1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB 1903.30-2022 English PDF

GB 1903.30-2022 English PDF

Regular price

$155.00

Regular price

Sale price

$155.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 1903.30-2022: National food safety standard - Food nutrition enhancer - Polyfructose

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB 1903.30-2022 (Self-service in 1-minute)

Historical versions (Master-website): GB 1903.30-2022

Preview True-PDF (Reload/Scroll-down if blank)

GB 1903.30-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard - Food nutrition enhancer -

Polyfructose

ISSUED ON: JUNE 30, 2022

IMPLEMENTED ON: DECEMBER 30, 2022

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

1 Scope ... 3

2 Molecular and structural formulas ... 3

3 Technical requirements ... 3

Annex A Inspection method Determination of polyfructose (≥DPS), average degree

of polymerization (DP), glucose + fructose + sucrose content... 5

Annex B Inspection method Determination of fructooligosaccharides (DP3-DP4)

content ... 12

National food safety standard - Food nutrition enhancer -

Polyfructose

1 Scope

This document specifies food nutrition fortifier polyfructose prepared by using

chrysanthemum or chrysanthemum root as raw material, using acid/alkali treatment or

other methods to remove impurities, and using drying process.

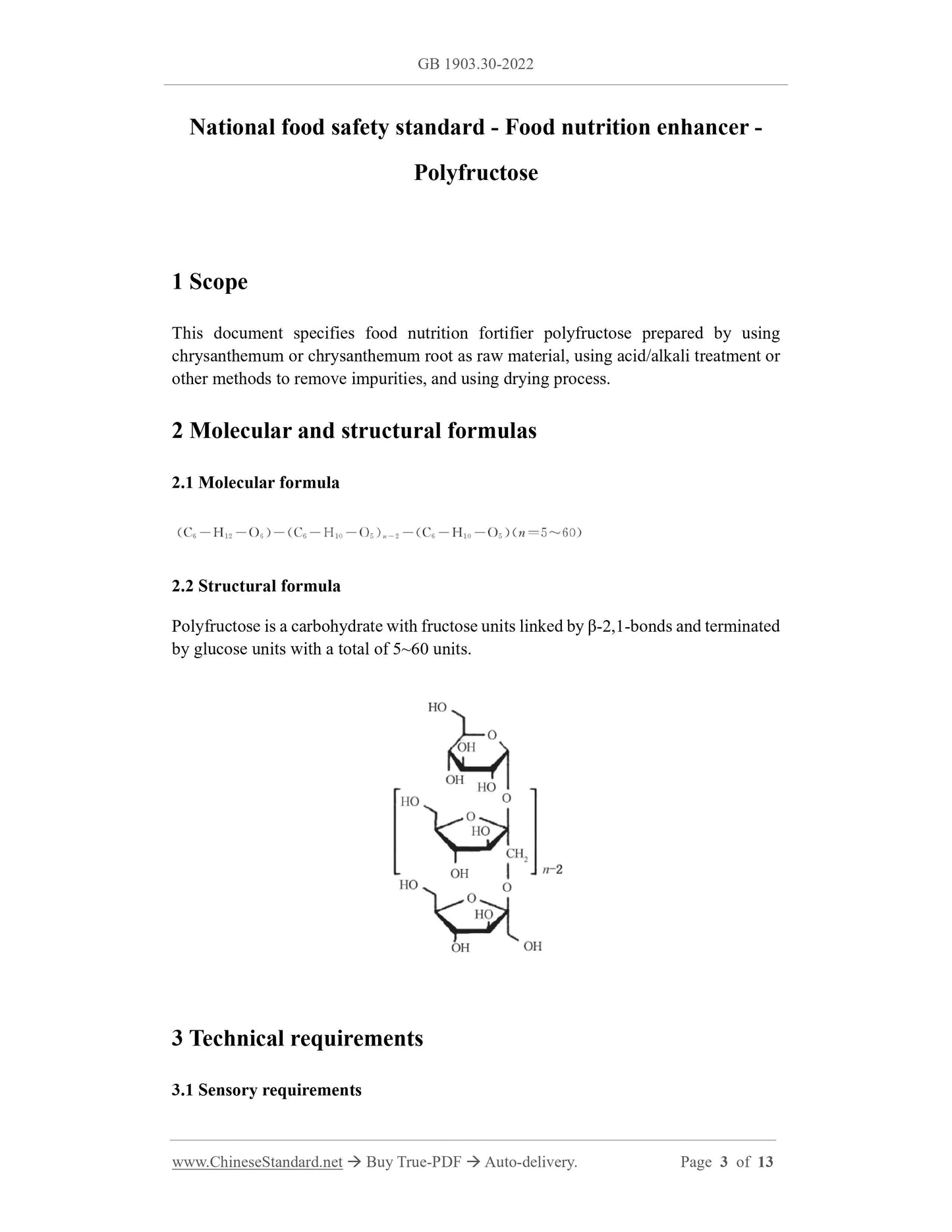

2 Molecular and structural formulas

2.1 Molecular formula

2.2 Structural formula

Polyfructose is a carbohydrate with fructose units linked by β-2,1-bonds and terminated

by glucose units with a total of 5~60 units.

