1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB 31604.58-2023 English PDF

GB 31604.58-2023 English PDF

Regular price

$335.00 USD

Regular price

Sale price

$335.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 31604.58-2023

Historical versions: GB 31604.58-2023

Preview True-PDF (Reload/Scroll if blank)

GB 31604.58-2023: National food safety standard - Food contact materials and products - Determination of migration of nine antioxidants

GB 31604.58-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National Food Safety Standard - Food Contact Materials

and Products - Determination of Migration of Nine

Antioxidants

ISSUED ON. SEPTEMBER 06, 2023

IMPLEMENTED ON. MARCH 06, 2024

Issued by. National Health Commission of the People’s Republic of China;

State Administration for Market Regulation.

Table of Contents

1 Scope... 3

2 Principle... 3

3 Reagents and Materials... 3

4 Instruments and Equipment... 5

5 Analytical Procedure... 5

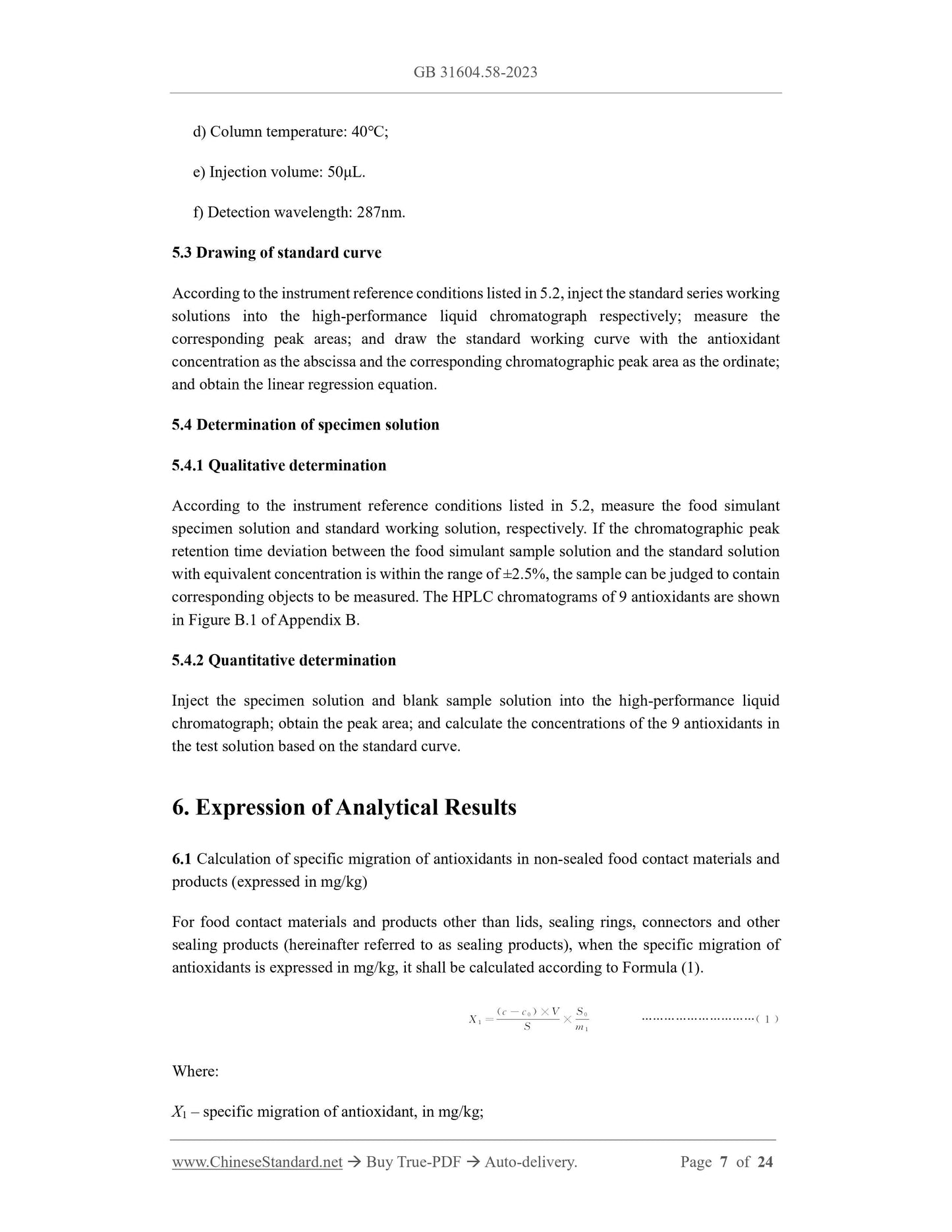

6.Expression of Analytical Results... 7

7 Precision... 9

8 Others... 9

9 Principle... 10

10 Reagents and Materials... 10

11 Apparatus... 12

12 Analytical Procedures... 12

13 Expression of Analytical Results... 14

14 Precision... 14

15 Others... 14

Appendix A Relevant Information of Standard Products of 9 Antioxidants... 16

Appendix B High Performance Liquid Chromatogram of 9 Antioxidants... 17

Appendix C Mass Spectrometry Reference Conditions... 18

Appendix D Total Ion Current (TIC) Chromatograms of Liquid Chromatography-

Tandem Mass Spectrometry of 9 Antioxidants... 19

Appendix E Multiple Reaction Monitoring (MRM) Spectra of Liquid

Chromatography-Tandem Mass Spectrometry of 9 Antioxidants... 20

National Food Safety Standard - Food Contact Materials

and Products - Determination of Migration of Nine

Antioxidants

1 Scope

This Standard specifies methods for the determination of migration of nine antioxidants in food

contact materials and products.

This Standard applies to the determination of migration of antioxidant 2246, antioxidant 264,

butylated hydroxyanisole (BHA), 2,4-di-tert-butylphenol, antioxidant 425, antioxidant 300,

