1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 3087-2008 English PDF

GB 3087-2008 English PDF

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB 3087-2008: [GB/T 3087-2008] Seamless steel tubes for low and medium pressure boiler

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.

Newer version: (Replacing this standard) GB/T 3087-2022

Get Quotation: Click GB 3087-2008 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 3087-2022

Preview True-PDF (Reload/Scroll-down if blank)

GB 3087-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

H 48

Replacing GB 3087-1999

Seamless Steel Tubes for

Low and Medium Pressure Boiler

(ISO 9329-1.1989, NEQ)

ISSUED ON. OCTOBER 24, 2008

IMPLEMENTED ON. OCTOBER 1, 2009

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (AQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Ordering Information ... 8

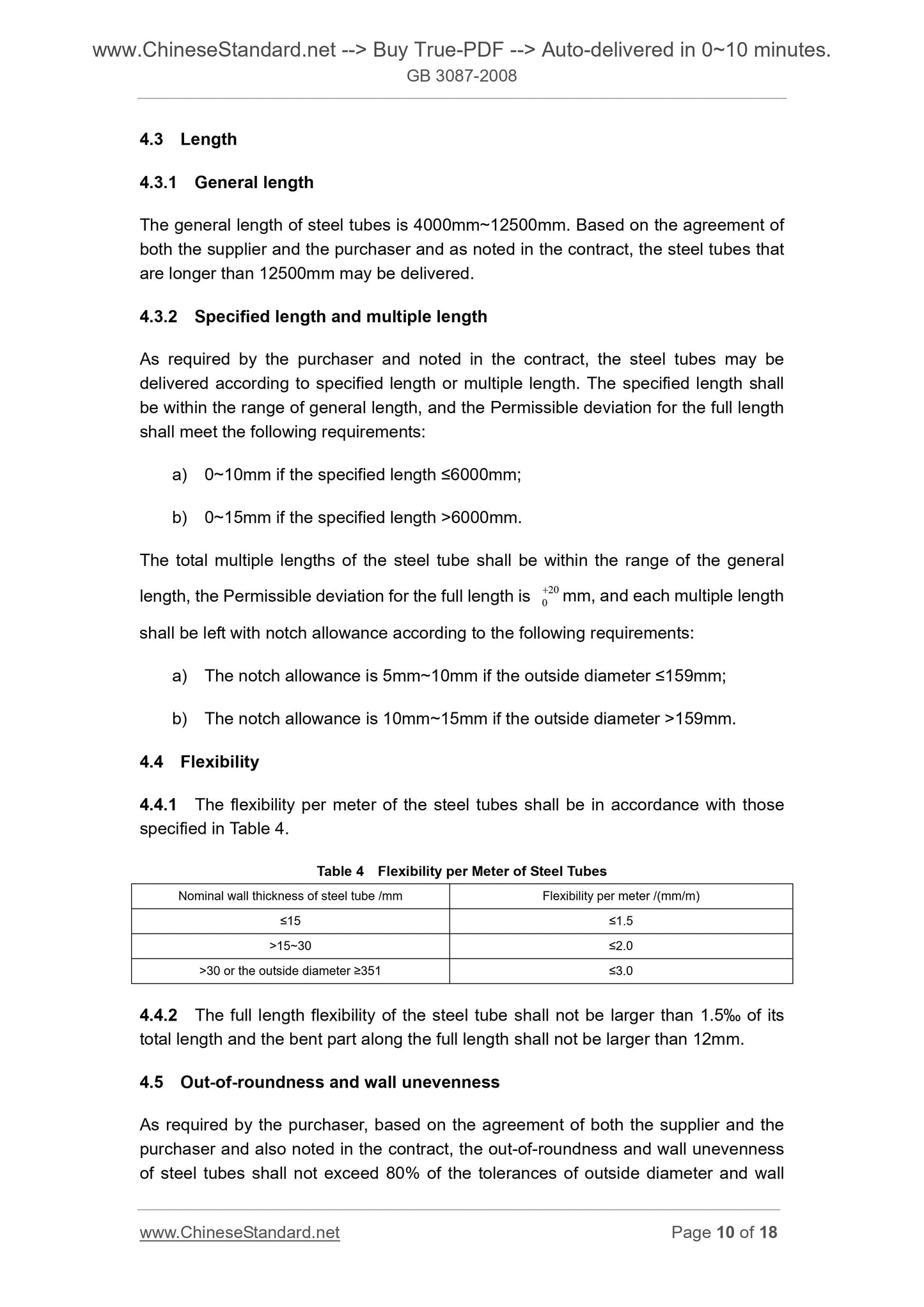

4 Dimension, Appearance and Weight ... 8

5 Technical Requirements ... 11

6 Test Methods ... 16

7 Inspection Rules ... 17

8 Packing, Marking and Quality Certificate ... 18

Foreword

This standard is corresponding to ISO 9329-1.1989 "Seamless Steel Tubes for

Pressure Purposes - Technical Delivery Conditions - Part 1. Unalloyed Steels with

Specified Room Temperature Properties" (English edition). This standard is not

equivalent to ISO 9329-1.1989.

GB 3087-1999 “Seamless Steel Tubes for Low and Medium Pressure" shall be

abolished, from the implementation data of this standard. And there have been some

significant changes in this standard over GB 3087-1999 in the following aspects.

— The application scope of steel tubes was modified;

— The "ordering information" was added;

— The allowable dimension deviations were modified;

— The requirements on full length flexibility were added;

— The requirements on oblique cutting of end socket were added;

— The marking examples were canceled;

— The smelting process of steel was modified;

— Provisions on the delivery condition of steel tubes were modified;

— Provisions on the specific manufacturing method of hot-extended steel tubes

were added;

— Provisions on the mechanical properties of steel tubes were modified;

— The judgement rules for Point 6 (bottom) and Point 12 (top) of the flattening

test sample of steel tube were added;

— Requirements on flanging test were canceled;

— The requirements on replacing hydraulic test with flaw detection were

modified.

Clauses 4.1, 4.2, 4.3, 4.5, 4.7, 5.1.3, 5.3.1, 5.4.2, 5.5.2 and 5.9 in this standard are

voluntary, and the rest are compulsory.

