1

/

of

6

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 20400-2006 English PDF

GB 20400-2006 English PDF

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 20400-2006: Leather and fur -- Limit of harmful matter

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB 20400-2006 (Self-service in 1-minute)

Historical versions (Master-website): GB 20400-2006

Preview True-PDF (Reload/Scroll-down if blank)

GB 20400-2006

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.140.30

Y 46

Leather and Fur - Limit of Harmful Matter

ISSUED ON. APRIL 03, 2006

IMPLEMENTED ON. DECEMBER 01, 2007

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (GAQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Classification ... 5

5 Requirements ... 5

6 Test Methods ... 5

6.1 Measuring of the Banned Azo Colourants ... 5

6.2 Measuring of Free Formaldehyde ... 5

7 Inspection Rules ... 6

7.1 Type Test ... 6

7.2 Sampling Quantity ... 6

8 Inspection Report ... 6

Appendix A (Normative) Names of 23 Kinds of Banned Aromatic Amine . 8

Appendix B (Informative) Example of the Product Classification ... 9

Foreword

Chapter 5 and Chapter 7 of this Standard are compulsory; the rest are

recommendatory.

The harmful substance limitation requirements of this Standard are consistent with

those in European Union, Japan and United States.

In this Standard, Appendix A is normative and Appendix B is informative.

This Standard was proposed by China National Light Industry Council.

This Standard shall be under the jurisdiction of National Leather Industry Standardized

Technique Commission (SAC/TC 252).

Drafting organizations of this Standard. China Leather and Shoes Manufacturing

Industry Institute, National Fur Quality Supervision Testing Center, Jiaxing Entry-Exit

Inspection and Quarantine Bureau, Xinji Perit Fur Industry Co., Ltd., Guang Dong

Xinhui Leather Chemical Plant Ltd., Xinxiang Black Field Lightness Tanning Co., Ltd.

Chief drafting staffs of this Standard. Zhao Liguo, Na Risu, Shen Bing, Liu Xiankui, Xu

Fashen, Luo Guoshu, He Mingling and Zheng Yushan.

Leather and Fur - Limit of Harmful Matter

1 Scope

This Standard specifies the limitation and inspection methods of the harmful substance

in the leather and fur products

This Standard is applicable to the daily-use leather and fur products.

This Standard is not applicable to the leather and fur products that are used in the

industrial and special trade. The exporting products shall meet the export contract

agreement and the provisions of importing countries.

2 Normative References

The following documents contain the provisions which, through reference in this text,

constitute the provisions of this Standard. For the dated reference, the subsequent

amendments (excluding corrigenda) or revisions of these publications do not apply.

However, all parties who enter into an agreement according to this Standard are

encouraged to study whether the latest edition of these documents is applicable. For

undated references, the latest edition of the normative document is applicable to this

Standard.

GB/T 19941 Leather and Fur - Chemical Tests - Determination of Formaldehyde

Content (GB/T 19941-2005, ISO TS 17226.2003, Leather - Chemical Tests -

Determination of Formaldehyde Content in Leather, MOD)

GB/T 19942 Leather and Fur - Chemical Test - Determination of Banned Azo

Colourants (GB/T 19942-2005; ISO/TS 17234.2003; Leather - Chemical Tests -

Determination of Certain Azo Colourants in Dyed Leather, MOD)

3 Terms and Definitions

The following terms and definitions are applicable to this Standard.

3.1 Products for babies

The products that are used by the infants less than 24 months (including 24 months).