3 Technical requirements

3.1 Sensory requirements

Annex A

Inspection method

Determination of polyfructose (≥DPS), average degree of polymerization (DP),

glucose + fructose + sucrose content

A.1 General provisions

Unless otherwise specified, only the reagents confirmed as analytically pure, and the

grade one water specified in GB/T 6682 are used in the analysis. All solutions used are

aqueous solutions unless otherwise specified.

A.2 Reagents and materials

A.2.1 Acetic acid: 0.2mol/L.

A.2.2 Sodium acetate: 0.2mol/L.

A.2.3 pH 4.5 acetate buffer solution: Mix 28.0mL of 0.2mol/L acetic acid and 22.0mL

of 0.2mol/L sodium acetate. Use water to dilute to 100mL.

A.2.4 Hydrochloric acid solution: 0.05mol/L.

A.2.5 Potassium hydroxide solution: 0.05mol/L.

A.2.6 Amyloglucosidase: For enzymatic hydrolysis of amylase to glucose. The content

of glucose, fructose and sucrose shall be less than 0.02%. Store in a 4°C refrigerator

when not in use.

A.2.7 Fructase: For enzymatic hydrolysis of polyfructose to glucose and fructose. The

content of glucose, fructose and sucrose shall be less than 0.005%. Store in a 4°C

refrigerator when not in use.

A.2.8 Acetonitrile.

A.2.9 Glucose: d (+) anhydrous dextrose.

A.2.10 Fructose: Dextrose.

A.2.11 Sucrose.

A.2.12 Sugar standard stock solution: Weigh 6.00g of the sugar standard product (2.00g

each of glucose, fructose, and sucrose) that has been dried at 96°C ± 2°C for 4 h. Put

into a 50mL beaker. Add water to stir till it is completely dissolved. Transfer it into a

50mL volumetric flask. Set volume constant to the scale. Obtain the sugar standard

stock solution (the glucose content is 40.0mg/mL, the fructose content is 40.0mg/mL,

and the sucrose content is 40.0mg/mL).

A.2.13 Standard working solution: Use water to respectively dilute the sugar standard

stock solution to 10.0mg/mL, 7.00mg/mL, 4.00mg/mL, 2.00mg/mL and 1.00mg/mL

solutions.

A.3 Instruments and equipment

A.3.1 Analytical balance: The resolution is 1mg and 0.01g.

A.3.2 pH meter: The accuracy is ±0.05.

A.3.3 Constant temperature water bath.

A.3.4 High performance liquid chromatograph (with differential refractive index or

equivalent detector).

A.3.5 0.22μm microporous membrane.

A.3.6 Oven.

A.3.7 25mL, 50mL volumetric flasks.

A.3.8 Pipettes (1mL, 5mL, 10mL).

A.4 Analysis steps

A.4.1 Sample weighing

Weigh about 1g of sample (to the nearest of 1mg, as mass m1) that has been dried at

96°C±2°C for 4h. Put it into a 100mL beaker. Add 50mL of boiling water. Moderately

stir. Use potassium hydroxide solution (A.2.5) or hydrochloric acid solution (A.2.4) to

adjust pH to 6.5~8.0. After the sample is completely dissolved, transfer it to a 100mL

volumetric flask. Incubate at 85°C ± 2°C for 10min. Then cool it to room temperature.

Use water to set volume to constant. Shake well. After that, take care to keep the sample

temperature above room temperature. Take a small amount of solution. Filter it through

a 0.22μm filter membrane. Then analyze it (test A0).

A.4.2 Enzymatic hydrolysis 1

Take 60.0mL of sample solution (A.4.1). Add 30.0mL of acetate buffer solution (A.2.3).

Mix well. Use 0.05mol/L hydrochloric acid solution (A.2.4) to adjust pH = 4.5±0.05.

Add a sufficient amount of amyloglucosidase (A.2.6) [if the approximate content of

starch and maltodextrin in the sample cannot be determined, it can be considered that

100% of the unknown part of the sample is starch, so as to calculate the amount of

enzyme]. The sample liquid water bath is heated to 60°C ± 2°C. Maintain at constant

temperature for 30min. Stir moderately but it shall not foam. There shall be no air

bubbles in the solution. After it is cooled to room temperature, transfer it to a 100mL

volumetric flask. Use water to set volume to constant. Take a small amount of solution.

