1

/

dari

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

SN/T 0481.7-2007 English PDF (SNT0481.7-2007)

SN/T 0481.7-2007 English PDF (SNT0481.7-2007)

Harga reguler

$110.00 USD

Harga reguler

Harga obral

$110.00 USD

Harga satuan

/

per

Biaya pengiriman dihitung saat checkout.

Tidak dapat memuat ketersediaan pengambilan

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click SN/T 0481.7-2007

Historical versions: SN/T 0481.7-2007

Preview True-PDF (Reload/Scroll if blank)

SN/T 0481.7-2007: Inspection of bauxite for import and export. Determination of Fe2O3, TiO2, SiO2, CaO, MgO content. Inductively coupled plasma atomic emission spectrometry

SN/T 0481.7-2007

ENTRY-EXIT INSPECTION AND QUARANTINE INDUSTRY

STANDARD OF THE PEOPLE’S REPUBLIC OF CHINA

Inspection of bauxite for import and export - Determination

of Fe2O3, TiO2, SiO2, CaO, MgO content - Inductively

coupled plasma atomic emission spectrometry

ISSUED ON: APRIL 06, 2007

IMPLEMENTED ON: OCTOBER 16, 2007

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Method summary ... 4

4 Reagents ... 5

5 Instruments and equipment ... 6

6 Sampling and sample preparation ... 6

7 Specimen preparation ... 7

8 Analysis steps ... 7

9 Calculation of analysis result ... 8

10 Precision ... 9

Annex A (informative) Working conditions and detection limit of instrument ... 10

Inspection of bauxite for import and export - Determination

of Fe2O3, TiO2, SiO2, CaO, MgO content - Inductively

coupled plasma atomic emission spectrometry

1 Scope

This Part of SN/T 0481 specifies inductively coupled plasma atomic emission

spectrometry (hereinafter referred as ICP-AES), the method to determine ferric oxide

(Fe2O3), titanium dioxide (TiO2), silicon dioxide (SiO2), calcium oxide (CaO),

magnesium oxide (MgO) content in bauxite.

This Part is applicable to the determination of Fe2O3, TiO2, SiO2, CaO, MgO content

in bauxite. See Table 1 for the determination range of each element.

2 Normative references

The provisions in following documents become the provisions of this Part of SN/T 0481

through reference in this Standard. For dated references, the subsequent amendments

(excluding corrigendum) or revisions do not apply to this Part, however, parties who

reach an agreement based on this Part are encouraged to study if the latest versions of

these documents are applicable. For undated references, the latest edition of the

referenced document applies.

GB/T 2007 (all parts), General rules for the sampling and sample preparation of

minerals in bulk

3 Method summary

The specimen uses lithium tetraborate as the flux. After it is melted at a high

temperature, use hydrochloric acid to extract. After the volume is set constant, use ICP-

AES instrument to determine the emission spectrum intensity of the test element in the

test solution. Find corresponding concentration from the working curve. Calculate its

content.

4 Reagents

Unless otherwise specified, it shall only use the confirmed analytically-pure reagents

and distilled water or equivalent-pure water in the analysis.

4.1 Graphite powder: Powder, 100 meshes, carbon content ≥ 98.5%.

4.2 Argon: ≥99.99%.

4.3 Hydrogen peroxide (ρ=1.10g/mL).

4.4 Hydrochloric acid (ρ=1.19g/mL).

4.5 Hydrochloric acid solution (1+9).

4.6 Hydrochloric acid solution (1+3).

4.7 Lithium tetraborate.

4.8 Lithium tetraborate solution (10g/L): Weigh 1.0g of lithium tetraborate (4.7). Add

50mL of hydrochloric acid solution (4.5). Slightly heat it to make it dissolved. Use

water to set the volume constant into a 100mL volumetric flask. Mix well for use.

4.9 Aluminum standard solution (10mg/mL): Accurately weigh 1.0000g of high purity

aluminum (99.99%) into a 200mL beaker. Add 40mL of hydrochloric acid solution (4.6).

