1

/

dari

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 664-2019 English PDF (QCT664-2019)

QC/T 664-2019 English PDF (QCT664-2019)

Harga reguler

$265.00 USD

Harga reguler

Harga obral

$265.00 USD

Harga satuan

/

per

Biaya pengiriman dihitung saat checkout.

Tidak dapat memuat ketersediaan pengambilan

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 664-2019

Historical versions: QC/T 664-2019

Preview True-PDF (Reload/Scroll if blank)

QC/T 664-2019: Automotive air-conditioning refrigerant hose

QC/T 664-2019

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.60

T 26

Replacing QC/T 664-2000

Automotive air-conditioning refrigerant hose

ISSUED ON: DECEMBER 24, 2019

IMPLEMENTED ON: JULY 01, 2020

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 5

1 Scope ... 7

2 Normative references ... 7

3 Terms and definitions... 7

4 Categories ... 8

5 Technical requirements ... 9

6 Test methods ... 12

7 Signs ... 23

8 Inspection, packaging, transportation, storage ... 23

Automotive air-conditioning refrigerant hose

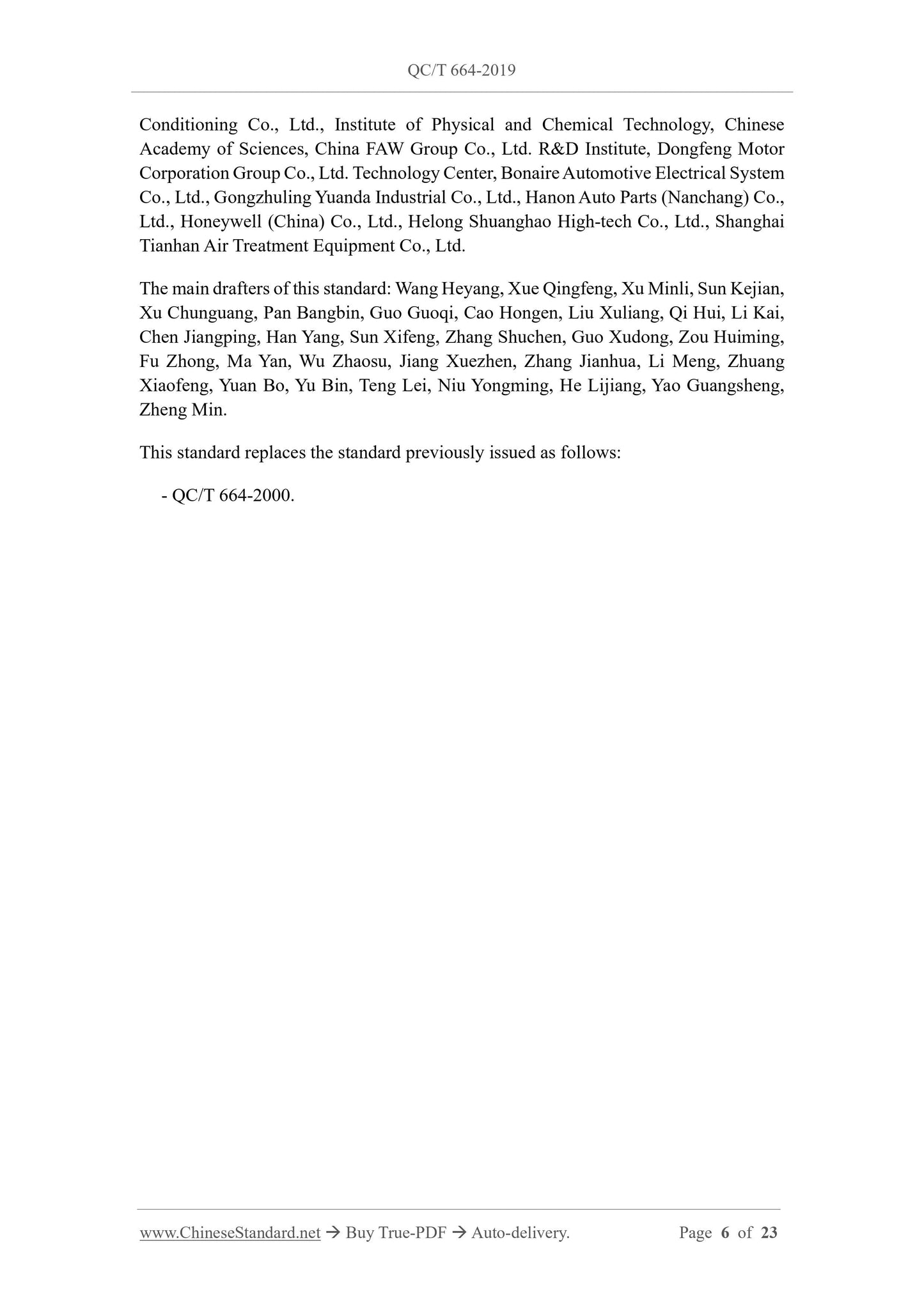

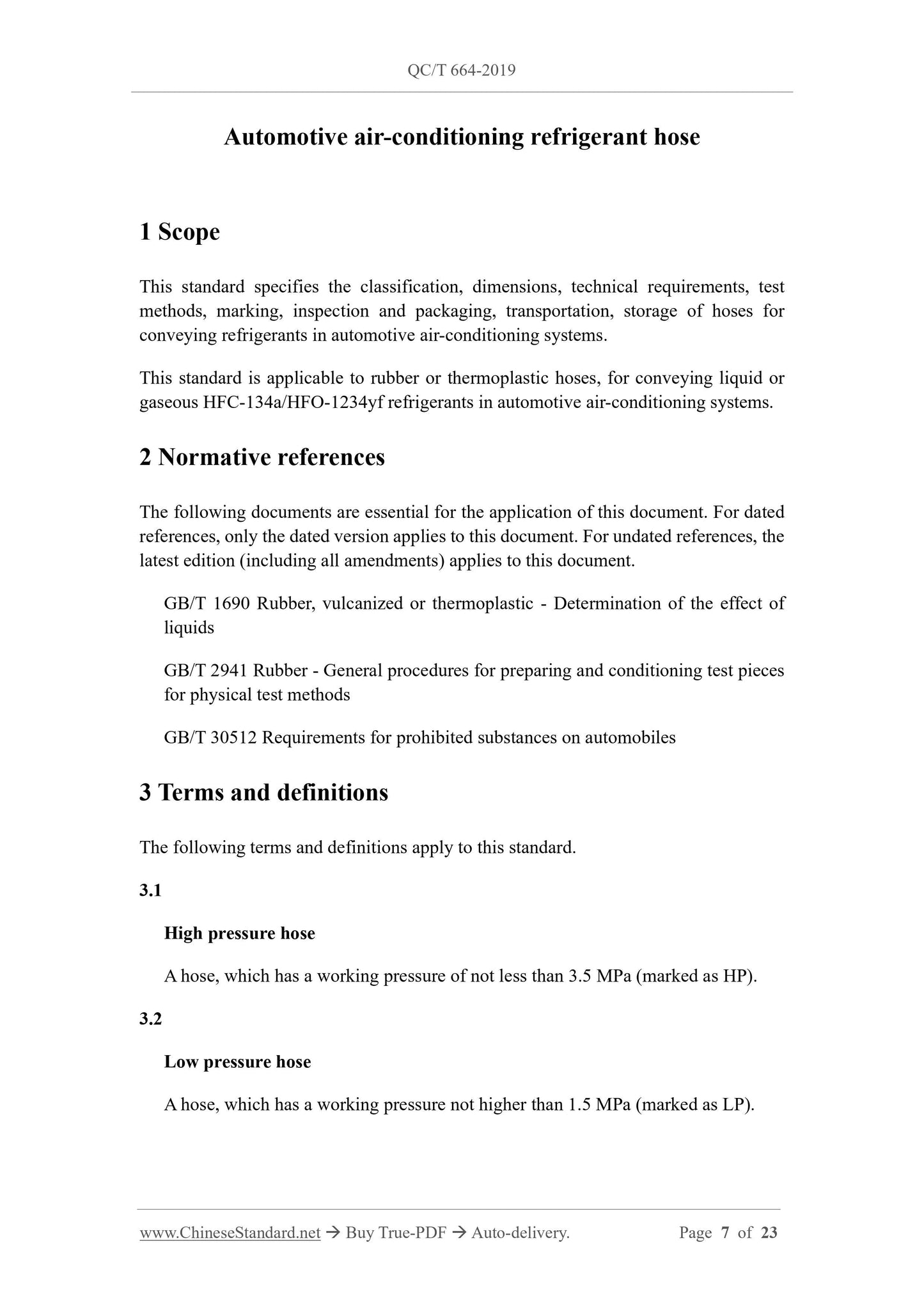

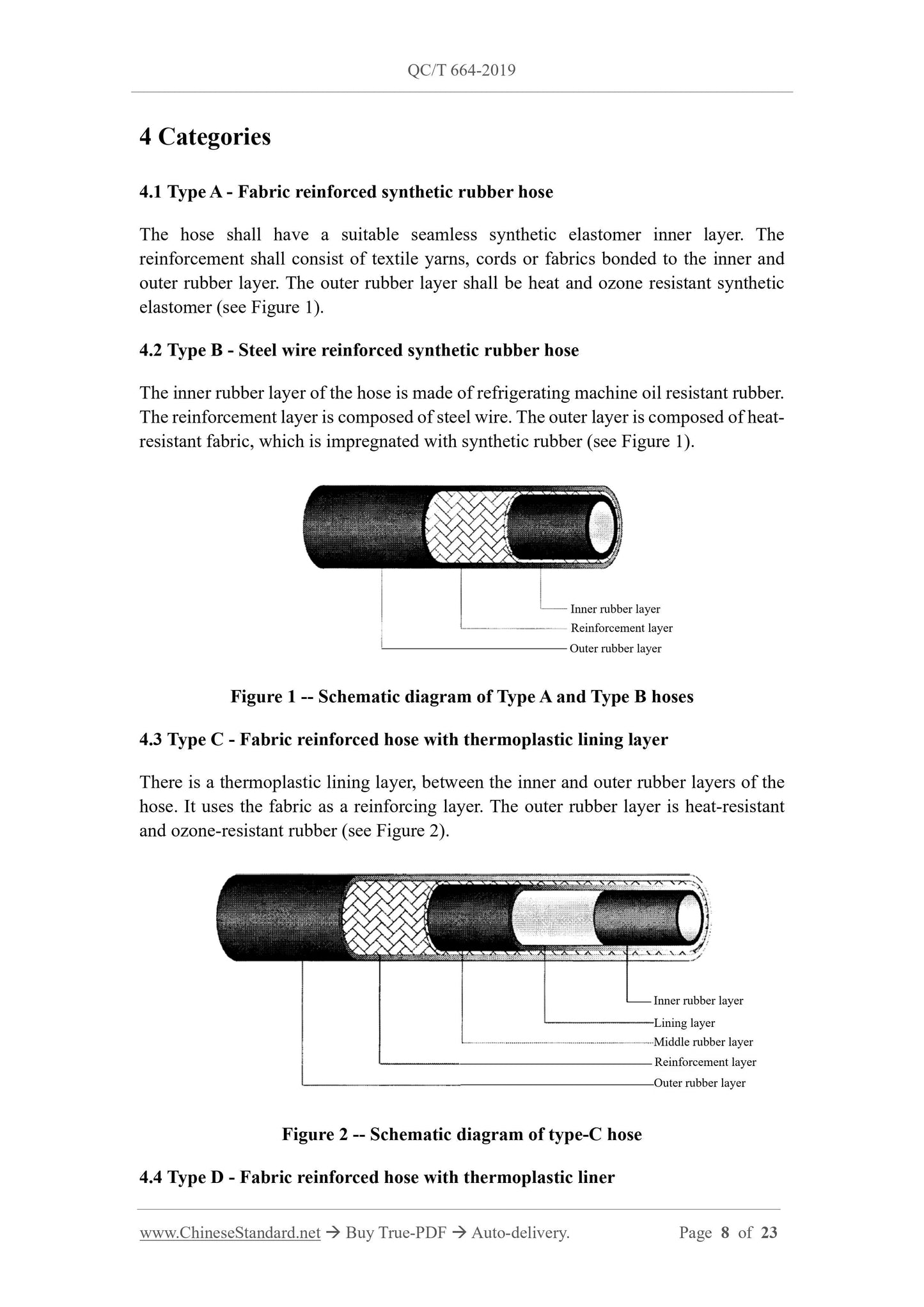

1 Scope

This standard specifies the classification, dimensions, technical requirements, test

methods, marking, inspection and packaging, transportation, storage of hoses for

conveying refrigerants in automotive air-conditioning systems.

This standard is applicable to rubber or thermoplastic hoses, for conveying liquid or

gaseous HFC-134a/HFO-1234yf refrigerants in automotive air-conditioning systems.

2 Normative references

The following documents are essential for the application of this document. For dated

references, only the dated version applies to this document. For undated references, the

latest edition (including all amendments) applies to this document.

GB/T 1690 Rubber, vulcanized or thermoplastic - Determination of the effect of

liquids

GB/T 2941 Rubber - General procedures for preparing and conditioning test pieces

for physical test methods

GB/T 30512 Requirements for prohibited substances on automobiles

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

High pressure hose

A hose, which has a working pressure of not less than 3.5 MPa (marked as HP).

3.2

Low pressure hose

A hose, which has a working pressure not higher than 1.5 MPa (marked as LP).

