1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 12960-2019 English PDF (GBT12960-2019)

GB/T 12960-2019 English PDF (GBT12960-2019)

Regular price

$210.00 USD

Regular price

Sale price

$210.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 12960-2019

Historical versions: GB/T 12960-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 12960-2019: Quantitative determination of constituents of cement

GB/T 12960-2019

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 91.100.10

Q 11

Replacing GB/T 12960-2007

Quantitative Determination of Constituents of Cement

ISSUED ON: OCTOBER 18, 2019

IMPLEMENTED ON: SEPTEMBER 1, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Basic Requirements for Test ... 5

4 Reagents and Materials ... 6

5 Instruments and Equipment ... 8

6 Preparation of Specimens ... 11

7 Determination of Cement Constituents - Method 1 ... 11

8 Determination of Cement Constituents - Method 2 ... 18

9 Precision ... 22

Quantitative Determination of Constituents of Cement

1 Scope

This Standard specifies the methods of quantitative determination of constituents of

Portland cement, ordinary Portland cement, slag Portland cement, pozzolanic Portland

cement, fly-ash Portland cement and composite Portland cement.

This Standard is applicable to cement containing one or more materials among

granulated blast-furnace slag, pozzolanic mixed material, fly ash, limestone,

sandstone, kiln dust, gypsum and Portland cement clinker.

2 Normative References

The following documents are indispensable to the application of this document. In

terms of references with a specified date, only versions with a specified date are

applicable to this document. In terms of references without a specified date, the latest

version (including all the modifications) is applicable to this document.

GB/T 176 Method for Chemical Analysis of Cement

GB/T 5484 Methods for Chemical Analysis of Gypsum

GB/T 6682 Water for Analytical Laboratory Use - Specification and Test Methods

GB/T 8170 Rules of Rounding off for Numerical Values and Expression and Judgement

of Limiting Values

GB/T 12573 Sampling Method for Cement

GB/T 35151 Determination of Total Organic Carbon in Limestone

3 Basic Requirements for Test

3.1 Test Number and Requirements

The number of tests for each determination is specified as two. Use the average value

of two test results to represent the determination result.

The methods of the determination of constituents of cement are divided into Method 1

and Method 2. If multiple determination methods are listed for the same constituent,

Method 1 shall prevail when there is a dispute.

3.2 Laboratory Temperature

It is required that laboratory temperature shall be between 16 °C ~ 30 °C.

3.3 Constant Mass

After the first drying or burning, cooling and weighing, through the method of

continuously drying or burning the vessel or specimen for 15 min each time, and then,

cooling and weighing it, determine the constant mass. When the difference of two

consecutive weighings is less than 0.0005 g, it reaches a constant mass.

3.4 Processing of Results

3.4.1 After selective dissolution, the content of insoluble slag, the content of carbon

dioxide and the content of sulfur trioxide shall be counted by mass fraction, and the

numerical value shall be expressed in a percentage (%) to two decimal places; the

content of sulfide (calculated by S) shall be counted by mass fraction, and the

numerical value shall be expressed in a percentage (%) to three decimal places.

3.4.2 The determination result of the content of various constituents in cement shall be

counted by mass fraction, and the numerical value shall be expressed in a percentage

(%) to one decimal place.

3.4.3 The rounding-off of numerical values shall be carried out in accordance with GB/T

8170.

4 Reagents and Materials

Unless it is otherwise specified, all reagents shall be not lower than analytically pure.

The used water shall be not lower than the requirements for Grade-3 water specified

in GB/T 6682. Carbon dioxide-free water refers to water that is freshly boiled and

cooled to room temperature.

4.1 Nitric acid (HNO3): density: 1.39 g/cm3 ~ 1.41 g/cm3; mass fraction: 65% ~ 68%.

NOTE: the density of commercially available concentrated liquid reagents listed in this

Standard refers to the density () at 20 °C, the same below.

4.2 Sulfuric acid (H2SO4): density: 1.84 g/cm3; mass fraction: 95% ~ 98%.

4.3 Phosphoric acid (H3PO4): density: 1.68 g/cm3; mass fraction ≥ 85%.

4.4 Triethanolamine [N(CH2CH2OH)3]: density: 1.12 g/cm3; mass fraction: 99%.

4.5 Ethanol (C2H5OH): mass fraction: 95%.

4.6 Nitric acid (1 + 5).

NOTE 1: use volume ratio to indicate the degree of reagent dilution, the same below. Nitric

standard buffer solution at different temperatures are shown in Table 1.

4.12 Copper sulfate (CuSO4 5H2O) saturated solution.

4.13 Hydrogen sulfide absorbent: place the weighed dry pumice with a particle size of

1 mm ~ 2.5 mm in a flat pan, then, use a certain volume of copper sulfate saturated

solution to soak it (see 4.12). The mass of the copper sulfate solution is about half the

mass of the pumice. Place the mixture in a drying oven (5.2) at 150 °C ± 5 °C; under

constant stirring with a glass rod, evaporate the mixture to dryness, then, dry it for

above 5 h. After the solid mixture is cooled, store it in a sealed bottle.

