1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 50987-2014 English PDF (GB50987-2014)

GB 50987-2014 English PDF (GB50987-2014)

Regular price

$350.00 USD

Regular price

Sale price

$350.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 50987-2014

Historical versions: GB 50987-2014

Preview True-PDF (Reload/Scroll if blank)

GB 50987-2014: Code for fire protection design of hydraulic engineering

GB 50987-2014

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

UDC

P GB 50987-2014

Code for fire protection design of

hydraulic engineering

ISSUED ON: DECEMBER 02, 2014

IMPLEMENTED ON: AUGUST 01, 2015

Issued by: Ministry of Housing and Urban-Rural Development of the

People's Republic of China;

General Administration of Quality Supervision, Inspection and

Quarantine.

Table of Contents

Announcement ... 5

Foreword ... 6

1 General provisions ... 8

2 Terms ... 9

3 Classification of production fire hazard and fire resistance rating ... 10

4 General layout ... 13

4.1 Fire separation distance ... 13

4.2 Fire lanes and rescue facilities ... 14

5 Building ... 16

5.1 Fire compartment ... 16

5.2 Safety evacuation ... 16

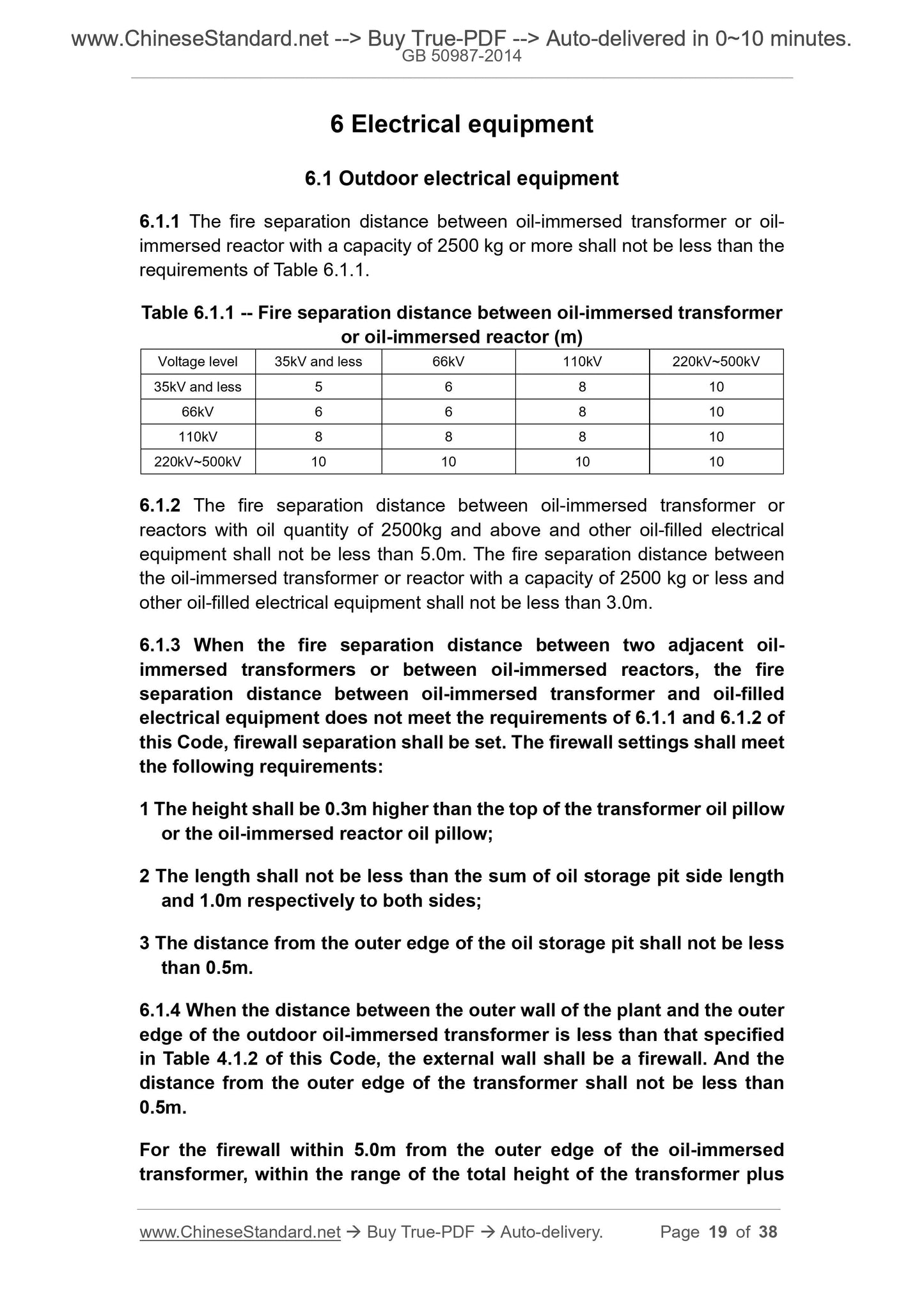

6 Electrical equipment ... 19

6.1 Outdoor electrical equipment ... 19

6.2 Indoor electrical equipment ... 21

6.3 Cable ... 21

7 Insulating oil and turbine oil system ... 23

8 Fire water supply and fire-extinguishing installation ... 24

8.1 General requirement ... 24

8.2 Water supply facilities ... 24

8.3 Indoor, outdoor fire water supply ... 26

8.4 Fire hydrant ... 27

8.5 Automatic fire extinguishing system ... 28

8.6 Fire fighting equipment ... 30

9 Ventilation, heating, smoke control and exhaust ... 31

9.1 Ventilation and heating ... 31

9.2 Smoke control and exhaust ... 31

10 Fire fighting electrical system ... 33

10.1 Power supply for fire fighting ... 33

10.2 Emergency lighting, evacuation sign ... 33

10.3 Automatic fire alarm system ... 33

10.4 Lightning and grounding ... 36