antioxidant 1010, antioxidant 1076, and antioxidant 168.

Method-I High Performance Liquid Chromatography

2 Principle

After food contact materials and products undergo migration tests in accordance with GB

31604.1 and GB 5009.156, high performance liquid chromatography is used for detection.

Among them, after filtration of water, 4% (volume fraction) acetic acid, 10% (volume fraction)

ethanol, 20% (volume fraction) ethanol, 50% (volume fraction) ethanol food simulant and

chemical alternative solvent 95% (volume fraction) ethanol soaking solution, the sample is

injected directly. After the nitrogen blowing of the chemical alternative solvent isooctane

soaking solution, dissolve it in methanol; and then inject the sample. Detect by UV detector or

diode array detector, and quantified by peak area external standard method.

3 Reagents and Materials

Unless otherwise stated, all reagents are chromatographically pure. The water is Class-I water

specified in GB/T 6682.During the test, plastic materials shall be avoided as much as possible

for containers and transfer equipment.

3.1 Reagents

3.1.1 Foods containing ethanol, acidic food simulants and chemical alternative solvents. the

reagents used must comply with the provisions of GB 5009.156.

3.1.2 Methanol (CH4O).

3.1.3 Ethyl acetate (C4H8O2).

3.2 Preparation of reagent

Foods containing ethanol, acidic food simulants and chemical alternative solvents. Prepared

according to the requirements of GB 5009.156.

3.3 Standard product

9 antioxidant standard products (see Table A.1 in Appendix A), with purity ≥98%, or standard

products certified by the country and awarded a reference material certificate.

3.4 Preparation of standard solution

3.4.1 9 Antioxidant standard stock solutions (1000 mg/L). Accurately weigh 25mg of each of

the 9 antioxidant standard products (accurate to 0.1mg); dissolve them in 1mL of ethyl acetate.

And then transfer to 9 pieces of 25mL brown volumetric flask; and make constant volume by

adding methanol and shake well. Transfer the solution to a brown glass container and store it

in an airtight container away from light in a 4°C refrigerator. The shelf life is 6 months.