3.2 Products with direct contact to skin

The products of which the most area directly contacts with human skin in wear or in

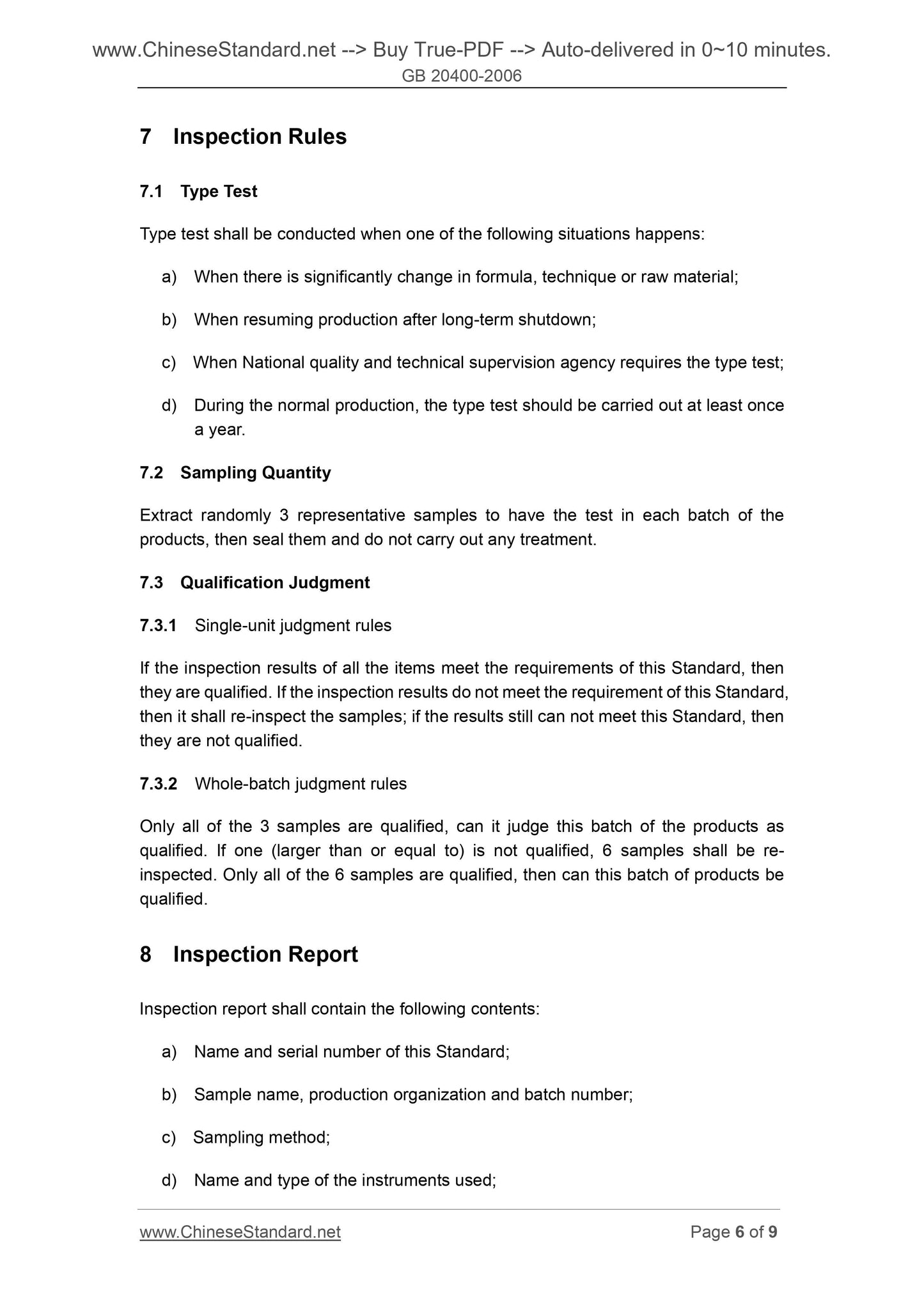

7 Inspection Rules

7.1 Type Test

Type test shall be conducted when one of the following situations happens.

a) When there is significantly change in formula, technique or raw material;

b) When resuming production after long-term shutdown;

c) When National quality and technical supervision agency requires the type test;

d) During the normal production, the type test should be carried out at least once

a year.

7.2 Sampling Quantity

Extract randomly 3 representative samples to have the test in each batch of the

products, then seal them and do not carry out any treatment.

7.3 Qualification Judgment

7.3.1 Single-unit judgment rules

If the inspection results of all the items meet the requirements of this Standard, then

they are qualified. If the inspection results do not meet the requirement of this Standard,

then it shall re-inspect the samples; if the results still can not meet this Standard, then

they are not qualified.

