1

/

of

11

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 19601-2013 English PDF

GB 19601-2013 English PDF

Regular price

$125.00 USD

Regular price

Sale price

$125.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 19601-2013

Historical versions: GB 19601-2013

Preview True-PDF (Reload/Scroll if blank)

GB 19601-2013: Limit and determination of 23 harmful aromatic amines in dye products

GB 19601-2013

ICS 71.100.01; 87.060.10

G 55

National Standard

of People’s Republic of China

Replacing GB 19601-2004

Limit and determination of 23 harmful

aromatic amines in dye products

ISSUED ON. SEPTEMBER 6, 2013

IMPLEMENTED ON. OCTOBER 1, 2014

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of People's Republic of China, AQSIQ;

Standardization Administration of the People's Republic of China, SAC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references... 5

3 Requirements ... 5

4 Principles ... 6

5 Experimental methods ... 6

6 Minimum qualitative limit, recovery and precision ... 10

7 Test report ... 11

Appendix A ... 12

Appendix B... 14

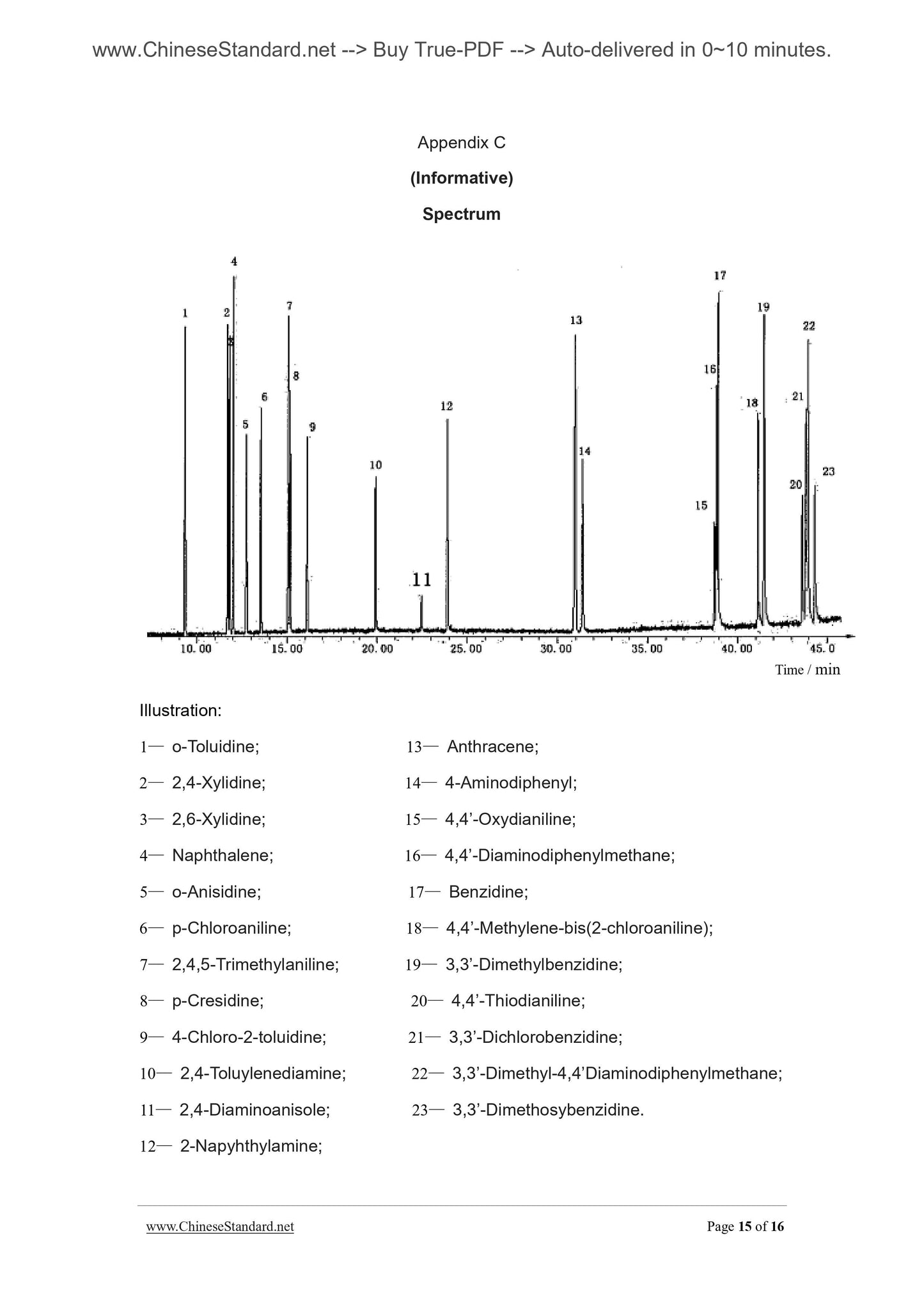

Appendix C ... 15

Foreword

All the technical content of this Standard is mandatory.

This Standard is drafted in accordance with the rules of GB/T 1.1-2009.

This Standard replaces GB 19601-2004 "Limit and determination of 23 harmful

aromatic amines in dye products". Compared with GB 19601-2004, except editorial

changes, the major technical changes are as follows.

— DELETE the analysis methods of gas chromatographic (4.4.3.2 in 2004

edition);

— Quantitative methods have been transformed from the external-standard

method into the internal-standard method (see 5.5.3, 4.4.4.2 in 2004 edition);

— DELETE the column extraction from the sample-preparation methods (4.4.1 in

2004 edition);

— MODIFY the sample-preparation methods (see 5.5.1, 4.4.1 in 2004 edition);

— COMBINE qualitative parts and quantitative parts to analysis steps (see 5.5.2,