4.14 Soda lime: particle size: 2 mm ~ 5 mm; medical or chemically pure; sealed and

stored.

4.15 Alkali asbestos: particle size: 1 mm ~ 2 mm (10 mesh ~ 20 mesh); chemically

pure; sealed and stored.

4.16 Anhydrous magnesium perchlorate [Mg (ClO4)2]: made into a particle size of 0.6

mm ~ 2 mm; stored in a sealed bottle.

5 Instruments and Equipment

5.1 Balance: division value is not less than 0.0001 g.

5.2 Drying oven: controlled temperature 105 °C ± 5 °C, 150 °C ± 5 °C.

5.3 Acidity meter: pH value measurement value 0 ~ 14, accurate to 0.02.

5.4 Glass sand core funnel: with a diameter of 35 mm ~ 60 mm; model G4 (average

pore size: 3 μm ~ 4 μm).

Glass sand core crucible of the same specification may also be used.

5.5 Suction filter flask: 1,000 mL.

5.6 Air pump: pumping speed 0.25 L/s.

5.7 Cement constituent determination device: able to maintain a constant temperature

of 20 °C ± 2 °C, as it is shown in Figure 1.

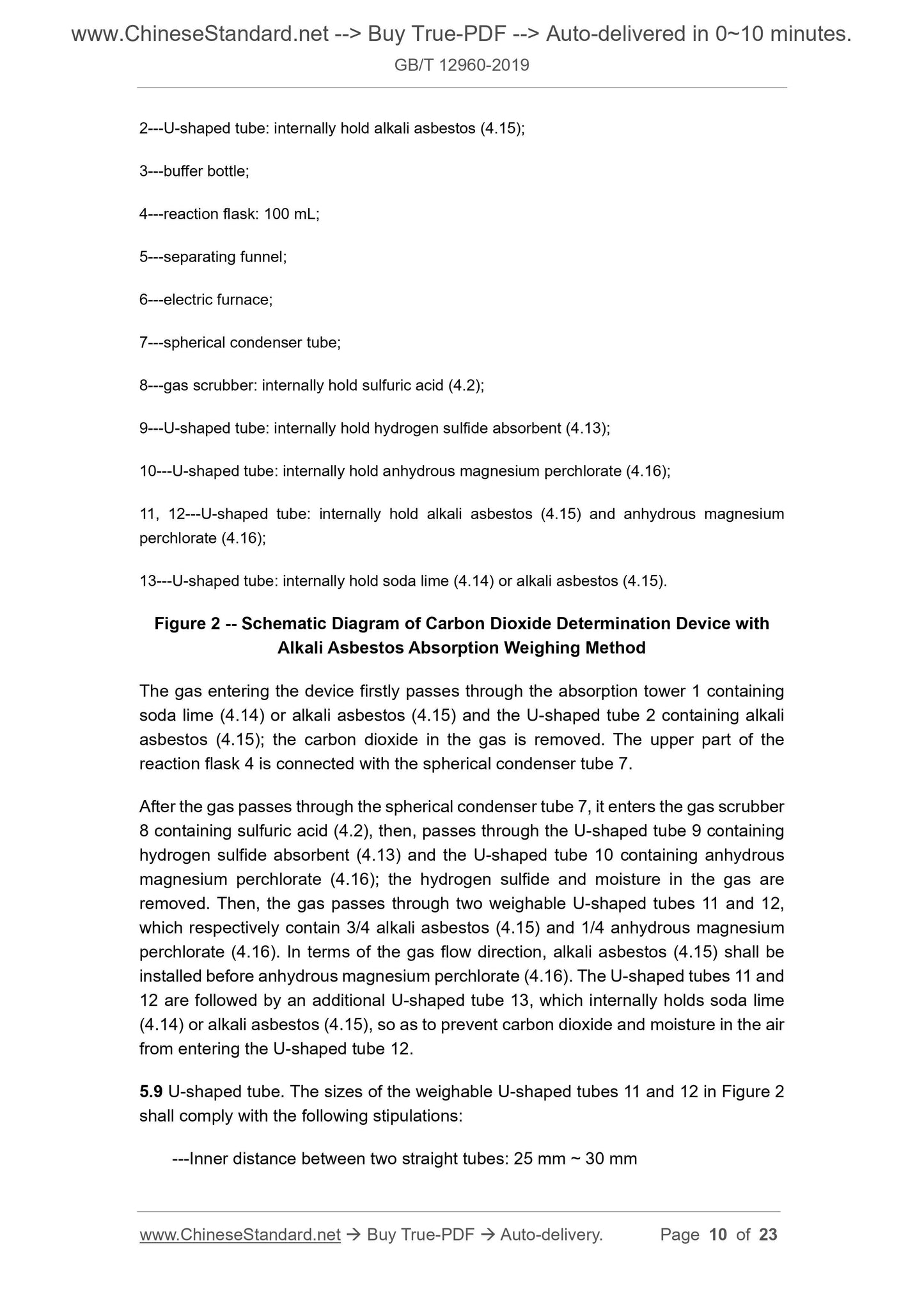

2---U-shaped tube: internally hold alkali asbestos (4.15);

