1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 1886.340-2021 English PDF

GB 1886.340-2021 English PDF

Regular price

$95.00

Regular price

Sale price

$95.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 1886.340-2021: National food safety standard - Food additives - Potassium pyrophosphate

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB 1886.340-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB 1886.340-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB 1886.340-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard - Food additives -

Potassium pyrophosphate

ISSUED ON: FEBRUARY 22, 2021

IMPLEMENTED ON: AUGUST 22, 2021

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Molecular formula and relative molecular mass ... 4

3 Technical requirements ... 4

Appendix A Inspection method ... 6

National food safety standard - Food additives -

Potassium pyrophosphate

1 Scope

This Standard applies to the food additive potassium pyrophosphate that is

produced with potassium hydroxide and the food additive phosphoric acid

(including wet-process phosphoric acid) as raw materials.

2 Molecular formula and relative molecular mass

2.1 Molecular formula

K4P2O7

2.2 Relative molecular mass

330.34 (according to the 2018 international relative atomic mass)

3 Technical requirements

3.1 Sensory requirements

Sensory requirements shall be in accordance with Table 1.

Table 1 – Sensory requirements

3.2 Physical and chemical indicators

Physical and chemical indicators shall be in accordance with Table 2.

Table 2 – Physical and chemical indicators

Appendix A

Inspection method

WARNING: Some reagents which are used in this test method are toxic or

corrosive, so, be careful during the operation! If necessary, perform it in

a fume hood. If it is splashed on the skin, use water to rinse it immediately.

If it is serious, seek medical attention immediately.

A.1 General provisions

The reagents and water that are used in this Standard, when no other

requirements are specified, refer to analytical reagents and grade-III water

which is specified in GB/T 6682. The standard titration solution, the standard

solutions, preparations and products for impurity determination, which are used

in the test, are all prepared in accordance with the provisions of GB/T 601, GB/T

602, and GB/T 603, when no other requirements are specified. The used

solution, if not indicated which solvent is used, refers to aqueous solution.

A.2 Identification test

A.2.1 Reagents and materials

A.2.1.1 Hydrochloric acid.

A.2.1.2 Nitric acid solution: 1+9.

A.2.1.3 Quinoxaline ketone solution.

A.2.1.4 Platinum wire ring.

A.2.2 Identification method

A.2.2.1 Identification of potassium ions

Take a small amount, about 0.1 g, of sample; add 10 mL of water to dissolve.

Dip a platinum wire ring in hydrochloric acid; burn it to colorless on the flame.

Then, dip the test solution and burn it on the flame. The flame shall be purple

under observation of the cobalt glass.

A.2.2.2 Identification of pyrophosphate

Perform the identification of pyrophosphate according to the following method:

a) Sample solution: Dissolve 0.1 g of sample in 100 mL of nitric acid solution;

b) Second crystallization: Use a small amount of water to heat the first

crystallization to dissolve it; cool in a cold water bath to precipitate crystals;

pour out the solution;

c) Third crystallization: Recrystallize the second crystallization according to

the method of the first crystallization;

d) Recrystallize sodium pyrophosphate from water three times and place it

in a porcelain crucible; then, burn it at 400 °C to a constant mass;

e) If using sodium pyrophosphate decahydrate, weigh 80 g and operate

according to the first and second crystallization methods.