This standard was proposed by China Iron and Steel Association.

This standard shall be under the jurisdiction of the National Technical Committee on

Iron and Steel of Standardization Administration of China.

Seamless Steel Tubes for

Low and Medium Pressure Boiler

1 Scope

This standard specifies the ordering information, dimension, appearance, weigh,

technical requirements, test methods, inspection rules, packing, marking and quality

certificate of the seamless steel tubes for low and medium pressure boilers.

This standard is applicable to the seamless steel tubes that are made of quality

carbon structural steels and used for manufacturing various low and medium pressure

boilers.

2 Normative References

The following standards contain provisions which, through reference in this text,

constitute provisions of this standard. For dated reference, subsequent amendments

to (excluding correction to), or revisions of, any of these publications do not apply.

However, the parties whose enter into agreement according to this standard are

encouraged to research whether the latest editions of these labels are applied or not.

For undated references, the latest edition of the normative document is applicable to

this standard.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel Products

GB/T 223.3 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Phosphomolybdate Gravimetric Method for the Determination

of Phosphorus Content

GB/T 223.5 Steel and Iron - Determination of Acid-soluble Silicon and Total

Silicon Content - Reduced Molybdosilicate Spectrophotometric Method

GB/T 223.10 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Cupferron Separation-Chrome Azurol S Photometric Method for the Determination

of Aluminium Content

GB/T 223.12 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Carbonate Separation-diphenyl Carbazide Photometric Method for the

Determination of Chromium Content

GB/T 223.18 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of Copper

Content

GB/T 223.19 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Neocuproine-chloroform Extraction Photometric Method for the Determination of

Copper Content

GB/T 223.23 Iron Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.37 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Indophenal Blue Photometric Methods for the Determination of Nitrogen Content

after Distillation Separation

GB/T 223.58 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Arsenite-sodium Nitrite Titrimetric Method for the Determination of