3.4.2 9 antioxidant standard intermediate solution A (solvent is methanol). Accurately pipet

2.50mL of each of BHA and antioxidant 300 standard stock solutions, and 5.00mL of each of

the other 7 antioxidants standard stock solutions into the same 50mL brown volumetric flask;

make constant volume by methanol to obtain standard intermediate solution A of BHA and

antioxidant 300 with mass concentration of 50.0 mg/L, and of the other 7 antioxidants with the

mass concentration of 100 mg/L. Transfer the solution to a brown glass container and store it

in an airtight container away from light in a 4°C refrigerator. The storage period is 3 months.

3.4.3 9 antioxidant standard intermediate solution B (solvent is ethyl acetate). Accurately pipet

2.50mL of each of BHA and antioxidant 300 standard stock solutions, and 5.00mL of each of

the other 7 standard stock solutions into the same 50mL brown volumetric flask; make constant

volume by ethyl acetate to obtain a standard intermediate solution B of BHA and antioxidant

300 with mass concentration of 50 mg/L, and the other 7 antioxidants with mass concentration

of 100 mg/L. Transfer the solution to a brown glass container and store it in an airtight container

away from light in a 4°C refrigerator. The storage period is 3 months.

3.4.4 Preparation of standard working solution

3.4.4.1 Chemical alternative solvent isooctane standard working solution

Accurately transfer 0.03mL, 0.1mL, 0.3mL, 1mL, and 3mL of 9 antioxidant standard

intermediate solutions B into 5 pieces of 10mL volumetric flasks; and make constant volume

with isooctane to obtain the standard working solutions of BHA and antioxidant 300 with mass

concentration of 0.15 mg/L, 0.50 mg/L, 1.5mg/L, 5mg/L, 15mg/L, respectively; and other 7

antioxidants with the mass concentration of 0.30mg/L, 1.0mg/L, 3.0mg/L, 10mg/ L, 30mg/L,

respectively. Accurately transfer 2.00mL of each standard working solution into 5 pieces of

10mL test tubes; blow with nitrogen at 40°C until nearly dry; then add 2.00mL of methanol to

dissolve. Vortex and shake to reconstitute; and filter through a needle nylon filter; and then

waiting to be measured on the machine.

3.4.4.2 Standard working solution of other food simulants and chemical alternative

solvents 95% (volume fraction) ethanol

Accurately transfer 0.03mL, 0.1mL, 0.3mL, 1mL, and 3mL of 9 antioxidant standard

intermediate solutions A into 5 pieces of 10mL volumetric flasks; and make constant volume

with 10% ethanol; and obtain the standard working solution of BHA and antioxidant 300 with

mass concentrations of 0.15mg/L, 0.50mg/L, 1.5 mg/L, 5 mg/L, 15 mg/L, respectively; and

other 7 antioxidants with mass concentrations of 0.30 mg/L, 1.0 mg/L, and 3.0mg/L, 10mg/L,

30mg/L, respectively. Using the same method, prepare 9 antioxidant standard working solutions

of the same concentration series by water, 4% acetic acid, 10% ethanol, 20% ethanol, 50%

ethanol food simulant and chemical alternative solvent 95% ethanol. Take 1 mL of each

standard working solution; filter it through a needle nylon filter; and then wait for measurement

on the machine.

4 Instruments and Equipment

4.1 High performance liquid chromatograph. Equipped with UV detector or diode array detector.

4.2 Analytical balance. Sensitivity is 0.0001g.

4.3 Nitrogen blowing concentrator.

4.4 Glass micro-syringe. 10μL, 100μL and 1000μL.

4.5 Thermostatic equipment.

4.6 Vortex oscillator.

4.7 Needle nylon filter. Pore size is 0.22μm.

5 Analytical Procedure

5.1 Preparation of test solution

5.1.1 Migration test

Food contact materials and produ...

