1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 674-2007 English PDF (QCT674-2007)

QC/T 674-2007 English PDF (QCT674-2007)

Regular price

$160.00 USD

Regular price

Sale price

$160.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 674-2007

Historical versions: QC/T 674-2007

Preview True-PDF (Reload/Scroll if blank)

QC/T 674-2007: Solenoid valve of CNG vehicles

QC/T 674-2007

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.080.99

T47

Replacing QC/T 674-2000

Solenoid Valve of CNG Vehicles

ISSUED ON. NOVEMBER 14, 2007

IMPLEMENTED ON. MAY 1, 2008

Issued by. National Development and Reform Committee

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Types and basic parameters ... 6

5 Requirements ... 7

6 Test methods ... 10

7 Inspection rules ... 16

8 Mark, packaging, transportation and storage ... 17

9 Exit-factory documents ... 18

Foreword

This Standard is a revision to QC/T 674-2000 Solenoid Valve of CNG Vehicles.

This Standard is mainly based on ECE/R110 Safety Requirements and Test Method for

CNG Vehicle Fuel System Components and ISO 15500-6 Road vehicles - CNG Vehicle

Fuel System Components - Part 6. Automatic Valve.

Compared with QC/T 674-2000, this Standard has mainly the following changes.

— “This Standard is applicable to rated working pressure not greater than 20MPa (the

pressure stated in this Standard all refers to the gauge pressure)” is added to

contents of the scope (Chapter 1 of Edition 2000; Chapter 1 of this version);

— Delete model marking (4.3 of Edition 2000);

— Delete change of power voltage (5.2.1 of Edition 2000);

— Delete temperature tolerance (5.2.7 of Edition 2000);

— Insulation resistance shall not be less than 10MΩ, from 20MΩ (5.2.2 of Edition 2000;

5.2.3 of this version);

— Test pressure of the hydrostatic pressure is changed from 30MPa to 45MPa (5.2.4

of Edition 2000, 5.2.4 of this version);

— Low pressure air tightness test and high air tightness test are changed from the

original ambient temperature condition to – conduct the external leakage test and

internal leakage test under normal, high and low temperature respectively (5.2.5

and 5.2.6 of Edition 2000; 5.2.5 of this version);

— Test standards for compatibility test are different (5.2.10 of Edition 2000; 5.2.9 of this

version);

— Durability tests is changed from 150000 times to 50000 times (5.2.12 of Edition

2000; 5.2.14 of this version);

— Add the high-temperature test (5.2.6 of this version);

— Add the low-temperature test (5.2.7 of this version);

— Add the drought-hot tolerance (5.2.8 of this version);

— Add the ozone resistance (5.2.10 of this version);

— Add the corrosion resistance (5.2.11 of this version);

Solenoid Valve of CNG Vehicles

1 Scope

This Standard specifies the type, basic parameters, requirements, test methods,

inspection rules, mark, package, transportation and storage of solenoid valves of CNG

vehicles (its definition is in GB/T 17895).

This Standard is applicable to the solenoid valve that controls the open-close functions in

compressed natural gas supply system of the gas vehicle, of which the working medium of

compressed natural gas for vehicles meets the requirements of GB 18047, the operation

environment is that - the working pressure is not greater than 20MPa (The pressure stated

in this Standard all refers to the gauge pressure), the environment temperature is

-40°C~+120°C, and the relative humidity is 5%~100%.

2 Normative references

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments (excluding

corrigendum) or revisions do not apply to this Standard, however, parties who reach an

agreement based on this Standard are encouraged to study if the latest versions of these

documents are applicable. For undated references, the latest edition of the referenced

document applies.