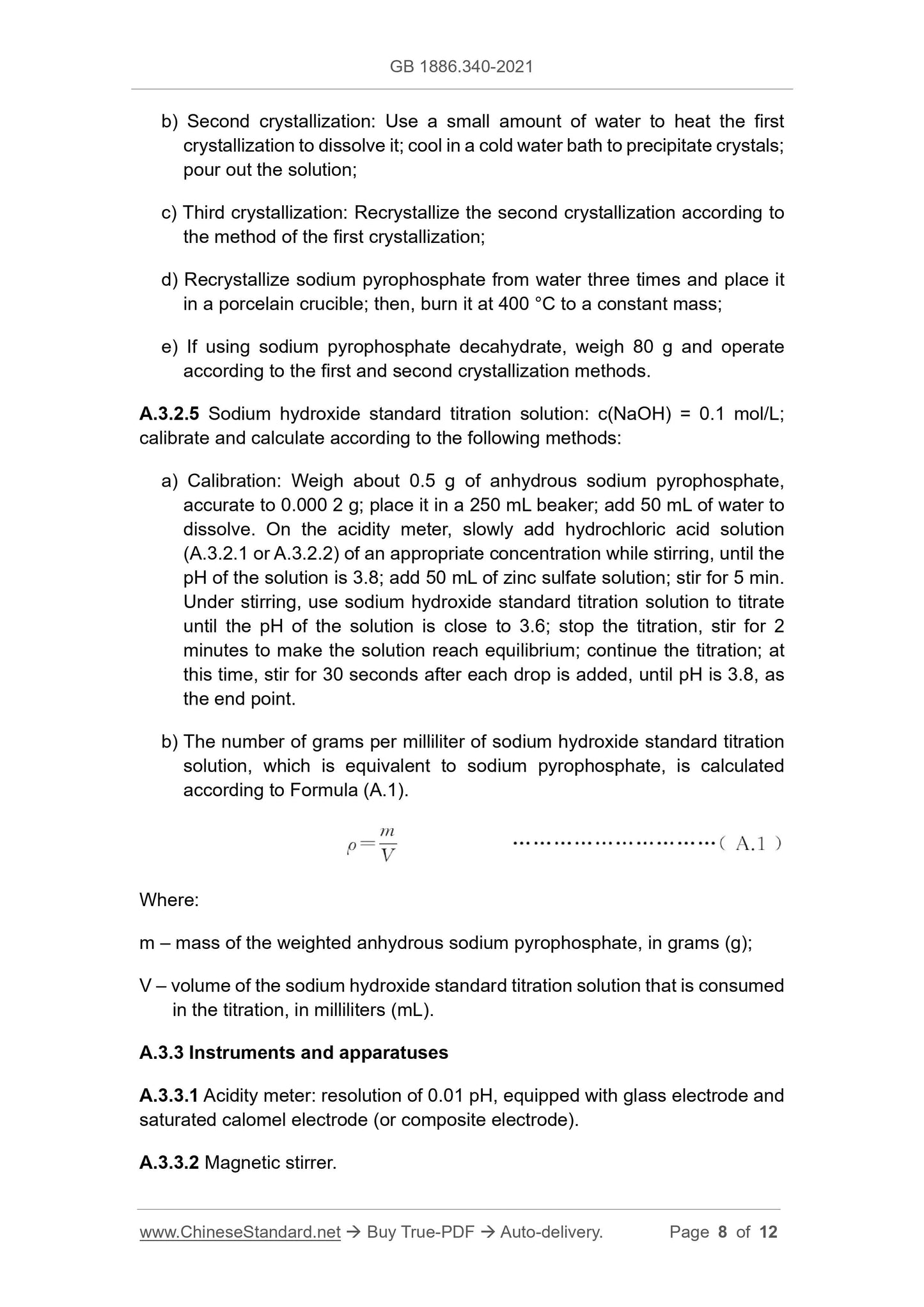

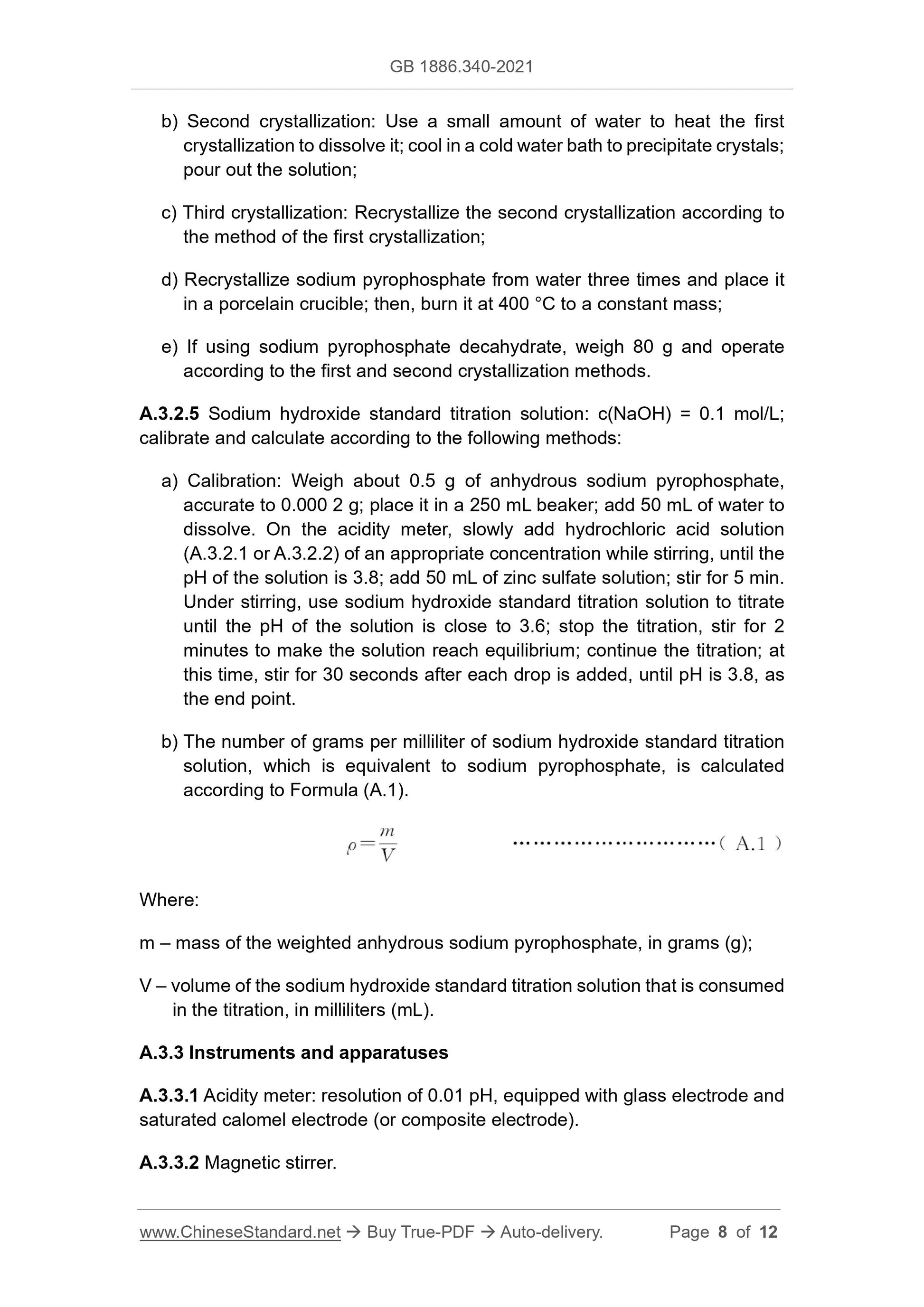

A.3.2.5 Sodium hydroxide standard titration solution: c(NaOH) = 0.1 mol/L;

calibrate and calculate according to the following methods:

a) Calibration: Weigh about 0.5 g of anhydrous sodium pyrophosphate,

accurate to 0.000 2 g; place it in a 250 mL beaker; add 50 mL of water to

dissolve. On the acidity meter, slowly add hydrochloric acid solution

(A.3.2.1 or A.3.2.2) of an appropriate concentration while stirring, until the

pH of the solution is 3.8; add 50 mL of zinc sulfate solution; stir for 5 min.

Under stirring, use sodium hydroxide standard titration solution to titrate

until the pH of the solution is close to 3.6; stop the titration, stir for 2

minutes to make the solution reach equilibrium; continue the titration; at

this time, stir for 30 seconds after each drop is added, until pH is 3.8, as

the end point.

b) The number of grams per milliliter of sodium hydroxide standard titration

solution, which is equivalent to sodium pyrophosphate, is calculated

according to Formula (A.1).

Where:

m – mass of the weighted anhydrous sodium pyrophosphate, in grams (g);

V – volume of the sodium hydroxide standard titration solution that is consumed

in the titration, in milliliters (mL).

A.3.3 Instruments and apparatuses

A.3.3.1 Acidity meter: resolution of 0.01 pH, equipped with glass electrode and

saturated calomel electrode (or composite electrode).

A.3.3.2 Magnetic stirrer.

A.4 Determination of loss on ignition

A.4.1 Instruments and apparatuses

High-temperature furnace: The temperature control range is 800 °C ± 20 °C.

A.4.2 Analysis steps

Use a porcelain crucible that is previously burned to constant mass at 800 °C ±

20 °C to weigh about 10 g of the sample, accurate to 0.01 g. Place the porcelain

crucible that contains the sample in a high-temperature furnace at 800 °C ±

20 °C for 30 minutes; take it out; cool it in a desiccator; weigh it.

