1

/

of

11

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 38995-2020 English PDF

GB 38995-2020 English PDF

Regular price

$285.00 USD

Regular price

Sale price

$285.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 38995-2020

Historical versions: GB 38995-2020

Preview True-PDF (Reload/Scroll if blank)

GB 38995-2020: Infant feeding bottles and teats

GB 38995-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.140.01

Y 28

Infant feeding bottles and teats

ISSUED ON: OCTOBER 21, 2020

IMPLEMENTED ON: NOVEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Technical requirements ... 8

4.1 General requirements... 8

4.2 Additional requirements ... 11

5 Test methods ... 12

5.1 Sample preparation ... 12

5.2 General requirements test method ... 13

5.3 Test method for additional requirements ... 22

6 Inspection rules ... 24

6.1 Classification of inspection ... 24

6.2 Exit-factory inspection ... 24

6.3 Type inspection ... 25

7 Marks, transport and storage ... 26

7.1 Marks ... 26

7.2 Transport and storage ... 30

Infant feeding bottles and teats

1 Scope

This Standard specifies technical requirements, test methods, inspection rules,

marks, transport and storage for infant feeding bottles and teats.

This Standard is applicable to infant feeding bottles (container, teat and

matched accessory) that are made of one or more of plastic, glass, metal,

ceramic, silicone rubber, rubber.

This Standard is not applicable to medical bottles and teats. It is not applicable

to pacifiers.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 131-2006, Geometrical Product Specifications (GPS) - Indication of

surface texture in technical Product documentation

GB/T 2828.1, Sampling procedures for inspection by attributea - Part 1:

Sampling schemes indexed by acceptance quality limit(AQL) for lot-by-lot

inspection

GB/T 2918, Plastics - Standard atmospheres for conditioning and testing

GB/T 4545, Test methods for stress examination of glass containers

GB/T 4547, Glass containers - Test methods of the thermal shock resistance

and thermal shock endurance

GB/T 6552, Glass containers - Test method for impact resistance

GB/T 6579, Laboratory glassware - Thermal shock and thermal shock

endurance - Test methods

GB/T 6582, Glass - Hydrolytic resistance of glass grains at 98°C - Method of

test and classification

3.4.6 handle

a part that is installed on the container to facilitate the use of the feeding bottle

3.4.7 tube disc

a part that connects the tube and seals the teat to help suck fluid food

3.4.8 tube

a hollow tube that is installed inside the feeding bottle to connect the gravity ball

and the tube disc

3.4.9 gravity ball

a part that is connected to the end of the tube and acts as a gravity guide

3.4.10 matched components

when feeding infants, other parts that are used in conjunction with container,

teat, drinking accessory, protective cover, locking ring, sealing disc, filtering

gauze, handle, tube disc, tube and gravity ball

3.5 numbered graduations

scale mark with numerical value and unit to show the volume of fluid food in the

feeding bottle

4 Technical requirements

4.1 General requirements

4.1.1 Components

4.1.1.1 Appearance

It shall be clean, neat, without foreign objects. There shall be no gaps, holes,

or deformations that affect the use (except for design requirements).

4.1.1.2 Edge and tip

The feeding bottle and its components shall not have sharp edges and sharp

tips that may cause injury or danger.