Filter it through a 0.22μm filter membrane. Then analyze it (test A1).

A.4.3 Enzymatic hydrolysis 2

Take 60.0mL of sample solution (A.4.2). Add enough fructase (A.2.7) (if the

polyfructose content cannot be determined, the unknown part of the sample can be

considered to be 100% polyfructose; if using megazyme 2000U/mL mixed fructase, add

100μL). The sample liquid water bath is heated to 60°C ± 2°C. Maintain at constant

temperature for 30min. Stir moderately. Prevent foaming. Prevent air from entering.

After it is cooled to room temperature, transfer it to a 100mL volumetric flask. Use

water to set volume to constant. Filter it through a 0.22μm filter membrane. Then

analyze it (test A2).

A.5 Chromatographic detection

Reference chromatographic conditions: Amino column or equivalent column. The

mobile phase is acetonitrile: water = 75%:25%. The flow rate is 1.0mL/min. The

injection volume is 20μL. The column temperature is 30°C.

Drawing of standard curve: Respectively pipette 20μL of standard working solution

(A.2.13). Inject it into the high-performance liquid chromatography. Determine the

peak height or peak area of the standard solution under the above chromatographic

conditions. Draw a standard curve with the concentration as the abscissa and the peak

height or peak area as the ordinate.

Determination of sugar in sample: Pipette 20μL of sample solution (test A0, A1 and A2).

Inject it into the high-performance liquid chromatography. Determine the peak height

or peak area of the sample under the above chromatographic conditions. Check the

contents of fructose, glucose, and sucrose in the sample solution from the standard

curve. The response values of fructose, glucose and sucrose in the sample solution shall

be within the linear range of the standard curve. If it exceeds the linear range, the

sampling amount shall be changed and re-tested.