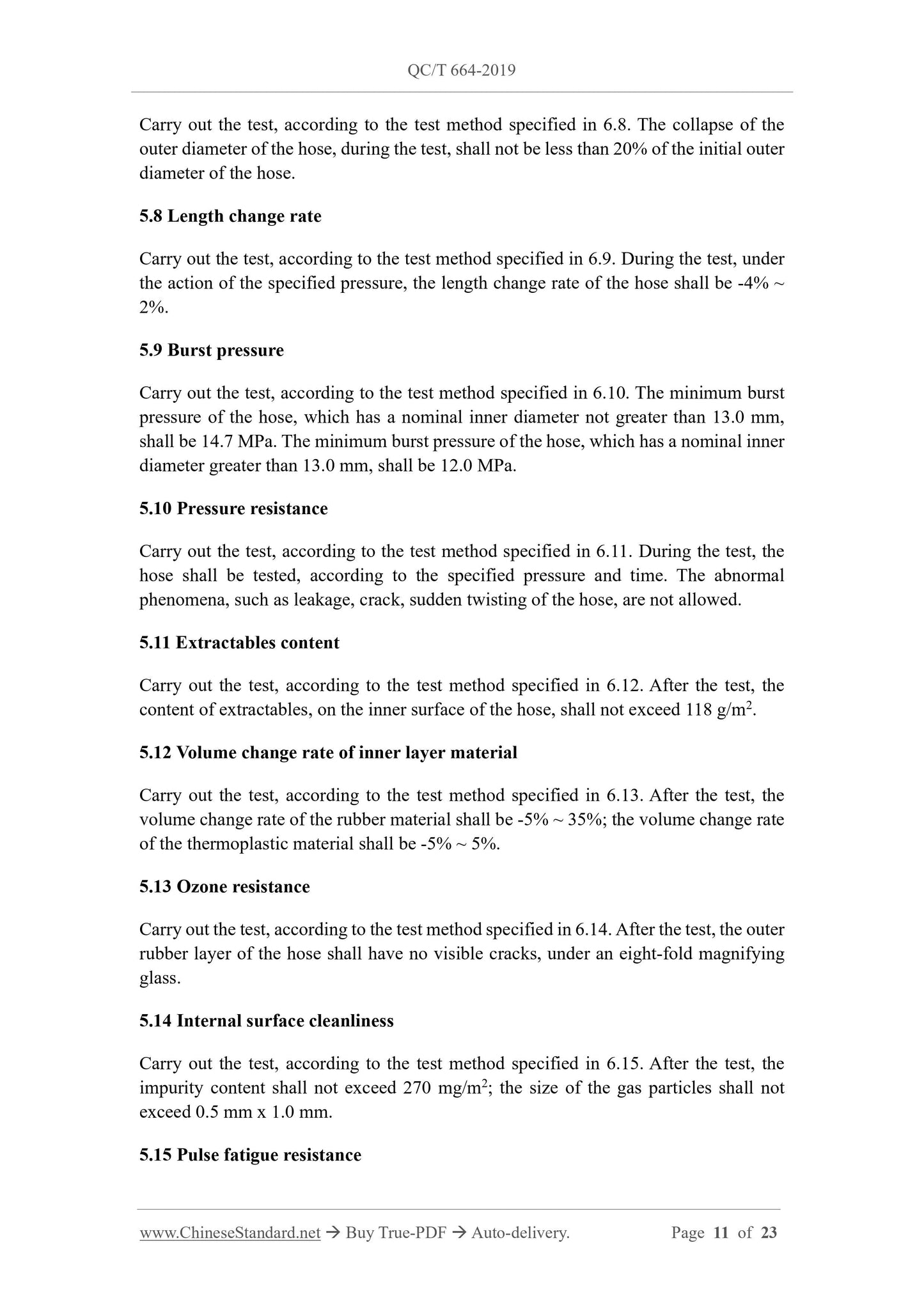

Carry out the test, according to the test method specified in 6.8. The collapse of the

outer diameter of the hose, during the test, shall not be less than 20% of the initial outer

diameter of the hose.

5.8 Length change rate

Carry out the test, according to the test method specified in 6.9. During the test, under

the action of the specified pressure, the length change rate of the hose shall be -4% ~

2%.

5.9 Burst pressure

Carry out the test, according to the test method specified in 6.10. The minimum burst

pressure of the hose, which has a nominal inner diameter not greater than 13.0 mm,

shall be 14.7 MPa. The minimum burst pressure of the hose, which has a nominal inner

diameter greater than 13.0 mm, shall be 12.0 MPa.

5.10 Pressure resistance

Carry out the test, according to the test method specified in 6.11. During the test, the

hose shall be tested, according to the specified pressure and time. The abnormal

phenomena, such as leakage, crack, sudden twisting of the hose, are not allowed.