Manganese Content

GB/T 223.59 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Reduced Molybdoantimonyl Phosphoric Acid Photometric Method for the

Determination of Phosphorus Content

GB/T 223.60 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Perchloric Acid Dehydration Gravimetric Method for the Determination of Silicon

Content

GB/T 223.61 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Ammonium Phosphomolybdate Volumetric Method for the Determination of

Phosphorus Content

GB/T 223.62 Methods for Chemical Analysis of Iron, Steel and Alloy - The Butyl

Acetate Extraction Photometric Method for the Determination of Phosphorus

Content

GB/T 223.63 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium(potassium)periodate Photometric Method for the Determination of

Manganese Content

GB/T 223.64 Iron Steel and Alloy- Determination of Manganese Content - Flame

Atomic Absorption Spectrometric Method

GB/T 223.68 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Potassium Iodate Titration Method after Combustion in the Pipe Furnace for the

Determination of Sulfur Content

GB/T 223.69 Iron Steel and Alloy - Determination of Carbon Contents -

Gas-volumetric Method after Combustion in the Pipe Furnace

GB/T 223.71 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Gravimetric Method after Combustion in the Pipe Furnace for the Determination of

Carbon Content

GB/T 223.72 Iron Steel and Alloy - Determination of Sulfur Content - Gravimetric

Method

GB/T 223.74 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Combustion Gravimetric/gas-volumetric Method for the Determination of

Combined Carbon Content

GB/T 226 Etch Test for Macrostructure and Defect of Steels

GB/T 228 Metallic Materials - Tensile Testing at Ambient Temperature (GB/T

228-2002, eqv ISO 6892.1998)

GB/T 241 Metal Materials - Tube - Hydrostatic Pressure Test

GB/T 242 Metal Materials - Tube - Drift-expending Test (GB/T 242-2007, ISO

8493.1998, IDT)

GB/T 244 Metallic Materials – Tube - Bend Test (GB/T 244-2008, ISO 8491.1998,

IDT)

GB/T 246 Metal Materials - Tube - Flattening Test (GB/T 246-2007, ISO

8492.1998, IDT)

GB/T 699 Quality Carbon Structural Steels

GB/T 1979 Standard Diagrams for Macrostructure and Defect of Structural Steels

GB/T 2102 Acceptance, Packing, Marking and Certification of Pipe

GB/T 2975 Steel and Steel Products - Location and Preparation of Test Pieces for

Mechanical Testing (GB/T 2975-1998, eqv ISO 377.1997)

GB/T 4336 Standard Test Method for Spark Discharge Atomic Emission

Spectrometric Analysis of Carbon and Low-alloy Steel (Routine Method)

GB/T 4338 Metallic Materials - Tensile Testing at Elevated Temperature (GB/T

4338-2006, ISO 783.1999, MOD)

GB/T 5777-2008 Seamless Steel Pipe and Tubing Methods for Ultrasonic Testing

(ISO 9303.1989(E), MOD)

GB/T 7735 Steel Tubes - The Inspection Method on Eddy Current Test (GB/T

7735-2004, ISO 9304.1989, MOD)

GB/T 12606 Steel Tubes - The Testing Method of Magnetic Flux Leakage (GB/T

12606-1999, eqv ISO 9402.1989 and ISO 9598.1989)

GB/T 17395 Dimensions, Shapes, Masses and Tolerances of Seamless Steel

Tubes (GB/T 17395-2008, ISO 1127.1992, ISO 4200.1991 and ISO 5252.1991,

MOD)

GB/T 20066 Steel and Iron - Sampling and Preparation of Samples for the

Determination of Chemical Composition (GB/T 20066-2006, ISO 14284.1996, IDT)

GB/T 20123 Steel and Iron - Determination of Total Carbon and Sulfur Content

Infrared Absorption Method after Combustion in an Induction Furnace (Routine

Method) (GB/T 20124-2006, ISO 15350.2000, IDT)

GB/T 20124 Steel and Iron - Determination of Nitrogen Content - Thermal

Conductimetric Method after Fusion in a Current of Inert Gas (GB/T 20124-2006,

ISO 15351.1999, IDT)

3 Ordering Information

The contract or order for purchasing steel tubes according to this standard shall

include, but not limited to the following contents.

a) Serial number of standard;

b) Product name;

c) Gr...