4.1.1.3 Ink adhesion of printing pattern

For reuse products or components, the ink adhesion of the marked printing

pattern (including text and numbered graduations) shall meet the requirements

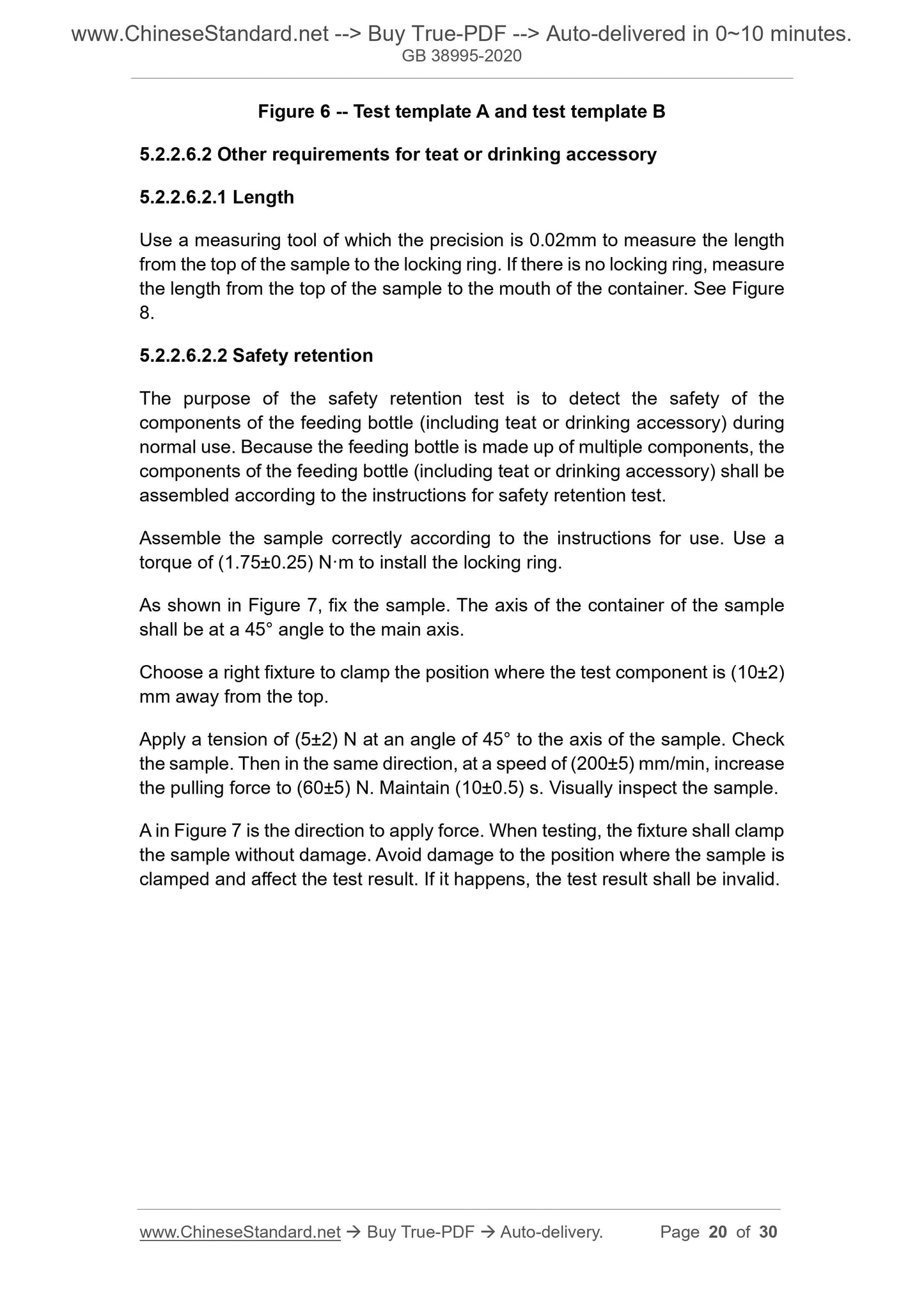

When tested according to 5.2.2.6.1, the components of the feeding bottle

(including teat or drinking accessory) shall not protrude from the bottom of the

test template A / template B.

If the teat or drinking accessory protrudes from the bottom of the test template

A / template B, it shall meet the requirements of 4.1.2.6.2.

If the components of the feeding bottle (excluding teat or drinking accessory)

protrude from the bottom of the test template A / template B, it shall meet the

requirements of 4.1.2.6.2.2.

4.1.2.6.2 Other requirements for teat or drinking accessory

4.1.2.6.2.1 Length

Assemble the teat or drinking accessory according to the instructions for use.

When tested according to 5.2.2.6.2.1, the length of the teat or drinking

accessory shall be less than or equal to 100mm.

4.1.2.6.2.2 Safety retention

When tested for safety retention according to 5.2.2.6.2.2, the components of

the feeding bottle (including teat or drinking accessory) shall not be broken,

cracked or separated from the container.

4.1.2.6.2.3 Flexibility test

When tested for flexibility according to 5.2.2.6.2.3, the distance between the

locking ring (without locking ring, it shall be the mouth of the container) and the

bending point of teat or drinking accessory is less than 40mm.