GB/T 191 Packaging - Pictorial markings for handling of goods

GB/T 528 Rubber, vulcanized or thermoplastic - Determination of tensile stress-strain

properties

GB/T 7762 Rubber, vulcanized or thermoplastic - Resistance to ozone cracking - Static

strain test

GB 9969.1 General principles for preparation of instructions for use of industrial

products

GB/T10125 Corrosion tests in artificial atmospheres - Salt spray tests

GB/T17895 Natural gas vehicle and liquefied petroleum gas vehicle - Vocabulary

GB 18047 Compressed natural gas as vehicle fuel

GB/T 19240 Mounting requirements of special equipment for compressed natural

vehicles

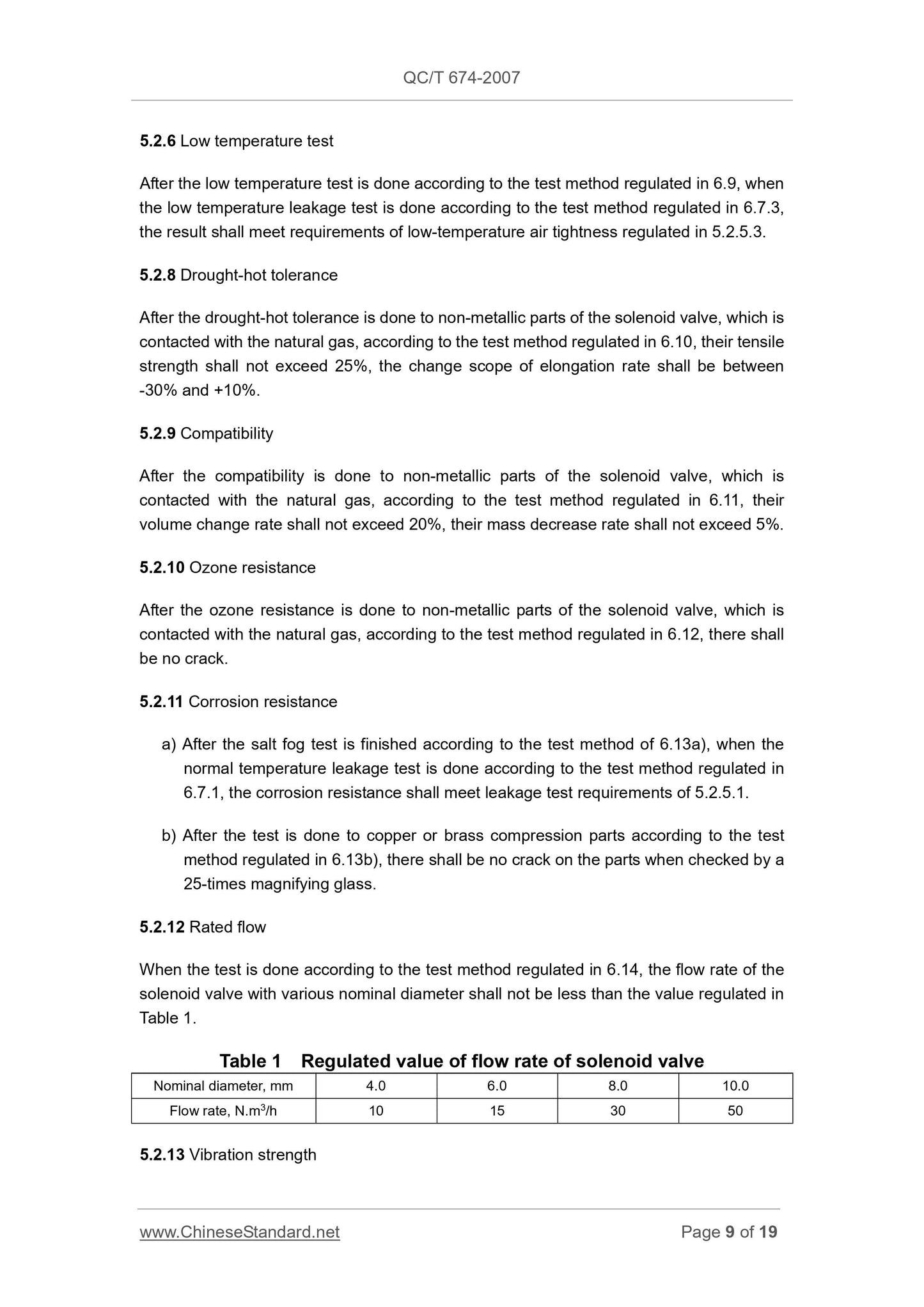

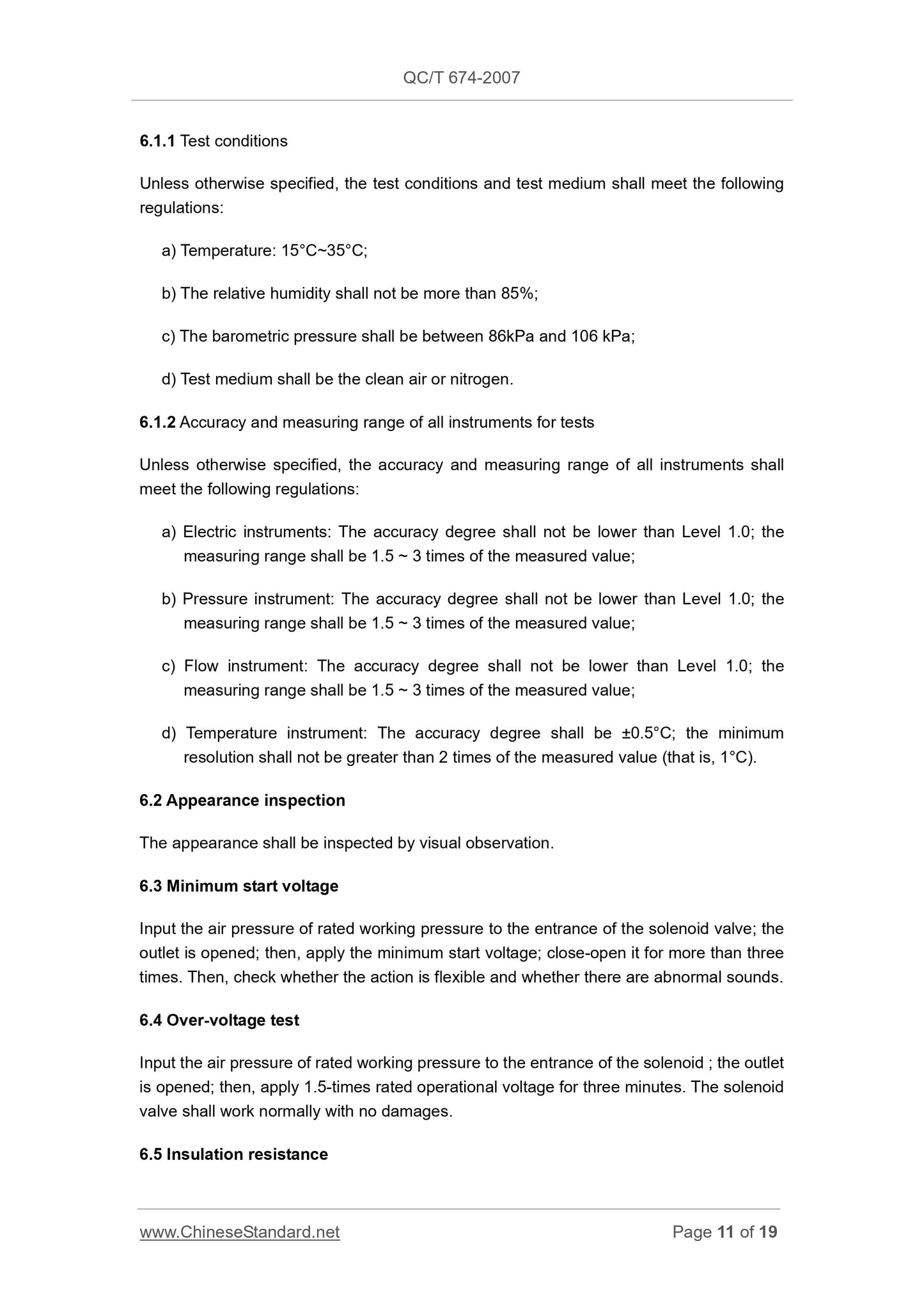

5.2.1 Minimum start voltage

When the rated voltage of the solenoid valve is 12V (DC), its minimum start voltage shall

be 8V (DC). When its rated voltage is 24V (DC), the minimum start voltage shall be 18V

(DC).

When the test is done according to the test method of 6.3, the solenoid valve shall be able

to work normally and no abnormal sound.

5.2.2 Over-voltage test

When the test is done according to the test method of 6.4, the solenoid valve shall be able

to work normally and no abnormal sound.

5.2.3 Insulation resistance

When the test is done according to the test method of 6.5, the insulation resistance

between the coupling end of the solenoid valve coil and the shell shall not be less than

10MΩ.

