1

/

of

7

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 18584-2001 English PDF (GB18584-2001)

GB 18584-2001 English PDF (GB18584-2001)

Regular price

$70.00 USD

Regular price

Sale price

$70.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 18584-2001

Historical versions: GB 18584-2001

Preview True-PDF (Reload/Scroll if blank)

GB 18584-2001: Indoor decorating and refurbishing materials -- Limit of harmful substances of wood-based furniture

GB 18584-2001

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 97.140

Y 80

Indoor Decorating and Refurbishing Materials –

Limit of Harmful Substance of Wood Based Furniture

ISSUED ON. DECEMBER 10, 2001

IMPLEMENTED ON. JANUARY 1, 2002

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative Reference ... 4

3 Terms and Definitions ... 5

4 Requirements ... 5

5 Test Method ... 5

6 Inspection Rules ... 11

Foreword

The Chapter 4 in this Standard is mandatory, while the rest are recommended.

Since January 1, 2002, the products produced by the manufacturer shall implement

this Standard; the transition period is 6 months; Since July 1, 2002, the products that

don’t conform to this Standard shall stop selling on the market.

This Standard was proposed by China Light Industry Council.

This Standard shall be under the jurisdiction of National Standardization Center of

Furniture.

Drafting organizations of this Standard. National Standardization Center of Furniture,

School of Wood Industry of Nanjing Forestry University, and Beijing Building Materials

Academy of Sciences Research.

Participating drafting organizations of this Standard. Tiantan Furniture Branch of

Beijing Tiantan Co., Ltd., Beijing Easyhome Decoration Development Co., Ltd.,

Shenzhen Dafuhao Industrial Development Co., Ltd., Shunde Meihua Home

Manufacturing Co., Ltd., and Shunde Hualong Coating Industrial Co., Ltd.

Chief drafting staffs of this Standard. Zhang Binyuan, Liu Yaoguo, Luo Xin, Yu

Zhengrong, Gu Ming, Zhang Zengbiao, Wang Linpeng, He Xunzheng, Chen Weiheng,

and Mai Quan.

Indoor Decorating and Refurbishing Materials –

Limit of Harmful Substance of Wood Based Furniture

1 Scope

This Standard specifies the limit requirements, test methods and inspection rules for

the harmful substance in the indoor wood based furniture.

This Standard is applicable to the various indoor wood based furniture products.

2 Normative Reference

The following documents contain the provisions which, through reference in this

Standard, become the provisions of this Standard. For dated references, their

subsequent amendments (excluding corrigendum) or revisions do not apply to this

Standard. However, the parties who enter into agreement based on this Standard are

encouraged to investigate whether the latest versions of these documents are

applicable. For undated reference documents, the latest versions apply to this

Standard.

GB/T 6682-1992 Water for Analytical Laboratory Use - Specification and Test

Methods (neq ISO 3696.1987)

GB/T 9758.1-1988 Paints and Varnishes - Determination of “Soluble” Metal

Content -Part 1. Determination of Lead Content - Flame Atomic Absorption

Spectrometric Method and Dithizone Spectrophotometric Method (idt ISO 3856-

1.1984)

GB/T 9758.4-1988 Paints and Varnishes - Determination of “Soluble” Metal

Content - Part 4. Determination of Cadmium Content - Flame Atomic Absorption

Spectrometric Method and Polarographic Method (idt ISO 3856-4.1984)

GB/T 9758.6-1988 Paints and Varnishes - Determination of “Soluble” Metal

Content -Part 6. Determination of Total Chromium Content of the Liquid Portion of

the Paint - Flame Atomic Absorption Spectrometric Method (idt ISO 3856-6.1984)

GB/T 9758.7-1988 Paints and Varnishes - Determination of “Soluble” Metal

Content - Part 7. Determination of Mercury Content of the Pigment Portion of the

Paint and of the Liquid Portion of Water-Dilutable Paints - Flameless Atomic

--- Glass mortar. diameter (100~120) mm;

--- Crystalizing dish. diameter 120mm, height 60mm;