A.6 Result calculation

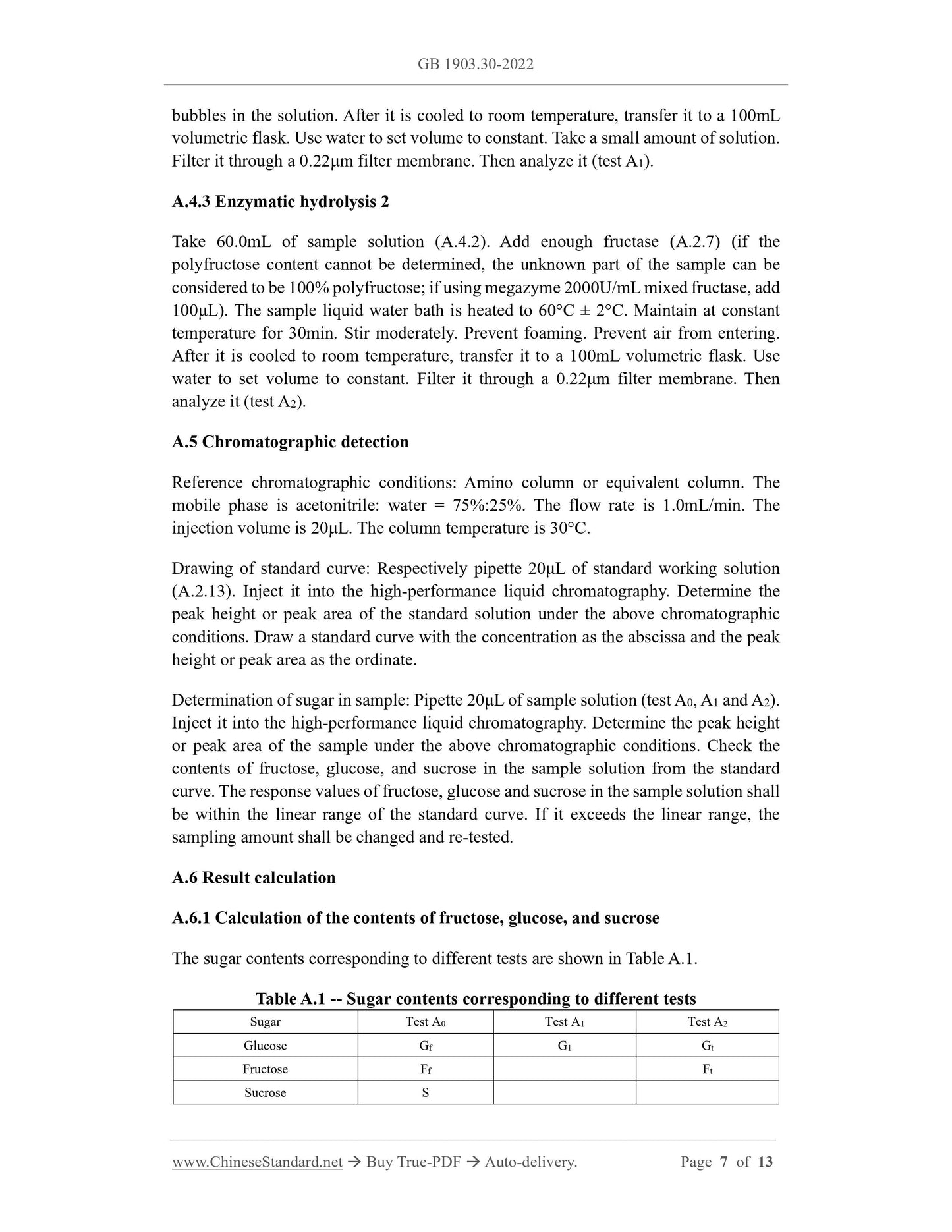

A.6.1 Calculation of the contents of fructose, glucose, and sucrose

The sugar contents corresponding to different tests are shown in Table A.1.

Table A.1 -- Sugar contents corresponding to different tests

Sugar Test A0 Test A1 Test A2

Glucose Gf G1 Gt

Fructose Ff Ft

Sucrose S

A.6.3 Calculation of average degree of polymerization (DP)

The content of glucose and fructose released from polyfructose is calculated according

to formula (A.8) and formula (A.9), respectively.

Where,

Gi - Glucose content (mass fraction) released from polyfructose, %;

Gs - Glucose (=S/1.9) content (mass fraction) released from sucrose, %;

G1 - Glucose content (mass fraction) after the first enzymatic hydrolysis, %;

Gt - Glucose content (mass fraction) after the second enzymatic hydrolysis, %;

Ft - Fructose content (mass fraction) after the second enzymatic hydrolysis, %;

Ff - Fructose content (mass fraction) in the initial extract, %;

Fi - Fructose content (mass fraction) released from polyfructose, %;

Fs - Fructose (=S/1.9) content (mass fraction) released from sucrose, %.

The average degree of polymerization is calculated according to the formula (A.10).

Where,

DP - Average degree of polymerization;

Fi - Fructose content (mass fraction) released from polyfructose, %;

Gi - Glucose content (mass fraction) released from polyfructose, %.

A.6.4 Calculation of polyfructose (≥DP5) content

The content of polyfructose (≥DP5) is calculated according to formula (A.11) and

formula (A.12).

Annex B

Inspection method

Determination of fructooligosaccharides (DP3-DP4) content

B.1 General provisions

Unless otherwise specified, only the reagents confirmed as analytically pure, and the

grade one water specified in GB/T 6682 are used in the analysis. All solutions used are

aqueous solutions unless otherwise specified.

B.2 Reagents and materials

B.2.1 Acetonitrile.

B.2.2 Kestose (content ≥ 99%).

B.2.3 Nystose (content ≥99%).

B.2.4 Sugar standard stock solution: Respectively weigh 1.000g of sugar standard

product that has been dried at 96°C±2°C for 4h (kestose and nystose) into a 50mL

volumetric flask. Add water to stir till it is completely dissolved. Set volume constant

to the scale. Obtain the 20mg/mL standard stock solution.

B.2.5 Working standard solution: Depending on the detector, the sugar standard stock

solution is diluted with water to the following concentrations:

a) Refractive index detector: 2.50mg/mL, 2.00mg/mL, 1.50mg/mL, 1.00mg/mL and

0.50mg/mL.

b) Evaporative light scattering detector: 2.00mg/mL, 1.00mg/mL, 0.50mg/mL,

0.20mg/mL and 0.08mg/mL.

B.3 Instruments and equipment

B.3.1 High performance liquid chromatograph (with evaporative light scattering or

refractive index detector).

B.3.2 Analytical balance: the resolution is 0.1mg.

B.3.3 0.22μm microporous membrane.

B.3.4 100mL volumetric flask.

B.4 Analysis steps

GB 1903.30-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard - Food nutrition enhancer -

Polyfructose

ISSUED ON: JUNE 30, 2022

IMPLEMENTED ON: DECEMBER 30, 2022

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

1 Scope ... 3

2 Molecular and structural formulas ... 3

3 Technical requirements ... 3

Annex A Inspection method Determination of polyfructose (≥DPS), average degree

of polymerization (DP), glucose + fructose + sucrose content... 5

Annex B Inspection method Determination of fructooligosaccharides (DP3-DP4)

content ... 12

National food safety standard - Food nutrition enhancer -

Polyfructose

1 Scope

This document specifies food nutrition fortifier polyfructose prepared by using

chrysanthemum or chrysanthemum root as raw material, using acid/alkali treatment or

other methods to remove impurities, and using drying process.