5.2.4 Hydro-static pressure

When the test is done according to the test method of 6.6, there shall be no fracture or

permanent deformation of the solenoid valve.

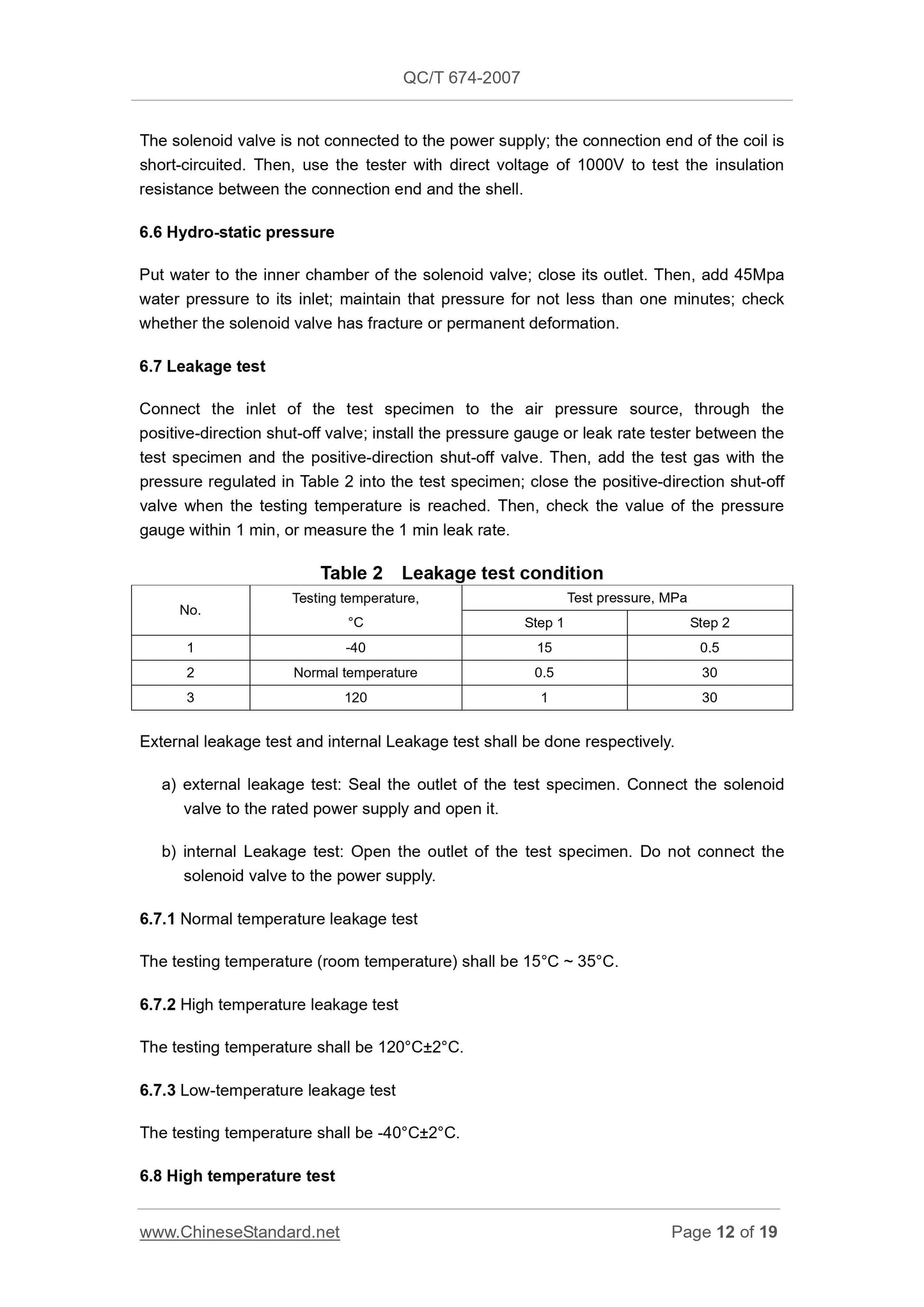

5.2.5 Leakage test

5.2.5.1 Normal temperature leakage test. When the normal temperature leakage test is

done according to the test method regulated in 6.7.1, the displayed value of the pressure

gauge shall not decline within one minute, or its leak rate shall not be more than

15*10-6N.m3/h.

