1

/

of

4

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 5413.30-2010 English PDF (GB5413.30-2010)

GB 5413.30-2010 English PDF (GB5413.30-2010)

Regular price

$70.00 USD

Regular price

Sale price

$70.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) GB 5413.30-2016

Get QUOTATION in 1-minute: Click GB 5413.30-2010

Historical versions: GB 5413.30-2010

Preview True-PDF (Reload/Scroll if blank)

GB 5413.30-2010: National food safety standard -- Determination of impurities in milk and milk products

GB 5413.30-2010

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

National Food Safety Standard

Determination of Impurities in Milk and Milk Products

ISSUED ON. MARCH 26, 2010

IMPLEMENTED ON. JUNE 1, 2010

Issued by. Ministry of Health of the People’s Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Principle ... 4

4 Apparatus and equipment ... 4

5 Analytical procedures ... 4

6 Expression of analytical results ... 5

7 Precision ... 5

Annex A ... 6

Annex B ... 8

Foreword

This Standard replaces GB/T 5413.30-1997 Milk and milk powder--Determination of impurities.

Annex A and Annex B of this Standard are normative.

The previous edition replaced by this Standard is as follows.

- GB/T 5413.30-1997.

National Food Safety Standard

Determination of Impurities in Milk and Milk Products

1 Scope

This Standard specifies a method for determination of impurities in milk and milk products.

This Standard is applicable to determination of impurities in pasteurized milk, sterilized

milk, raw milk, condensed milk and milk powder. It is not applicable to those additives

containing nondairy protein, starch ingredients, insoluble color substances and affecting

filtration.

2 Normative references

Documents referenced in this Standard are indispensable for application of this Standard.

For dated references, only the dated edition is applicable to this Standard. For undated

references, the latest edition (including all amendments) is applicable to this Standard.

3 Principle

Impurity level is determined according to the quantity of visible colored impurities retained

on the filter plate after the sample is filtered by a filter plate and washed.

4 Apparatus and equipment

4.1 Filter equipment. Impurity filter or 2000 mL - 2500 mL filter flask equipped with the filter

plate funnel.

4.2 Filter plate. 32 mm in diameter, 135 g/m2 in mass per unit area, conforming to the

requirements of Annex A, and 28.6 mm in diameter of discharge area during filtration.

4.3 Impurity standard plate.

4.4 See Annex B for preparation methods of impurity standard plates.

4.5 Balance. Sensibility is 0.1 g.

5 Analytical procedures

Measure 500 mL of liquid milk sample. Weigh 62.5 g (accurate to 0.1 g) of milk powder

sample. Use 8 times of water to fully mix and dissolve. Heat to 60 °C. Weigh 125 g

(accurate to 0.1 g) of condensed milk sample. Dissolve in 4 times of water. Heat to 60 °C.

Filter by the filter plate (a vacuum pump can be used to quicken the filtration). Wash the

filter plate with water. Take down the filter plate. Put in a drying oven for drying. Then

compare the impurities on the filter plate with those on the impurity standard plate to get the

impurity level.

When the content of impurities on the filter plate is between two levels, the impurity level

with higher content of impurities is determined.

6 Expression of analytical results

The impurity level on the filter plate that is obtained by comparing with the impurity

standard is the impurity of this sample.

7 Precision

The results of two repeated determinations of the same sample by the methods described in

this Standard shall be consistent, otherwise another 2 determinations shall be repeated.

tube (outlet diameter is 3 mm). Use water to dilute to 1000 mL.

A.2 Apparatus and equipment

A.2.1 Balance. Sensibility is 0.1 mg.

A.2.2 Dryer. Containing effective drying agent.

A.2.3 Drying oven.

A.2.4 Filter appratatus.

A.2.5 Filter plate.

A.2.6 Filter paper. 7 cm or 9 cm in diameter.

A.3 Analytical procedures

A.3.1 Put the filter paper (A.2.6) into a Buchner funnel. Wash with about 200 mL of water. Then

put into the 100 °C drying oven for drying to constant weight.

A.3.2 Fully stir 60 mL of refined impurity mixture (A.1.4). Filter through the filter plate (A.2.5)

installed on the filter apparatus. It is equivalent to 12 mg of impurities.

Collect the filtrate with a clean conical flask. Transfer the filtrate into the beaker. Wash the

conical flask twice with water. Add all washing liquid to the beaker.

A.3.3 Filter the filtrate once again with the cleaned, dried and weighed filter paper (A.3.1) fixed in

the Buchner funnel. Fully wash the beaker and the filter paper. Then put the filter paper into

the 100 °C drying oven for drying to constant weight.

A.3.4 Inspect at least more than two filter plates.

A.4 Evaluation

Average weight of impurities passing through three or more filter plates is not more than 2.8

mg. Impurities shall not appear below the surface of the standard plates that are prepared

and based on the refined impurity mixture.

