/T 474. The particle size shall be less than 0.2mm.

7 Preparation of Specimen

Place the air-dried coal sample (Clause 6) in the mortar (5.4) of the grinding facility and grind

it to a particle size less than 75μm.

8 Analytical Procedures

8.1 Determination of moisture content in the specimen

Test the moisture content of the specimen (Clause 7) according to the provisions of GB/T 212.

Weigh a certain amount of air-dried coal sample (Clause 6), place it in a 105°C oven; and dry

it in the air flow to constant weight. The moisture content shall be calculated according to the

mass loss of the specimen.

8.2 Preparation of specimen sheet

Accurately weigh 7g of the ground specimen (Clause 7) and 1g of microcrystalline cellulose in

the mortar (5.4) of the grinding facility, accurate to 0.2mg. After grinding until fully mixed,

weigh about 6g, accurate to 0.1g; rim with boric acid (4.3) as the base; and press with a tablet

press (5.3) under a pressure of 300kN for 40 s to form a specimen sheet. Use an ear cleaning

ball to blow away any particulate matter that may be present on the surface and place it in a

dryer. Avoid contact with the surface of the specimen to prevent contamination and damage to

the specimen sheet.

After preparing the specimen sheet, visually inspect whether the specimen is smooth and flat.

If the test piece has defects such as cracks or falling off, it shall be discarded and a new qualified

specimen sheet shall be prepared.

8.3 Preparation of standard sample sheet

The selected standard samples shall cover the content range of each element given in Table 1.

The serial standard samples are formed by using coal certified reference materials, coal certified

reference materials compounded with coal certified reference materials and mixed with silicon

dioxide (4.1), sodium chloride (4.2) and other methods, see Appendix A.

Prepare standard samples into standard sample sheets according to 8.2.

8.4 Drawing of standard curve

8.4.1 Measurement conditions

The measurement conditions for the characteristic spectral lines of each element were obtained

through optimization, see Appendix B.

8.4.2 Preparation and calibration of standard curve

Get QUOTATION in 1-minute: Click SN/T 2697-2010

Historical versions: SN/T 2697-2010

Preview True-PDF (Reload/Scroll if blank)

SN/T 2697-2010: Determination of sulfur, phosphorus, arsenic and chloride in coal for import and export. X-ray fluorescence spectrometric method

SN/T 2697-2010

SN

ENTRY-EXIT INSPECTION AND QUARANTINE INDUSTRY

STANDARD OF THE PEOPLE’S REPUBLIC OF CHINA

Determination of Sulfur, Phosphorus, Arsenic and Chloride

in Coal for Import and Export – X-Ray Fluorescence

Spectrometric Method

ISSUED ON: NOVEMBER 1, 2010

IMPLEMENTED ON: MAY 1, 2011

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Method Summary ... 5

4 Reagents and Materials ... 5

5 Apparatus ... 5

6 Sampling and Sample Preparation ... 5

7 Preparation of Specimen ... 6

8 Analytical Procedures ... 6

9 Measurement ... 7

10 Calculation of Results... 7

11 Precision ... 7

Appendix A (Informative) Preparation of Standard Sample ... 8

Appendix B (Informative) Measurement Conditions of X-Ray Fluorescence

Spectrometer ... 10

Determination of Sulfur, Phosphorus, Arsenic and Chloride

in Coal for Import and Export – X-Ray Fluorescence

Spectrometric Method

1 Scope

This Standard specifies the X-ray fluorescence spectrometric method for determination of

sulfur, phosphorus, arsenic and chloride in coal.

This Standard is applicable to the determination of sulfur, phosphorus, arsenic and chlorine

content in imported and exported bitumite, anthracite and lignite. The measurement range of

each element is shown in Table 1.

Table 1 – Measurement Range of Each Element

2 Normative References

The following documents are essential to the application of this Document. For the dated

documents, only the versions with the dates indicated are applicable to this Document; for the

undated documents, only the latest version (including all the amendments) is applicable to this

Document.