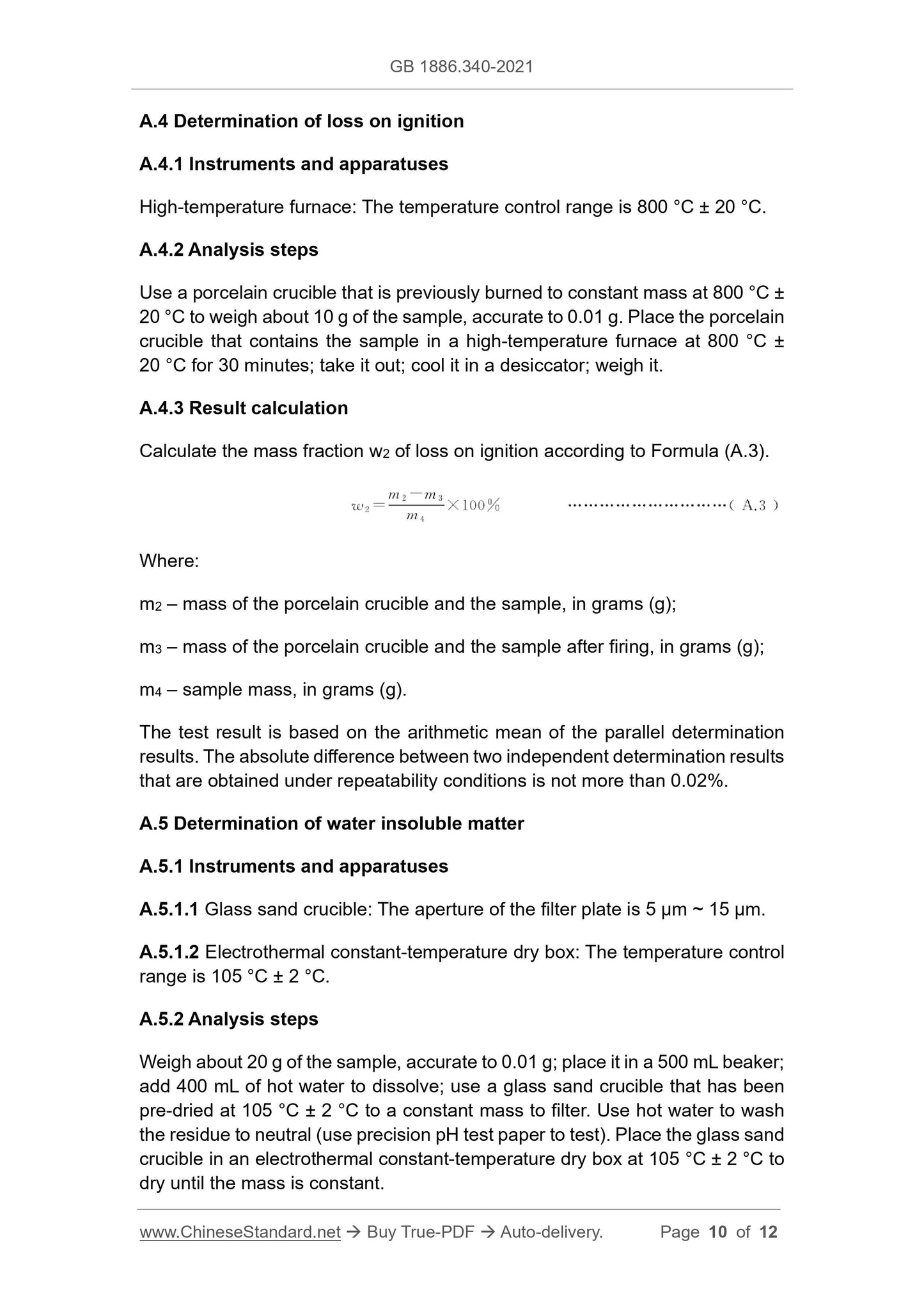

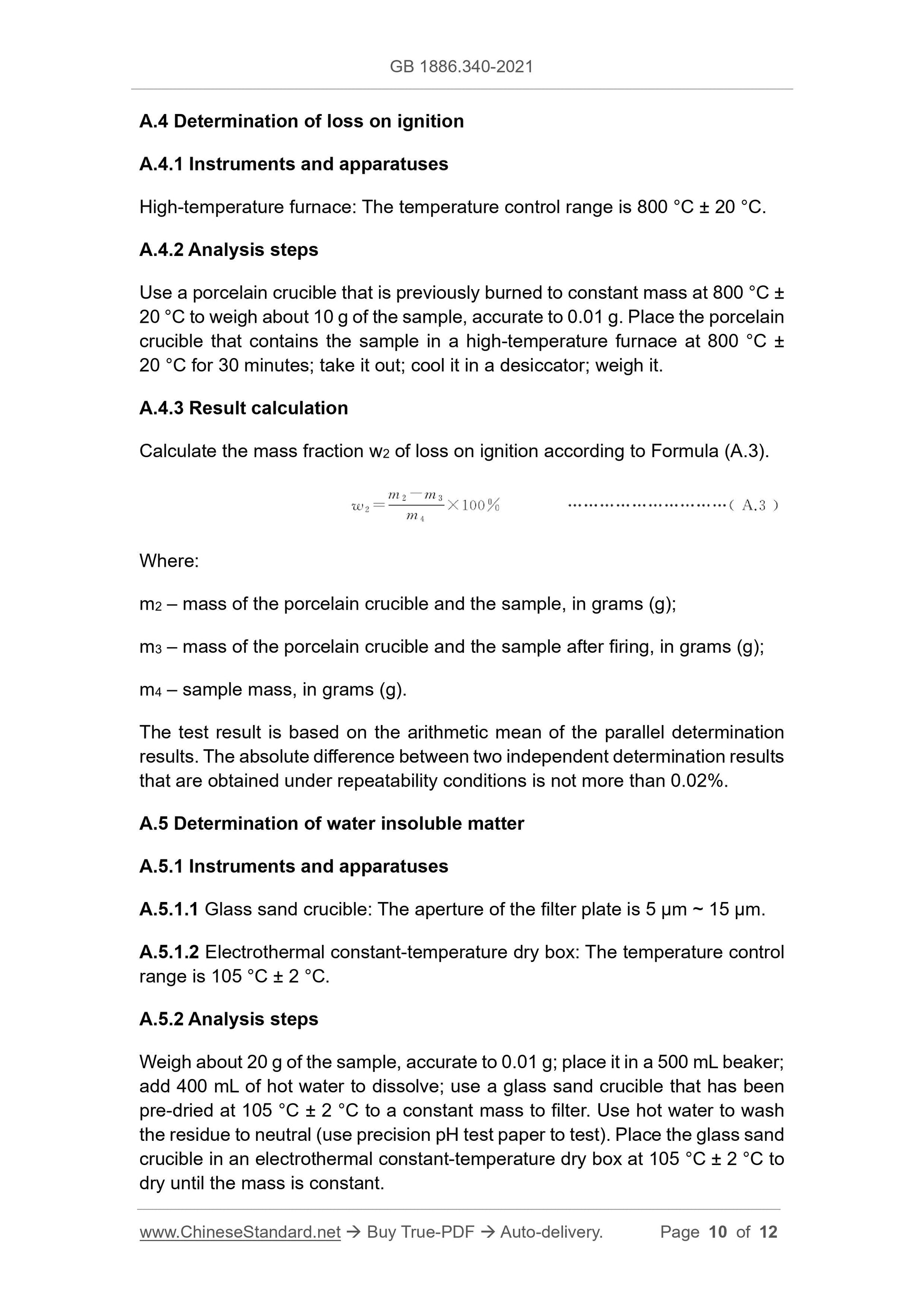

A.4.3 Result calculation

Calculate the mass fraction w2 of loss on ignition according to Formula (A.3).