4.4.3 in 2004 edition);

— REMOVE the reserved time from Appendix A (Appendix A in 2004 edition);

— DELETE the recovery-rate table (Table 2 in 2004 edition).

This Standard is proposed by China Petroleum and Chemical Industry Federation.

This Standard is administered by the National Technical Committee of Dye

Standardization (SAC/TC 134)

This Standard is drafted by organizations. Shenyang Chemical Institute Co., Ltd.,

Xuzhou Kaida Fine Chemical Co., Ltd., State-Key Laboratory of Fine Chemicals of

Dalian University of Technology, Jiangsu Yabang Dye Co., Ltd., Beijing Institute of

Clothing, Institute of Product Quality Supervision and Inspection of Taizhou City, and

National Dye Quality Supervision and Inspection Center.

Chief drafters of this Standard. Ji Hao, Piao Kezhuang, Fu Ping, Peng Xiaojun, Zheng

Junliang, Shen Rijong, Ji Lanqin, Zhou Yongkai, and Li Xinggen.

The standard of previous version replaced by this Standard is.

—GB 19601-2004.

Limit and determination of 23 harmful aromatic

amines in dye products

Warning. Personnel using this Standard shall have practical working experience in

qualified laboratory. This Standard does not point out all possible safety problems.

Users are responsible for taking appropriate safety and healthy measures, and to

ensure compliance with the relevant conditions of the national regulations.

1 Scope

This Standard specifies the allowable limit and determination methods of harmful

aromatic amines in dye products (see Appendix A).

This Standard is applicable to all kinds of commercial dyes, dye products, dye

intermediates and textile-dye auxiliaries.

2 Normative references

The following documents are indispensable for the application of this document. For

dated references, only the dated edition is applicable for this document. For undated

documents, the latest version (including all amendments) applies to this document.