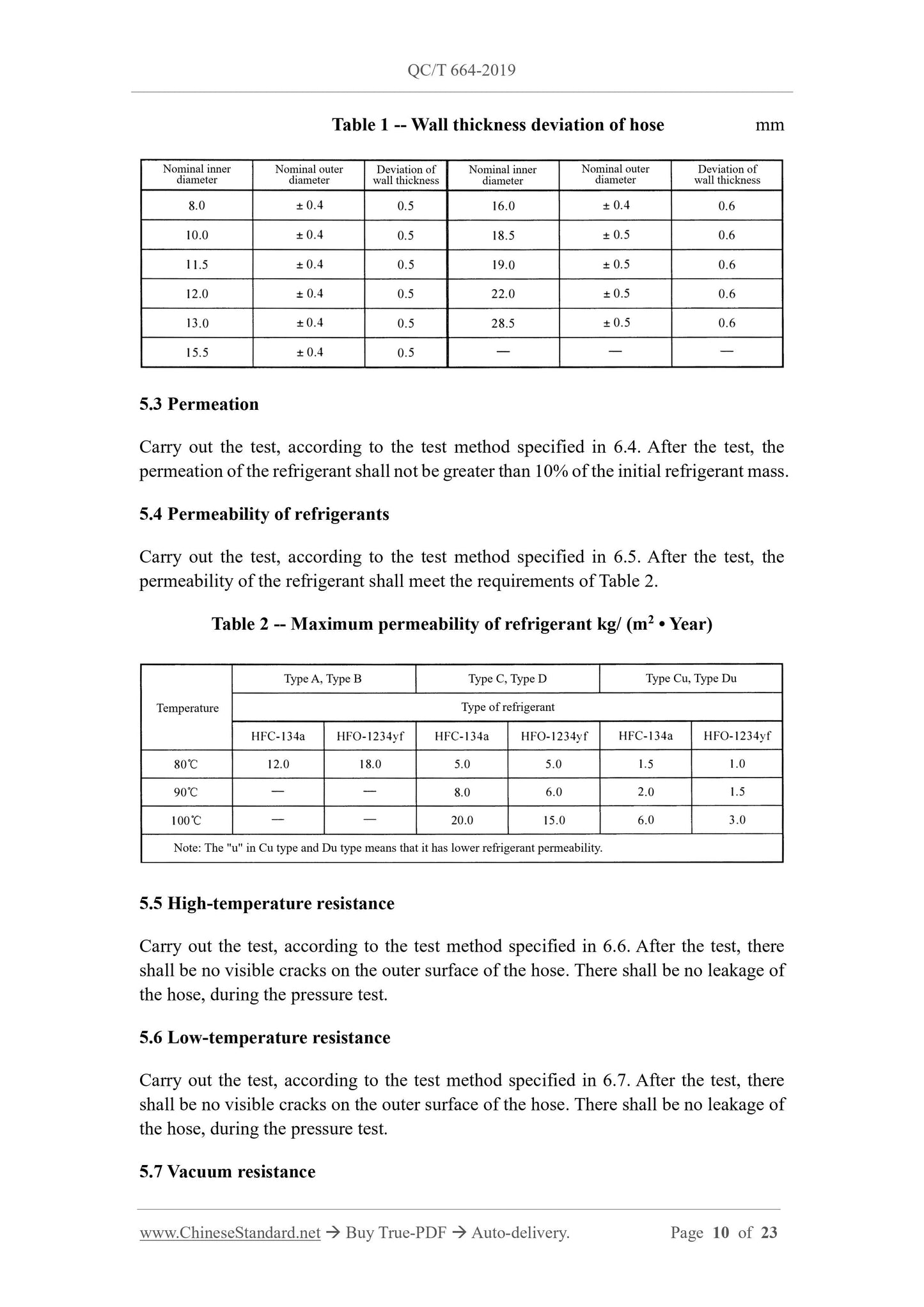

5.11 Extractables content

Carry out the test, according to the test method specified in 6.12. After the test, the

content of extractables, on the inner surface of the hose, shall not exceed 118 g/m2.

5.12 Volume change rate of inner layer material

Carry out the test, according to the test method specified in 6.13. After the test, the

volume change rate of the rubber material shall be -5% ~ 35%; the volume change rate

of the thermoplastic material shall be -5% ~ 5%.

5.13 Ozone resistance

Carry out the test, according to the test method specified in 6.14. After the test, the outer

rubber layer of the hose shall have no visible cracks, under an eight-fold magnifying

glass.

5.14 Internal surface cleanliness

Carry out the test, according to the test method specified in 6.15. After the test, the

impurity content shall not exceed 270 mg/m2; the size of the gas particles shall not

exceed 0.5 mm x 1.0 mm.