Boil it till it is clear. If it is insoluble, it may add a certain amount of hydrogen peroxide

(4.3). Cool down. Transfer it into a 100mL volumetric flask. Use water to dilute to the

scale. Mix well. 1mL of this solution contains 10mg of aluminum.

4.10 Iron, titanium, calcium, and magnesium standard stock solutions (1mg/mL).

4.11 Silicon standard stock solution (0.5mg/mL).

4.12 Mixed standard solution: Respectively pipette 40.00mL of silicon standard stock

solution (4.9.3); 15.00mL of iron, titanium standard stock solutions (4.9.2) each;

5.00mL of calcium, magnesium standard stock solutions (4.9.2) each -- into 100mL

volumetric flasks. Then add 10.00mL of concentrated hydrochloric acid (4.4). Set the

volume constant. Mix well for use. See Table 2 of the content of each element.

tweezers to take the molten beads out. Use a brush to remove the graphite powder

attached to the surface. Put the molten beads into the beaker. Add 40mL of hydrochloric

acid solution (4.6). Place it in the (55 ± 5)°C constant temperature water bath oscillator.

Immerse till the molten beads are completely dissolved. Filter into a 250mL volumetric

flask. Set the volume constant. Mix well for ICP-AES determination.

8.4 Spectral measurement

8.4.1 Instrument optimization

Start the ICP-AES instrument. Adjust the working conditions and measurement

parameters of the instrument to the best state (see Annex A).

8.4.2 Drawing of working curve

Introduce the standard solution series (8.3.1) into the plasma in sequence. Measure the

spectral signal intensity of each analysis line. Use the strength as Y-axis, the

concentration (µg/mL) of each test element in each standard solution as X-axis, to

obtain the working curve of each element. Perform linear regression. Calculate the

correlation coefficient. The correlation coefficient shall meet the requirements of 5.4.4.

8.4.3 Determination of test solution

Introduce the blank solution (8.2) and the test material solution (8.3.2) into the plasma.

Respectively measure the spectral intensity of each test element. According to the

working curve, obtain the concentration of each corresponding component. If the

number of samples is large, the standard sample can be inserted into the sample

measurement gap as a control sample, so as to control the accuracy of the analysis result.