GB/T 6682-2008 Water for analytical laboratory use. Specification and test methods (ISO,

3696.1987, MOD)

GB/T 8170-2008 Rules of rounding off for numerical values and expression and judgment of

limiting values

3 Requirements

The content of harmful aromatic amines (see Appendix A) in dye products shall be

less than 150mg (aromatic amines)/kg (product), in which the limit of harmful aromatic

amines in dye products, such as solution dyes and pigment paste, shall be converted

according to the solid content.

4 Principles

In dielectric of citrate buffer solution (pH=6.0), The dye sample uses sodium

hyposulfite to achieve the reductive decomposition, and then uses the organic solvent

to directly extract the aromatic amines from the lysis solution. After concentration, it

uses gas chromatography-mass spectrometry instrument to detect.

5 Experimental methods

5.1 General provisions

Unless otherwise specified, it shall only use the reagents confirmed as analytical

reagents and grade 3 water specified by GB/T 6682-2008. Judgment of the inspection

results shall be conducted according to 4.3.3 rounding-value-comparison method in

GB/T 8170–2008.

5.2 Reagents and materials

5.2.1 Standard sample of aromatic amines. 23 kinds of known-content harmful

aromatic amines (see Appendix A).

5.2.2 Standard sample of internal standard. known-content internal standard (see

Appendix B).

5.2.3 Chloroform.

5.2.4 Glacial acetic acid.

5.2.5 Citrate buffer solution. 0.06 mol/L aqueous solution, pH = 6 (TAKE 12.526g citric

acid and 6.320g sodium hydroxide, DISSOLVE them in water, and then DILUTE to

1000 mL).

5 2.6 Sodium hyposulfite. 200 g/L aqueous solution, when using, TAKE solid sodium

hyposulfite (content of Na2S2O4 ≥ 85%) and DISSOLVE it in water for preparation.

5.2.7 The solution of sodium carbonate anhydrous. 200 g/L.

5.2.8 Volumetric flask. 10 mL, 25 mL.

5.2.9 Graduated pipettes. 1 mL, 5 mL.

5.2.10 Separating funnel. 60mL.

5.2.11 Grinding-mouth conical flask with stopper. 100 mL.

WEIGH 0.2g of sample (accurate to 0.0002g), PLACE in a 100mL grinding-mouth

conical flask, ADD 24mL of citrate buffer solution, ADD 1.0mL of internal standard

solution, COVER the stopper. PUT the conical bottle into the water-bath pan in which

the temperature is 70°C±2°C to preheat for about 15 min, KEEP shaking from time to

time, LET the sample to be completely dissolved as possible. At the same time,

PREPARE sodium dithionite. After preheating, TAKE out the erlenmeyer flask, ADD

6.0 mL of sodium dithionite solution in each bottle, COVER with cork immediately,

SHAKE well. PUT the conical bottle into the water-bath pan which is 70 °C ± 2°C to

maintain for 30 min; SHAKE from time to time to make it fully restored. After restored,

TAKE out the conical bottle and USE cool water to make it reach to room temperature

quickly, USE anhydrous sodium carbonate solution to adjust to pH 8~9 (add about

5mL). Extract the sample three times with chloroform in a separating funnel, and each

time USE 20mL of chloroform. ADD 2~4 drops of glacial acetic acid into the

first-extracted solution for acidity. Three-time extracted solution shall be combined in

a 125 mL grinding-mouth flat flask and be concentrated to a volume of about 1 mL on

a rotating evaporator. REMOVE the concentrated liquid with a suction tube into a

10mL volumetric flask. WASH the flask repeatedly with chloroform, the lotion shall be

also added into the volumetric flask, VOLUME to the mark with chloroform. This

solution is the sample solution.

Non-water soluble dyes may be added with 3 mL ~ 5 mL of acetone before sample

processing, so as to make it disperse in the buffer solution uniformly, then process it

according to this Method.