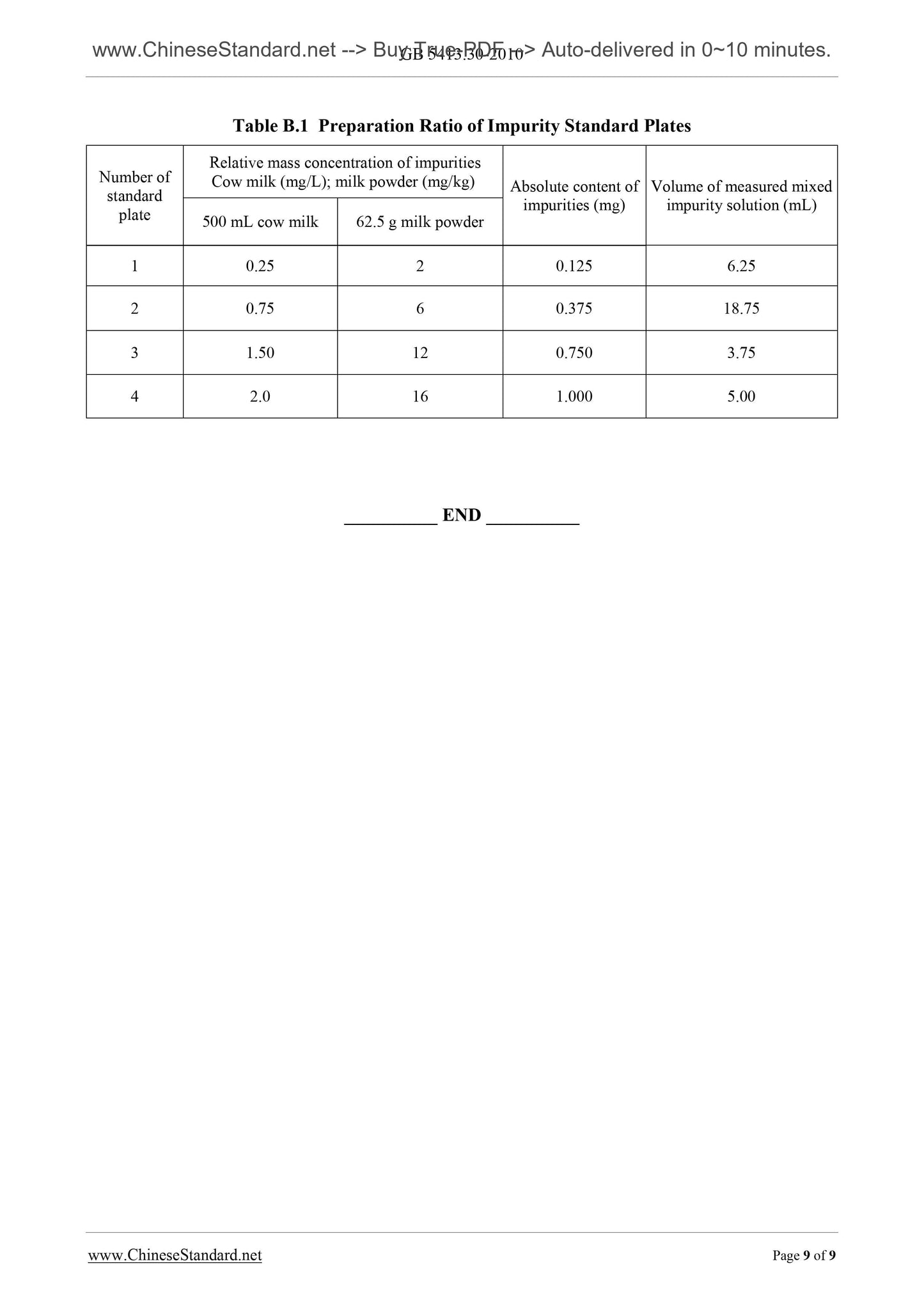

Table B.1 Preparation Ratio of Impurity Standard Plates

Number of

standard

plate

Relative mass concentration of impurities

Cow milk (mg/L); milk powder (mg/kg) Absolute content of

impurities (mg)

Volume of measured mixed

impurity solution (mL)

500 mL cow milk 62.5 g milk powder

1 0.25 2 0.125 6.25

2 0.75 6 0.375 18.75

3 1.50 12 0.750 3.75

4 2.0 16 1.000 5.00

Get QUOTATION in 1-minute: Click GB 5413.30-2010

Historical versions: GB 5413.30-2010

Preview True-PDF (Reload/Scroll if blank)

GB 5413.30-2010: National food safety standard -- Determination of impurities in milk and milk products

GB 5413.30-2010

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

National Food Safety Standard

Determination of Impurities in Milk and Milk Products

ISSUED ON. MARCH 26, 2010

IMPLEMENTED ON. JUNE 1, 2010

Issued by. Ministry of Health of the People’s Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Principle ... 4

4 Apparatus and equipment ... 4

5 Analytical procedures ... 4

6 Expression of analytical results ... 5

7 Precision ... 5

Annex A ... 6

Annex B ... 8

Foreword

This Standard replaces GB/T 5413.30-1997 Milk and milk powder--Determination of impurities.