5.2.5.2 High temperature leakage test. When the high temperature leakage test is done

according to the test method regulated in 6.7.2, the displayed value of the pressure gauge

shall not decline within one minute, or its leak rate shall not be more than 15*10-6N.m3/h.

5.2.5.3 Low temperature leakage test. When the low temperature leakage test is done

according to the test method regulated in 6.7.3, the displayed value of the pressure gauge

shall not decline within one minute, or its leak rate shall not be more than 15*10-6N.m3/h.

5.2.6 High temperature test

After the high temperature test is done according to the test method regulated in 6.8,

when the high temperature leakage test is done according to the test method regulated in

6.7.2, the result shall meet requirements of low-temperature air tightness regulated in

5.2.5.2.

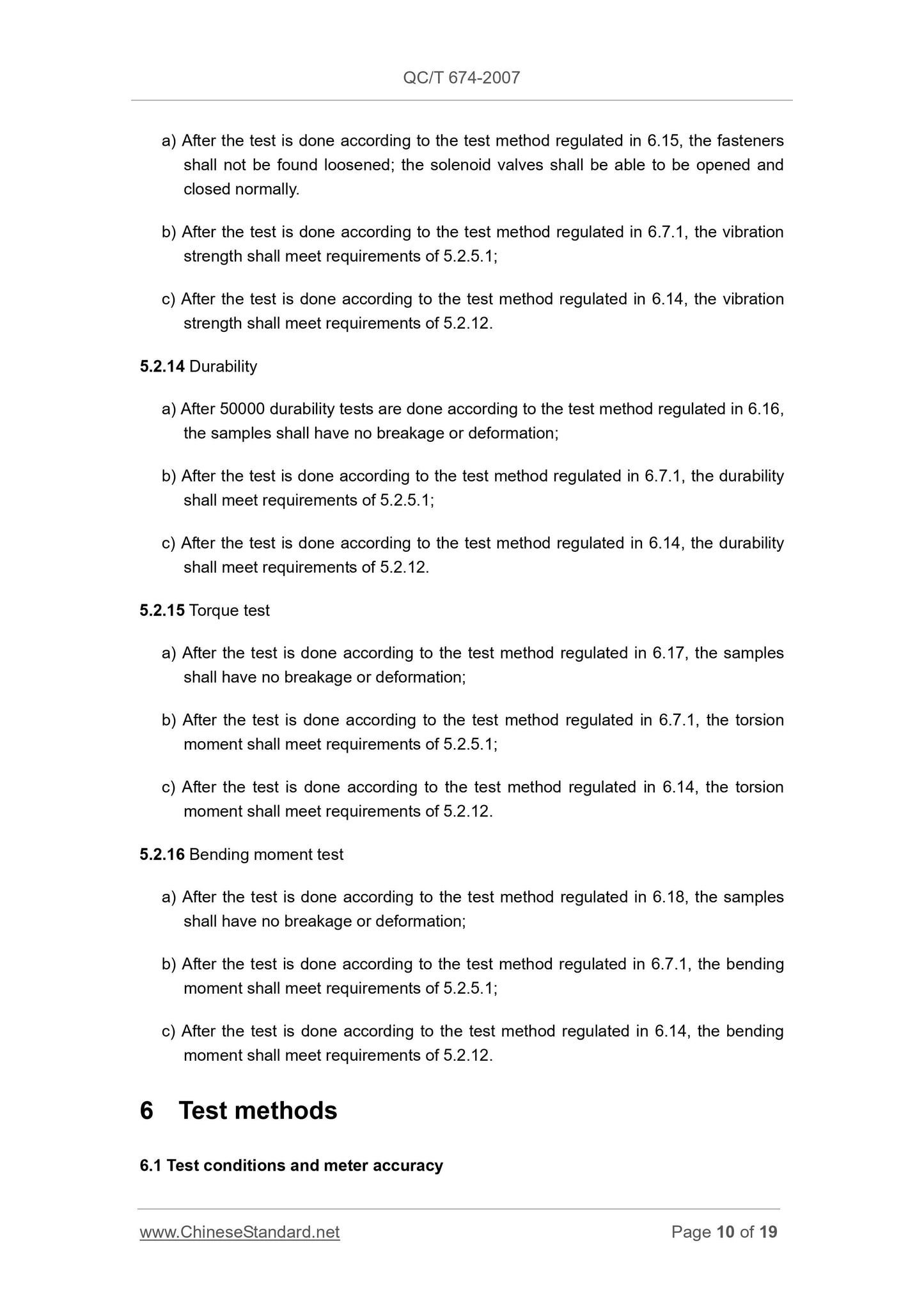

a) After the test is done according to the test method regulated in 6.15, the fasteners