3---buffer bottle;

4---reaction flask: 100 mL;

5---separating funnel;

6---electric furnace;

7---spherical condenser tube;

8---gas scrubber: internally hold sulfuric acid (4.2);

9---U-shaped tube: internally hold hydrogen sulfide absorbent (4.13);

10---U-shaped tube: internally hold anhydrous magnesium perchlorate (4.16);

11, 12---U-shaped tube: internally hold alkali asbestos (4.15) and anhydrous magnesium

perchlorate (4.16);

13---U-shaped tube: internally hold soda lime (4.14) or alkali asbestos (4.15).

Figure 2 -- Schematic Diagram of Carbon Dioxide Determination Device with

Alkali Asbestos Absorption Weighing Method

The gas entering the device firstly passes through the absorption tower 1 containing

soda lime (4.14) or alkali asbestos (4.15) and the U-shaped tube 2 containing alkali

asbestos (4.15); the carbon dioxide in the gas is removed. The upper part of the

reaction flask 4 is connected with the spherical condenser tube 7.

After the gas passes through the spherical condenser tube 7, it enters the gas scrubber

8 containing sulfuric acid (4.2), then, passes through the U-shaped tube 9 containing

hydrogen sulfide absorbent (4.13) and the U-shaped tube 10 containing anhydrous

magnesium perchlorate (4.16); the hydrogen sulfide and moisture in the gas ...

Get QUOTATION in 1-minute: Click GB/T 12960-2019

Historical versions: GB/T 12960-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 12960-2019: Quantitative determination of constituents of cement

GB/T 12960-2019

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 91.100.10

Q 11

Replacing GB/T 12960-2007

Quantitative Determination of Constituents of Cement

ISSUED ON: OCTOBER 18, 2019

IMPLEMENTED ON: SEPTEMBER 1, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Basic Requirements for Test ... 5

4 Reagents and Materials ... 6

5 Instruments and Equipment ... 8

6 Preparation of Specimens ... 11

7 Determination of Cement Constituents - Method 1 ... 11

8 Determination of Cement Constituents - Method 2 ... 18

9 Precision ... 22

Quantitative Determination of Constituents of Cement

1 Scope

This Standard specifies the methods of quantitative determination of constituents of

Portland cement, ordinary Portland cement, slag Portland cement, pozzolanic Portland

cement, fly-ash Portland cement and composite Portland cement.

This Standard is applicable to cement containing one or more materials among

granulated blast-furnace slag, pozzolanic mixed material, fly ash, limestone,

sandstone, kiln dust, gypsum and Portland cement clinker.

2 Normative References

The following documents are indispensable to the application of this document. In

terms of references with a specified date, only versions with a specified date are

applicable to this document. In terms of references without a specified date, the latest

version (including all the modifications) is applicable to this document.

GB/T 176 Method for Chemical Analysis of Cement

GB/T 5484 Methods for Chemical Analysis of Gypsum

GB/T 6682 Water for Analytical Laboratory Use - Specification and Test Methods

GB/T 8170 Rules of Rounding off for Numerical Values and Expression and Judgement

of Limiting Values

GB/T 12573 Sampling Method for Cement

GB/T 35151 Determination of Total Organic Carbon in Limestone

3 Basic Requirements for Test

3.1 Test Number and Requirements

The number of tests for each determination is specified as two. Use the average value

of two test results to represent the determination result.

The methods of the determination of constituents of cement are divided into Method 1

and Method 2. If multiple determination methods are listed for the same constituent,

Method 1 shall prevail when there is a dispute.

3.2 Laboratory Temperature

It is required that laboratory temperature shall be between 16 °C ~ 30 °C.

3.3 Constant Mass

After the first drying or burning, cooling and weighing, through the method of

continuously drying or burning the vessel or specimen for 15 min each time, and then,

cooling and weighing it, determine the constant mass. When the difference of two

consecutive weighings is less than 0.0005 g, it reaches a constant mass.

3.4 Processing of Results

3.4.1 After selective dissolution, the content of insoluble slag, the content of carbon

dioxide and the content of sulfur trioxide shall be counted by mass fraction, and the

numerical value shall be expressed in a percentage (%) to two decimal places; the

content of sulfide (calculated by S) shall be counted by mass fraction, and the

numerical value shall be expressed in a percentage (%) to three decimal places.