GB 3087-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

H 48

Replacing GB 3087-1999

Seamless Steel Tubes for

Low and Medium Pressure Boiler

(ISO 9329-1.1989, NEQ)

ISSUED ON. OCTOBER 24, 2008

IMPLEMENTED ON. OCTOBER 1, 2009

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (AQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Ordering Information ... 8

4 Dimension, Appearance and Weight ... 8

5 Technical Requirements ... 11

6 Test Methods ... 16

7 Inspection Rules ... 17

8 Packing, Marking and Quality Certificate ... 18

Foreword

This standard is corresponding to ISO 9329-1.1989 "Seamless Steel Tubes for

Pressure Purposes - Technical Delivery Conditions - Part 1. Unalloyed Steels with

Specified Room Temperature Properties" (English edition). This standard is not

equivalent to ISO 9329-1.1989.

GB 3087-1999 “Seamless Steel Tubes for Low and Medium Pressure" shall be

abolished, from the implementation data of this standard. And there have been some

significant changes in this standard over GB 3087-1999 in the following aspects.

— The application scope of steel tubes was modified;

— The "ordering information" was added;

— The allowable dimension deviations were modified;

— The requirements on full length flexibility were added;

— The requirements on oblique cutting of end socket were added;

— The marking examples were canceled;

— The smelting process of steel was modified;

— Provisions on the delivery condition of steel tubes were modified;

— Provisions on the specific manufacturing method of hot-extended steel tubes

were added;

— Provisions on the mechanical properties of steel tubes were modified;

— The judgement rules for Point 6 (bottom) and Point 12 (top) of the flattening

test sample of steel tube were added;

— Requirements on flanging test were canceled;

— The requirements on replacing hydraulic test with flaw detection were

modified.

Clauses 4.1, 4.2, 4.3, 4.5, 4.7, 5.1.3, 5.3.1, 5.4.2, 5.5.2 and 5.9 in this standard are

voluntary, and the rest are compulsory.

This standard was proposed by China Iron and Steel Association.

This standard shall be under the jurisdiction of the National Technical Committee on

Iron and Steel of Standardization Administration of China.

Seamless Steel Tubes for

Low and Medium Pressure Boiler

1 Scope

This standard specifies the ordering information, dimension, appearance, weigh,

technical requirements, test methods, inspection rules, packing, marking and quality

certificate of the seamless steel tubes for low and medium pressure boilers.

This standard is applicable to the seamless steel tubes that are made of quality

carbon structural steels and used for manufacturing various low and medium pressure

boilers.

2 Normative References

The following standards contain provisions which, through reference in this text,

constitute provisions of this standard. For dated reference, subsequent amendments

to (excluding correction to), or revisions of, any of these publications do not apply.

However, the parties whose enter into agreement according to this standard are

encouraged to research whether the latest editions of these labels are applied or not.

For undated references, the latest edition of the normative document is applicable to

this standard.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel Products

GB/T 223.3 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Phosphomolybdate Gravimetric Method for the Determination

of Phosphorus Content

GB/T 223.5 Steel and Iron - Determination of Acid-soluble Silicon and Total

Silicon Content - Reduced Molybdosilicate Spectrophotometric Method

GB/T 223.10 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Cupferron Separation-Chrome Azurol S Photometric Method for the Determination

of Aluminium Content

GB/T 223.12 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Carbonate Separation-diphenyl Carbazide Photometric Method for the

Determination of Chromium Content

GB/T 223.18 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of Copper

Content

GB/T 223.19 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Neocuproine-chloroform Extraction Photometric Method for the Determination of

Copper Content

GB/T 223.23 Iron Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.37 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Indophenal Blue Photometric Methods for the Determination of Nitrogen Content

after Distillation Separation

GB/T 223.58 Methods for Chemical Analysis ...