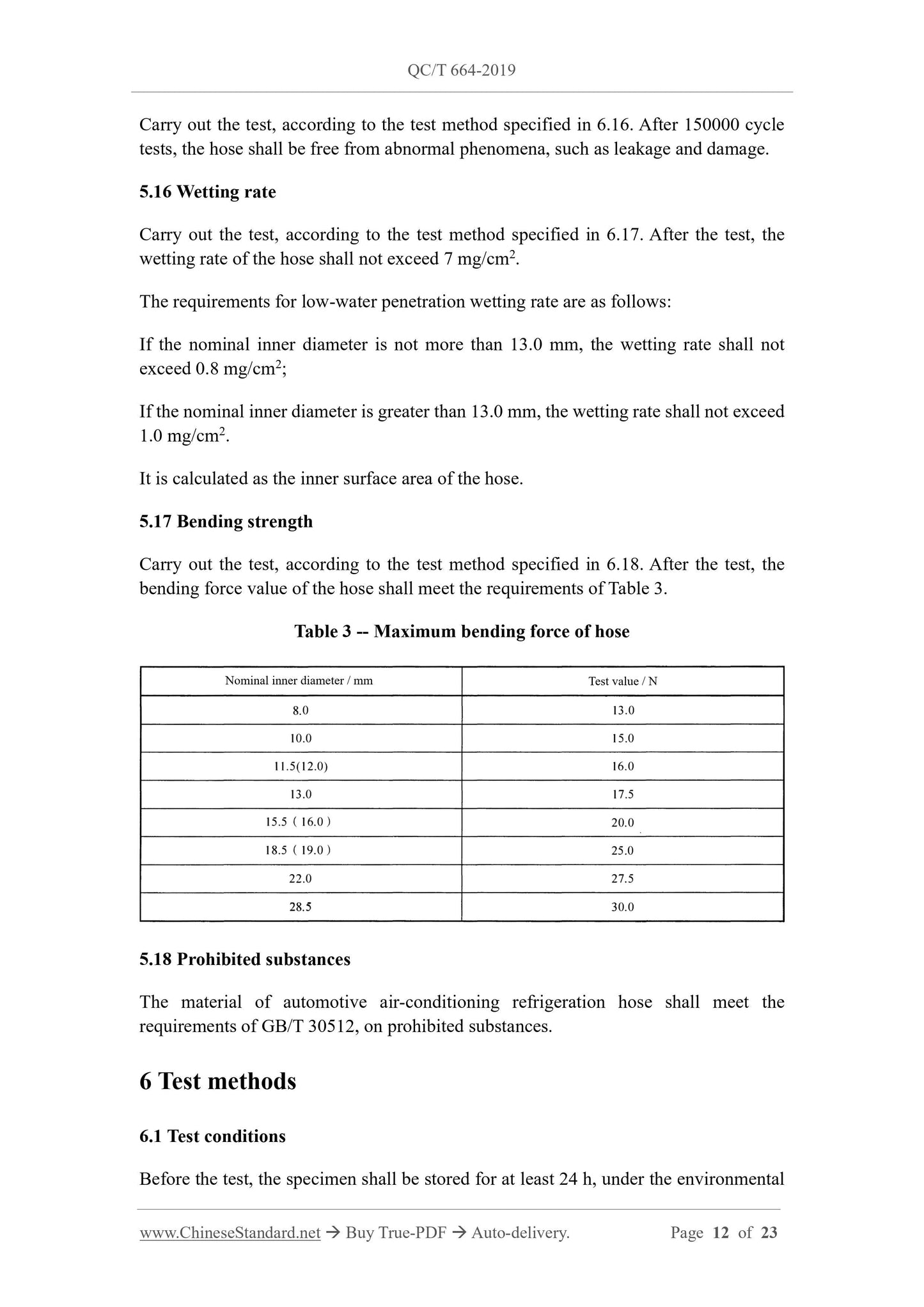

5.15 Pulse fatigue resistance

conditions specified in GB/T 2941.

6.2 Test medium

The test medium used in the test shall be a mixture of HFC-134a, which has a mass

fraction of 90% or HFO-1234yf refrigerant and 10% refrigerating machine oil.

6.3 Dimensional measurement

6.3.1 Inner and outer diameters of hoses

The inner diameter of the hose shall be measured by a special measuring tool, such as

a tapered plug gauge, expanding ball type or retractable meter, etc. The diameter is

measured 3 times; the results are averaged.

6.3.2 Deviation of hose's wall thickness

The deviation of wall thickness of the hose shall be measured by a special meter, such

as a caliper with a probe that can touch the inner wall of the hose. Measure the wall

thickness of the cross section of the hose, at four points; take the difference between the

maximum value and the minimum value measured. Make 3 measurements. Take the

average of the results.

6.4 Permeation

Take 3 hoses. Fill the hoses with the specified test medium, according to the method in

6.5.3.1. Weigh the hoses and accessories. Then place the samples at a temperature of

100 °C ± 2 °C, for 24 hours. After taking out, weigh the mass of the hose and accessories

again. Calculate the mass loss.