4.1.2.7 Overall drop performance

When tested according to 5.2.2.7, the container, the teat (or drinking accessary)

and the locking ring shall not be separated. There shall be no visible breaks

and cracks. This requirement does not apply to glass feeding bottle, ceramic

feeding bottle. But safety warning shall be set (see 7.1.5).

4.2 Additional requirements

4.2.1 Resistance to compressive deformation of plastic feeding bottle

container

When tested according to 5.3.1, the diameter change rate of the plastic feeding

bottle container along the compression direction shall be less than or equal to

10%.

If the product declares that the container is a compressible product, this

to boiling. Maintain for 10min (the sample shall not be in contact with the inner

wall of the boiling water container). Then take it out. Perform the state

conditioning according to 5.1.3.

NOTE: Boiling water treatment is suitable for test items except appearance.

5.1.2 Disposable products or components

Perform the sample state conditioning according to 5.1.3.

5.1.3 State conditioning

According to the standard environment specified by GB/T 2918, in the

environment of which the temperature is (23±2)°C and the relative humidity is

(50±5)%, the time for state conditioning is not less than 40h. Until the test, all

samples shall be placed in this environment. The test may not be carried out

under the conditions of this standard environment.

5.1.4 Requirements for test water

Except for the specific provisions in the method, the test water in this Standard

shall meet the requirements for grade three water in GB/T 6682.

5.2 General requirements test method

5.2.1 Components

5.2.1.1 Appearance

Visually inspect under natural light.

5.2.1.2 Edge and tip

5.2.1.2.1 Edge

Test according to the method specified in 5.8 of GB 6675.2-2014.

5.2.1.2.2 Tip

Test according to the method specified in 5.9 of GB 6675.2-2014.

Choose three different positions for each sample for testing.

Take three samples for testing. When all three samples are conforming, this

item is conforming.

5.2.1.3 Ink adhesion of printing pattern

For reused products or components, the ink adhesion of printing pattern

The hardness is HRC 45~50.

Figure 5 – Sharp needle

5.2.1.7.2 Pull resistance

Get QUOTATION in 1-minute: Click GB 38995-2020

Historical versions: GB 38995-2020

Preview True-PDF (Reload/Scroll if blank)

GB 38995-2020: Infant feeding bottles and teats

GB 38995-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.140.01

Y 28

Infant feeding bottles and teats

ISSUED ON: OCTOBER 21, 2020

IMPLEMENTED ON: NOVEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Technical requirements ... 8

4.1 General requirements... 8

4.2 Additional requirements ... 11

5 Test methods ... 12

5.1 Sample preparation ... 12

5.2 General requirements test method ... 13

5.3 Test method for additional requirements ... 22

6 Inspection rules ... 24

6.1 Classification of inspection ... 24

6.2 Exit-factory inspection ... 24

6.3 Type inspection ... 25

7 Marks, transport and storage ... 26

7.1 Marks ... 26

7.2 Transport and storage ... 30

Infant feeding bottles and teats

1 Scope

This Standard specifies technical requirements, test methods, inspection rules,

marks, transport and storage for infant feeding bottles and teats.

This Standard is applicable to infant feeding bottles (container, teat and

matched accessory) that are made of one or more of plastic, glass, metal,

ceramic, silicone rubber, rubber.

This Standard is not applicable to medical bottles and teats. It is not applicable

to pacifiers.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 131-2006, Geometrical Product Specifications (GPS) - Indication of

surface texture in technical Product documentation

GB/T 2828.1, Sampling procedures for inspection by attributea - Part 1:

Sampling schemes indexed by acceptance quality limit(AQL) for lot-by-lot

inspection

GB/T 2918, Plastics - Standard atmospheres for conditioning and testing

GB/T 4545, Test methods for stress examination of glass containers

GB/T 4547, Glass containers - Test methods of the thermal shock resistance

and thermal shock endurance

GB/T 6552, Glass containers - Test method for impact resistance

GB/T 6579, Laboratory glassware - Thermal shock and thermal shock

endurance - Test methods

GB/T 6582, Glass - Hydrolytic resistance of glass grains at 98°C - Method of

test and classification

3.4.6 handle

a part that is installed on the container to facilitate the use of the feeding bottle