Annex A and Annex B of this Standard are normative.

The previous edition replaced by this Standard is as follows.

- GB/T 5413.30-1997.

National Food Safety Standard

Determination of Impurities in Milk and Milk Products

1 Scope

This Standard specifies a method for determination of impurities in milk and milk products.

This Standard is applicable to determination of impurities in pasteurized milk, sterilized

milk, raw milk, condensed milk and milk powder. It is not applicable to those additives

containing nondairy protein, starch ingredients, insoluble color substances and affecting

filtration.

2 Normative references

Documents referenced in this Standard are indispensable for application of this Standard.

For dated references, only the dated edition is applicable to this Standard. For undated

references, the latest edition (including all amendments) is applicable to this Standard.

3 Principle

Impurity level is determined according to the quantity of visible colored impurities retained

on the filter plate after the sample is filtered by a filter plate and washed.

4 Apparatus and equipment

4.1 Filter equipment. Impurity filter or 2000 mL - 2500 mL filter flask equipped with the filter

plate funnel.

4.2 Filter plate. 32 mm in diameter, 135 g/m2 in mass per unit area, conforming to the

requirements of Annex A, and 28.6 mm in diameter of discharge area during filtration.

4.3 Impurity standard plate.

4.4 See Annex B for preparation methods of impurity standard plates.

4.5 Balance. Sensibility is 0.1 g.

5 Analytical procedures

Measure 500 mL of liquid milk sample. Weigh 62.5 g (accurate to 0.1 g) of milk powder

sample. Use 8 times of water to fully mix and dissolve. Heat to 60 °C. Weigh 125 g

(accurate to 0.1 g) of condensed milk sample. Dissolve in 4 times of water. Heat to 60 °C.

Filter by the filter plate (a vacuum pump can be used to quicken the filtration). Wash the

filter plate with water. Take down the filter plate. Put in a drying oven for drying. Then

compare the impurities on the filter plate with those on the impurity standard plate to get the

impurity level.

When the content of impurities on the filter plate is between two levels, the impurity level

with higher content of impurities is determined.

6 Expression of analytical results

The impurity level on the filter plate that is obtained by comparing with the impurity

standard is the impurity of this sample.

7 Precision

The results of two repeated determinations of the same sample by the methods described in

this Standard shall be consistent, otherwise another 2 determinations shall be repeated.

tube (outlet diameter is 3 mm). Use water to dilute to 1000 mL.

A.2 Apparatus and equipment

A.2.1 Balance. Sensibility is 0.1 mg.

A.2.2 Dryer. Containing effective drying agent.

A.2.3 Drying oven.

A.2.4 Filter appratatus.

A.2.5 Filter plate.

A.2.6 Filter paper. 7 cm or 9 cm in diameter.

A.3 Analytical procedures

A.3.1 Put the filter paper (A.2.6) into a Buchner funnel. Wash with about 200 mL of water. Then

put into the 100 °C drying oven for drying to constant weight.

A.3.2 Fully stir 60 mL of refined impurity mixture (A.1.4). Filter through the filter plate (A.2.5)

installed on the filter apparatus. It is equivalent to 12 mg of impurities.

Collect the filtrate with a clean conical flask. Transfer the filtrate into the beaker. Wash the

conical flask twice with water. Add all washing liquid to the beaker.

A.3.3 Filter the filtrate once again with the cleaned, dried and weighed filter paper (A.3.1) fixed in

the Buchner funnel. Fully wash the beaker and the filter paper. Then put the filter paper into

the 100 °C drying oven for drying to constant weight.

A.3.4 Inspect at least more than two filter plates.

A.4 Evaluation

Average weight of impurities passing through three or more filter plates is not more than 2.8

mg. Impurities shall not appear below the surface of the standard plates that are prepared

and based on the refined impurity mixture.

Table B.1 Preparation Ratio of Impurity Standard Plates

Number of

standard

plate

Relative mass concentration of impurities

Cow milk (mg/L); milk powder (mg/kg) Absolute content of

impurities (mg)

Volume of measured mixed

impurity solution (mL)

500 mL cow milk 62.5 g milk powder

1 0.25 2 0.125 6.25

2 0.75 6 0.375 18.75

3 1.50 12 0.750 3.75

4 2.0 16 1.000 5.00

Share