Get QUOTATION in 1-minute: Click GB 31604.58-2023

Historical versions: GB 31604.58-2023

Preview True-PDF (Reload/Scroll if blank)

GB 31604.58-2023: National food safety standard - Food contact materials and products - Determination of migration of nine antioxidants

GB 31604.58-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National Food Safety Standard - Food Contact Materials

and Products - Determination of Migration of Nine

Antioxidants

ISSUED ON. SEPTEMBER 06, 2023

IMPLEMENTED ON. MARCH 06, 2024

Issued by. National Health Commission of the People’s Republic of China;

State Administration for Market Regulation.

Table of Contents

1 Scope... 3

2 Principle... 3

3 Reagents and Materials... 3

4 Instruments and Equipment... 5

5 Analytical Procedure... 5

6.Expression of Analytical Results... 7

7 Precision... 9

8 Others... 9

9 Principle... 10

10 Reagents and Materials... 10

11 Apparatus... 12

12 Analytical Procedures... 12

13 Expression of Analytical Results... 14

14 Precision... 14

15 Others... 14

Appendix A Relevant Information of Standard Products of 9 Antioxidants... 16

Appendix B High Performance Liquid Chromatogram of 9 Antioxidants... 17

Appendix C Mass Spectrometry Reference Conditions... 18

Appendix D Total Ion Current (TIC) Chromatograms of Liquid Chromatography-

Tandem Mass Spectrometry of 9 Antioxidants... 19

Appendix E Multiple Reaction Monitoring (MRM) Spectra of Liquid

Chromatography-Tandem Mass Spectrometry of 9 Antioxidants... 20

National Food Safety Standard - Food Contact Materials

and Products - Determination of Migration of Nine

Antioxidants

1 Scope

This Standard specifies methods for the determination of migration of nine antioxidants in food

contact materials and products.

This Standard applies to the determination of migration of antioxidant 2246, antioxidant 264,

butylated hydroxyanisole (BHA), 2,4-di-tert-butylphenol, antioxidant 425, antioxidant 300,

antioxidant 1010, antioxidant 1076, and antioxidant 168.

Method-I High Performance Liquid Chromatography

2 Principle

After food contact materials and products undergo migration tests in accordance with GB

31604.1 and GB 5009.156, high performance liquid chromatography is used for detection.

Among them, after filtration of water, 4% (volume fraction) acetic acid, 10% (volume fraction)

ethanol, 20% (volume fraction) ethanol, 50% (volume fraction) ethanol food simulant and

chemical alternative solvent 95% (volume fraction) ethanol soaking solution, the sample is

injected directly. After the nitrogen blowing of the chemical alternative solvent isooctane

soaking solution, dissolve it in methanol; and then inject the sample. Detect by UV detector or

diode array detector, and quantified by peak area external standard method.

3 Reagents and Materials

Unless otherwise stated, all reagents are chromatographically pure. The water is Class-I water

specified in GB/T 6682.During the test, plastic materials shall be avoided as much as possible

for containers and transfer equipment.

3.1 Reagents

3.1.1 Foods containing ethanol, acidic food simulants and chemical alternative solvents. the

reagents used must comply with the provisions of GB 5009.156.

3.1.2 Methanol (CH4O).

3.1.3 Ethyl acetate (C4H8O2).

3.2 Preparation of reagent

Foods containing ethanol, acidic food simulants and chemical alternative solvents. Prepared

according to the requirements of GB 5009.156.

3.3 Standard product

9 antioxidant standard products (see Table A.1 in Appendix A), with purity ≥98%, or standard

products certified by the country and awarded a reference material certificate.

3.4 Preparation of standard solution

3.4.1 9 Antioxidant standard stock solutions (1000 mg/L). Accurately weigh 25mg of each of

the 9 antioxidant standard products (accurate to 0.1mg); dissolve them in 1mL of ethyl acetate.

And then transfer to 9 pieces of 25mL brown volumetric flask; and make constant volume by

adding methanol and shake well. Transfer the solution to a brown glass container and store it

in an airtight container away from light in a 4°C refrigerator. The shelf life is 6 months.