Explanation of wording in the code ... 37

List of quoted standards ... 38

Code for fire protection design of

hydraulic engineering

1 General provisions

1.0.1 This Code was prepared in order to prevent fires in hydraulic engineering,

reduce fire hazards, and protect personal and property safety.

1.0.2 This Code is applicable to the fire protection design of large and medium-

sized hydropower plants, pumping stations, sluices and navigation facilities of

new construction, expansion and reconstruction of hydraulic engineering.

1.0.3 The fire protection design of hydraulic engineering shall proceed from the

overall situation and make overall considerations to ensure safety, application,

advanced technology and economic rationality.

1.0.4 In addition to complying with this Code, the fire protection design of

hydraulic engineering shall also comply with the relevant national standards.

2 Terms

2.0.1 ground plant (powerhouse or pump house)

a hydroelectric power plant or pumping station that the motor layer or the

installation floor can be directly connected to the external road, and the doors

and windows are directly connected to the atmosphere

2.0.2 plant within dam

a hydroelectric power plant or pumping station plant that is located in the cavity

of the retaining dam body

2.0.3 underground plant

a hydroelectric power plant or pumping station plant that is set up in

underground cavern

2.0.4 main plant

the general name for the installation of the hydro-generator unit or pump unit

and its auxiliary equipment, and the installation room for installation and

maintenance work

2.0.5 auxiliary plant

other electromechanical equipment rooms other than the main plant, as well as

work and living rooms for operation, maintenance, testing and management

2.0.6 multilayer auxiliary plant

auxiliary plant with two floors and above, of which the building height is less

than or equal to 24.0m

2.0.7 high-rise auxiliary plant

auxiliary plant with two floors and above, of which the building height is greater