5.5.2 Chromatography

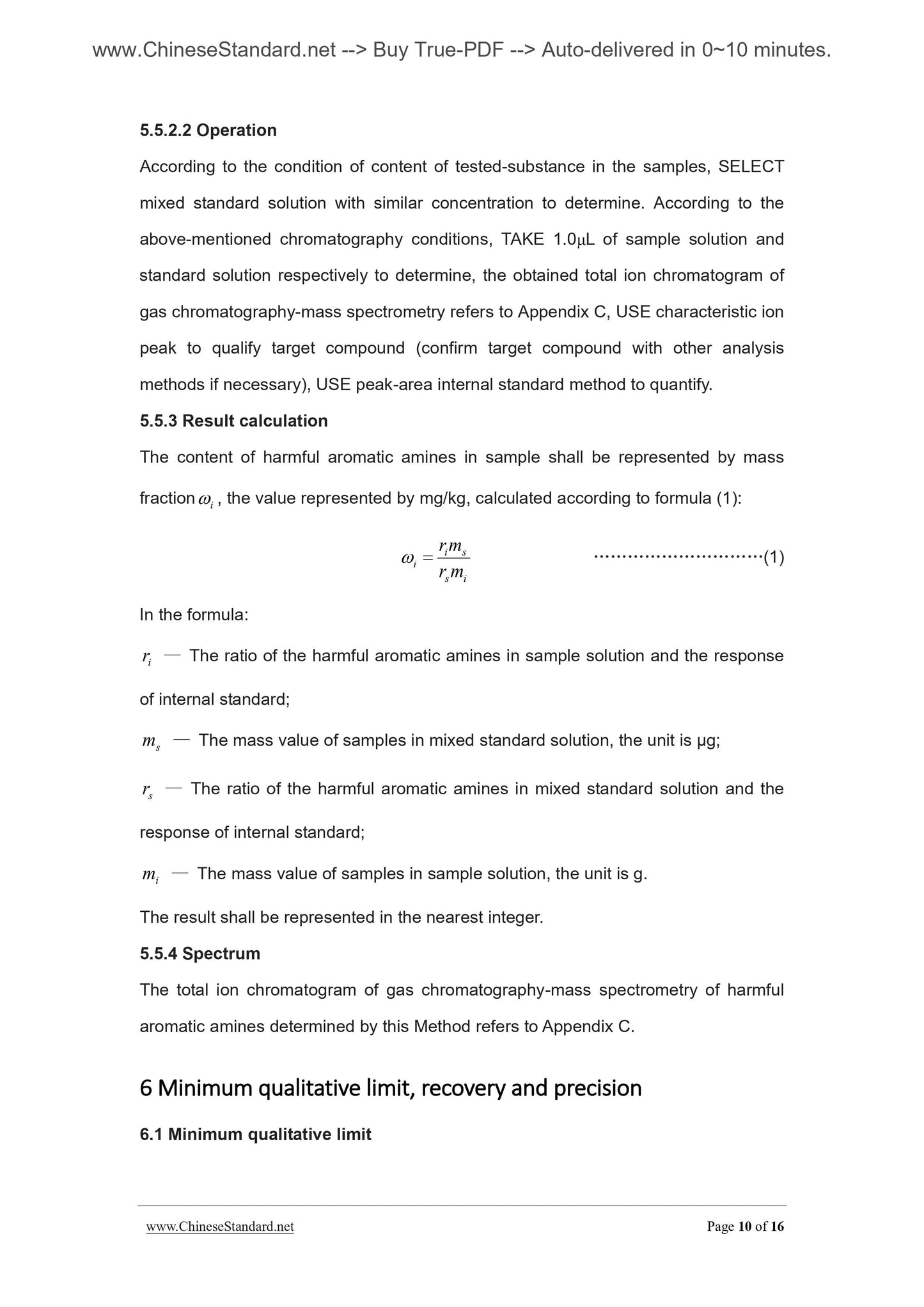

5.5.2.1 Operating conditions of gas chromatography-mass spectrometry

Because test result depends on the instrument to be used, so it is impossible to

provide general parameters of chromatography. Using...

