1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 10573-2020 English PDF (GB/T10573-2020)

GB/T 10573-2020 English PDF (GB/T10573-2020)

Regular price

$135.00

Regular price

Sale price

$135.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 10573-2020: Tensile testing method for fine wire of nonferrous metals

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 10573-2020 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 10573-2020

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 10573-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.10

H 22

Replacing GB/T 10573-1989

Tensile testing method for fine wire of nonferrous

metals

ISSUED ON: SEPTEMBER 29, 2020

IMPLEMENTED ON: AUGUST 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Symbols and descriptions ... 6

5 Method summary ... 6

6 Instruments and equipment... 7

7 Specimen ... 7

8 Test requirements ... 7

9 Test steps ... 8

10 Test data processing ... 12

11 Test report ... 13

Tensile testing method for fine wire of nonferrous

metals

1 Scope

This Standard specifies method summary, instruments and equipment,

specimen, test requirements, test steps, test data processing and test report of

tensile testing method for fine wire of nonferrous metals.

This Standard is applicable to determination of tensile mechanical properties at

room temperature of fine wire of nonferrous metals of which the nominal

diameter is not more than 0.25mm or cross-sectional area is not more than

0.0491mm2.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 10623, Metallic material - Mechanical testing - Vocabulary

GB/T 15077, Geometric size measuring methods of precious metals and

their alloy materials

JJG 139, Verification Regulation of Universal Tension and Compression

Testing Machine

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T

10623 as well as the followings apply.

3.1 proof force of total elongation; Ft

the force used to make the total extension (including elastic extension and

6 Instruments and equipment

6.1 The measurement error of the testing machine complies with the relevant

regulations in JJG 139. The accuracy of the force value shall be level 1 or better.

6.2 The testing machine shall be calibrated or verified regularly. The force value

range used in the test shall be within the tested range.

7 Specimen

7.1 Specimens shall be taken at least 300mm from the end of the wire. The

spacing between each specimen shall not be less than 300mm.

7.2 The original gauge length of the specimen, L0, shall be 100mm. When there

are other requirements, it can be 200mm or 50mm. When it is not necessary to

determine the percentage extension, the original gauge length L0 of the

specimen shall be 50mm.

7.3 The total length of the specimen shall be determined according to the

original gauge length of the specimen and the length of the clamping end.

7.4 The specimen shall not have mechanical damage and bending that affect

the test result.

8 Test requirements

8.1 Test temperature

The test is generally carried out in the room temperature range of 10°C~35°C.

For tests with strict temperature requirements, the test temperature shall be

23°C ± 5°C.

8.2 Chuck spacing

The spacing between the two chucks of the testing machine is L0±0.5mm.

8.3 Specimen processing

When clamping the specimen, keep the specimen free droop and straight.

Apply pre-tension to the specimen if necessary. Its size generally does not

exceed 5% of the maximum force of the wire. It may also stick the tested

specimen on the straight line at both ends of the paper frame. The bonding

length h and paper frame width b are determined by the size of the chuck, as

shown in Figure 1. Cut the paper frame after the specimen is installed.

Where,

S0 - Original cross-sectional area of the specimen, in square millimeters (mm2);

d0 - Original diameter of the specimen, in millimeters (mm).

9.1.2 For wires with a nominal diameter of not more than 0.1mm, measure the

cross-sectional area of specimen S0 according to the weighing method

specified in GB/T 15077.

9.1.3 If allowed by relevant standards or agreements, the nominal size can also

be used to calculate the original cross-sectional area of the wire specimen.

9.1.4 The calculation of the original cross-sectional area of the specimen is

rounded to three significant figures. The rounding method is carried out

according to GB/T 8170.

9.1.5 Without the need to determine the strength index, the cross-sectional area

of the specimen may not be measured.

9.2 Performance determination

9.2.1 Determination of proof force of total elongation Ft and proof strength of

total elongation Rt

On the force-extension (displacement) curve, make a straight line parallel to the

force axis and the distance from the force axis equal to the proof force of total

elongation. The straight line intersects the curve. The force corresponding to

the intersection point is the proof force of total elongation Ft, see Figure 2.