3.4.2 9 antioxidant standard intermediate solution A (solvent is methanol). Accurately pipet

2.50mL of each of BHA and antioxidant 300 standard stock solutions, and 5.00mL of each of

the other 7 antioxidants standard stock solutions into the same 50mL brown volumetric flask;

make constant volume by methanol to obtain standard intermediate solution A of BHA and

antioxidant 300 with mass concentration of 50.0 mg/L, and of the other 7 antioxidants with the

mass concentration of 100 mg/L. Transfer the solution to a brown glass container and store it

in an airtight container away from light in a 4°C refrigerator. The storage period is 3 months.

3.4.3 9 antioxidant standard intermediate solution B (solvent is ethyl acetate). Accurately pipet

2.50mL of each of BHA and antioxidant 300 standard stock solutions, and 5.00mL of each of

the other 7 standard stock solutions into the same 50mL brown volumetric flask; make constant

volume by ethyl acetate to obtain a standard intermediate solution B of BHA and antioxidant

300 with mass concentration of 50 mg/L, and the other 7 antioxidants with mass concentration

of 100 mg/L. Transfer the solution to a brown glass container and store it in an airtight container

away from light in a 4°C refrigerator. The storage period is 3 months.

3.4.4 Preparation of standard working solution

3.4.4.1 Chemical alternative solvent isooctane standard working solution

Accurately transfer 0.03mL, 0.1mL, 0.3mL, 1mL, and 3mL of 9 antioxidant standard

intermediate solutions B into 5 pieces of 10mL volumetric flasks; and make constant volume

with isooctane to obtain the standard working solutions of BHA and antioxidant 300 with mass

concentration of 0.15 mg/L, 0.50 mg/L, 1.5mg/L, 5mg/L, 15mg/L, respectively; and other 7

antioxidants with the mass concentration of 0.30mg/L, 1.0mg/L, 3.0mg/L, 10mg/ L, 30mg/L,

respectively. Accurately transfer 2.00mL of each standard working solution into 5 pieces of

10mL test tubes; blow with nitrogen at 40°C until nearly dry; then add 2.00mL of methanol to

dissolve. Vortex and shake to reconstitute; and filter through a needle nylon filter; and then

waiting to be measured on the machine.

3.4.4.2 Standard working solution of other food simulants and chemical alternative

solvents 95% (volume fraction) ethanol

Accurately transfer 0.03mL, 0.1mL, 0.3mL, 1mL, and 3mL of 9 antioxidant standard

intermediate solutions A into 5 pieces of 10mL volumetric flasks; and make constant volume

with 10% ethanol; and obtain the standard working solution of BHA and antioxidant 300 with

mass concentrations of 0.15mg/L, 0.50mg/L, 1.5 mg/L, 5 mg/L, 15 mg/L, respectively; and

other 7 antioxidants with mass concentrations of 0.30 mg/L, 1.0 mg/L, and 3.0mg/L, 10mg/L,

30mg/L, respectively. Using the same method, prepare 9 antioxidant standard working solutions

of the same concentration series by water, 4% acetic acid, 10% ethanol, 20% ethanol, 50%

ethanol food simulant and chemical alternative solvent 95% ethanol. Take 1 mL of each

standard working solution; filter it through a needle nylon filter; and then wait for measurement

on the machine.

4 Instruments and Equipment

4.1 High performance liquid chromatograph. Equipped with UV detector or diode array detector.

4.2 Analytical balance. Sensitivity is 0.0001g.

4.3 Nitrogen blowing concentrator.

4.4 Glass micro-syringe. 10μL, 100μL and 1000μL.

4.5 Thermostatic equipment.

4.6 Vortex oscillator.

4.7 Needle nylon filter. Pore size is 0.22μm.

5 Analytical Procedure

5.1 Preparation of test solution

5.1.1 Migration test

Food contact materials and produ...

Share