GB/T 212 Proximate analysis of coal

GB/T 474 Preparation method of coal sample

GB/T 475 Method for manual sampling of commercial coal

GB/T 483 General rules for analytical and testing methods of coal

GB/T 6682 Water for analytical laboratory use - Specification and test methods

Element Measurement range (mass fraction)

GB/T 16597 Analytical methods of metallurgical products - General rule for X-ray

fluorescence spectrometric methods

3 Method Summary

Grind the coal sample to a certain fineness and press it into sheets; and measure the X-ray

fluorescence intensity of the element to be measured. Based on the quantitative relationship

between the X-ray fluorescence intensity of the element to be measured and the content of the

element to be measured, the regression equation and mathematical correction mode are selected

to calculate the content of the element to be measured.

4 Reagents and Materials

Unless otherwise specifies, all the used reagents are analytically pure, while water is Class-II

water specified in GB/T 6682.

4.1 Silicon dioxide, reference reagent; burn for 1h at 1000°C; and store in the dryer.

4.2 Sodium chloride, reference reagent; bake to constant weight at 500°C; and store in the dryer.

4.3 Boric acid, bake for 1h at 105°C; and store in the dryer.

4.4 Microcrystalline cellulose.

4.5 Gas, the gas ratio used by the flow counter is a mixture of 90% argon and 10% methane.

5 Apparatus

5.1 Wavelength dispersive X-ray fluorescence spectrometer, in compliance with the provisions

of GB/T 16597.

5.2 Analytical balance, sensitivity is 0.2mg.

5.3 Tablet press, the pressure is no less than 200kN.

5.4 Grinding facilities, agate, corundum or tungsten carbide mortar and pestle; automatic

grinding equipment can also be used.

6 Sampling and Sample Preparation

Sampling and sample preparation shall be carried out in accordance with the provisions of GB/T

475 and GB/T 474. The particle size shall be less than 0.2mm.

7 Preparation of Specimen

Place the air-dried coal sample (Clause 6) in the mortar (5.4) of the grinding facility and grind

it to a particle size less than 75μm.

8 Analytical Procedures

8.1 Determination of moisture content in the specimen

Test the moisture content of the specimen (Clause 7) according to the provisions of GB/T 212.

Weigh a certain amount of air-dried coal sample (Clause 6), place it in a 105°C oven; and dry

it in the air flow to constant weight. The moisture content shall be calculated according to the

mass loss of the specimen.

8.2 Preparation of specimen sheet

Accurately weigh 7g of the ground specimen (Clause 7) and 1g of microcrystalline cellulose in

the mortar (5.4) of the grinding facility, accurate to 0.2mg. After grinding until fully mixed,

weigh about 6g, accurate to 0.1g; rim with boric acid (4.3) as the base; and press with a tablet

press (5.3) under a pressure of 300kN for 40 s to form a specimen sheet. Use an ear cleaning

ball to blow away any particulate matter that may be present on the surface and place it in a

dryer. Avoid contact with the surface of the specimen to prevent contamination and damage to

the specimen sheet.

After preparing the specimen sheet, visually inspect whether the specimen is smooth and flat.

If the test piece has defects such as cracks or falling off, it shall be discarded and a new qualified

specimen sheet shall be prepared.

8.3 Preparation of standard sample sheet

The selected standard samples shall cover the content range of each element given in Table 1.

The serial standard samples are formed by using coal certified reference materials, coal certified

reference materials compounded with coal certified reference materials and mixed with silicon

dioxide (4.1), sodium chloride (4.2) and other methods, see Appendix A.

Prepare standard samples into standard sample sheets according to 8.2.

8.4 Drawing of standard curve

8.4.1 Measurement conditions

The measurement conditions for the characteristic spectral lines of each element were obtained

through optimization, see Appendix B.

8.4.2 Preparation and calibration of standard curve

Share