According to formula (2), the proof strength of total elongation Rt is calculated:

Where,

Rt - Proof strength of total elongation, in megapascals (MPa);

Ft - Proof force of total elongation, in newtons (N);

S0 - Original cross-sectional area of specimen, in square millimeters (mm2).

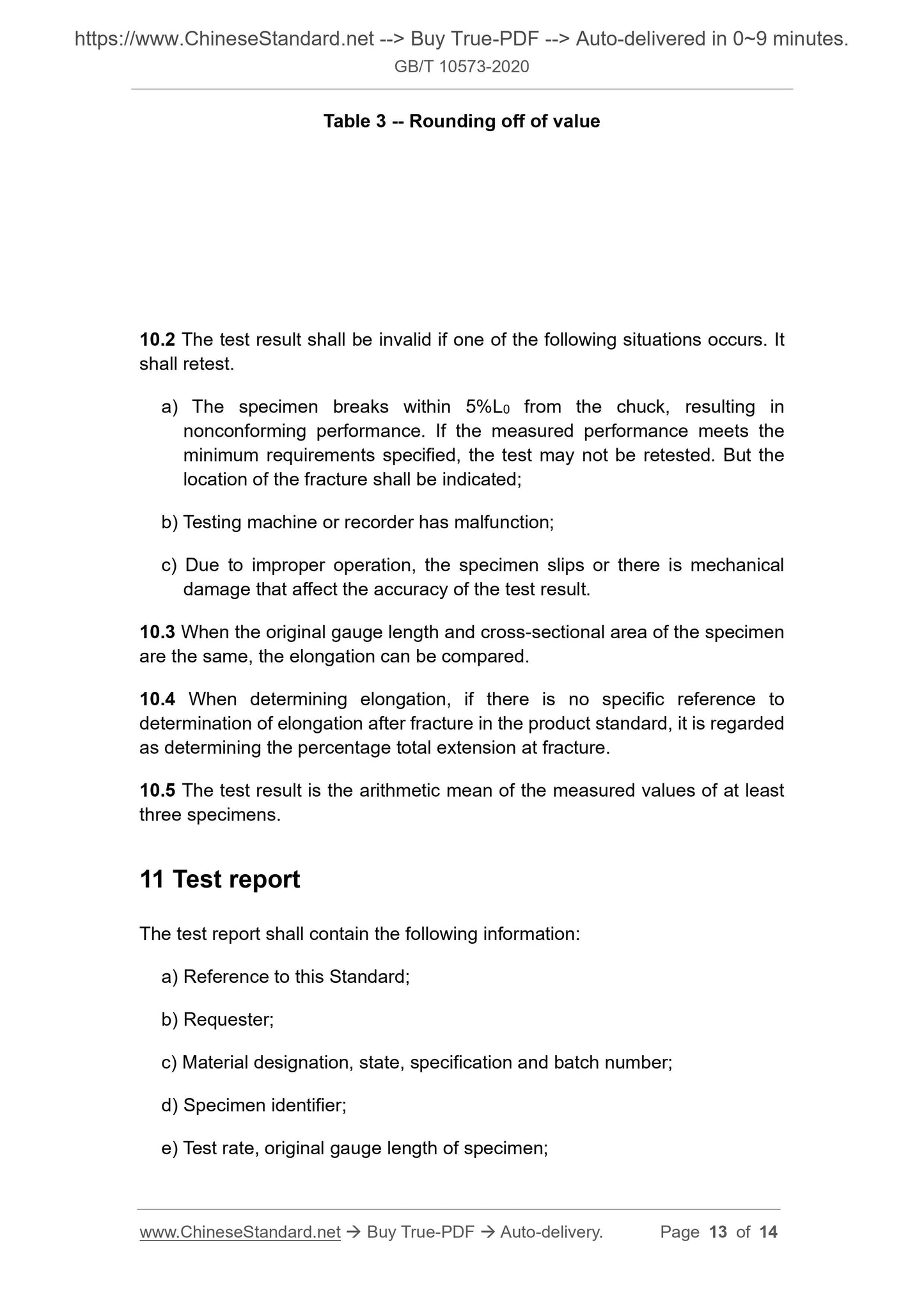

Table 3 -- Rounding off of value

10.2 The test result shall be invalid if one of the following situations occurs. It

shall retest.

a) The specimen breaks within 5%L0 from the chuck, resulting in

nonconforming performance. If the measured performance meets the

minimum requirements specified, the test may not be retested. But the

location of the fracture shall be indicated;

b) Testing machine or recorder has malfunction;

c) Due to improper operation, the specimen slips or there is mechanical

damage that affect the accuracy of the test result.