3.4.2 The determination result of the content of various constituents in cement shall be

counted by mass fraction, and the numerical value shall be expressed in a percentage

(%) to one decimal place.

3.4.3 The rounding-off of numerical values shall be carried out in accordance with GB/T

8170.

4 Reagents and Materials

Unless it is otherwise specified, all reagents shall be not lower than analytically pure.

The used water shall be not lower than the requirements for Grade-3 water specified

in GB/T 6682. Carbon dioxide-free water refers to water that is freshly boiled and

cooled to room temperature.

4.1 Nitric acid (HNO3): density: 1.39 g/cm3 ~ 1.41 g/cm3; mass fraction: 65% ~ 68%.

NOTE: the density of commercially available concentrated liquid reagents listed in this

Standard refers to the density () at 20 °C, the same below.

4.2 Sulfuric acid (H2SO4): density: 1.84 g/cm3; mass fraction: 95% ~ 98%.

4.3 Phosphoric acid (H3PO4): density: 1.68 g/cm3; mass fraction ≥ 85%.

4.4 Triethanolamine [N(CH2CH2OH)3]: density: 1.12 g/cm3; mass fraction: 99%.

4.5 Ethanol (C2H5OH): mass fraction: 95%.

4.6 Nitric acid (1 + 5).

NOTE 1: use volume ratio to indicate the degree of reagent dilution, the same below. Nitric

standard buffer solution at different temperatures are shown in Table 1.

4.12 Copper sulfate (CuSO4 5H2O) saturated solution.

4.13 Hydrogen sulfide absorbent: place the weighed dry pumice with a particle size of

1 mm ~ 2.5 mm in a flat pan, then, use a certain volume of copper sulfate saturated

solution to soak it (see 4.12). The mass of the copper sulfate solution is about half the

mass of the pumice. Place the mixture in a drying oven (5.2) at 150 °C ± 5 °C; under

constant stirring with a glass rod, evaporate the mixture to dryness, then, dry it for

above 5 h. After the solid mixture is cooled, store it in a sealed bottle.

4.14 Soda lime: particle size: 2 mm ~ 5 mm; medical or chemically pure; sealed and

stored.

4.15 Alkali asbestos: particle size: 1 mm ~ 2 mm (10 mesh ~ 20 mesh); chemically

pure; sealed and stored.

4.16 Anhydrous magnesium perchlorate [Mg (ClO4)2]: made into a particle size of 0.6

mm ~ 2 mm; stored in a sealed bottle.

5 Instruments and Equipment

5.1 Balance: division value is not less than 0.0001 g.

5.2 Drying oven: controlled temperature 105 °C ± 5 °C, 150 °C ± 5 °C.

5.3 Acidity meter: pH value measurement value 0 ~ 14, accurate to 0.02.

5.4 Glass sand core funnel: with a diameter of 35 mm ~ 60 mm; model G4 (average

pore size: 3 μm ~ 4 μm).

Glass sand core crucible of the same specification may also be used.

5.5 Suction filter flask: 1,000 mL.

5.6 Air pump: pumping speed 0.25 L/s.

5.7 Cement constituent determination device: able to maintain a constant temperature

of 20 °C ± 2 °C, as it is shown in Figure 1.

2---U-shaped tube: internally hold alkali asbestos (4.15);

3---buffer bottle;

4---reaction flask: 100 mL;

5---separating funnel;

6---electric furnace;

7---spherical condenser tube;

8---gas scrubber: internally hold sulfuric acid (4.2);

9---U-shaped tube: internally hold hydrogen sulfide absorbent (4.13);

10---U-shaped tube: internally hold anhydrous magnesium perchlorate (4.16);

11, 12---U-shaped tube: internally hold alkali asbestos (4.15) and anhydrous magnesium

perchlorate (4.16);

13---U-shaped tube: internally hold soda lime (4.14) or alkali asbestos (4.15).

Figure 2 -- Schematic Diagram of Carbon Dioxide Determination Device with

Alkali Asbestos Absorption Weighing Method

The gas entering the device firstly passes through the absorption tower 1 containing

soda lime (4.14) or alkali asbestos (4.15) and the U-shaped tube 2 containing alkali

asbestos (4.15); the carbon dioxide in the gas is removed. The upper part of the

reaction flask 4 is connected with the spherical condenser tube 7.

After the gas passes through the spherical condenser tube 7, it enters the gas scrubber

8 containing sulfuric acid (4.2), then, passes through the U-shaped tube 9 containing

hydrogen sulfide absorbent (4.13) and the U-shaped tube 10 containing anhydrous

magnesium perchlorate (4.16); the hydrogen sulfide and moisture in the gas ...

Share