Get QUOTATION in 1-minute: Click GB 19601-2013

Historical versions: GB 19601-2013

Preview True-PDF (Reload/Scroll if blank)

GB 19601-2013: Limit and determination of 23 harmful aromatic amines in dye products

GB 19601-2013

ICS 71.100.01; 87.060.10

G 55

National Standard

of People’s Republic of China

Replacing GB 19601-2004

Limit and determination of 23 harmful

aromatic amines in dye products

ISSUED ON. SEPTEMBER 6, 2013

IMPLEMENTED ON. OCTOBER 1, 2014

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of People's Republic of China, AQSIQ;

Standardization Administration of the People's Republic of China, SAC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references... 5

3 Requirements ... 5

4 Principles ... 6

5 Experimental methods ... 6

6 Minimum qualitative limit, recovery and precision ... 10

7 Test report ... 11

Appendix A ... 12

Appendix B... 14

Appendix C ... 15

Foreword

All the technical content of this Standard is mandatory.

This Standard is drafted in accordance with the rules of GB/T 1.1-2009.

This Standard replaces GB 19601-2004 "Limit and determination of 23 harmful

aromatic amines in dye products". Compared with GB 19601-2004, except editorial

changes, the major technical changes are as follows.

— DELETE the analysis methods of gas chromatographic (4.4.3.2 in 2004

edition);

— Quantitative methods have been transformed from the external-standard

method into the internal-standard method (see 5.5.3, 4.4.4.2 in 2004 edition);

— DELETE the column extraction from the sample-preparation methods (4.4.1 in

2004 edition);

— MODIFY the sample-preparation methods (see 5.5.1, 4.4.1 in 2004 edition);

— COMBINE qualitative parts and quantitative parts to analysis steps (see 5.5.2,

4.4.3 in 2004 edition);

— REMOVE the reserved time from Appendix A (Appendix A in 2004 edition);

— DELETE the recovery-rate table (Table 2 in 2004 edition).

This Standard is proposed by China Petroleum and Chemical Industry Federation.

This Standard is administered by the National Technical Committee of Dye

Standardization (SAC/TC 134)

This Standard is drafted by organizations. Shenyang Chemical Institute Co., Ltd.,

Xuzhou Kaida Fine Chemical Co., Ltd., State-Key Laboratory of Fine Chemicals of

Dalian University of Technology, Jiangsu Yabang Dye Co., Ltd., Beijing Institute of

Clothing, Institute of Product Quality Supervision and Inspection of Taizhou City, and

National Dye Quality Supervision and Inspection Center.

Chief drafters of this Standard. Ji Hao, Piao Kezhuang, Fu Ping, Peng Xiaojun, Zheng

Junliang, Shen Rijong, Ji Lanqin, Zhou Yongkai, and Li Xinggen.

The standard of previous version replaced by this Standard is.

—GB 19601-2004.

Limit and determination of 23 harmful aromatic

amines in dye products

Warning. Personnel using this Standard shall have practical working experience in

qualified laboratory. This Standard does not point out all possible safety problems.

Users are responsible for taking appropriate safety and healthy measures, and to

ensure compliance with the relevant conditions of the national regulations.

1 Scope

This Standard specifies the allowable limit and determination methods of harmful

aromatic amines in dye products (see Appendix A).

This Standard is applicable to all kinds of commercial dyes, dye products, dye

intermediates and textile-dye auxiliaries.

2 Normative references

The following documents are indispensable for the application of this document. For

dated references, only the dated edition is applicable for this document. For undated

documents, the latest version (including all amendments) applies to this document.