10.3 When the original gauge length and cross-sectional area of the specimen

are the same, the elongation can be compared.

10.4 When determining elongation, if there is no specific reference to

determination of elongation after fracture in the product standard, it is regarded

as determining the percentage total extension at fracture.

10.5 The test result is the arithmetic mean of the measured values of at least

three specimens.

11 Test report

The test report shall contain the following information:

a) Reference to this Standard;

b) Requester;

c) Material designation, state, specification and batch number;

d) Specimen identifier;

e) Test rate, original gauge length of specimen;

GB/T 10573-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.10

H 22

Replacing GB/T 10573-1989

Tensile testing method for fine wire of nonferrous

metals

ISSUED ON: SEPTEMBER 29, 2020

IMPLEMENTED ON: AUGUST 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Symbols and descriptions ... 6

5 Method summary ... 6

6 Instruments and equipment... 7

7 Specimen ... 7

8 Test requirements ... 7

9 Test steps ... 8

10 Test data processing ... 12

11 Test report ... 13

Tensile testing method for fine wire of nonferrous

metals

1 Scope

This Standard specifies method summary, instruments and equipment,

specimen, test requirements, test steps, test data processing and test report of

tensile testing method for fine wire of nonferrous metals.

This Standard is applicable to determination of tensile mechanical properties at

room temperature of fine wire of nonferrous metals of which the nominal

diameter is not more than 0.25mm or cross-sectional area is not more than

0.0491mm2.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 10623, Metallic material - Mechanical testing - Vocabulary

GB/T 15077, Geometric size measuring methods of precious metals and

their alloy materials

JJG 139, Verification Regulation of Universal Tension and Compression

Testing Machine

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T

10623 as well as the followings apply.

3.1 proof force of total elongation; Ft

the force used to make the total extension (including elastic extension and

6 Instruments and equipment

6.1 The measurement error of the testing machine complies with the relevant

regulations in JJG 139. The accuracy of the force value shall be level 1 or better.

6.2 The testing machine shall be calibrated or verified regularly. The force value

range used in the test shall be within the tested range.

7 Specimen

7.1 Specimens shall be taken at least 300mm from the end of the wire. The

spacing between each specimen shall not be less than 300mm.

7.2 The original gauge length of the specimen, L0, shall be 100mm. When there

are other requirements, it can be 200mm or 50mm. When it is not necessary to

determine the percentage extension, the original gauge length L0 of the

specimen shall be 50mm.

7.3 The total length of the specimen shall be determined according to the

original gauge length of the specimen and the length of the clamping end.

7.4 The specimen shall not have mechanical damage and bending that affect

the test result.

8 Test requirements

8.1 Test temperature

The test is generally carried out in the room temperature range of 10°C~35°C.

For tests with strict temperature requirements, the test temperature shall be

23°C ± 5°C.

8.2 Chuck spacing

The spacing between the two chucks of the testing machine is L0±0.5mm.

8.3 Specimen processing

When clamping the specimen, keep the specimen free droop and straight.

Apply pre-tension to the specimen if necessary. Its size generally does not

exceed 5% of the maximum force of the wire. It may also stick the tested

specimen on the straight line at both ends of the paper frame. The bonding

length h and paper frame width b are determined by the size of the chuck, as

shown in Figure 1. Cut the paper frame after the specimen is installed.

Where,

S0 - Original cross-sectional area of the specimen, in square millimeters (mm2);

d0 - Original diameter of the specimen, in millimeters (mm).

9.1.2 For wires with a nominal diameter of not more than 0.1mm, measure the

cross-sectional area of specimen S0 according to the weighing method

specified in GB/T 15077.