5.1.2.6 Small-mouth plastic bottle. 500mL, 1000mL.

5.1.3 Reagent

--- Potassium iodide (KI). analytically pure;

--- Potassium dichromate (K2Cr2O7). guaranteed reagent;

--- Sodium thiosulfate (Na2S2O3 • 5H2O). analytically pure;

--- Mercury iodide (HgI2). analytically pure;

--- Anhydrous sodium carbonate (Na2CO3). analytically pure;

--- Sulfuric acid (H2SO4). ρ=1.84g/mL, analytically pure;

--- Hydrochloric acid (HCL). ρ=1.19g/mL, analytically pure;

--- Sodium hydroxide (NaOH). analytically pure;

--- Iodine (I2). analytically pure;

--- Soluble starch. analytically pure;

--- Acetylacetone (CH3COCH2COCH3). guaranteed reagent;

--- Ammonium acetate (CH3COONH4). guaranteed reagent;

--- Formaldehyde (CH2O) solution. concentration 35%~40%.

5.1.4 Specimen preparation

5.1.4.1 Specimen sampling

The specimen shall take sampling from the exit-factory qualified products that conform

to the test provisions. If the product is made of several kinds of wood materials, then

sampling from the component of each material.

5.1.4.2 The specimen shall be prepared within the distance about 50mm away from

the furniture component edge.

5.1.4.3 Specimen specification. length (150±1)mm, width (50±1)mm.

5.1.4.4 Specimen quantity

The quantity of the specimen is 10 blocks. When preparing the specimen, consider the

5.2.2.3 Membrane filter. pore size 0.45µm.

5.2.2.4 Magnetic stirrer. the outer layer of stirrer is plastic or glass.

5.2.2.5 Single-scale pipette. 25mL.

5.2.2.6 White volumetric flask. 50mL.

5.2.2.7 Scraper. tool with sharp blade.

5.2.3 Reagent

The used reagent is analytically pure, the used water meet the requirement for Grade-

III water stipulated in GB/T 6682-1992.

5.2.3.1 Hydrochloric acid solution

0.07 mol/L, 1 mol/L, 2 mol/L.

5.2.3.2 Nitric acid solution

Mass fraction is 65%~68%.

5.2.4 Preparation of coating powder

Use the scraper to scratch proper amount of coating from the coasting surface of

furniture product, crush the scratched coating by magnetic stirrer under the room

temperature, then make it penetrate through the 0.5mm metal sieve, and wait for

treatment.

5.2.5 Test procedures

5.2.5.1 Sample treatment

Weigh 0.5g (accurate to 0.0001g) of sieved powder, put it into white volumetric flask;

add 25mL of 0.07 mol/L hydrochloric acid solution, mix 1min, determine its acidity; if

pH is greater than 1.5, shake the solution as drop the hydrochloric acid solution with

concentration of 2 mol/L till pH decreases to 1.0~1.5. Stir such mixture continuously

under room temperature for 1h, after that stand for 1h, then use membrane filter to

filter and keep in dark place.

The sample treatment shall be finished within 4h. If it can’t finish within 4h, add 25mL

of 1 mol/L hydrochloric acid solution to treat the sample, the treatment method can see

above.

5.2.5.2 Determination of soluble metal content

5.2.5.2.1 Determination of soluble lead content shall be performed as per the Chapter

3 in GB/T 9758.1-1988.

5.2.5.2.2 Determination of soluble cadmium content shall be performed as per the

Chapter 3 in GB/T 9758.4-1988.

5.2.5.2.3 Determination of soluble chromium content shall be performed as per GB/T

9758.6-1988.

5.2.5.2.4 Determination of soluble mercury content shall be performed as per GB/T

9758.7-1988.