7.3.2 Whole-batch judgment rules

Only all of the 3 samples are qualified, can it judge this batch of the products as

qualified. If one (larger than or equal to) is not qualified, 6 samples shall be re-

inspected. Only all of the 6 samples are qualified, then can this batch of products be

qualified.

8 Inspection Report

Inspection report shall contain the following contents.

a) Name and serial number of this Standard;

b) Sample name, production organization and batch number;

c) Sampling method;

d) Name and type of the instruments used;

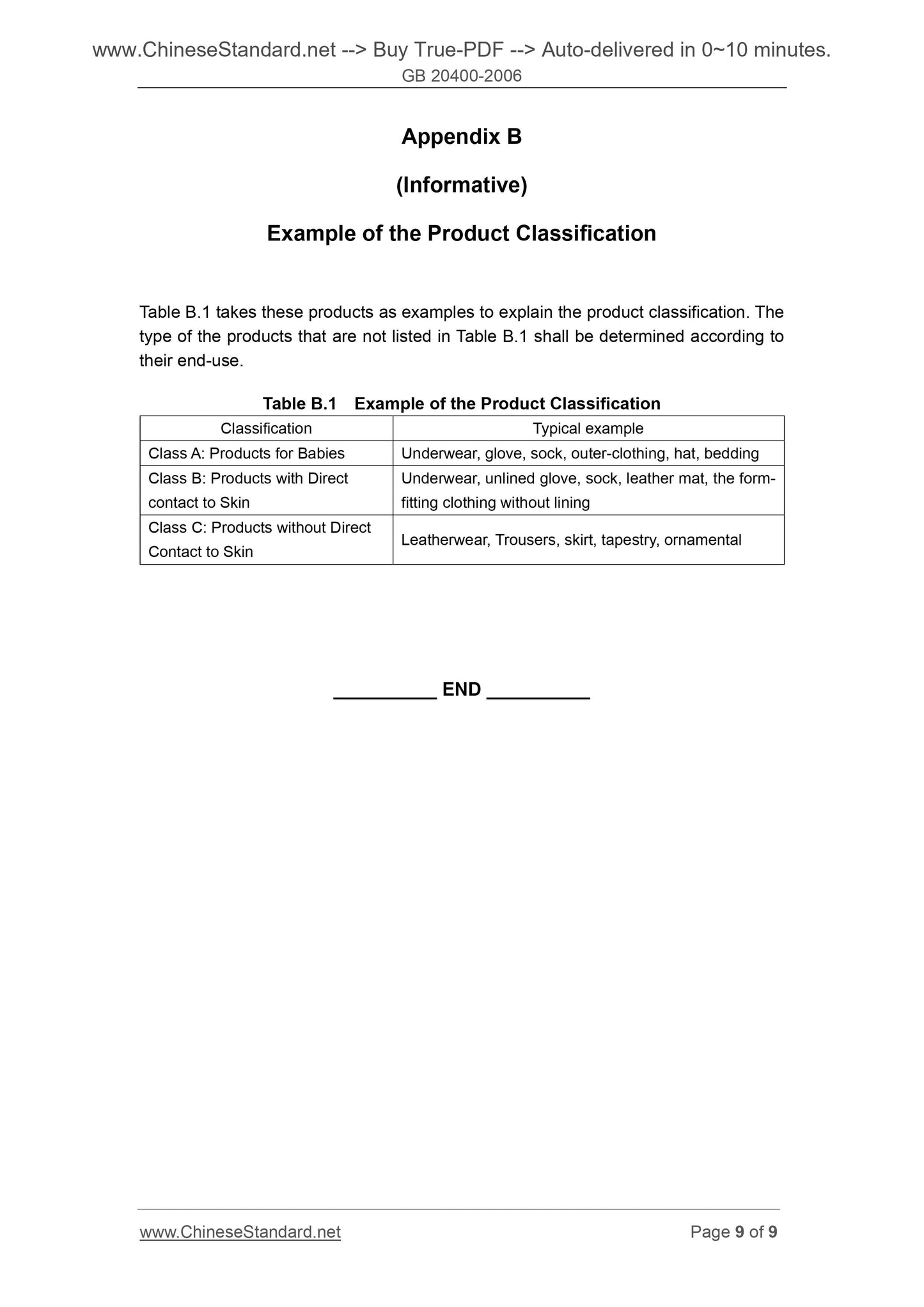

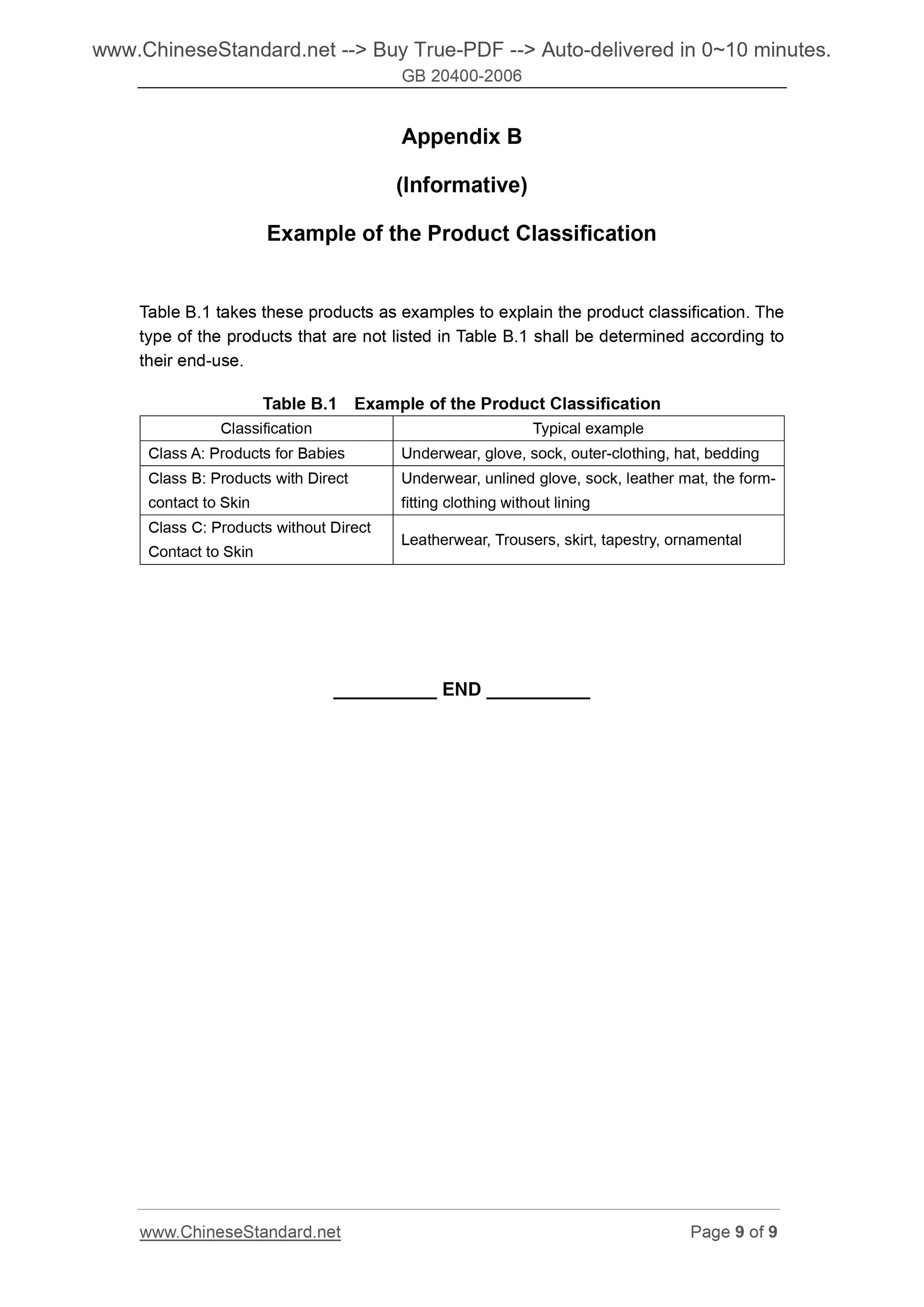

Appendix B

(Informative)

Example of the Product Classification

Table B.1 takes these products as examples to explain the product classification. The

type of the products that are not listed in Table B.1 shall be determined according to

their end-use.