9.1.3 If allowed by relevant standards or agreements, the nominal size can also

be used to calculate the original cross-sectional area of the wire specimen.

9.1.4 The calculation of the original cross-sectional area of the specimen is

rounded to three significant figures. The rounding method is carried out

according to GB/T 8170.

9.1.5 Without the need to determine the strength index, the cross-sectional area

of the specimen may not be measured.

9.2 Performance determination

9.2.1 Determination of proof force of total elongation Ft and proof strength of

total elongation Rt

On the force-extension (displacement) curve, make a straight line parallel to the

force axis and the distance from the force axis equal to the proof force of total

elongation. The straight line intersects the curve. The force corresponding to

the intersection point is the proof force of total elongation Ft, see Figure 2.

According to formula (2), the proof strength of total elongation Rt is calculated:

Where,

Rt - Proof strength of total elongation, in megapascals (MPa);

Ft - Proof force of total elongation, in newtons (N);

S0 - Original cross-sectional area of specimen, in square millimeters (mm2).

Table 3 -- Rounding off of value

10.2 The test result shall be invalid if one of the following situations occurs. It

shall retest.

a) The specimen breaks within 5%L0 from the chuck, resulting in

nonconforming performance. If the measured performance meets the

minimum requirements specified, the test may not be retested. But the

location of the fracture shall be indicated;

b) Testing machine or recorder has malfunction;

c) Due to improper operation, the specimen slips or there is mechanical

damage that affect the accuracy of the test result.

10.3 When the original gauge length and cross-sectional area of the specimen

are the same, the elongation can be compared.

10.4 When determining elongation, if there is no specific reference to

determination of elongation after fracture in the product standard, it is regarded

as determining the percentage total extension at fracture.

10.5 The test result is the arithmetic mean of the measured values of at least

three specimens.

11 Test report

The test report shall contain the following information:

a) Reference to this Standard;

b) Requester;

c) Material designation, state, specification and batch number;

d) Specimen identifier;

e) Test rate, original gauge length of specimen;

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 10573-2020 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 10573-2020

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 10573-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.10

H 22

Replacing GB/T 10573-1989

Tensile testing method for fine wire of nonferrous

metals

ISSUED ON: SEPTEMBER 29, 2020

IMPLEMENTED ON: AUGUST 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Symbols and descriptions ... 6

5 Method summary ... 6

6 Instruments and equipment... 7

7 Specimen ... 7

8 Test requirements ... 7

9 Test steps ... 8

10 Test data processing ... 12

11 Test report ... 13

Tensile testing method for fine wire of nonferrous

metals

1 Scope

This Standard specifies method summary, instruments and equipment,

specimen, test requirements, test steps, test data processing and test report of

tensile testing method for fine wire of nonferrous metals.

This Standard is applicable to determination of tensile mechanical properties at

room temperature of fine wire of nonferrous metals of which the nominal

diameter is not more than 0.25mm or cross-sectional area is not more than

0.0491mm2.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 10623, Metallic material - Mechanical testing - Vocabulary

GB/T 15077, Geometric size measuring methods of precious metals and

their alloy materials

JJG 139, Verification Regulation of Universal Tension and Compression

Testing Machine

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T

10623 as well as the followings apply.

3.1 proof force of total elongation; Ft

the force used to make the total extension (including elastic extension and

6 Instruments and equipment

6.1 The measurement error of the testing machine complies with the relevant

regulations in JJG 139. The accuracy of the force value shall be level 1 or better.

6.2 The testing machine shall be calibrated or verified regularly. The force value

range used in the test shall be within the tested range.

7 Specimen

7.1 Specimens shall be taken at least 300mm from the end of the wire. The

spacing between each specimen shall not be less than 300mm.

7.2 The original gauge length of the specimen, L0, shall be 100mm. When there

are other requirements, it can be 200mm or 50mm. When it is not necessary to

determine the percentage extension, the original gauge length L0 of the

specimen shall be 50mm.

7.3 The total length of the specimen shall be determined according to the

original gauge length of the specimen and the length of the clamping end.