Where:

m2 – mass of the porcelain crucible and the sample, in grams (g);

m3 – mass of the porcelain crucible and the sample after firing, in grams (g);

m4 – sample mass, in grams (g).

The test result is based on the arithmetic mean of the parallel determination

results. The absolute difference between two independent determination results

that are obtained under repeatability conditions is not more than 0.02%.

A.5 Determination of water insoluble matter

A.5.1 Instruments and apparatuses

A.5.1.1 Glass sand crucible: The aperture of the filter plate is 5 μm ~ 15 μm.

A.5.1.2 Electrothermal constant-temperature dry box: The temperature control

range is 105 °C ± 2 °C.

A.5.2 Analysis steps

Weigh about 20 g of the sample, accurate to 0.01 g; place it in a 500 mL beaker;

add 400 mL of hot water to dissolve; use a glass sand crucible that has been

pre-dried at 105 °C ± 2 °C to a constant mass to filter. Use hot water to wash

the residue to neutral (use precision pH test paper to test). Place the glass sand

crucible in an electrothermal constant-temperature dry box at 105 °C ± 2 °C to

dry until the mass is constant.

GB 1886.340-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard - Food additives -

Potassium pyrophosphate

ISSUED ON: FEBRUARY 22, 2021

IMPLEMENTED ON: AUGUST 22, 2021

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Molecular formula and relative molecular mass ... 4

3 Technical requirements ... 4

Appendix A Inspection method ... 6

National food safety standard - Food additives -

Potassium pyrophosphate

1 Scope

This Standard applies to the food additive potassium pyrophosphate that is

produced with potassium hydroxide and the food additive phosphoric acid

(including wet-process phosphoric acid) as raw materials.

2 Molecular formula and relative molecular mass

2.1 Molecular formula

K4P2O7

2.2 Relative molecular mass

330.34 (according to the 2018 international relative atomic mass)

3 Technical requirements

3.1 Sensory requirements

Sensory requirements shall be in accordance with Table 1.

Table 1 – Sensory requirements

3.2 Physical and chemical indicators

Physical and chemical indicators shall be in accordance with Table 2.

Table 2 – Physical and chemical indicators

Appendix A

Inspection method

WARNING: Some reagents which are used in this test method are toxic or

corrosive, so, be careful during the operation! If necessary, perform it in

a fume hood. If it is splashed on the skin, use water to rinse it immediately.

If it is serious, seek medical attention immediately.

A.1 General provisions

The reagents and water that are used in this Standard, when no other

requirements are specified, refer to analytical reagents and grade-III water

which is specified in GB/T 6682. The standard titration solution, the standard

solutions, preparations and products for impurity determination, which are used

in the test, are all prepared in accordance with the provisions of GB/T 601, GB/T

602, and GB/T 603, when no other requirements are specified. The used

solution, if not indicated which solvent is used, refers to aqueous solution.

A.2 Identification test

A.2.1 Reagents and materials

A.2.1.1 Hydrochloric acid.

A.2.1.2 Nitric acid solution: 1+9.

A.2.1.3 Quinoxaline ketone solution.

A.2.1.4 Platinum wire ring.

A.2.2 Identification method

A.2.2.1 Identification of potassium ions

Take a small amount, about 0.1 g, of sample; add 10 mL of water to dissolve.

Dip a platinum wire ring in hydrochloric acid; burn it to colorless on the flame.

Then, dip the test solution and burn it on the flame. The flame shall be purple

under observation of the cobalt glass.

A.2.2.2 Identification of pyrophosphate

Perform the identification of pyrophosphate according to the following method:

a) Sample solution: Dissolve 0.1 g of sample in 100 mL of nitric acid solution;

b) Second crystallization: Use a small amount of water to heat the first

crystallization to dissolve it; cool in a cold water bath to precipitate crystals;

pour out the solution;

c) Third crystallization: Recrystallize the second crystallization according to

the method of the first crystallization;

d) Recrystallize sodium pyrophosphate from water three times and place it

in a porcelain crucible; then, burn it at 400 °C to a constant mass;

e) If using sodium pyrophosphate decahydrate, weigh 80 g and operate

according to the first and second crystallization methods.

A.3.2.5 Sodium hydroxide standard titration solution: c(NaOH) = 0.1 mol/L;

calibrate and calculate according to the following methods:

a) Calibration: Weigh about 0.5 g of anhydrous sodium pyrophosphate,

accurate to 0.000 2 g; place it in a 250 mL beaker; add 50 mL of water to

dissolve. On the acidity meter, slowly add hydrochloric acid solution

(A.3.2.1 or A.3.2.2) of an appropriate concentration while stirring, until the

pH of the solution is 3.8; add 50 mL of zinc sulfate solution; stir for 5 min.