Table B.1 Example of the Product Classification

Classification Typical example

Class A. Products for Babies Underwear, glove, sock, outer-clothing, hat, bedding

Class B. Products with Direct

contact to Skin

Underwear, unlined glove, sock, leather mat, the form-

fitting clothing without lining

Class C. Products without Direct

Contact to Skin Leatherwear, Trousers, skirt, tapestry, ornamental

GB 20400-2006

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.140.30

Y 46

Leather and Fur - Limit of Harmful Matter

ISSUED ON. APRIL 03, 2006

IMPLEMENTED ON. DECEMBER 01, 2007

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (GAQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Classification ... 5

5 Requirements ... 5

6 Test Methods ... 5

6.1 Measuring of the Banned Azo Colourants ... 5

6.2 Measuring of Free Formaldehyde ... 5

7 Inspection Rules ... 6

7.1 Type Test ... 6

7.2 Sampling Quantity ... 6

8 Inspection Report ... 6

Appendix A (Normative) Names of 23 Kinds of Banned Aromatic Amine . 8

Appendix B (Informative) Example of the Product Classification ... 9

Foreword

Chapter 5 and Chapter 7 of this Standard are compulsory; the rest are

recommendatory.

The harmful substance limitation requirements of this Standard are consistent with

those in European Union, Japan and United States.

In this Standard, Appendix A is normative and Appendix B is informative.

This Standard was proposed by China National Light Industry Council.

This Standard shall be under the jurisdiction of National Leather Industry Standardized

Technique Commission (SAC/TC 252).

Drafting organizations of this Standard. China Leather and Shoes Manufacturing

Industry Institute, National Fur Quality Supervision Testing Center, Jiaxing Entry-Exit

Inspection and Quarantine Bureau, Xinji Perit Fur Industry Co., Ltd., Guang Dong

Xinhui Leather Chemical Plant Ltd., Xinxiang Black Field Lightness Tanning Co., Ltd.

Chief drafting staffs of this Standard. Zhao Liguo, Na Risu, Shen Bing, Liu Xiankui, Xu

Fashen, Luo Guoshu, He Mingling and Zheng Yushan.

Leather and Fur - Limit of Harmful Matter

1 Scope

This Standard specifies the limitation and inspection methods of the harmful substance

in the leather and fur products

This Standard is applicable to the daily-use leather and fur products.

This Standard is not applicable to the leather and fur products that are used in the

industrial and special trade. The exporting products shall meet the export contract

agreement and the provisions of importing countries.

2 Normative References

The following documents contain the provisions which, through reference in this text,

constitute the provisions of this Standard. For the dated reference, the subsequent

amendments (excluding corrigenda) or revisions of these publications do not apply.

However, all parties who enter into an agreement according to this Standard are

encouraged to study whether the latest edition of these documents is applicable. For

undated references, the latest edition of the normative document is applicable to this

Standard.

GB/T 19941 Leather and Fur - Chemical Tests - Determination of Formaldehyde

Content (GB/T 19941-2005, ISO TS 17226.2003, Leather - Chemical Tests -

Determination of Formaldehyde Content in Leather, MOD)

GB/T 19942 Leather and Fur - Chemical Test - Determination of Banned Azo

Colourants (GB/T 19942-2005; ISO/TS 17234.2003; Leather - Chemical Tests -

Determination of Certain Azo Colourants in Dyed Leather, MOD)

3 Terms and Definitions

The following terms and definitions are applicable to this Standard.

3.1 Products for babies

The products that are used by the infants less than 24 months (including 24 months).