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.

Newer version: (Replacing this standard) GB/T 3087-2022

Get Quotation: Click GB 3087-2008 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 3087-2022

Preview True-PDF (Reload/Scroll-down if blank)

GB 3087-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

H 48

Replacing GB 3087-1999

Seamless Steel Tubes for

Low and Medium Pressure Boiler

(ISO 9329-1.1989, NEQ)

ISSUED ON. OCTOBER 24, 2008

IMPLEMENTED ON. OCTOBER 1, 2009

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (AQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Ordering Information ... 8

4 Dimension, Appearance and Weight ... 8

5 Technical Requirements ... 11

6 Test Methods ... 16

7 Inspection Rules ... 17

8 Packing, Marking and Quality Certificate ... 18

Foreword

This standard is corresponding to ISO 9329-1.1989 "Seamless Steel Tubes for

Pressure Purposes - Technical Delivery Conditions - Part 1. Unalloyed Steels with

Specified Room Temperature Properties" (English edition). This standard is not

equivalent to ISO 9329-1.1989.

GB 3087-1999 “Seamless Steel Tubes for Low and Medium Pressure" shall be

abolished, from the implementation data of this standard. And there have been some

significant changes in this standard over GB 3087-1999 in the following aspects.

— The application scope of steel tubes was modified;

— The "ordering information" was added;

— The allowable dimension deviations were modified;

— The requirements on full length flexibility were added;

— The requirements on oblique cutting of end socket were added;

— The marking examples were canceled;

— The smelting process of steel was modified;

— Provisions on the delivery condition of steel tubes were modified;

— Provisions on the specific manufacturing method of hot-extended steel tubes

were added;

— Provisions on the mechanical properties of steel tubes were modified;

— The judgement rules for Point 6 (bottom) and Point 12 (top) of the flattening

test sample of steel tube were added;

— Requirements on flanging test were canceled;

— The requirements on replacing hydraulic test with flaw detection were

modified.

Clauses 4.1, 4.2, 4.3, 4.5, 4.7, 5.1.3, 5.3.1, 5.4.2, 5.5.2 and 5.9 in this standard are

voluntary, and the rest are compulsory.

This standard was proposed by China Iron and Steel Association.

This standard shall be under the jurisdiction of the National Technical Committee on

Iron and Steel of Standardization Administration of China.

Seamless Steel Tubes for

Low and Medium Pressure Boiler

1 Scope

This standard specifies the ordering information, dimension, appearance, weigh,

technical requirements, test methods, inspection rules, packing, marking and quality

certificate of the seamless steel tubes for low and medium pressure boilers.

This standard is applicable to the seamless steel tubes that are made of quality

carbon structural steels and used for manufacturing various low and medium pressure

boilers.

2 Normative References

The following standards contain provisions which, through reference in this text,

constitute provisions of this standard. For dated reference, subsequent amendments

to (excluding correction to), or revisions of, any of these publications do not apply.

However, the parties whose enter into agreement according to this standard are

encouraged to research whether the latest editions of these labels are applied or not.

For undated references, the latest edition of the normative document is applicable to

this standard.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel Products

GB/T 223.3 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Phosphomolybdate Gravimetric Method for the Determination

of Phosphorus Content

GB/T 223.5 Steel and Iron - Determination of Acid-soluble Silicon and Total

Silicon Content - Reduced Molybdosilicate Spectrophotometric Method

GB/T 223.10 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Cupferron Separation-Chrome Azurol S Photometric Method for the Determination

of Aluminium Content

GB/T 223.12 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Carbonate Separation-diphenyl Carbazide Photometric Method for the

Determination of Chromium Content

GB/T 223.18 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of Copper

Content

GB/T 223.19 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Neocuproine-chloroform Extraction Photometric Method for the Determination of

Copper Content

GB/T 223.23 Iron Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.37 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Indophenal Blue Photometric Methods for the Determination of Nitrogen Content

after Distillation Separation

GB/T 223.58 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Arsenite-sodium Nitrite Titrimetric Method for the Determination of