2 Molecular and structural formulas

2.1 Molecular formula

2.2 Structural formula

Polyfructose is a carbohydrate with fructose units linked by β-2,1-bonds and terminated

by glucose units with a total of 5~60 units.

3 Technical requirements

3.1 Sensory requirements

Annex A

Inspection method

Determination of polyfructose (≥DPS), average degree of polymerization (DP),

glucose + fructose + sucrose content

A.1 General provisions

Unless otherwise specified, only the reagents confirmed as analytically pure, and the

grade one water specified in GB/T 6682 are used in the analysis. All solutions used are

aqueous solutions unless otherwise specified.

A.2 Reagents and materials

A.2.1 Acetic acid: 0.2mol/L.

A.2.2 Sodium acetate: 0.2mol/L.

A.2.3 pH 4.5 acetate buffer solution: Mix 28.0mL of 0.2mol/L acetic acid and 22.0mL

of 0.2mol/L sodium acetate. Use water to dilute to 100mL.

A.2.4 Hydrochloric acid solution: 0.05mol/L.

A.2.5 Potassium hydroxide solution: 0.05mol/L.

A.2.6 Amyloglucosidase: For enzymatic hydrolysis of amylase to glucose. The content

of glucose, fructose and sucrose shall be less than 0.02%. Store in a 4°C refrigerator

when not in use.

A.2.7 Fructase: For enzymatic hydrolysis of polyfructose to glucose and fructose. The

content of glucose, fructose and sucrose shall be less than 0.005%. Store in a 4°C

refrigerator when not in use.

A.2.8 Acetonitrile.

A.2.9 Glucose: d (+) anhydrous dextrose.

A.2.10 Fructose: Dextrose.

A.2.11 Sucrose.

A.2.12 Sugar standard stock solution: Weigh 6.00g of the sugar standard product (2.00g

each of glucose, fructose, and sucrose) that has been dried at 96°C ± 2°C for 4 h. Put

into a 50mL beaker. Add water to stir till it is completely dissolved. Transfer it into a

50mL volumetric flask. Set volume constant to the scale. Obtain the sugar standard

stock solution (the glucose content is 40.0mg/mL, the fructose content is 40.0mg/mL,

and the sucrose content is 40.0mg/mL).

A.2.13 Standard working solution: Use water to respectively dilute the sugar standard

stock solution to 10.0mg/mL, 7.00mg/mL, 4.00mg/mL, 2.00mg/mL and 1.00mg/mL

solutions.

A.3 Instruments and equipment

A.3.1 Analytical balance: The resolution is 1mg and 0.01g.

A.3.2 pH meter: The accuracy is ±0.05.

A.3.3 Constant temperature water bath.

A.3.4 High performance liquid chromatograph (with differential refractive index or

equivalent detector).

A.3.5 0.22μm microporous membrane.

A.3.6 Oven.

A.3.7 25mL, 50mL volumetric flasks.

A.3.8 Pipettes (1mL, 5mL, 10mL).

A.4 Analysis steps

A.4.1 Sample weighing

Weigh about 1g of sample (to the nearest of 1mg, as mass m1) that has been dried at

96°C±2°C for 4h. Put it into a 100mL beaker. Add 50mL of boiling water. Moderately

stir. Use potassium hydroxide solution (A.2.5) or hydrochloric acid solution (A.2.4) to

adjust pH to 6.5~8.0. After the sample is completely dissolved, transfer it to a 100mL

volumetric flask. Incubate at 85°C ± 2°C for 10min. Then cool it to room temperature.

Use water to set volume to constant. Shake well. After that, take care to keep the sample

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB 1903.30-2022 (Self-service in 1-minute)

Historical versions (Master-website): GB 1903.30-2022

Preview True-PDF (Reload/Scroll-down if blank)

GB 1903.30-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard - Food nutrition enhancer -

Polyfructose

ISSUED ON: JUNE 30, 2022

IMPLEMENTED ON: DECEMBER 30, 2022

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

1 Scope ... 3

2 Molecular and structural formulas ... 3

3 Technical requirements ... 3

Annex A Inspection method Determination of polyfructose (≥DPS), average degree

of polymerization (DP), glucose + fructose + sucrose content... 5

Annex B Inspection method Determination of fructooligosaccharides (DP3-DP4)

content ... 12

National food safety standard - Food nutrition enhancer -

Polyfructose

1 Scope

This document specifies food nutrition fortifier polyfructose prepared by using

chrysanthemum or chrysanthemum root as raw material, using acid/alkali treatment or

other methods to remove impurities, and using drying process.