shall not be found loosened; the solenoid valves shall be able to be opened and

closed normally.

b) After the test is done according to the test method regulated in 6.7.1, the vibration

strength shall meet requirements of 5.2.5.1;

c) After the test is done according to the test method regulated in 6.14, the vibration

strength shall meet requirements of 5.2.12.

5.2.14 Durability

a) After 50000 durability tests are done according to the test method regulated in 6.16,

the samples shall have no breakage or deformation;

b) After the test is done according to the test method regulated in 6.7.1, the durability

shall meet requirements of 5.2.5.1;

c) After the test is done according to the test method regulated in 6.14, the durability

shall meet requirements of 5.2.12.

5.2.15 Torque test

a) After the test is done according to the test method regulated in 6.17, the samples

shall have no breakage or deformation;

b) After the test is done according to the test method regulated in 6.7.1, the torsion

moment shall meet requirements of 5....

Get QUOTATION in 1-minute: Click QC/T 674-2007

Historical versions: QC/T 674-2007

Preview True-PDF (Reload/Scroll if blank)

QC/T 674-2007: Solenoid valve of CNG vehicles

QC/T 674-2007

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.080.99

T47

Replacing QC/T 674-2000

Solenoid Valve of CNG Vehicles

ISSUED ON. NOVEMBER 14, 2007

IMPLEMENTED ON. MAY 1, 2008

Issued by. National Development and Reform Committee

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Types and basic parameters ... 6

5 Requirements ... 7

6 Test methods ... 10

7 Inspection rules ... 16

8 Mark, packaging, transportation and storage ... 17

9 Exit-factory documents ... 18

Foreword

This Standard is a revision to QC/T 674-2000 Solenoid Valve of CNG Vehicles.

This Standard is mainly based on ECE/R110 Safety Requirements and Test Method for

CNG Vehicle Fuel System Components and ISO 15500-6 Road vehicles - CNG Vehicle

Fuel System Components - Part 6. Automatic Valve.

Compared with QC/T 674-2000, this Standard has mainly the following changes.

— “This Standard is applicable to rated working pressure not greater than 20MPa (the

pressure stated in this Standard all refers to the gauge pressure)” is added to

contents of the scope (Chapter 1 of Edition 2000; Chapter 1 of this version);

— Delete model marking (4.3 of Edition 2000);

— Delete change of power voltage (5.2.1 of Edition 2000);

— Delete temperature tolerance (5.2.7 of Edition 2000);

— Insulation resistance shall not be less than 10MΩ, from 20MΩ (5.2.2 of Edition 2000;

5.2.3 of this version);

— Test pressure of the hydrostatic pressure is changed from 30MPa to 45MPa (5.2.4

of Edition 2000, 5.2.4 of this version);

— Low pressure air tightness test and high air tightness test are changed from the

original ambient temperature condition to – conduct the external leakage test and

internal leakage test under normal, high and low temperature respectively (5.2.5

and 5.2.6 of Edition 2000; 5.2.5 of this version);

— Test standards for compatibility test are different (5.2.10 of Edition 2000; 5.2.9 of this

version);

— Durability tests is changed from 150000 times to 50000 times (5.2.12 of Edition

2000; 5.2.14 of this version);

— Add the high-temperature test (5.2.6 of this version);

— Add the low-temperature test (5.2.7 of this version);

— Add the drought-hot tolerance (5.2.8 of this version);

— Add the ozone resistance (5.2.10 of this version);

— Add the corrosion resistance (5.2.11 of this version);

Solenoid Valve of CNG Vehicles

1 Scope

This Standard specifies the type, basic parameters, requirements, test methods,

inspection rules, mark, package, transportation and storage of solenoid valves of CNG

vehicles (its definition is in GB/T 17895).