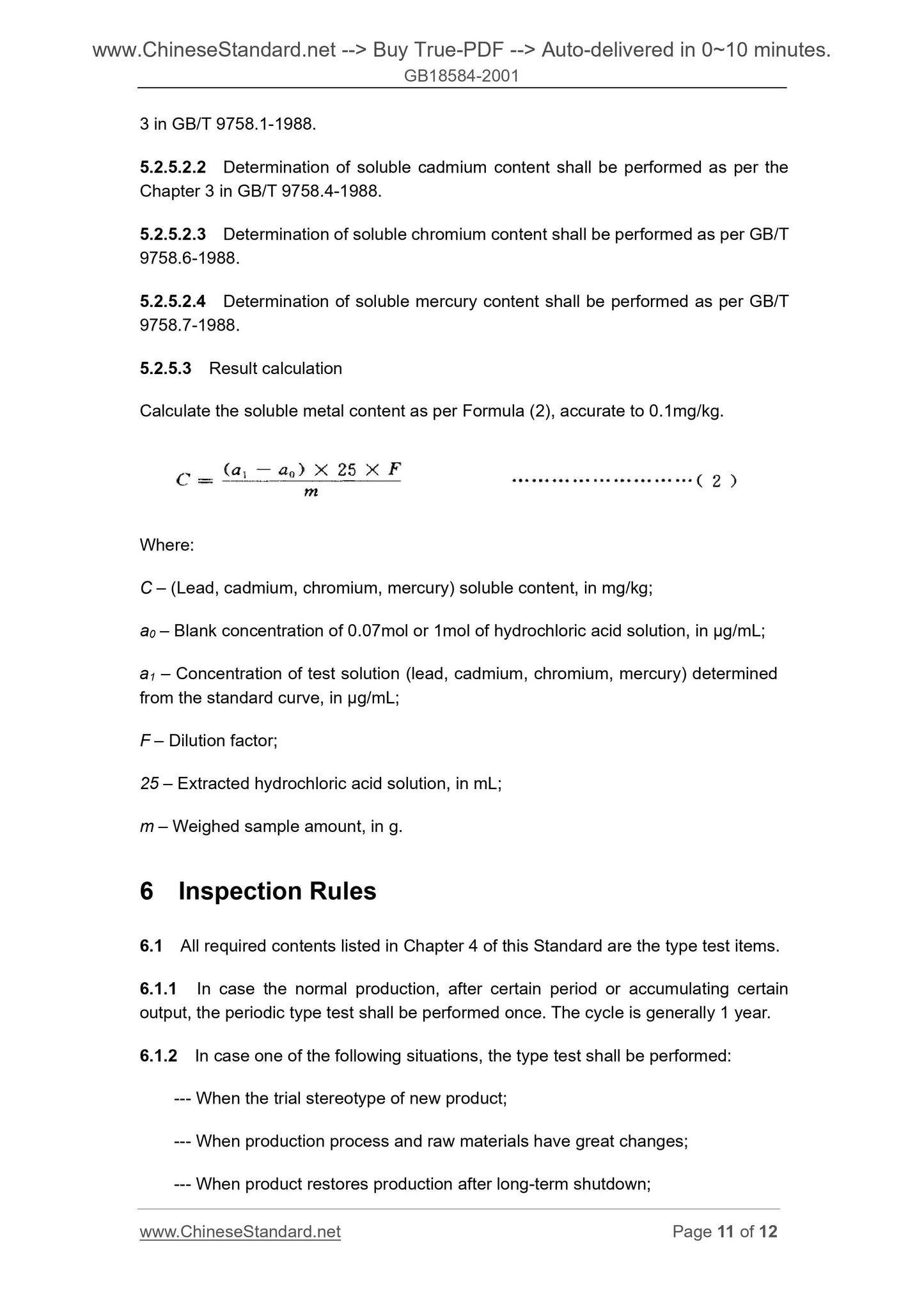

5.2.5.3 Result calculation

Calculate the soluble metal content as per Formula (2), accurate to 0.1mg/kg.

Where.

C – (Lead, cadmium, chromium, mercury) soluble content, in mg/kg;

a0 – Blank concentration of 0.07mol or 1mol of hydrochloric acid solution, in µg/mL;

a1 – Concentration of test solution (lead, cadmium, chromium, mercury) determined

from the standard curve, in µg/mL;

F – Dilution factor;

25 – Extracted hydrochloric acid solution, in mL;

m – Weighed ...