2 Molecular and structural formulas

2.1 Molecular formula

2.2 Structural formula

Polyfructose is a carbohydrate with fructose units linked by β-2,1-bonds and terminated

by glucose units with a total of 5~60 units.

3 Technical requirements

3.1 Sensory requirements

Annex A

Inspection method

Determination of polyfructose (≥DPS), average degree of polymerization (DP),

glucose + fructose + sucrose content

A.1 General provisions

Unless otherwise specified, only the reagents confirmed as analytically pure, and the

grade one water specified in GB/T 6682 are used in the analysis. All solutions used are

aqueous solutions unless otherwise specified.

A.2 Reagents and materials

A.2.1 Acetic acid: 0.2mol/L.

A.2.2 Sodium acetate: 0.2mol/L.

A.2.3 pH 4.5 acetate buffer solution: Mix 28.0mL of 0.2mol/L acetic acid and 22.0mL

of 0.2mol/L sodium acetate. Use water to dilute to 100mL.

A.2.4 Hydrochloric acid solution: 0.05mol/L.

A.2.5 Potassium hydroxide solution: 0.05mol/L.

A.2.6 Amyloglucosidase: For enzymatic hydrolysis of amylase to glucose. The content

of glucose, fructose and sucrose shall be less than 0.02%. Store in a 4°C refrigerator

when not in use.

A.2.7 Fructase: For enzymatic hydrolysis of polyfructose to glucose and fructose. The

content of glucose, fructose and sucrose shall be less than 0.005%. Store in a 4°C

refrigerator when not in use.

A.2.8 Acetonitrile.

A.2.9 Glucose: d (+) anhydrous dextrose.

A.2.10 Fructose: Dextrose.

A.2.11 Sucrose.

A.2.12 Sugar standard stock solution: Weigh 6.00g of the sugar standard product (2.00g

each of glucose, fructose, and sucrose) that has been dried at 96°C ± 2°C for 4 h. Put

into a 50mL beaker. Add water to stir till it is completely dissolved. Transfer it into a

50mL volumetric flask. Set volume constant to the scale. Obtain the sugar standard

stock solution (the glucose content is 40.0mg/mL, the fructose content is 40.0mg/mL,

and the sucrose content is 40.0mg/mL).

A.2.13 Standard working solution: Use water to respectively dilute the sugar standard

stock solution to 10.0mg/mL, 7.00mg/mL, 4.00mg/mL, 2.00mg/mL and 1.00mg/mL

solutions.

A.3 Instruments and equipment

A.3.1 Analytical balance: The resolution is 1mg and 0.01g.

A.3.2 pH meter: The accuracy is ±0.05.

A.3.3 Constant temperature water bath.

A.3.4 High performance liquid chromatograph (with differential refractive index or

equivalent detector).

A.3.5 0.22μm microporous membrane.

A.3.6 Oven.

A.3.7 25mL, 50mL volumetric flasks.

A.3.8 Pipettes (1mL, 5mL, 10mL).

A.4 Analysis steps

A.4.1 Sample weighing

Weigh about 1g of sample (to the nearest of 1mg, as mass m1) that has been dried at

96°C±2°C for 4h. Put it into a 100mL beaker. Add 50mL of boiling water. Moderately

stir. Use potassium hydroxide solution (A.2.5) or hydrochloric acid solution (A.2.4) to

adjust pH to 6.5~8.0. After the sample is completely dissolved, transfer it to a 100mL

volumetric flask. Incubate at 85°C ± 2°C for 10min. Then cool it to room temperature.

Use water to set volume to constant. Shake well. After that, take care to keep the sample

temperature above room temperature. Take a small amount of solution. Filter it through

a 0.22μm filter membrane. Then analyze it (test A0).

A.4.2 Enzymatic hydrolysis 1

Take 60.0mL of sample solution (A.4.1). Add 30.0mL of acetate buffer solution (A.2.3).

Mix well. Use 0.05mol/L hydrochloric acid solution (A.2.4) to adjust pH = 4.5±0.05.

Add a sufficient amount of amyloglucosidase (A.2.6) [if the approximate content of

starch and maltodextrin in the sample cannot be determined, it can be considered that

100% of the unknown part of the sample is starch, so as to calculate the amount of

enzyme]. The sample liquid water bath is heated to 60°C ± 2°C. Maintain at constant

temperature for 30min. Stir moderately but it shall not foam. There shall be no air

bubbles in the solution. After it is cooled to room temperature, transfer it to a 100mL

volumetric flask. Use water to set volume to constant. Take a small amount of solution.