3.2 Products with direct contact to skin

The products of which the most area directly contacts with human skin in wear or in

7 Inspection Rules

7.1 Type Test

Type test shall be conducted when one of the following situations happens.

a) When there is significantly change in formula, technique or raw material;

b) When resuming production after long-term shutdown;

c) When National quality and technical supervision agency requires the type test;

d) During the normal production, the type test should be carried out at least once

a year.

7.2 Sampling Quantity

Extract randomly 3 representative samples to have the test in each batch of the

products, then seal them and do not carry out any treatment.

7.3 Qualification Judgment

7.3.1 Single-unit judgment rules

If the inspection results of all the items meet the requirements of this Standard, then

they are qualified. If the inspection results do not meet the requirement of this Standard,

then it shall re-inspect the samples; if the results still can not meet this Standard, then

they are not qualified.

7.3.2 Whole-batch judgment rules

Only all of the 3 samples are qualified, can it judge this batch of the products as

qualified. If one (larger than or equal to) is not qualified, 6 samples shall be re-

inspected. Only all of the 6 samples are qualified, then can this batch of products be

qualified.

8 Inspection Report

Inspection report shall contain the following contents.

a) Name and serial number of this Standard;

b) Sample name, production organization and batch number;

c) Sampling method;

d) Name and type of the instruments used;

Appendix B

(Informative)

Example of the Product Classification

Table B.1 takes these products as examples to explain the product classification. The

type of the products that are not listed in Table B.1 shall be determined according to

their end-use.

Table B.1 Example of the Product Classification

Classification Typical example

Class A. Products for Babies Underwear, glove, sock, outer-clothing, hat, bedding

Class B. Products with Direct

contact to Skin

Underwear, unlined glove, sock, leather mat, the form-

fitting clothing without lining

Class C. Products without Direct

Contact to Skin Leatherwear, Trousers, skirt, tapestry, ornamental

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB 20400-2006 (Self-service in 1-minute)

Historical versions (Master-website): GB 20400-2006

Preview True-PDF (Reload/Scroll-down if blank)

GB 20400-2006

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.140.30

Y 46

Leather and Fur - Limit of Harmful Matter

ISSUED ON. APRIL 03, 2006

IMPLEMENTED ON. DECEMBER 01, 2007

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (GAQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Classification ... 5

5 Requirements ... 5

6 Test Methods ... 5

6.1 Measuring of the Banned Azo Colourants ... 5

6.2 Measuring of Free Formaldehyde ... 5

7 Inspection Rules ... 6

7.1 Type Test ... 6

7.2 Sampling Quantity ... 6

8 Inspection Report ... 6

Appendix A (Normative) Names of 23 Kinds of Banned Aromatic Amine . 8

Appendix B (Informative) Example of the Product Classification ... 9

Foreword

Chapter 5 and Chapter 7 of this Standard are compulsory; the rest are

recommendatory.

The harmful substance limitation requirements of this Standard are consistent with

those in European Union, Japan and United States.

In this Standard, Appendix A is normative and Appendix B is informative.

This Standard was proposed by China National Light Industry Council.

This Standard shall be under the jurisdiction of National Leather Industry Standardized

Technique Commission (SAC/TC 252).

Drafting organizations of this Standard. China Leather and Shoes Manufacturing

Industry Institute, National Fur Quality Supervision Testing Center, Jiaxing Entry-Exit

Inspection and Quarantine Bureau, Xinji Perit Fur Industry Co., Ltd., Guang Dong

Xinhui Leather Chemical Plant Ltd., Xinxiang Black Field Lightness Tanning Co., Ltd.

Chief drafting staffs of this Standard. Zhao Liguo, Na Risu, Shen Bing, Liu Xiankui, Xu

Fashen, Luo Guoshu, He Mingling and Zheng Yushan.

Leather and Fur - Limit of Harmful Matter

1 Scope

This Standard specifies the limitation and inspection methods of the harmful substance

in the leather and fur products

This Standard is applicable to the daily-use leather and fur products.