Get QUOTATION in 1-minute: Click GB 18584-2001

Historical versions: GB 18584-2001

Preview True-PDF (Reload/Scroll if blank)

GB 18584-2001: Indoor decorating and refurbishing materials -- Limit of harmful substances of wood-based furniture

GB 18584-2001

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 97.140

Y 80

Indoor Decorating and Refurbishing Materials –

Limit of Harmful Substance of Wood Based Furniture

ISSUED ON. DECEMBER 10, 2001

IMPLEMENTED ON. JANUARY 1, 2002

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative Reference ... 4

3 Terms and Definitions ... 5

4 Requirements ... 5

5 Test Method ... 5

6 Inspection Rules ... 11

Foreword

The Chapter 4 in this Standard is mandatory, while the rest are recommended.

Since January 1, 2002, the products produced by the manufacturer shall implement

this Standard; the transition period is 6 months; Since July 1, 2002, the products that

don’t conform to this Standard shall stop selling on the market.

This Standard was proposed by China Light Industry Council.

This Standard shall be under the jurisdiction of National Standardization Center of

Furniture.

Drafting organizations of this Standard. National Standardization Center of Furniture,

School of Wood Industry of Nanjing Forestry University, and Beijing Building Materials

Academy of Sciences Research.

Participating drafting organizations of this Standard. Tiantan Furniture Branch of

Beijing Tiantan Co., Ltd., Beijing Easyhome Decoration Development Co., Ltd.,

Shenzhen Dafuhao Industrial Development Co., Ltd., Shunde Meihua Home

Manufacturing Co., Ltd., and Shunde Hualong Coating Industrial Co., Ltd.

Chief drafting staffs of this Standard. Zhang Binyuan, Liu Yaoguo, Luo Xin, Yu

Zhengrong, Gu Ming, Zhang Zengbiao, Wang Linpeng, He Xunzheng, Chen Weiheng,

and Mai Quan.

Indoor Decorating and Refurbishing Materials –

Limit of Harmful Substance of Wood Based Furniture

1 Scope

This Standard specifies the limit requirements, test methods and inspection rules for

the harmful substance in the indoor wood based furniture.

This Standard is applicable to the various indoor wood based furniture products.

2 Normative Reference

The following documents contain the provisions which, through reference in this

Standard, become the provisions of this Standard. For dated references, their

subsequent amendments (excluding corrigendum) or revisions do not apply to this

Standard. However, the parties who enter into agreement based on this Standard are

encouraged to investigate whether the latest versions of these documents are

applicable. For undated reference documents, the latest versions apply to this

Standard.

GB/T 6682-1992 Water for Analytical Laboratory Use - Specification and Test

Methods (neq ISO 3696.1987)

GB/T 9758.1-1988 Paints and Varnishes - Determination of “Soluble” Metal

Content -Part 1. Determination of Lead Content - Flame Atomic Absorption

Spectrometric Method and Dithizone Spectrophotometric Method (idt ISO 3856-

1.1984)

GB/T 9758.4-1988 Paints and Varnishes - Determination of “Soluble” Metal

Content - Part 4. Determination of Cadmium Content - Flame Atomic Absorption

Spectrometric Method and Polarographic Method (idt ISO 3856-4.1984)

GB/T 9758.6-1988 Paints and Varnishes - Determination of “Soluble” Metal

Content -Part 6. Determination of Total Chromium Content of the Liquid Portion of

the Paint - Flame Atomic Absorption Spectrometric Method (idt ISO 3856-6.1984)

GB/T 9758.7-1988 Paints and Varnishes - Determination of “Soluble” Metal

Content - Part 7. Determination of Mercury Content of the Pigment Portion of the

Paint and of the Liquid Portion of Water-Dilutable Paints - Flameless Atomic

--- Glass mortar. diameter (100~120) mm;

--- Crystalizing dish. diameter 120mm, height 60mm;

5.1.2.6 Small-mouth plastic bottle. 500mL, 1000mL.

5.1.3 Reagent

--- Potassium iodide (KI). analytically pure;