Under stirring, use sodium hydroxide standard titration solution to titrate

until the pH of the solution is close to 3.6; stop the titration, stir for 2

minutes to make the solution reach equilibrium; continue the titration; at

this time, stir for 30 seconds after each drop is added, until pH is 3.8, as

the end point.

b) The number of grams per milliliter of sodium hydroxide standard titration

solution, which is equivalent to sodium pyrophosphate, is calculated

according to Formula (A.1).

Where:

m – mass of the weighted anhydrous sodium pyrophosphate, in grams (g);

V – volume of the sodium hydroxide standard titration solution that is consumed

in the titration, in milliliters (mL).

A.3.3 Instruments and apparatuses

A.3.3.1 Acidity meter: resolution of 0.01 pH, equipped with glass electrode and

saturated calomel electrode (or composite electrode).

A.3.3.2 Magnetic stirrer.

A.4 Determination of loss on ignition

A.4.1 Instruments and apparatuses

High-temperature furnace: The temperature control range is 800 °C ± 20 °C.

A.4.2 Analysis steps

Use a porcelain crucible that is previously burned to constant mass at 800 °C ±

20 °C to weigh about 10 g of the sample, accurate to 0.01 g. Place the porcelain

crucible that contains the sample in a high-temperature furnace at 800 °C ±

20 °C for 30 minutes; take it out; cool it in a desiccator; weigh it.

A.4.3 Result calculation

Calculate the mass fraction w2 of loss on ignition according to Formula (A.3).

Where:

m2 – mass of the porcelain crucible and the sample, in grams (g);

m3 – mass of the porcelain crucible and the sample after firing, in grams (g);

m4 – sample mass, in grams (g).

The test result is based on the arithmetic mean of the parallel determination

results. The absolute difference between two independent determination results

that are obtained under repeatability conditions is not more than 0.02%.

A.5 Determination of water insoluble matter

A.5.1 Instruments and apparatuses

A.5.1.1 Glass sand crucible: The aperture of the filter plate is 5 μm ~ 15 μm.

A.5.1.2 Electrothermal constant-temperature dry box: The temperature control

range is 105 °C ± 2 °C.

A.5.2 Analysis steps

Weigh about 20 g of the sample, accurate to 0.01 g; place it in a 500 mL beaker;

add 400 mL of hot water to dissolve; use a glass sand crucible that has been

pre-dried at 105 °C ± 2 °C to a constant mass to filter. Use hot water to wash

the residue to neutral (use precision pH test paper to test). Place the glass sand

crucible in an electrothermal constant-temperature dry box at 105 °C ± 2 °C to

dry until the mass is constant.

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB 1886.340-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB 1886.340-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB 1886.340-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard - Food additives -

Potassium pyrophosphate

ISSUED ON: FEBRUARY 22, 2021

IMPLEMENTED ON: AUGUST 22, 2021

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Molecular formula and relative molecular mass ... 4

3 Technical requirements ... 4

Appendix A Inspection method ... 6

National food safety standard - Food additives -

Potassium pyrophosphate

1 Scope

This Standard applies to the food additive potassium pyrophosphate that is

produced with potassium hydroxide and the food additive phosphoric acid

(including wet-process phosphoric acid) as raw materials.

2 Molecular formula and relative molecular mass

2.1 Molecular formula

K4P2O7

2.2 Relative molecular mass

330.34 (according to the 2018 international relative atomic mass)

3 Technical requirements

3.1 Sensory requirements

Sensory requirements shall be in accordance with Table 1.

Table 1 – Sensory requirements

3.2 Physical and chemical indicators

Physical and chemical indicators shall be in accordance with Table 2.

Table 2 – Physical and chemical indicators

Appendix A

Inspection method

WARNING: Some reagents which are used in this test method are toxic or

corrosive, so, be careful during the operation! If necessary, perform it in

a fume hood. If it is splashed on the skin, use water to rinse it immediately.

If it is serious, seek medical attention immediately.

A.1 General provisions

The reagents and water that are used in this Standard, when no other

requirements are specified, refer to analytical reagents and grade-III water

which is specified in GB/T 6682. The standard titration solution, the standard

solutions, preparations and products for impurity determination, which are used

in the test, are all prepared in accordance with the provisions of GB/T 601, GB/T

602, and GB/T 603, when no other requirements are specified. The used

solution, if not indicated which solvent is used, refers to aqueous solution.

A.2 Identification test

A.2.1 Reagents and materials

A.2.1.1 Hydrochloric acid.

A.2.1.2 Nitric acid solution: 1+9.

A.2.1.3 Quinoxaline ketone solution.

A.2.1.4 Platinum wire ring.

A.2.2 Identification method

A.2.2.1 Identification of potassium ions

Take a small amount, about 0.1 g, of sample; add 10 mL of water to dissolve.

Dip a platinum wire ring in hydrochloric acid; burn it to colorless on the flame.