This Standard is not applicable to the leather and fur products that are used in the

industrial and special trade. The exporting products shall meet the export contract

agreement and the provisions of importing countries.

2 Normative References

The following documents contain the provisions which, through reference in this text,

constitute the provisions of this Standard. For the dated reference, the subsequent

amendments (excluding corrigenda) or revisions of these publications do not apply.

However, all parties who enter into an agreement according to this Standard are

encouraged to study whether the latest edition of these documents is applicable. For

undated references, the latest edition of the normative document is applicable to this

Standard.

GB/T 19941 Leather and Fur - Chemical Tests - Determination of Formaldehyde

Content (GB/T 19941-2005, ISO TS 17226.2003, Leather - Chemical Tests -

Determination of Formaldehyde Content in Leather, MOD)

GB/T 19942 Leather and Fur - Chemical Test - Determination of Banned Azo

Colourants (GB/T 19942-2005; ISO/TS 17234.2003; Leather - Chemical Tests -

Determination of Certain Azo Colourants in Dyed Leather, MOD)

3 Terms and Definitions

The following terms and definitions are applicable to this Standard.

3.1 Products for babies

The products that are used by the infants less than 24 months (including 24 months).

3.2 Products with direct contact to skin

The products of which the most area directly contacts with human skin in wear or in

7 Inspection Rules

7.1 Type Test

Type test shall be conducted when one of the following situations happens.

a) When there is significantly change in formula, technique or raw material;

b) When resuming production after long-term shutdown;

c) When National quality and technical supervision agency requires the type test;

d) During the normal production, the type test should be carried out at least once

a year.

7.2 Sampling Quantity

Extract randomly 3 representative samples to have the test in each batch of the

products, then seal them and do not carry out any treatment.

7.3 Qualification Judgment

7.3.1 Single-unit judgment rules

If the inspection results of all the items meet the requirements of this Standard, then

they are qualified. If the inspection results do not meet the requirement of this Standard,

then it shall re-inspect the samples; if the results still can not meet this Standard, then

they are not qualified.

7.3.2 Whole-batch judgment rules

Only all of the 3 samples are qualified, can it judge this batch of the products as

qualified. If one (larger than or equal to) is not qualified, 6 samples shall be re-

inspected. Only all of the 6 samples are qualified, then can this batch of products be

qualified.

8 Inspection Report

Inspection report shall contain the following contents.

a) Name and serial number of this Standard;

b) Sample name, production organization and batch number;

c) Sampling method;

d) Name and type of the instruments used;

Appendix B

(Informative)

Example of the Product Classification

Table B.1 takes these products as examples to explain the product classification. The

type of the products that are not listed in Table B.1 shall be determined according to

their end-use.

Table B.1 Example of the Product Classification

Classification Typical example

Class A. Products for Babies Underwear, glove, sock, outer-clothing, hat, bedding

Class B. Products with Direct

contact to Skin

Underwear, unlined glove, sock, leather mat, the form-

fitting clothing without lining

Class C. Products without Direct

Contact to Skin Leatherwear, Trousers, skirt, tapestry, ornamental

GB 20400-2006

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.140.30

Y 46

Leather and Fur - Limit of Harmful Matter

ISSUED ON. APRIL 03, 2006

IMPLEMENTED ON. DECEMBER 01, 2007

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (GAQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Classification ... 5

5 Requirements ... 5

6 Test Methods ... 5

6.1 Measuring of the Banned Azo Colourants ... 5

6.2 Measuring of Free Formaldehyde ... 5

7 Inspection Rules ... 6

7.1 Type Test ... 6

7.2 Sampling Quantity ... 6

8 Inspection Report ... 6

Appendix A (Normative) Names of 23 Kinds of Banned Aromatic Amine . 8

Appendix B (Informative) Example of the Product Classification ... 9

Foreword

Chapter 5 and Chapter 7 of this Standard are compulsory; the rest are

recommendatory.

The harmful substance limitation requirements of this Standard are consistent with

those in European Union, Japan and United States.

In this Standard, Appendix A is normative and Appendix B is informative.