--- Potassium dichromate (K2Cr2O7). guaranteed reagent;

--- Sodium thiosulfate (Na2S2O3 • 5H2O). analytically pure;

--- Mercury iodide (HgI2). analytically pure;

--- Anhydrous sodium carbonate (Na2CO3). analytically pure;

--- Sulfuric acid (H2SO4). ρ=1.84g/mL, analytically pure;

--- Hydrochloric acid (HCL). ρ=1.19g/mL, analytically pure;

--- Sodium hydroxide (NaOH). analytically pure;

--- Iodine (I2). analytically pure;

--- Soluble starch. analytically pure;

--- Acetylacetone (CH3COCH2COCH3). guaranteed reagent;

--- Ammonium acetate (CH3COONH4). guaranteed reagent;

--- Formaldehyde (CH2O) solution. concentration 35%~40%.

5.1.4 Specimen preparation

5.1.4.1 Specimen sampling

The specimen shall take sampling from the exit-factory qualified products that conform

to the test provisions. If the product is made of several kinds of wood materials, then

sampling from the component of each material.

5.1.4.2 The specimen shall be prepared within the distance about 50mm away from

the furniture component edge.

5.1.4.3 Specimen specification. length (150±1)mm, width (50±1)mm.

5.1.4.4 Specimen quantity

The quantity of the specimen is 10 blocks. When preparing the specimen, consider the

5.2.2.3 Membrane filter. pore size 0.45µm.

5.2.2.4 Magnetic stirrer. the outer layer of stirrer is plastic or glass.

5.2.2.5 Single-scale pipette. 25mL.

5.2.2.6 White volumetric flask. 50mL.

5.2.2.7 Scraper. tool with sharp blade.

5.2.3 Reagent

The used reagent is analytically pure, the used water meet the requirement for Grade-

III water stipulated in GB/T 6682-1992.

5.2.3.1 Hydrochloric acid solution

0.07 mol/L, 1 mol/L, 2 mol/L.

5.2.3.2 Nitric acid solution

Mass fraction is 65%~68%.

5.2.4 Preparation of coating powder

Use the scraper to scratch proper amount of coating from the coasting surface of

furniture product, crush the scratched coating by magnetic stirrer under the room

temperature, then make it penetrate through the 0.5mm metal sieve, and wait for

treatment.

5.2.5 Test procedures

5.2.5.1 Sample treatment

Weigh 0.5g (accurate to 0.0001g) of sieved powder, put it into white volumetric flask;

add 25mL of 0.07 mol/L hydrochloric acid solution, mix 1min, determine its acidity; if

pH is greater than 1.5, shake the solution as drop the hydrochloric acid solution with

concentration of 2 mol/L till pH decreases to 1.0~1.5. Stir such mixture continuously

under room temperature for 1h, after that stand for 1h, then use membrane filter to

filter and keep in dark place.

The sample treatment shall be finished within 4h. If it can’t finish within 4h, add 25mL

of 1 mol/L hydrochloric acid solution to treat the sample, the treatment method can see

above.

5.2.5.2 Determination of soluble metal content

5.2.5.2.1 Determination of soluble lead content shall be performed as per the Chapter

3 in GB/T 9758.1-1988.

5.2.5.2.2 Determination of soluble cadmium content shall be performed as per the

Chapter 3 in GB/T 9758.4-1988.

5.2.5.2.3 Determination of soluble chromium content shall be performed as per GB/T

9758.6-1988.

5.2.5.2.4 Determination of soluble mercury content shall be performed as per GB/T

9758.7-1988.

5.2.5.3 Result calculation

Calculate the soluble metal content as per Formula (2), accurate to 0.1mg/kg.

Where.

C – (Lead, cadmium, chromium, mercury) soluble content, in mg/kg;

a0 – Blank concentration of 0.07mol or 1mol of hydrochloric acid solution, in µg/mL;

a1 – Concentration of test solution (lead, cadmium, chromium, mercury) determined

from the standard curve, in µg/mL;

F – Dilution factor;

25 – Extracted hydrochloric acid solution, in mL;

m – Weighed ...

Share