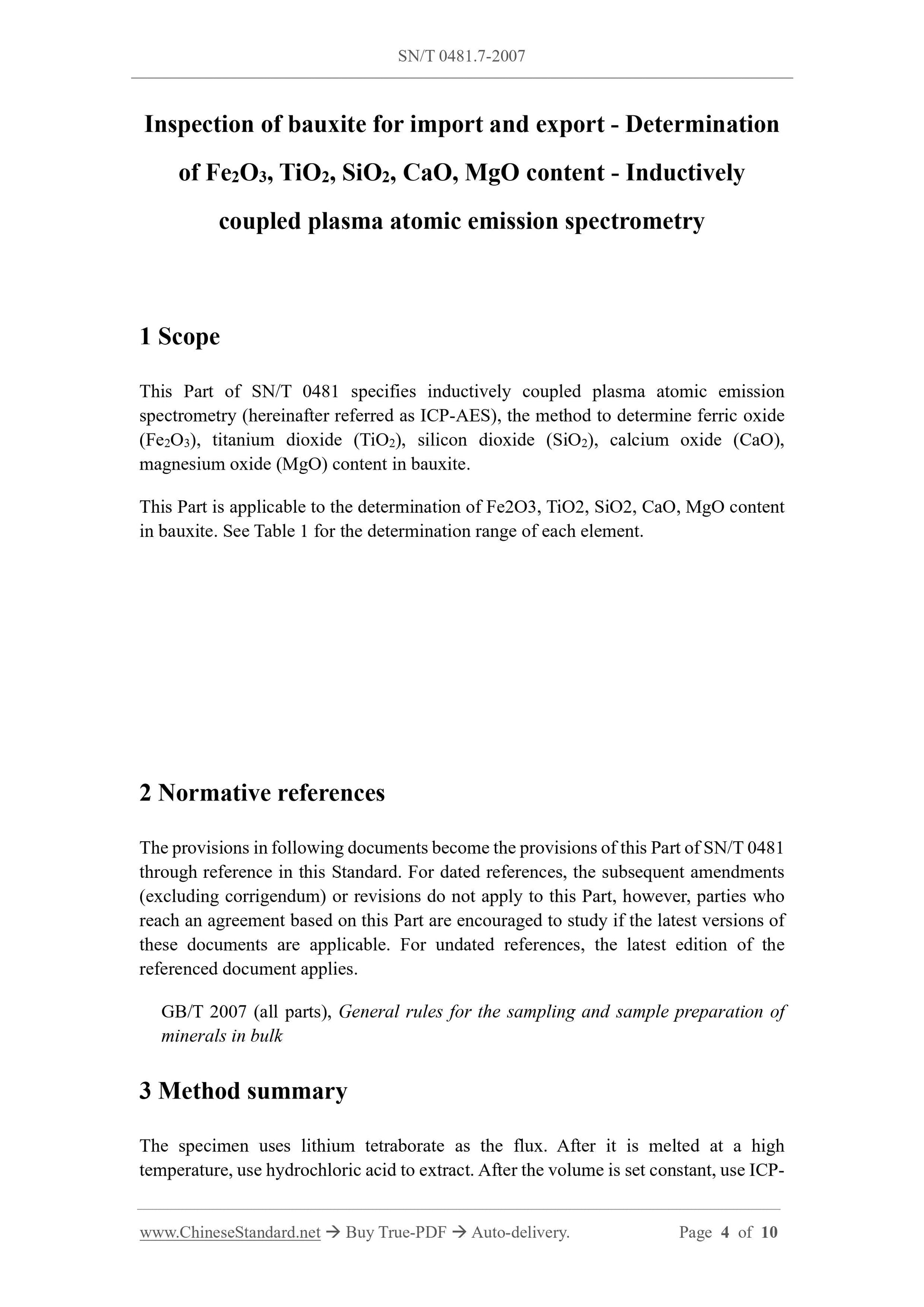

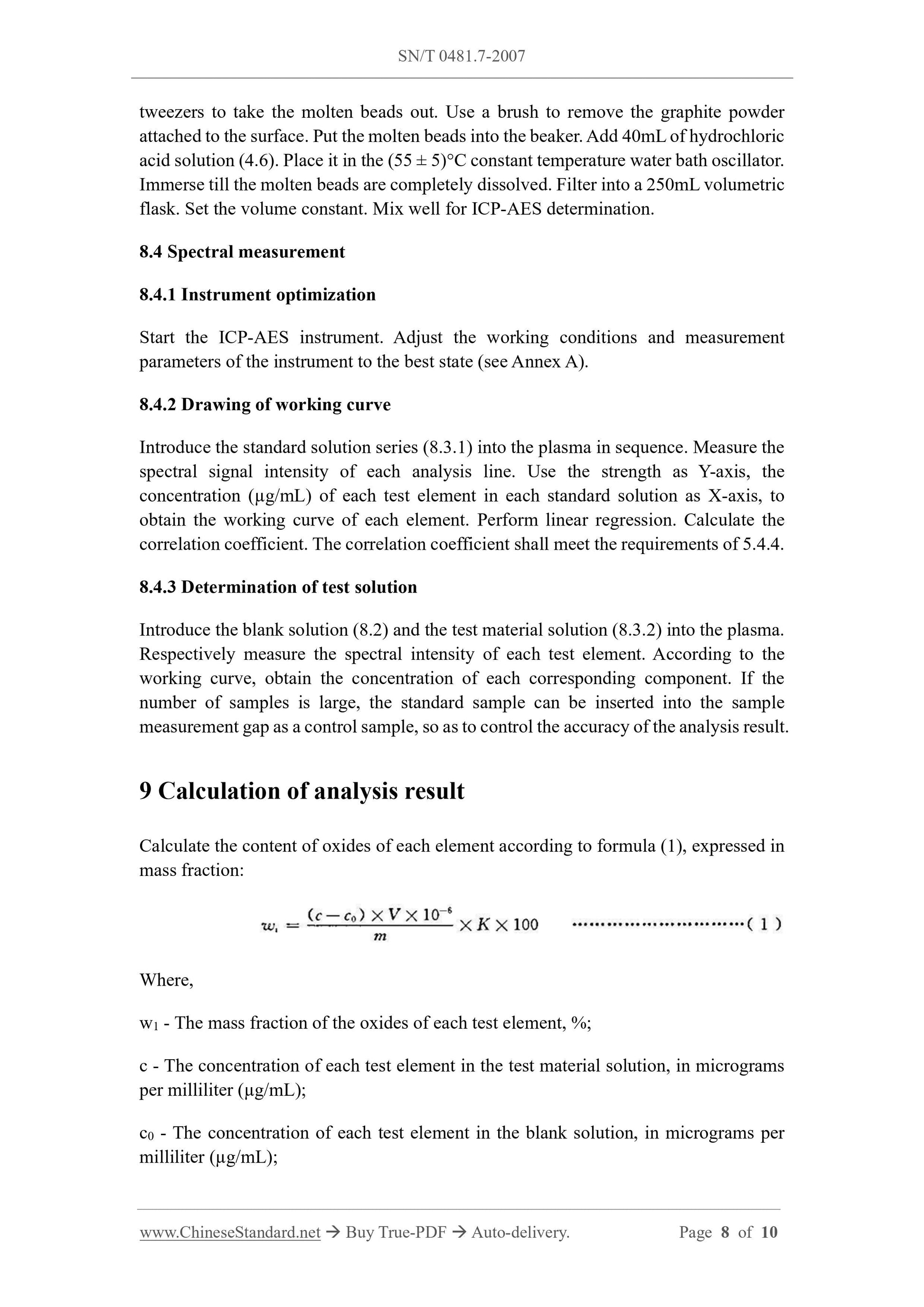

9 Calculation of analysis result

Calculate the content of oxides of each element according to formula (1), expressed in

mass fraction:

Where,

w1 - The mass fraction of the oxides of each test element, %;

c - The concentration of each test element in the test material solution, in micrograms

per milliliter (µg/mL);

c0 - The concentration of each test element in the blank solution, in micrograms per

milliliter (µg/mL);

Get QUOTATION in 1-minute: Click SN/T 0481.7-2007

Historical versions: SN/T 0481.7-2007

Preview True-PDF (Reload/Scroll if blank)

SN/T 0481.7-2007: Inspection of bauxite for import and export. Determination of Fe2O3, TiO2, SiO2, CaO, MgO content. Inductively coupled plasma atomic emission spectrometry

SN/T 0481.7-2007

ENTRY-EXIT INSPECTION AND QUARANTINE INDUSTRY

STANDARD OF THE PEOPLE’S REPUBLIC OF CHINA

Inspection of bauxite for import and export - Determination

of Fe2O3, TiO2, SiO2, CaO, MgO content - Inductively

coupled plasma atomic emission spectrometry

ISSUED ON: APRIL 06, 2007

IMPLEMENTED ON: OCTOBER 16, 2007

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Method summary ... 4

4 Reagents ... 5

5 Instruments and equipment ... 6

6 Sampling and sample preparation ... 6

7 Specimen preparation ... 7

8 Analysis steps ... 7

9 Calculation of analysis result ... 8

10 Precision ... 9

Annex A (informative) Working conditions and detection limit of instrument ... 10

Inspection of bauxite for import and export - Determination

of Fe2O3, TiO2, SiO2, CaO, MgO content - Inductively

coupled plasma atomic emission spectrometry

1 Scope

This Part of SN/T 0481 specifies inductively coupled plasma atomic emission

spectrometry (hereinafter referred as ICP-AES), the method to determine ferric oxide

(Fe2O3), titanium dioxide (TiO2), silicon dioxide (SiO2), calcium oxide (CaO),

magnesium oxide (MgO) content in bauxite.

This Part is applicable to the determination of Fe2O3, TiO2, SiO2, CaO, MgO content

in bauxite. See Table 1 for the determination range of each element.

2 Normative references

The provisions in following documents become the provisions of this Part of SN/T 0481

through reference in this Standard. For dated references, the subsequent amendments

(excluding corrigendum) or revisions do not apply to this Part, however, parties who

reach an agreement based on this Part are encouraged to study if the latest versions of

these documents are applicable. For undated references, the latest edition of the

referenced document applies.