Then, dip the test solution and burn it on the flame. The flame shall be purple

under observation of the cobalt glass.

A.2.2.2 Identification of pyrophosphate

Perform the identification of pyrophosphate according to the following method:

a) Sample solution: Dissolve 0.1 g of sample in 100 mL of nitric acid solution;

b) Second crystallization: Use a small amount of water to heat the first

crystallization to dissolve it; cool in a cold water bath to precipitate crystals;

pour out the solution;

c) Third crystallization: Recrystallize the second crystallization according to

the method of the first crystallization;

d) Recrystallize sodium pyrophosphate from water three times and place it

in a porcelain crucible; then, burn it at 400 °C to a constant mass;

e) If using sodium pyrophosphate decahydrate, weigh 80 g and operate

according to the first and second crystallization methods.

A.3.2.5 Sodium hydroxide standard titration solution: c(NaOH) = 0.1 mol/L;

calibrate and calculate according to the following methods:

a) Calibration: Weigh about 0.5 g of anhydrous sodium pyrophosphate,

accurate to 0.000 2 g; place it in a 250 mL beaker; add 50 mL of water to

dissolve. On the acidity meter, slowly add hydrochloric acid solution

(A.3.2.1 or A.3.2.2) of an appropriate concentration while stirring, until the

pH of the solution is 3.8; add 50 mL of zinc sulfate solution; stir for 5 min.

Under stirring, use sodium hydroxide standard titration solution to titrate

until the pH of the solution is close to 3.6; stop the titration, stir for 2

minutes to make the solution reach equilibrium; continue the titration; at

this time, stir for 30 seconds after each drop is added, until pH is 3.8, as

the end point.

b) The number of grams per milliliter of sodium hydroxide standard titration

solution, which is equivalent to sodium pyrophosphate, is calculated

according to Formula (A.1).

Where:

m – mass of the weighted anhydrous sodium pyrophosphate, in grams (g);

V – volume of the sodium hydroxide standard titration solution that is consumed

in the titration, in milliliters (mL).

A.3.3 Instruments and apparatuses

A.3.3.1 Acidity meter: resolution of 0.01 pH, equipped with glass electrode and

saturated calomel electrode (or composite electrode).

A.3.3.2 Magnetic stirrer.

A.4 Determination of loss on ignition

A.4.1 Instruments and apparatuses

High-temperature furnace: The temperature control range is 800 °C ± 20 °C.

A.4.2 Analysis steps

Use a porcelain crucible that is previously burned to constant mass at 800 °C ±

20 °C to weigh about 10 g of the sample, accurate to 0.01 g. Place the porcelain

crucible that contains the sample in a high-temperature furnace at 800 °C ±

20 °C for 30 minutes; take it out; cool it in a desiccator; weigh it.

A.4.3 Result calculation

Calculate the mass fraction w2 of loss on ignition according to Formula (A.3).

Where:

m2 – mass of the porcelain crucible and the sample, in grams (g);

m3 – mass of the porcelain crucible and the sample after firing, in grams (g);

m4 – sample mass, in grams (g).

The test result is based on the arithmetic mean of the parallel determination

results. The absolute difference between two independent determination results

that are obtained under repeatability conditions is not more than 0.02%.

A.5 Determination of water insoluble matter

A.5.1 Instruments and apparatuses

A.5.1.1 Glass sand crucible: The aperture of the filter plate is 5 μm ~ 15 μm.

A.5.1.2 Electrothermal constant-temperature dry box: The temperature control

range is 105 °C ± 2 °C.

A.5.2 Analysis steps

Weigh about 20 g of the sample, accurate to 0.01 g; place it in a 500 mL beaker;

add 400 mL of hot water to dissolve; use a glass sand crucible that has been

pre-dried at 105 °C ± 2 °C to a constant mass to filter. Use hot water to wash

the residue to neutral (use precision pH test paper to test). Place the glass sand

crucible in an electrothermal constant-temperature dry box at 105 °C ± 2 °C to

dry until the mass is constant.

GB 1886.340-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard - Food additives -

Potassium pyrophosphate

ISSUED ON: FEBRUARY 22, 2021

IMPLEMENTED ON: AUGUST 22, 2021

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Molecular formula and relative molecular mass ... 4

3 Technical requirements ... 4

Appendix A Inspection method ... 6

National food safety standard - Food additives -

Potassium pyrophosphate

1 Scope

This Standard applies to the food additive potassium pyrophosphate that is

produced with potassium hydroxide and the food additive phosphoric acid

(including wet-process phosphoric acid) as raw materials.

2 Molecular formula and relative molecular mass

2.1 Molecular formula

K4P2O7

2.2 Relative molecular mass

330.34 (according to the 2018 international relative atomic mass)

3 Technical requirements

3.1 Sensory requirements

Sensory requirements shall be in accordance with Table 1.

Table 1 – Sensory requirements

3.2 Physical and chemical indicators

Physical and chemical indicators shall be in accordance with Table 2.

Table 2 – Physical and chemical indicators

Appendix A

Inspection method

WARNING: Some reagents which are used in this test method are toxic or

corrosive, so, be careful during the operation! If necessary, perform it in

a fume hood. If it is splashed on the skin, use water to rinse it immediately.