7.4 The specimen shall not have mechanical damage and bending that affect

the test result.

8 Test requirements

8.1 Test temperature

The test is generally carried out in the room temperature range of 10°C~35°C.

For tests with strict temperature requirements, the test temperature shall be

23°C ± 5°C.

8.2 Chuck spacing

The spacing between the two chucks of the testing machine is L0±0.5mm.

8.3 Specimen processing

When clamping the specimen, keep the specimen free droop and straight.

Apply pre-tension to the specimen if necessary. Its size generally does not

exceed 5% of the maximum force of the wire. It may also stick the tested

specimen on the straight line at both ends of the paper frame. The bonding

length h and paper frame width b are determined by the size of the chuck, as

shown in Figure 1. Cut the paper frame after the specimen is installed.

Where,

S0 - Original cross-sectional area of the specimen, in square millimeters (mm2);

d0 - Original diameter of the specimen, in millimeters (mm).

9.1.2 For wires with a nominal diameter of not more than 0.1mm, measure the

cross-sectional area of specimen S0 according to the weighing method

specified in GB/T 15077.

9.1.3 If allowed by relevant standards or agreements, the nominal size can also

be used to calculate the original cross-sectional area of the wire specimen.

9.1.4 The calculation of the original cross-sectional area of the specimen is

rounded to three significant figures. The rounding method is carried out

according to GB/T 8170.

9.1.5 Without the need to determine the strength index, the cross-sectional area

of the specimen may not be measured.

9.2 Performance determination

9.2.1 Determination of proof force of total elongation Ft and proof strength of

total elongation Rt

On the force-extension (displacement) curve, make a straight line parallel to the

force axis and the distance from the force axis equal to the proof force of total

elongation. The straight line intersects the curve. The force corresponding to

the intersection point is the proof force of total elongation Ft, see Figure 2.

According to formula (2), the proof strength of total elongation Rt is calculated:

Where,

Rt - Proof strength of total elongation, in megapascals (MPa);

Ft - Proof force of total elongation, in newtons (N);

S0 - Original cross-sectional area of specimen, in square millimeters (mm2).

Table 3 -- Rounding off of value

10.2 The test result shall be invalid if one of the following situations occurs. It

shall retest.

a) The specimen breaks within 5%L0 from the chuck, resulting in

nonconforming performance. If the measured performance meets the

minimum requirements specified, the test may not be retested. But the

location of the fracture shall be indicated;

b) Testing machine or recorder has malfunction;

c) Due to improper operation, the specimen slips or there is mechanical

damage that affect the accuracy of the test result.

10.3 When the original gauge length and cross-sectional area of the specimen

are the same, the elongation can be compared.

10.4 When determining elongation, if there is no specific reference to

determination of elongation after fracture in the product standard, it is regarded

as determining the percentage total extension at fracture.

10.5 The test result is the arithmetic mean of the measured values of at least

three specimens.

11 Test report

The test report shall contain the following information:

a) Reference to this Standard;

b) Requester;

c) Material designation, state, specification and batch number;

d) Specimen identifier;

e) Test rate, original gauge length of specimen;

GB/T 10573-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.10

H 22

Replacing GB/T 10573-1989

Tensile testing method for fine wire of nonferrous

metals

ISSUED ON: SEPTEMBER 29, 2020

IMPLEMENTED ON: AUGUST 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Symbols and descriptions ... 6

5 Method summary ... 6

6 Instruments and equipment... 7

7 Specimen ... 7

8 Test requirements ... 7

9 Test steps ... 8

10 Test data processing ... 12

11 Test report ... 13

Tensile testing method for fine wire of nonferrous

metals

1 Scope

This Standard specifies method summary, instruments and equipment,

specimen, test requirements, test steps, test data processing and test report of

tensile testing method for fine wire of nonferrous metals.

This Standard is applicable to determination of tensile mechanical properties at

room temperature of fine wire of nonferrous metals of which the nominal

diameter is not more than 0.25mm or cross-sectional area is not more than

0.0491mm2.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 10623, Metallic material - Mechanical testing - Vocabulary

GB/T 15077, Geometric size measuring methods of precious metals and

their alloy materials

JJG 139, Verification Regulation of Universal Tension and Compression

Testing Machine

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T

10623 as well as the followings apply.