3.4.7 tube disc

a part that connects the tube and seals the teat to help suck fluid food

3.4.8 tube

a hollow tube that is installed inside the feeding bottle to connect the gravity ball

and the tube disc

3.4.9 gravity ball

a part that is connected to the end of the tube and acts as a gravity guide

3.4.10 matched components

when feeding infants, other parts that are used in conjunction with container,

teat, drinking accessory, protective cover, locking ring, sealing disc, filtering

gauze, handle, tube disc, tube and gravity ball

3.5 numbered graduations

scale mark with numerical value and unit to show the volume of fluid food in the

feeding bottle

4 Technical requirements

4.1 General requirements

4.1.1 Components

4.1.1.1 Appearance

It shall be clean, neat, without foreign objects. There shall be no gaps, holes,

or deformations that affect the use (except for design requirements).

4.1.1.2 Edge and tip

The feeding bottle and its components shall not have sharp edges and sharp

tips that may cause injury or danger.

4.1.1.3 Ink adhesion of printing pattern

For reuse products or components, the ink adhesion of the marked printing

pattern (including text and numbered graduations) shall meet the requirements

When tested according to 5.2.2.6.1, the components of the feeding bottle

(including teat or drinking accessory) shall not protrude from the bottom of the

test template A / template B.

If the teat or drinking accessory protrudes from the bottom of the test template

A / template B, it shall meet the requirements of 4.1.2.6.2.

If the components of the feeding bottle (excluding teat or drinking accessory)

protrude from the bottom of the test template A / template B, it shall meet the

requirements of 4.1.2.6.2.2.

4.1.2.6.2 Other requirements for teat or drinking accessory

4.1.2.6.2.1 Length

Assemble the teat or drinking accessory according to the instructions for use.

When tested according to 5.2.2.6.2.1, the length of the teat or drinking

accessory shall be less than or equal to 100mm.

4.1.2.6.2.2 Safety retention

When tested for safety retention according to 5.2.2.6.2.2, the components of

the feeding bottle (including teat or drinking accessory) shall not be broken,

cracked or separated from the container.

4.1.2.6.2.3 Flexibility test

When tested for flexibility according to 5.2.2.6.2.3, the distance between the

locking ring (without locking ring, it shall be the mouth of the container) and the

bending point of teat or drinking accessory is less than 40mm.

4.1.2.7 Overall drop performance

When tested according to 5.2.2.7, the container, the teat (or drinking accessary)

and the locking ring shall not be separated. There shall be no visible breaks

and cracks. This requirement does not apply to glass feeding bottle, ceramic

feeding bottle. But safety warning shall be set (see 7.1.5).

4.2 Additional requirements

4.2.1 Resistance to compressive deformation of plastic feeding bottle

container

When tested according to 5.3.1, the diameter change rate of the plastic feeding

bottle container along the compression direction shall be less than or equal to

10%.

If the product declares that the container is a compressible product, this

to boiling. Maintain for 10min (the sample shall not be in contact with the inner

wall of the boiling water container). Then take it out. Perform the state

conditioning according to 5.1.3.

NOTE: Boiling water treatment is suitable for test items except appearance.

5.1.2 Disposable products or components

Perform the sample state conditioning according to 5.1.3.

5.1.3 State conditioning

According to the standard environment specified by GB/T 2918, in the

environment of which the temperature is (23±2)°C and the relative humidity is

(50±5)%, the time for state conditioning is not less than 40h. Until the test, all

samples shall be placed in this environment. The test may not be carried out

under the conditions of this standard environment.

5.1.4 Requirements for test water

Except for the specific provisions in the method, the test water in this Standard

shall meet the requirements for grade three water in GB/T 6682.

5.2 General requirements test method

5.2.1 Components

5.2.1.1 Appearance

Visually inspect under natural light.

5.2.1.2 Edge and tip

5.2.1.2.1 Edge

Test according to the method specified in 5.8 of GB 6675.2-2014.

5.2.1.2.2 Tip

Test according to the method specified in 5.9 of GB 6675.2-2014.

Choose three different positions for each sample for testing.

Take three samples for testing. When all three samples are conforming, this

item is conforming.

5.2.1.3 Ink adhesion of printing pattern

For reused products or components, the ink adhesion of printing pattern

The hardness is HRC 45~50.

Figure 5 – Sharp needle

5.2.1.7.2 Pull resistance

Share