If it is serious, seek medical attention immediately.

A.1 General provisions

The reagents and water that are used in this Standard, when no other

requirements are specified, refer to analytical reagents and grade-III water

which is specified in GB/T 6682. The standard titration solution, the standard

solutions, preparations and products for impurity determination, which are used

in the test, are all prepared in accordance with the provisions of GB/T 601, GB/T

602, and GB/T 603, when no other requirements are specified. The used

solution, if not indicated which solvent is used, refers to aqueous solution.

A.2 Identification test

A.2.1 Reagents and materials

A.2.1.1 Hydrochloric acid.

A.2.1.2 Nitric acid solution: 1+9.

A.2.1.3 Quinoxaline ketone solution.

A.2.1.4 Platinum wire ring.

A.2.2 Identification method

A.2.2.1 Identification of potassium ions

Take a small amount, about 0.1 g, of sample; add 10 mL of water to dissolve.

Dip a platinum wire ring in hydrochloric acid; burn it to colorless on the flame.

Then, dip the test solution and burn it on the flame. The flame shall be purple

under observation of the cobalt glass.

A.2.2.2 Identification of pyrophosphate

Perform the identification of pyrophosphate according to the following method:

a) Sample solution: Dissolve 0.1 g of sample in 100 mL of nitric acid solution;

b) Second crystallization: Use a small amount of water to heat the first

crystallization to dissolve it; cool in a cold water bath to precipitate crystals;

pour out the solution;

c) Third crystallization: Recrystallize the second crystallization according to

the method of the first crystallization;

d) Recrystallize sodium pyrophosphate from water three times and place it

in a porcelain crucible; then, burn it at 400 °C to a constant mass;

e) If using sodium pyrophosphate decahydrate, weigh 80 g and operate

according to the first and second crystallization methods.

A.3.2.5 Sodium hydroxide standard titration solution: c(NaOH) = 0.1 mol/L;

calibrate and calculate according to the following methods:

a) Calibration: Weigh about 0.5 g of anhydrous sodium pyrophosphate,

accurate to 0.000 2 g; place it in a 250 mL beaker; add 50 mL of water to

dissolve. On the acidity meter, slowly add hydrochloric acid solution

(A.3.2.1 or A.3.2.2) of an appropriate concentration while stirring, until the

pH of the solution is 3.8; add 50 mL of zinc sulfate solution; stir for 5 min.

Under stirring, use sodium hydroxide standard titration solution to titrate

until the pH of the solution is close to 3.6; stop the titration, stir for 2

minutes to make the solution reach equilibrium; continue the titration; at

this time, stir for 30 seconds after each drop is added, until pH is 3.8, as

the end point.

b) The number of grams per milliliter of sodium hydroxide standard titration

solution, which is equivalent to sodium pyrophosphate, is calculated

according to Formula (A.1).

Where:

m – mass of the weighted anhydrous sodium pyrophosphate, in grams (g);

V – volume of the sodium hydroxide standard titration solution that is consumed

in the titration, in milliliters (mL).

A.3.3 Instruments and apparatuses

A.3.3.1 Acidity meter: resolution of 0.01 pH, equipped with glass electrode and

saturated calomel electrode (or composite electrode).

A.3.3.2 Magnetic stirrer.

A.4 Determination of loss on ignition

A.4.1 Instruments and apparatuses

High-temperature furnace: The temperature control range is 800 °C ± 20 °C.

A.4.2 Analysis steps

Use a porcelain crucible that is previously burned to constant mass at 800 °C ±

20 °C to weigh about 10 g of the sample, accurate to 0.01 g. Place the porcelain

crucible that contains the sample in a high-temperature furnace at 800 °C ±

20 °C for 30 minutes; take it out; cool it in a desiccator; weigh it.

A.4.3 Result calculation

Calculate the mass fraction w2 of loss on ignition according to Formula (A.3).

Where:

m2 – mass of the porcelain crucible and the sample, in grams (g);

m3 – mass of the porcelain crucible and the sample after firing, in grams (g);

m4 – sample mass, in grams (g).

The test result is based on the arithmetic mean of the parallel determination

results. The absolute difference between two independent determination results

that are obtained under repeatability conditions is not more than 0.02%.

A.5 Determination of water insoluble matter

A.5.1 Instruments and apparatuses

A.5.1.1 Glass sand crucible: The aperture of the filter plate is 5 μm ~ 15 μm.

A.5.1.2 Electrothermal constant-temperature dry box: The temperature control

range is 105 °C ± 2 °C.

A.5.2 Analysis steps

Weigh about 20 g of the sample, accurate to 0.01 g; place it in a 500 mL beaker;

add 400 mL of hot water to dissolve; use a glass sand crucible that has been

pre-dried at 105 °C ± 2 °C to a constant mass to filter. Use hot water to wash

the residue to neutral (use precision pH test paper to test). Place the glass sand

crucible in an electrothermal constant-temperature dry box at 105 °C ± 2 °C to

dry until the mass is constant.

Share