Filter it through a 0.22μm filter membrane. Then analyze it (test A1).

A.4.3 Enzymatic hydrolysis 2

Take 60.0mL of sample solution (A.4.2). Add enough fructase (A.2.7) (if the

polyfructose content cannot be determined, the unknown part of the sample can be

considered to be 100% polyfructose; if using megazyme 2000U/mL mixed fructase, add

100μL). The sample liquid water bath is heated to 60°C ± 2°C. Maintain at constant

temperature for 30min. Stir moderately. Prevent foaming. Prevent air from entering.

After it is cooled to room temperature, transfer it to a 100mL volumetric flask. Use

water to set volume to constant. Filter it through a 0.22μm filter membrane. Then

analyze it (test A2).

A.5 Chromatographic detection

Reference chromatographic conditions: Amino column or equivalent column. The

mobile phase is acetonitrile: water = 75%:25%. The flow rate is 1.0mL/min. The

injection volume is 20μL. The column temperature is 30°C.

Drawing of standard curve: Respectively pipette 20μL of standard working solution

(A.2.13). Inject it into the high-performance liquid chromatography. Determine the

peak height or peak area of the standard solution under the above chromatographic

conditions. Draw a standard curve with the concentration as the abscissa and the peak

height or peak area as the ordinate.

Determination of sugar in sample: Pipette 20μL of sample solution (test A0, A1 and A2).

Inject it into the high-performance liquid chromatography. Determine the peak height

or peak area of the sample under the above chromatographic conditions. Check the

contents of fructose, glucose, and sucrose in the sample solution from the standard

curve. The response values of fructose, glucose and sucrose in the sample solution shall

be within the linear range of the standard curve. If it exceeds the linear range, the

sampling amount shall be changed and re-tested.

A.6 Result calculation

A.6.1 Calculation of the contents of fructose, glucose, and sucrose

The sugar contents corresponding to different tests are shown in Table A.1.

Table A.1 -- Sugar contents corresponding to different tests

Sugar Test A0 Test A1 Test A2

Glucose Gf G1 Gt

Fructose Ff Ft

Sucrose S

A.6.3 Calculation of average degree of polymerization (DP)

The content of glucose and fructose released from polyfructose is calculated according

to formula (A.8) and formula (A.9), respectively.

Where,

Gi - Glucose content (mass fraction) released from polyfructose, %;

Gs - Glucose (=S/1.9) content (mass fraction) released from sucrose, %;

G1 - Glucose content (mass fraction) after the first enzymatic hydrolysis, %;

Gt - Glucose content (mass fraction) after the second enzymatic hydrolysis, %;

Ft - Fructose content (mass fraction) after the second enzymatic hydrolysis, %;

Ff - Fructose content (mass fraction) in the initial extract, %;

Fi - Fructose content (mass fraction) released from polyfructose, %;

Fs - Fructose (=S/1.9) content (mass fraction) released from sucrose, %.

The average degree of polymerization is calculated according to the formula (A.10).

Where,

DP - Average degree of polymerization;

Fi - Fructose content (mass fraction) released from polyfructose, %;

Gi - Glucose content (mass fraction) released from polyfructose, %.

A.6.4 Calculation of polyfructose (≥DP5) content

The content of polyfructose (≥DP5) is calculated according to formula (A.11) and

formula (A.12).

Annex B

Inspection method

Determination of fructooligosaccharides (DP3-DP4) content

B.1 General provisions

Unless otherwise specified, only the reagents confirmed as analytically pure, and the

grade one water specified in GB/T 6682 are used in the analysis. All solutions used are

aqueous solutions unless otherwise specified.

B.2 Reagents and materials

B.2.1 Acetonitrile.

B.2.2 Kestose (content ≥ 99%).

B.2.3 Nystose (content ≥99%).

B.2.4 Sugar standard stock solution: Respectively weigh 1.000g of sugar standard

product that has been dried at 96°C±2°C for 4h (kestose and nystose) into a 50mL

volumetric flask. Add water to stir till it is completely dissolved. Set volume constant

to the scale. Obtain the 20mg/mL standard stock solution.

B.2.5 Working standard solution: Depending on the detector, the sugar standard stock

solution is diluted with water to the following concentrations:

a) Refractive index detector: 2.50mg/mL, 2.00mg/mL, 1.50mg/mL, 1.00mg/mL and

0.50mg/mL.

b) Evaporative light scattering detector: 2.00mg/mL, 1.00mg/mL, 0.50mg/mL,

0.20mg/mL and 0.08mg/mL.