GB/T 2007 (all parts), General rules for the sampling and sample preparation of

minerals in bulk

3 Method summary

The specimen uses lithium tetraborate as the flux. After it is melted at a high

temperature, use hydrochloric acid to extract. After the volume is set constant, use ICP-

AES instrument to determine the emission spectrum intensity of the test element in the

test solution. Find corresponding concentration from the working curve. Calculate its

content.

4 Reagents

Unless otherwise specified, it shall only use the confirmed analytically-pure reagents

and distilled water or equivalent-pure water in the analysis.

4.1 Graphite powder: Powder, 100 meshes, carbon content ≥ 98.5%.

4.2 Argon: ≥99.99%.

4.3 Hydrogen peroxide (ρ=1.10g/mL).

4.4 Hydrochloric acid (ρ=1.19g/mL).

4.5 Hydrochloric acid solution (1+9).

4.6 Hydrochloric acid solution (1+3).

4.7 Lithium tetraborate.

4.8 Lithium tetraborate solution (10g/L): Weigh 1.0g of lithium tetraborate (4.7). Add

50mL of hydrochloric acid solution (4.5). Slightly heat it to make it dissolved. Use

water to set the volume constant into a 100mL volumetric flask. Mix well for use.

4.9 Aluminum standard solution (10mg/mL): Accurately weigh 1.0000g of high purity

aluminum (99.99%) into a 200mL beaker. Add 40mL of hydrochloric acid solution (4.6).

Boil it till it is clear. If it is insoluble, it may add a certain amount of hydrogen peroxide

(4.3). Cool down. Transfer it into a 100mL volumetric flask. Use water to dilute to the

scale. Mix well. 1mL of this solution contains 10mg of aluminum.

4.10 Iron, titanium, calcium, and magnesium standard stock solutions (1mg/mL).

4.11 Silicon standard stock solution (0.5mg/mL).

4.12 Mixed standard solution: Respectively pipette 40.00mL of silicon standard stock

solution (4.9.3); 15.00mL of iron, titanium standard stock solutions (4.9.2) each;

5.00mL of calcium, magnesium standard stock solutions (4.9.2) each -- into 100mL

volumetric flasks. Then add 10.00mL of concentrated hydrochloric acid (4.4). Set the

volume constant. Mix well for use. See Table 2 of the content of each element.

tweezers to take the molten beads out. Use a brush to remove the graphite powder

attached to the surface. Put the molten beads into the beaker. Add 40mL of hydrochloric

acid solution (4.6). Place it in the (55 ± 5)°C constant temperature water bath oscillator.

Immerse till the molten beads are completely dissolved. Filter into a 250mL volumetric

flask. Set the volume constant. Mix well for ICP-AES determination.

8.4 Spectral measurement

8.4.1 Instrument optimization

Start the ICP-AES instrument. Adjust the working conditions and measurement

parameters of the instrument to the best state (see Annex A).

8.4.2 Drawing of working curve

Introduce the standard solution series (8.3.1) into the plasma in sequence. Measure the

spectral signal intensity of each analysis line. Use the strength as Y-axis, the

concentration (µg/mL) of each test element in each standard solution as X-axis, to

obtain the working curve of each element. Perform linear regression. Calculate the

correlation coefficient. The correlation coefficient shall meet the requirements of 5.4.4.

8.4.3 Determination of test solution

Introduce the blank solution (8.2) and the test material solution (8.3.2) into the plasma.

Respectively measure the spectral intensity of each test element. According to the

working curve, obtain the concentration of each corresponding component. If the

number of samples is large, the standard sample can be inserted into the sample

measurement gap as a control sample, so as to control the accuracy of the analysis result.

9 Calculation of analysis result

Calculate the content of oxides of each element according to formula (1), expressed in

mass fraction:

Where,

w1 - The mass fraction of the oxides of each test element, %;

c - The concentration of each test element in the test material solution, in micrograms

per milliliter (µg/mL);

c0 - The concentration of each test element in the blank solution, in micrograms per

milliliter (µg/mL);

Share