than 24.0m

4 General layout

4.1 Fire separation distance

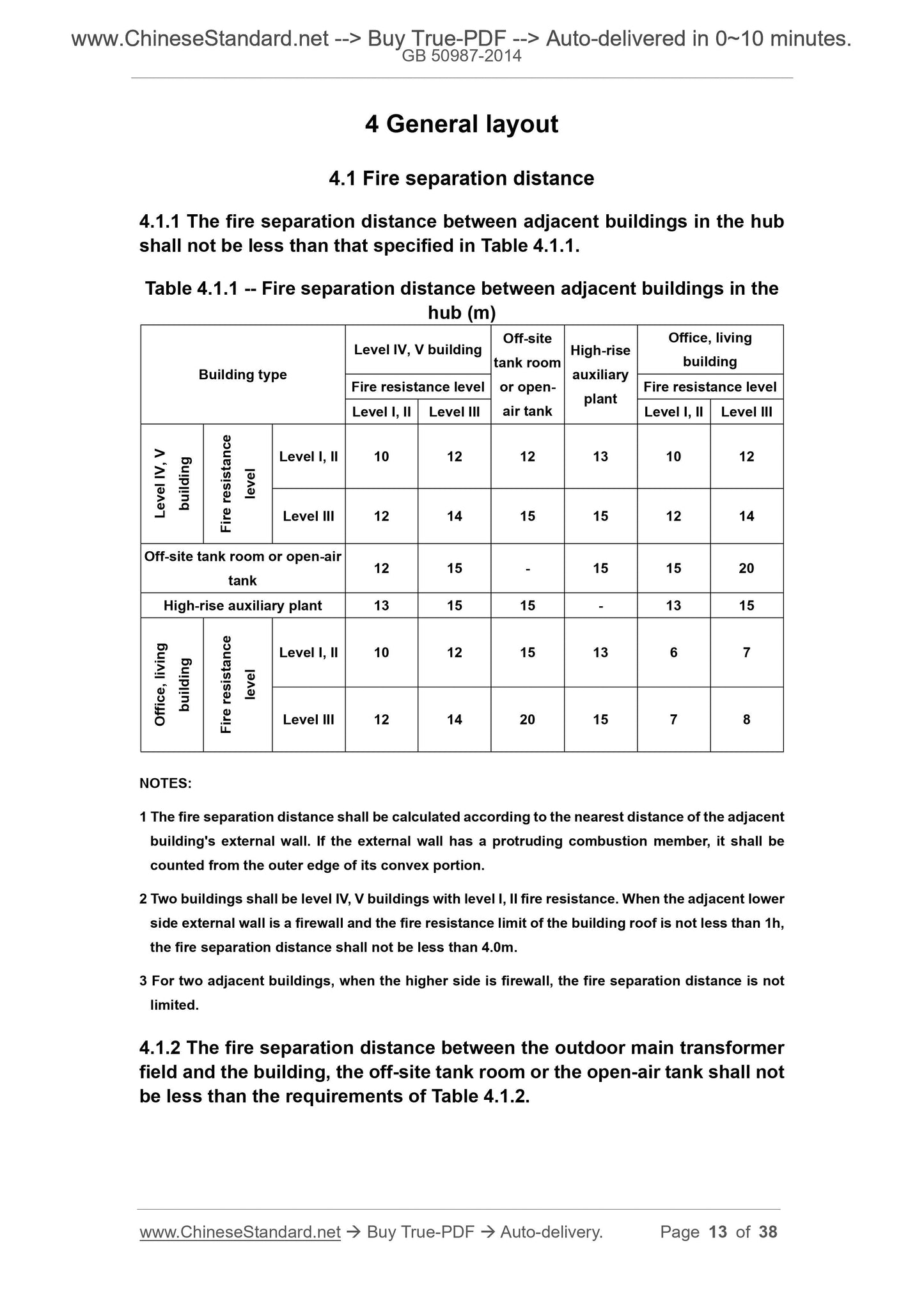

4.1.1 The fire separation distance between adjacent buildings in the hub

shall not be less than that specified in Table 4.1.1.

Table 4.1.1 -- Fire separation distance between adjacent buildings in the

hub (m)

Building type

Level IV, V building Off-site tank room

or open-

air tank

High-rise

auxiliary

plant

Office, living

building

Fire resistance level Fire resistance level

Level I, II Level III Level I, II Level III

Le

ve

l IV

, V

bu

ild

ing

Fir

e r

es

ist

an

ce

lev

el

Level I, II 10 12 12 13 10 12

Level III 12 14 15 15 12 14

Off-site tank room or open-air

tank 12 15 - 15 15 20

High-rise auxiliary plant 13 15 15 - 13 15

Of

fic

e,

liv

ing

bu

ild

ing

Fir

e r

es

ist

an

ce

lev

el

Level I, II 10 12 15 13 6 7

Level III 12 14 20 15 7 8

NOTES:

1 The fire separation distance shall be calculated according to the nearest distance of the adjacent

building's external wall. If the external wall has a protruding combustion member, it shall be

counted from the outer edge of its convex portion.

2 Two buildings shall be level IV, V buildings with level I, II fire resistance. When the adjacent lower

side external wall is a firewall and the fire resistance limit of the building roof is not less than 1h,

the fire separation distance shall not be less than 4.0m.

3 For two adjacent buildings, when the higher side is firewall, the fire separation distance is not

limited.