Manganese Content

GB/T 223.59 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Reduced Molybdoantimonyl Phosphoric Acid Photometric Method for the

Determination of Phosphorus Content

GB/T 223.60 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Perchloric Acid Dehydration Gravimetric Method for the Determination of Silicon

Content

GB/T 223.61 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Ammonium Phosphomolybdate Volumetric Method for the Determination of

Phosphorus Content

GB/T 223.62 Methods for Chemical Analysis of Iron, Steel and Alloy - The Butyl

Acetate Extraction Photometric Method for the Determination of Phosphorus

Content

GB/T 223.63 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium(potassium)periodate Photometric Method for the Determination of

Manganese Content

GB/T 223.64 Iron Steel and Alloy- Determination of Manganese Content - Flame

Atomic Absorption Spectrometric Method

GB/T 223.68 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Potassium Iodate Titration Method after Combustion in the Pipe Furnace for the

Determination of Sulfur Content

GB/T 223.69 Iron Steel and Alloy - Determination of Carbon Contents -

Gas-volumetric Method after Combustion in the Pipe Furnace

GB/T 223.71 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Gravimetric Method after Combustion in the Pipe Furnace for the Determination of

Carbon Content

GB/T 223.72 Iron Steel and Alloy - Determination of Sulfur Content - Gravimetric

Method

GB/T 223.74 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Combustion Gravimetric/gas-volumetric Method for the Determination of

Combined Carbon Content

GB/T 226 Etch Test for Macrostructure and Defect of Steels

GB/T 228 Metallic Materials - Tensile Testing at Ambient Temperature (GB/T

228-2002, eqv ISO 6892.1998)

GB/T 241 Metal Materials - Tube - Hydrostatic Pressure Test

GB/T 242 Metal Materials - Tube - Drift-expending Test (GB/T 242-2007, ISO

8493.1998, IDT)

GB/T 244 Metallic Materials – Tube - Bend Test (GB/T 244-2008, ISO 8491.1998,

IDT)

GB/T 246 Metal Materials - Tube - Flattening Test (GB/T 246-2007, ISO

8492.1998, IDT)

GB/T 699 Quality Carbon Structural Steels

GB/T 1979 Standard Diagrams for Macrostructure and Defect of Structural Steels

GB/T 2102 Acceptance, Packing, Marking and Certification of Pipe

GB/T 2975 Steel and Steel Products - Location and Preparation of Test Pieces for

Mechanical Testing (GB/T 2975-1998, eqv ISO 377.1997)

GB/T 4336 Standard Test Method for Spark Discharge Atomic Emission

Spectrometric Analysis of Carbon and Low-alloy Steel (Routine Method)

GB/T 4338 Metallic Materials - Tensile Testing at Elevated Temperature (GB/T

4338-2006, ISO 783.1999, MOD)

GB/T 5777-2008 Seamless Steel Pipe and Tubing Methods for Ultrasonic Testing

(ISO 9303.1989(E), MOD)

GB/T 7735 Steel Tubes - The Inspection Method on Eddy Current Test (GB/T

7735-2004, ISO 9304.1989, MOD)

GB/T 12606 Steel Tubes - The Testing Method of Magnetic Flux Leakage (GB/T

12606-1999, eqv ISO 9402.1989 and ISO 9598.1989)

GB/T 17395 Dimensions, Shapes, Masses and Tolerances of Seamless Steel

Tubes (GB/T 17395-2008, ISO 1127.1992, ISO 4200.1991 and ISO 5252.1991,

MOD)

GB/T 20066 Steel and Iron - Sampling and Preparation of Samples for the

Determination of Chemical Composition (GB/T 20066-2006, ISO 14284.1996, IDT)

GB/T 20123 Steel and Iron - Determination of Total Carbon and Sulfur Content

Infrared Absorption Method after Combustion in an Induction Furnace (Routine

Method) (GB/T 20124-2006, ISO 15350.2000, IDT)

GB/T 20124 Steel and Iron - Determination of Nitrogen Content - Thermal

Conductimetric Method after Fusion in a Current of Inert Gas (GB/T 20124-2006,

ISO 15351.1999, IDT)

3 Ordering Information

The contract or order for purchasing steel tubes according to this standard shall

include, but not limited to the following contents.

a) Serial number of standard;

b) Product name;

c) Gr...