GB/T 6682-2008 Water for analytical laboratory use. Specification and test methods (ISO,

3696.1987, MOD)

GB/T 8170-2008 Rules of rounding off for numerical values and expression and judgment of

limiting values

3 Requirements

The content of harmful aromatic amines (see Appendix A) in dye products shall be

less than 150mg (aromatic amines)/kg (product), in which the limit of harmful aromatic

amines in dye products, such as solution dyes and pigment paste, shall be converted

according to the solid content.

4 Principles

In dielectric of citrate buffer solution (pH=6.0), The dye sample uses sodium

hyposulfite to achieve the reductive decomposition, and then uses the organic solvent

to directly extract the aromatic amines from the lysis solution. After concentration, it

uses gas chromatography-mass spectrometry instrument to detect.

5 Experimental methods

5.1 General provisions

Unless otherwise specified, it shall only use the reagents confirmed as analytical

reagents and grade 3 water specified by GB/T 6682-2008. Judgment of the inspection

results shall be conducted according to 4.3.3 rounding-value-comparison method in

GB/T 8170–2008.

5.2 Reagents and materials

5.2.1 Standard sample of aromatic amines. 23 kinds of known-content harmful

aromatic amines (see Appendix A).

5.2.2 Standard sample of internal standard. known-content internal standard (see

Appendix B).

5.2.3 Chloroform.

5.2.4 Glacial acetic acid.

5.2.5 Citrate buffer solution. 0.06 mol/L aqueous solution, pH = 6 (TAKE 12.526g citric

acid and 6.320g sodium hydroxide, DISSOLVE them in water, and then DILUTE to

1000 mL).

5 2.6 Sodium hyposulfite. 200 g/L aqueous solution, when using, TAKE solid sodium

hyposulfite (content of Na2S2O4 ≥ 85%) and DISSOLVE it in water for preparation.

5.2.7 The solution of sodium carbonate anhydrous. 200 g/L.

5.2.8 Volumetric flask. 10 mL, 25 mL.

5.2.9 Graduated pipettes. 1 mL, 5 mL.

5.2.10 Separating funnel. 60mL.

5.2.11 Grinding-mouth conical flask with stopper. 100 mL.

WEIGH 0.2g of sample (accurate to 0.0002g), PLACE in a 100mL grinding-mouth

conical flask, ADD 24mL of citrate buffer solution, ADD 1.0mL of internal standard

solution, COVER the stopper. PUT the conical bottle into the water-bath pan in which

the temperature is 70°C±2°C to preheat for about 15 min, KEEP shaking from time to

time, LET the sample to be completely dissolved as possible. At the same time,

PREPARE sodium dithionite. After preheating, TAKE out the erlenmeyer flask, ADD

6.0 mL of sodium dithionite solution in each bottle, COVER with cork immediately,

SHAKE well. PUT the conical bottle into the water-bath pan which is 70 °C ± 2°C to

maintain for 30 min; SHAKE from time to time to make it fully restored. After restored,

TAKE out the conical bottle and USE cool water to make it reach to room temperature

quickly, USE anhydrous sodium carbonate solution to adjust to pH 8~9 (add about

5mL). Extract the sample three times with chloroform in a separating funnel, and each

time USE 20mL of chloroform. ADD 2~4 drops of glacial acetic acid into the

first-extracted solution for acidity. Three-time extracted solution shall be combined in

a 125 mL grinding-mouth flat flask and be concentrated to a volume of about 1 mL on

a rotating evaporator. REMOVE the concentrated liquid with a suction tube into a

10mL volumetric flask. WASH the flask repeatedly with chloroform, the lotion shall be

also added into the volumetric flask, VOLUME to the mark with chloroform. This

solution is the sample solution.

Non-water soluble dyes may be added with 3 mL ~ 5 mL of acetone before sample

processing, so as to make it disperse in the buffer solution uniformly, then process it

according to this Method.

5.5.2 Chromatography

5.5.2.1 Operating conditions of gas chromatography-mass spectrometry

Because test result depends on the instrument to be used, so it is impossible to

provide general parameters of chromatography. Using...

Share