6.5 Refrigerant permeability

6.5.1 Test device

6.5.1.1 Accessories and fixtures

Accessories and clamps shall be sealed and leak-free, when subjected to the pressure in

the hose.

6.5.1.2 Leak detector

The sensitivity of the leak detector shall be higher than 2 g/year (under the same volume

and temperature conditions, the refrigerant's equivalent ratio HFC-134a:HFO-1234yf =

1:0.92).

6.5.1.3 Constant temperature chamber

The control accuracy of the constant temperature chamber shall be ±2 °C.

6.5.1.4 Balances

The measurement accuracy of the balance shall be 0.01 g.

6.5.2 Test conditions

For use of hoses at higher working pressures, the test temperature shall be 90 °C ± 2 °C

or 100 °C ± 2 °C (high-pressure hose). For use of hoses at lower working pressures, the

test temperature shall be 80 °C ± 2 °C (low-pressure hose).

6.5.3 Test method

6.5.3.1 Preparation before the test

Take 4 hoses, which have an exposed length of 1m, and accessories. Use seals to seal

them at both ends. Three of them are used to measure the loss of refrigerant; the fourth

one is connected with a joint, which is used as a comparison hose, to detect the change

of the mass torsion of the hose itself. In the standard state, measure the exposed length

of the hose (L1, L2), the accuracy is required to be ±1 mm. Weigh the mass of each hose

and accessories (including joints), which is required to be accurate to ± 0.1 g. The hose

assembly is filled with 0.6 mg of test medium per millimeter volume; the filling volume

is accurate to ±5 g. The number of filled hoses is 3. Use a leak detector, to check that

each hose is leaking.

Filling of refrigerant

Method 1:

Before filling the hoses and accessories, they must be kept in a low temperature

chamber of -30 °C or lower, for 4 hours. Use the density of the test medium, at this

temperature, to calculate the mass of the test medium to be filled. Keep the test medium

and the hose at this temperature Use an electronic balance, to weigh the test medium.

Then fill the test medium into the hose. The filled hose and accessories are sealed at

this temperature.

Method 2:

The hose and accessories are filled with the test medium, under a certain pressure, at

ambient temperature. The device, to keep the test medium flowing, has a storage

compressed air system, a piston pump, a device for controlling and measuring the flow.

6.5.3....

Get QUOTATION in 1-minute: Click QC/T 664-2019

Historical versions: QC/T 664-2019

Preview True-PDF (Reload/Scroll if blank)

QC/T 664-2019: Automotive air-conditioning refrigerant hose

QC/T 664-2019

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.60

T 26

Replacing QC/T 664-2000

Automotive air-conditioning refrigerant hose

ISSUED ON: DECEMBER 24, 2019

IMPLEMENTED ON: JULY 01, 2020

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 5

1 Scope ... 7

2 Normative references ... 7

3 Terms and definitions... 7

4 Categories ... 8

5 Technical requirements ... 9

6 Test methods ... 12

7 Signs ... 23

8 Inspection, packaging, transportation, storage ... 23

Automotive air-conditioning refrigerant hose

1 Scope

This standard specifies the classification, dimensions, technical requirements, test

methods, marking, inspection and packaging, transportation, storage of hoses for

conveying refrigerants in automotive air-conditioning systems.

This standard is applicable to rubber or thermoplastic hoses, for conveying liquid or

gaseous HFC-134a/HFO-1234yf refrigerants in automotive air-conditioning systems.

2 Normative references

The following documents are essential for the application of this document. For dated

references, only the dated version applies to this document. For undated references, the

latest edition (including all amendments) applies to this document.

GB/T 1690 Rubber, vulcanized or thermoplastic - Determination of the effect of

liquids

GB/T 2941 Rubber - General procedures for preparing and conditioning test pieces

for physical test methods

GB/T 30512 Requirements for prohibited substances on automobiles

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

High pressure hose

A hose, which has a working pressure of not less than 3.5 MPa (marked as HP).

3.2

Low pressure hose

A hose, which has a working pressure not higher than 1.5 MPa (marked as LP).

Carry out the test, according to the test method specified in 6.8. The collapse of the

outer diameter of the hose, during the test, shall not be less than 20% of the initial outer

diameter of the hose.

5.8 Length change rate

Carry out the test, according to the test method specified in 6.9. During the test, under

the action of the specified pressure, the length change rate of the hose shall be -4% ~

2%.

5.9 Burst pressure

Carry out the test, according to the test method specified in 6.10. The minimum burst

pressure of the hose, which has a nominal inner diameter not greater than 13.0 mm,

shall be 14.7 MPa. The minimum burst pressure of the hose, which has a nominal inner

diameter greater than 13.0 mm, shall be 12.0 MPa.