B.3 Instruments and equipment

B.3.1 High performance liquid chromatograph (with evaporative light scattering or

refractive index detector).

B.3.2 Analytical balance: the resolution is 0.1mg.

B.3.3 0.22μm microporous membrane.

B.3.4 100mL volumetric flask.

B.4 Analysis steps

GB 1903.30-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard - Food nutrition enhancer -

Polyfructose

ISSUED ON: JUNE 30, 2022

IMPLEMENTED ON: DECEMBER 30, 2022

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

1 Scope ... 3

2 Molecular and structural formulas ... 3

3 Technical requirements ... 3

Annex A Inspection method Determination of polyfructose (≥DPS), average degree

of polymerization (DP), glucose + fructose + sucrose content... 5

Annex B Inspection method Determination of fructooligosaccharides (DP3-DP4)

content ... 12

National food safety standard - Food nutrition enhancer -

Polyfructose

1 Scope

This document specifies food nutrition fortifier polyfructose prepared by using

chrysanthemum or chrysanthemum root as raw material, using acid/alkali treatment or

other methods to remove impurities, and using drying process.

2 Molecular and structural formulas

2.1 Molecular formula

2.2 Structural formula

Polyfructose is a carbohydrate with fructose units linked by β-2,1-bonds and terminated

by glucose units with a total of 5~60 units.

3 Technical requirements

3.1 Sensory requirements

Annex A

Inspection method

Determination of polyfructose (≥DPS), average degree of polymerization (DP),

glucose + fructose + sucrose content

A.1 General provisions

Unless otherwise specified, only the reagents confirmed as analytically pure, and the

grade one water specified in GB/T 6682 are used in the analysis. All solutions used are

aqueous solutions unless otherwise specified.

A.2 Reagents and materials

A.2.1 Acetic acid: 0.2mol/L.

A.2.2 Sodium acetate: 0.2mol/L.

A.2.3 pH 4.5 acetate buffer solution: Mix 28.0mL of 0.2mol/L acetic acid and 22.0mL

of 0.2mol/L sodium acetate. Use water to dilute to 100mL.

A.2.4 Hydrochloric acid solution: 0.05mol/L.

A.2.5 Potassium hydroxide solution: 0.05mol/L.

A.2.6 Amyloglucosidase: For enzymatic hydrolysis of amylase to glucose. The content

of glucose, fructose and sucrose shall be less than 0.02%. Store in a 4°C refrigerator

when not in use.

A.2.7 Fructase: For enzymatic hydrolysis of polyfructose to glucose and fructose. The

content of glucose, fructose and sucrose shall be less than 0.005%. Store in a 4°C

refrigerator when not in use.

A.2.8 Acetonitrile.

A.2.9 Glucose: d (+) anhydrous dextrose.

A.2.10 Fructose: Dextrose.

A.2.11 Sucrose.

A.2.12 Sugar standard stock solution: Weigh 6.00g of the sugar standard product (2.00g

each of glucose, fructose, and sucrose) that has been dried at 96°C ± 2°C for 4 h. Put

into a 50mL beaker. Add water to stir till it is completely dissolved. Transfer it into a

50mL volumetric flask. Set volume constant to the scale. Obtain the sugar standard

stock solution (the glucose content is 40.0mg/mL, the fructose content is 40.0mg/mL,

and the sucrose content is 40.0mg/mL).

A.2.13 Standard working solution: Use water to respectively dilute the sugar standard

stock solution to 10.0mg/mL, 7.00mg/mL, 4.00mg/mL, 2.00mg/mL and 1.00mg/mL

solutions.

A.3 Instruments and equipment

A.3.1 Analytical balance: The resolution is 1mg and 0.01g.

A.3.2 pH meter: The accuracy is ±0.05.

A.3.3 Constant temperature water bath.

A.3.4 High performance liquid chromatograph (with differential refractive index or

equivalent detector).

A.3.5 0.22μm microporous membrane.

A.3.6 Oven.

A.3.7 25mL, 50mL volumetric flasks.

A.3.8 Pipettes (1mL, 5mL, 10mL).

A.4 Analysis steps

A.4.1 Sample weighing

Weigh about 1g of sample (to the nearest of 1mg, as mass m1) that has been dried at

96°C±2°C for 4h. Put it into a 100mL beaker. Add 50mL of boiling water. Moderately

stir. Use potassium hydroxide solution (A.2.5) or hydrochloric acid solution (A.2.4) to

adjust pH to 6.5~8.0. After the sample is completely dissolved, transfer it to a 100mL

volumetric flask. Incubate at 85°C ± 2°C for 10min. Then cool it to room temperature.

Use water to set volume to constant. Shake well. After that, take care to keep the sample

Share