This Standard was proposed by China National Light Industry Council.

This Standard shall be under the jurisdiction of National Leather Industry Standardized

Technique Commission (SAC/TC 252).

Drafting organizations of this Standard. China Leather and Shoes Manufacturing

Industry Institute, National Fur Quality Supervision Testing Center, Jiaxing Entry-Exit

Inspection and Quarantine Bureau, Xinji Perit Fur Industry Co., Ltd., Guang Dong

Xinhui Leather Chemical Plant Ltd., Xinxiang Black Field Lightness Tanning Co., Ltd.

Chief drafting staffs of this Standard. Zhao Liguo, Na Risu, Shen Bing, Liu Xiankui, Xu

Fashen, Luo Guoshu, He Mingling and Zheng Yushan.

Leather and Fur - Limit of Harmful Matter

1 Scope

This Standard specifies the limitation and inspection methods of the harmful substance

in the leather and fur products

This Standard is applicable to the daily-use leather and fur products.

This Standard is not applicable to the leather and fur products that are used in the

industrial and special trade. The exporting products shall meet the export contract

agreement and the provisions of importing countries.

2 Normative References

The following documents contain the provisions which, through reference in this text,

constitute the provisions of this Standard. For the dated reference, the subsequent

amendments (excluding corrigenda) or revisions of these publications do not apply.

However, all parties who enter into an agreement according to this Standard are

encouraged to study whether the latest edition of these documents is applicable. For

undated references, the latest edition of the normative document is applicable to this

Standard.

GB/T 19941 Leather and Fur - Chemical Tests - Determination of Formaldehyde

Content (GB/T 19941-2005, ISO TS 17226.2003, Leather - Chemical Tests -

Determination of Formaldehyde Content in Leather, MOD)

GB/T 19942 Leather and Fur - Chemical Test - Determination of Banned Azo

Colourants (GB/T 19942-2005; ISO/TS 17234.2003; Leather - Chemical Tests -

Determination of Certain Azo Colourants in Dyed Leather, MOD)

3 Terms and Definitions

The following terms and definitions are applicable to this Standard.

3.1 Products for babies

The products that are used by the infants less than 24 months (including 24 months).

3.2 Products with direct contact to skin

The products of which the most area directly contacts with human skin in wear or in

7 Inspection Rules

7.1 Type Test

Type test shall be conducted when one of the following situations happens.

a) When there is significantly change in formula, technique or raw material;

b) When resuming production after long-term shutdown;

c) When National quality and technical supervision agency requires the type test;

d) During the normal production, the type test should be carried out at least once

a year.

7.2 Sampling Quantity

Extract randomly 3 representative samples to have the test in each batch of the

products, then seal them and do not carry out any treatment.

7.3 Qualification Judgment

7.3.1 Single-unit judgment rules

If the inspection results of all the items meet the requirements of this Standard, then

they are qualified. If the inspection results do not meet the requirement of this Standard,

then it shall re-inspect the samples; if the results still can not meet this Standard, then

they are not qualified.

7.3.2 Whole-batch judgment rules

Only all of the 3 samples are qualified, can it judge this batch of the products as

qualified. If one (larger than or equal to) is not qualified, 6 samples shall be re-

inspected. Only all of the 6 samples are qualified, then can this batch of products be

qualified.

8 Inspection Report

Inspection report shall contain the following contents.

a) Name and serial number of this Standard;

b) Sample name, production organization and batch number;

c) Sampling method;

d) Name and type of the instruments used;

Appendix B

(Informative)

Example of the Product Classification

Table B.1 takes these products as examples to explain the product classification. The

type of the products that are not listed in Table B.1 shall be determined according to

their end-use.

Table B.1 Example of the Product Classification

Classification Typical example

Class A. Products for Babies Underwear, glove, sock, outer-clothing, hat, bedding

Class B. Products with Direct

contact to Skin

Underwear, unlined glove, sock, leather mat, the form-

fitting clothing without lining

Class C. Products without Direct

Contact to Skin Leatherwear, Trousers, skirt, tapestry, ornamental

Share