3.1 proof force of total elongation; Ft

the force used to make the total extension (including elastic extension and

6 Instruments and equipment

6.1 The measurement error of the testing machine complies with the relevant

regulations in JJG 139. The accuracy of the force value shall be level 1 or better.

6.2 The testing machine shall be calibrated or verified regularly. The force value

range used in the test shall be within the tested range.

7 Specimen

7.1 Specimens shall be taken at least 300mm from the end of the wire. The

spacing between each specimen shall not be less than 300mm.

7.2 The original gauge length of the specimen, L0, shall be 100mm. When there

are other requirements, it can be 200mm or 50mm. When it is not necessary to

determine the percentage extension, the original gauge length L0 of the

specimen shall be 50mm.

7.3 The total length of the specimen shall be determined according to the

original gauge length of the specimen and the length of the clamping end.

7.4 The specimen shall not have mechanical damage and bending that affect

the test result.

8 Test requirements

8.1 Test temperature

The test is generally carried out in the room temperature range of 10°C~35°C.

For tests with strict temperature requirements, the test temperature shall be

23°C ± 5°C.

8.2 Chuck spacing

The spacing between the two chucks of the testing machine is L0±0.5mm.

8.3 Specimen processing

When clamping the specimen, keep the specimen free droop and straight.

Apply pre-tension to the specimen if necessary. Its size generally does not

exceed 5% of the maximum force of the wire. It may also stick the tested

specimen on the straight line at both ends of the paper frame. The bonding

length h and paper frame width b are determined by the size of the chuck, as

shown in Figure 1. Cut the paper frame after the specimen is installed.

Where,

S0 - Original cross-sectional area of the specimen, in square millimeters (mm2);

d0 - Original diameter of the specimen, in millimeters (mm).

9.1.2 For wires with a nominal diameter of not more than 0.1mm, measure the

cross-sectional area of specimen S0 according to the weighing method

specified in GB/T 15077.

9.1.3 If allowed by relevant standards or agreements, the nominal size can also

be used to calculate the original cross-sectional area of the wire specimen.

9.1.4 The calculation of the original cross-sectional area of the specimen is

rounded to three significant figures. The rounding method is carried out

according to GB/T 8170.

9.1.5 Without the need to determine the strength index, the cross-sectional area

of the specimen may not be measured.

9.2 Performance determination

9.2.1 Determination of proof force of total elongation Ft and proof strength of

total elongation Rt

On the force-extension (displacement) curve, make a straight line parallel to the

force axis and the distance from the force axis equal to the proof force of total

elongation. The straight line intersects the curve. The force corresponding to

the intersection point is the proof force of total elongation Ft, see Figure 2.

According to formula (2), the proof strength of total elongation Rt is calculated:

Where,

Rt - Proof strength of total elongation, in megapascals (MPa);

Ft - Proof force of total elongation, in newtons (N);

S0 - Original cross-sectional area of specimen, in square millimeters (mm2).

Table 3 -- Rounding off of value

10.2 The test result shall be invalid if one of the following situations occurs. It

shall retest.

a) The specimen breaks within 5%L0 from the chuck, resulting in

nonconforming performance. If the measured performance meets the

minimum requirements specified, the test may not be retested. But the

location of the fracture shall be indicated;

b) Testing machine or recorder has malfunction;

c) Due to improper operation, the specimen slips or there is mechanical

damage that affect the accuracy of the test result.

10.3 When the original gauge length and cross-sectional area of the specimen

are the same, the elongation can be compared.

10.4 When determining elongation, if there is no specific reference to

determination of elongation after fracture in the product standard, it is regarded

as determining the percentage total extension at fracture.

10.5 The test result is the arithmetic mean of the measured values of at least

three specimens.

11 Test report

The test report shall contain the following information:

a) Reference to this Standard;

b) Requester;

c) Material designation, state, specification and batch number;

d) Specimen identifier;

e) Test rate, original gauge length of specimen;

Share