4.1.2 The fire separation distance between the outdoor main transformer

field and the building, the off-site tank room or the open-air tank shall not

be less than the requirements of Table 4.1.2.

5 Building

5.1 Fire compartment

5.1.1 The maximum allowable floor space for fire compartment of the main plant

and multilayer auxiliary plant is not limited.

5.1.2 The maximum allowable building area for each fire compartment of the

high-rise auxiliary plant shall not exceed 4000m2. The maximum allowable

building area for each fire compartment of underground auxiliary plant, auxiliary

plant within dam shall not exceed 2000m2.

5.1.3 When a level III production site is set within a factory building with level

IV fire hazard, it shall use non-combustible partition wall with a fire endurance

of not less than 2.00h and non-combustible floor slab with a fire resistance of

not less than 1.50h to separate it from other parts. The door shall be A1.50 fire-

proof door, equipped with corresponding firefighting facilities.

5.1.4 The fire compartment division of other buildings shall comply with the

provisions of current national standard GB 50016 “Code of Design on Building

Fire Protection and Prevention”.

5.2 Safety evacuation

5.2.1 Safety exits shall be decentralized. For each fire compartment, each floor

of one fire compartment, the horizontal distance between the nearest edges of

the two adjacent safety exits shall not be less than 5.0m.

5.2.2 The safety exits and evacuation walkways of hydropower plants and

pumping stations for hydraulic engineering shall comply with the following

provisions:

1 The generator floor or motor layer of the ground plant shall have no less than

2 safety exits that are directly connected to outdoor ground;

2 There shall be 2 safety exits in the generator floor or motor layer of the

underground plant and the plant within dam. And there is at least 1 that is

directly connected to outdoor ground. The incoming traffic tunnel can be used

as a safe exit to the outdoor ground;

3 The safety exit of the whole plant operation corridor below the generator floor

or motor l...

Get QUOTATION in 1-minute: Click GB 50987-2014

Historical versions: GB 50987-2014

Preview True-PDF (Reload/Scroll if blank)

GB 50987-2014: Code for fire protection design of hydraulic engineering

GB 50987-2014

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

UDC

P GB 50987-2014

Code for fire protection design of

hydraulic engineering

ISSUED ON: DECEMBER 02, 2014

IMPLEMENTED ON: AUGUST 01, 2015

Issued by: Ministry of Housing and Urban-Rural Development of the

People's Republic of China;

General Administration of Quality Supervision, Inspection and

Quarantine.

Table of Contents

Announcement ... 5

Foreword ... 6

1 General provisions ... 8

2 Terms ... 9

3 Classification of production fire hazard and fire resistance rating ... 10

4 General layout ... 13

4.1 Fire separation distance ... 13

4.2 Fire lanes and rescue facilities ... 14

5 Building ... 16

5.1 Fire compartment ... 16

5.2 Safety evacuation ... 16

6 Electrical equipment ... 19

6.1 Outdoor electrical equipment ... 19

6.2 Indoor electrical equipment ... 21

6.3 Cable ... 21

7 Insulating oil and turbine oil system ... 23

8 Fire water supply and fire-extinguishing installation ... 24

8.1 General requirement ... 24

8.2 Water supply facilities ... 24

8.3 Indoor, outdoor fire water supply ... 26

8.4 Fire hydrant ... 27

8.5 Automatic fire extinguishing system ... 28

8.6 Fire fighting equipment ... 30

9 Ventilation, heating, smoke control and exhaust ... 31

9.1 Ventilation and heating ... 31

9.2 Smoke control and exhaust ... 31

10 Fire fighting electrical system ... 33

10.1 Power supply for fire fighting ... 33

10.2 Emergency lighting, evacuation sign ... 33

10.3 Automatic fire alarm system ... 33

10.4 Lightning and grounding ... 36

Explanation of wording in the code ... 37

List of quoted standards ... 38

Code for fire protection design of

hydraulic engineering

1 General provisions

1.0.1 This Code was prepared in order to prevent fires in hydraulic engineering,

reduce fire hazards, and protect personal and property safety.

1.0.2 This Code is applicable to the fire protection design of large and medium-

sized hydropower plants, pumping stations, sluices and navigation facilities of

new construction, expansion and reconstruction of hydraulic engineering.

1.0.3 The fire protection design of hydraulic engineering shall proceed from the

overall situation and make overall considerations to ensure safety, application,

advanced technology and economic rationality.