GB 3087-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

H 48

Replacing GB 3087-1999

Seamless Steel Tubes for

Low and Medium Pressure Boiler

(ISO 9329-1.1989, NEQ)

ISSUED ON. OCTOBER 24, 2008

IMPLEMENTED ON. OCTOBER 1, 2009

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (AQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Ordering Information ... 8

4 Dimension, Appearance and Weight ... 8

5 Technical Requirements ... 11

6 Test Methods ... 16

7 Inspection Rules ... 17

8 Packing, Marking and Quality Certificate ... 18

Foreword

This standard is corresponding to ISO 9329-1.1989 "Seamless Steel Tubes for

Pressure Purposes - Technical Delivery Conditions - Part 1. Unalloyed Steels with

Specified Room Temperature Properties" (English edition). This standard is not

equivalent to ISO 9329-1.1989.

GB 3087-1999 “Seamless Steel Tubes for Low and Medium Pressure" shall be

abolished, from the implementation data of this standard. And there have been some

significant changes in this standard over GB 3087-1999 in the following aspects.

— The application scope of steel tubes was modified;

— The "ordering information" was added;

— The allowable dimension deviations were modified;

— The requirements on full length flexibility were added;

— The requirements on oblique cutting of end socket were added;

— The marking examples were canceled;

— The smelting process of steel was modified;

— Provisions on the delivery condition of steel tubes were modified;

— Provisions on the specific manufacturing method of hot-extended steel tubes

were added;

— Provisions on the mechanical properties of steel tubes were modified;

— The judgement rules for Point 6 (bottom) and Point 12 (top) of the flattening

test sample of steel tube were added;

— Requirements on flanging test were canceled;

— The requirements on replacing hydraulic test with flaw detection were

modified.

Clauses 4.1, 4.2, 4.3, 4.5, 4.7, 5.1.3, 5.3.1, 5.4.2, 5.5.2 and 5.9 in this standard are

voluntary, and the rest are compulsory.

This standard was proposed by China Iron and Steel Association.

This standard shall be under the jurisdiction of the National Technical Committee on

Iron and Steel of Standardization Administration of China.

Seamless Steel Tubes for

Low and Medium Pressure Boiler

1 Scope

This standard specifies the ordering information, dimension, appearance, weigh,

technical requirements, test methods, inspection rules, packing, marking and quality

certificate of the seamless steel tubes for low and medium pressure boilers.

This standard is applicable to the seamless steel tubes that are made of quality

carbon structural steels and used for manufacturing various low and medium pressure

boilers.

2 Normative References

The following standards contain provisions which, through reference in this text,

constitute provisions of this standard. For dated reference, subsequent amendments

to (excluding correction to), or revisions of, any of these publications do not apply.

However, the parties whose enter into agreement according to this standard are

encouraged to research whether the latest editions of these labels are applied or not.

For undated references, the latest edition of the normative document is applicable to

this standard.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel Products

GB/T 223.3 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Phosphomolybdate Gravimetric Method for the Determination

of Phosphorus Content

GB/T 223.5 Steel and Iron - Determination of Acid-soluble Silicon and Total

Silicon Content - Reduced Molybdosilicate Spectrophotometric Method

GB/T 223.10 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Cupferron Separation-Chrome Azurol S Photometric Method for the Determination

of Aluminium Content

GB/T 223.12 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Carbonate Separation-diphenyl Carbazide Photometric Method for the

Determination of Chromium Content

GB/T 223.18 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of Copper

Content

GB/T 223.19 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Neocuproine-chloroform Extraction Photometric Method for the Determination of

Copper Content

GB/T 223.23 Iron Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.37 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Indophenal Blue Photometric Methods for the Determination of Nitrogen Content

after Distillation Separation

GB/T 223.58 Methods for Chemical Analysis ...

Share