This Standard is applicable to the solenoid valve that controls the open-close functions in

compressed natural gas supply system of the gas vehicle, of which the working medium of

compressed natural gas for vehicles meets the requirements of GB 18047, the operation

environment is that - the working pressure is not greater than 20MPa (The pressure stated

in this Standard all refers to the gauge pressure), the environment temperature is

-40°C~+120°C, and the relative humidity is 5%~100%.

2 Normative references

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments (excluding

corrigendum) or revisions do not apply to this Standard, however, parties who reach an

agreement based on this Standard are encouraged to study if the latest versions of these

documents are applicable. For undated references, the latest edition of the referenced

document applies.

GB/T 191 Packaging - Pictorial markings for handling of goods

GB/T 528 Rubber, vulcanized or thermoplastic - Determination of tensile stress-strain

properties

GB/T 7762 Rubber, vulcanized or thermoplastic - Resistance to ozone cracking - Static

strain test

GB 9969.1 General principles for preparation of instructions for use of industrial

products

GB/T10125 Corrosion tests in artificial atmospheres - Salt spray tests

GB/T17895 Natural gas vehicle and liquefied petroleum gas vehicle - Vocabulary

GB 18047 Compressed natural gas as vehicle fuel

GB/T 19240 Mounting requirements of special equipment for compressed natural

vehicles

5.2.1 Minimum start voltage

When the rated voltage of the solenoid valve is 12V (DC), its minimum start voltage shall

be 8V (DC). When its rated voltage is 24V (DC), the minimum start voltage shall be 18V

(DC).

When the test is done according to the test method of 6.3, the solenoid valve shall be able

to work normally and no abnormal sound.

5.2.2 Over-voltage test

When the test is done according to the test method of 6.4, the solenoid valve shall be able

to work normally and no abnormal sound.

5.2.3 Insulation resistance

When the test is done according to the test method of 6.5, the insulation resistance

between the coupling end of the solenoid valve coil and the shell shall not be less than

10MΩ.

5.2.4 Hydro-static pressure

When the test is done according to the test method of 6.6, there shall be no fracture or

permanent deformation of the solenoid valve.

5.2.5 Leakage test

5.2.5.1 Normal temperature leakage test. When the normal temperature leakage test is

done according to the test method regulated in 6.7.1, the displayed value of the pressure

gauge shall not decline within one minute, or its leak rate shall not be more than

15*10-6N.m3/h.

5.2.5.2 High temperature leakage test. When the high temperature leakage test is done

according to the test method regulated in 6.7.2, the displayed value of the pressure gauge

shall not decline within one minute, or its leak rate shall not be more than 15*10-6N.m3/h.

5.2.5.3 Low temperature leakage test. When the low temperature leakage test is done

according to the test method regulated in 6.7.3, the displayed value of the pressure gauge

shall not decline within one minute, or its leak rate shall not be more than 15*10-6N.m3/h.

5.2.6 High temperature test

After the high temperature test is done according to the test method regulated in 6.8,

when the high temperature leakage test is done according to the test method regulated in

6.7.2, the result shall meet requirements of low-temperature air tightness regulated in

5.2.5.2.

a) After the test is done according to the test method regulated in 6.15, the fasteners

shall not be found loosened; the solenoid valves shall be able to be opened and

closed normally.

b) After the test is done according to the test method regulated in 6.7.1, the vibration

strength shall meet requirements of 5.2.5.1;

c) After the test is done according to the test method regulated in 6.14, the vibration

strength shall meet requirements of 5.2.12.

5.2.14 Durability

a) After 50000 durability tests are done according to the test method regulated in 6.16,

the samples shall have no breakage or deformation;

b) After the test is done according to the test method regulated in 6.7.1, the durability

shall meet requirements of 5.2.5.1;

c) After the test is done according to the test method regulated in 6.14, the durability

shall meet requirements of 5.2.12.

5.2.15 Torque test

a) After the test is done according to the test method regulated in 6.17, the samples

shall have no breakage or deformation;

b) After the test is done according to the test method regulated in 6.7.1, the torsion

moment shall meet requirements of 5....

Share