1.0.4 In addition to complying with this Code, the fire protection design of

hydraulic engineering shall also comply with the relevant national standards.

2 Terms

2.0.1 ground plant (powerhouse or pump house)

a hydroelectric power plant or pumping station that the motor layer or the

installation floor can be directly connected to the external road, and the doors

and windows are directly connected to the atmosphere

2.0.2 plant within dam

a hydroelectric power plant or pumping station plant that is located in the cavity

of the retaining dam body

2.0.3 underground plant

a hydroelectric power plant or pumping station plant that is set up in

underground cavern

2.0.4 main plant

the general name for the installation of the hydro-generator unit or pump unit

and its auxiliary equipment, and the installation room for installation and

maintenance work

2.0.5 auxiliary plant

other electromechanical equipment rooms other than the main plant, as well as

work and living rooms for operation, maintenance, testing and management

2.0.6 multilayer auxiliary plant

auxiliary plant with two floors and above, of which the building height is less

than or equal to 24.0m

2.0.7 high-rise auxiliary plant

auxiliary plant with two floors and above, of which the building height is greater

than 24.0m

4 General layout

4.1 Fire separation distance

4.1.1 The fire separation distance between adjacent buildings in the hub

shall not be less than that specified in Table 4.1.1.

Table 4.1.1 -- Fire separation distance between adjacent buildings in the

hub (m)

Building type

Level IV, V building Off-site tank room

or open-

air tank

High-rise

auxiliary

plant

Office, living

building

Fire resistance level Fire resistance level

Level I, II Level III Level I, II Level III

Le

ve

l IV

, V

bu

ild

ing

Fir

e r

es

ist

an

ce

lev

el

Level I, II 10 12 12 13 10 12

Level III 12 14 15 15 12 14

Off-site tank room or open-air

tank 12 15 - 15 15 20

High-rise auxiliary plant 13 15 15 - 13 15

Of

fic

e,

liv

ing

bu

ild

ing

Fir

e r

es

ist

an

ce

lev

el

Level I, II 10 12 15 13 6 7

Level III 12 14 20 15 7 8

NOTES:

1 The fire separation distance shall be calculated according to the nearest distance of the adjacent

building's external wall. If the external wall has a protruding combustion member, it shall be

counted from the outer edge of its convex portion.

2 Two buildings shall be level IV, V buildings with level I, II fire resistance. When the adjacent lower

side external wall is a firewall and the fire resistance limit of the building roof is not less than 1h,

the fire separation distance shall not be less than 4.0m.

3 For two adjacent buildings, when the higher side is firewall, the fire separation distance is not

limited.

4.1.2 The fire separation distance between the outdoor main transformer

field and the building, the off-site tank room or the open-air tank shall not

be less than the requirements of Table 4.1.2.

5 Building

5.1 Fire compartment

5.1.1 The maximum allowable floor space for fire compartment of the main plant

and multilayer auxiliary plant is not limited.

5.1.2 The maximum allowable building area for each fire compartment of the

high-rise auxiliary plant shall not exceed 4000m2. The maximum allowable

building area for each fire compartment of underground auxiliary plant, auxiliary

plant within dam shall not exceed 2000m2.

5.1.3 When a level III production site is set within a factory building with level

IV fire hazard, it shall use non-combustible partition wall with a fire endurance

of not less than 2.00h and non-combustible floor slab with a fire resistance of

not less than 1.50h to separate it from other parts. The door shall be A1.50 fire-

proof door, equipped with corresponding firefighting facilities.

5.1.4 The fire compartment division of other buildings shall comply with the

provisions of current national standard GB 50016 “Code of Design on Building

Fire Protection and Prevention”.

5.2 Safety evacuation

5.2.1 Safety exits shall be decentralized. For each fire compartment, each floor

of one fire compartment, the horizontal distance between the nearest edges of

the two adjacent safety exits shall not be less than 5.0m.

5.2.2 The safety exits and evacuation walkways of hydropower plants and

pumping stations for hydraulic engineering shall comply with the following

provisions:

1 The generator floor or motor layer of the ground plant shall have no less than

2 safety exits that are directly connected to outdoor ground;

2 There shall be 2 safety exits in the generator floor or motor layer of the

underground plant and the plant within dam. And there is at least 1 that is

directly connected to outdoor ground. The incoming traffic tunnel can be used

as a safe exit to the outdoor ground;

3 The safety exit of the whole plant operation corridor below the generator floor

or motor l...

Share