5.10 Pressure resistance

Carry out the test, according to the test method specified in 6.11. During the test, the

hose shall be tested, according to the specified pressure and time. The abnormal

phenomena, such as leakage, crack, sudden twisting of the hose, are not allowed.

5.11 Extractables content

Carry out the test, according to the test method specified in 6.12. After the test, the

content of extractables, on the inner surface of the hose, shall not exceed 118 g/m2.

5.12 Volume change rate of inner layer material

Carry out the test, according to the test method specified in 6.13. After the test, the

volume change rate of the rubber material shall be -5% ~ 35%; the volume change rate

of the thermoplastic material shall be -5% ~ 5%.

5.13 Ozone resistance

Carry out the test, according to the test method specified in 6.14. After the test, the outer

rubber layer of the hose shall have no visible cracks, under an eight-fold magnifying

glass.

5.14 Internal surface cleanliness

Carry out the test, according to the test method specified in 6.15. After the test, the

impurity content shall not exceed 270 mg/m2; the size of the gas particles shall not

exceed 0.5 mm x 1.0 mm.

5.15 Pulse fatigue resistance

conditions specified in GB/T 2941.

6.2 Test medium

The test medium used in the test shall be a mixture of HFC-134a, which has a mass

fraction of 90% or HFO-1234yf refrigerant and 10% refrigerating machine oil.

6.3 Dimensional measurement

6.3.1 Inner and outer diameters of hoses

The inner diameter of the hose shall be measured by a special measuring tool, such as

a tapered plug gauge, expanding ball type or retractable meter, etc. The diameter is

measured 3 times; the results are averaged.

6.3.2 Deviation of hose's wall thickness

The deviation of wall thickness of the hose shall be measured by a special meter, such

as a caliper with a probe that can touch the inner wall of the hose. Measure the wall

thickness of the cross section of the hose, at four points; take the difference between the

maximum value and the minimum value measured. Make 3 measurements. Take the

average of the results.

6.4 Permeation

Take 3 hoses. Fill the hoses with the specified test medium, according to the method in

6.5.3.1. Weigh the hoses and accessories. Then place the samples at a temperature of

100 °C ± 2 °C, for 24 hours. After taking out, weigh the mass of the hose and accessories

again. Calculate the mass loss.

6.5 Refrigerant permeability

6.5.1 Test device

6.5.1.1 Accessories and fixtures

Accessories and clamps shall be sealed and leak-free, when subjected to the pressure in

the hose.

6.5.1.2 Leak detector

The sensitivity of the leak detector shall be higher than 2 g/year (under the same volume

and temperature conditions, the refrigerant's equivalent ratio HFC-134a:HFO-1234yf =

1:0.92).

6.5.1.3 Constant temperature chamber

The control accuracy of the constant temperature chamber shall be ±2 °C.

6.5.1.4 Balances

The measurement accuracy of the balance shall be 0.01 g.

6.5.2 Test conditions

For use of hoses at higher working pressures, the test temperature shall be 90 °C ± 2 °C

or 100 °C ± 2 °C (high-pressure hose). For use of hoses at lower working pressures, the

test temperature shall be 80 °C ± 2 °C (low-pressure hose).

6.5.3 Test method

6.5.3.1 Preparation before the test

Take 4 hoses, which have an exposed length of 1m, and accessories. Use seals to seal

them at both ends. Three of them are used to measure the loss of refrigerant; the fourth

one is connected with a joint, which is used as a comparison hose, to detect the change

of the mass torsion of the hose itself. In the standard state, measure the exposed length

of the hose (L1, L2), the accuracy is required to be ±1 mm. Weigh the mass of each hose

and accessories (including joints), which is required to be accurate to ± 0.1 g. The hose

assembly is filled with 0.6 mg of test medium per millimeter volume; the filling volume

is accurate to ±5 g. The number of filled hoses is 3. Use a leak detector, to check that

each hose is leaking.

Filling of refrigerant

Method 1:

Before filling the hoses and accessories, they must be kept in a low temperature

chamber of -30 °C or lower, for 4 hours. Use the density of the test medium, at this

temperature, to calculate the mass of the test medium to be filled. Keep the test medium

and the hose at this temperature Use an electronic balance, to weigh the test medium.

Then fill the test medium into the hose. The filled hose and accessories are sealed at

this temperature.

Method 2:

The hose and accessories are filled with the test medium, under a certain pressure, at

ambient temperature. The device, to keep the test medium flowing, has a storage

compressed air system, a piston pump, a device for controlling and measuring the flow.

6.5.3....

Share