1

/

of

8

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 1591-2018 English PDF (GB/T1591-2018)

GB/T 1591-2018 English PDF (GB/T1591-2018)

Regular price

$125.00

Regular price

Sale price

$125.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 1591-2018: High strength low alloy structural steels

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 1591-2018 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 1591-2018

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 1591-2018

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.01

H 40

GB/T 1591-2008

High strength low alloy structural steels

ISSUED ON: MAY 14, 2018

IMPLEMENTED ON: FEBRUARY 01, 2019

Issued by: State Market Regulatory Administration;

Standardization Administration of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 8

4 Designation representation ... 9

5 Ordering content ... 9

6 Size, shape, weight ... 10

7 Technical requirements ... 11

8 Test methods ... 25

9 Inspection rules ... 26

10 Packaging, marking and quality certificate ... 28

Appendix A (Informative) Domestic and international standards’ designation

comparison ... 29

High strength low alloy structural steels

1 Scope

This Standard specifies the designation representation method, ordering

content, size, shape, weight, technical requirements, test methods, inspection

rules, packaging, marking, and quality certificate of high strength low alloy

structural steel.

This Standard is applicable to high strength low alloy structural steel plates,

steel strips, steel sections, steel bars, etc. for general structural and engineering

purposes. Its chemical composition is also applicable to steel billets.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this Standard.

GB/T 222 Permissible tolerances for chemical composition of steel products

GB/T 223.3 Methods for chemical analysis of steels and alloys -

Determination of phosphorus content by diantipyryl methane

phosphomolybdate gravimetric method

GB/T 223.9 Iron steel and alloy - Determination of aluminum content -

Chrome azurol S photometric method

GB/T 223.11 Iron, steel and alloy - Determination of chromium content -

Visual titration or potentiometric titration method

GB/T 223.14 Methods for chemical analysis of iron, steel and alloy - The N-

Benzoyl-N-Phenylhydroxylamine extraction photometric method for the

determination of vanadium content

GB/T 223.17 Methods for chemical analysis of steels and alloys – Diantipyryl

methane photometric method for the determination of titanium content

GB/T 223.18 Methods for chemical analysis of iron, steel and alloy - The

sodium thiosulfate separation iodometric method for the determination of

copper content

GB/T 247 General rule of package mark and certification for steel plates

(sheets) and strips

GB/T 702 Hot-rolled round and square steel bars - Dimension, shape, weight

and tolerance

GB/T 706 Hot-rolled section steel

GB/T 709 Dimension, shape, weight and tolerances for hot-rolled sheets and

strip

GB/T 2101 General requirement of acceptance packaging marking and

certification for section steel

GB/T 2975-2018 Steel and steel products - Location and preparation of

samples and test pieces for mechanical testing

GB/T 4336 Carbon and low-alloy steel - Determination of multi-element

contents - Spark discharge atomic emission spectrometric method (Routine

method)

GB/T 5313 Steel plates with through-thickness characteristics

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 11263 Hot-rolled H and cut T section steel

GB/T 14977 General requirement for surface condition of hot-rolled steel

plates

GB/T 17505 Steel and steel products General technical delivery

requirements

GB/T 20066 Steel and iron - Sampling and preparation of samples for the

determination of chemical composition

GB/T 20123 Steel and iron - Determination of total carbon and sulfur content

Infrared absorption method after combustion in an induction furnace (routine

method)

GB/T 20124 Steel and iron - Determination of nitrogen content - Thermal

conductimetric method after fusion in a current of inert gas

GB/T 20125 Low-alloy steel - Determination of multi-element contents -

Inductively coupled plasma atomic emission spectrometric method

GB/T 28300 Surface quality classes for hot-rolled bars and rods technical

delivery conditions

Note 1: Thermoforming that may reduce the steel strength value or steel

post-weld heat treatment at temperatures above 580 °C may not be suitable.

In accordance with the relevant technical specifications, flame straightening

is allowed.

Note 2: Thermomechanical processing may include a process of increasing

the cooling rate in a tempered or non-tempered state, the tempering includes

self-tempering but not includes direct quenching and quenching and tempering.

Note 3: Also known as TMCP (thermomechanical controlled process), also

referred to as “controlled rolling” in some publications.

4 Designation representation

4.1 The steel designation consists of four parts: the initial Pinyin Q of the yield

strength “Qu”, the specified minimum upper yield strength value, the delivery

status code, and the quality-grade symbol (B, C, D, E, F).

Note 1: When the delivery status is as-rolled, the delivery status code AR or

WAR can be omitted; when the delivery status is normalized or normalizing

rolling, the delivery status code is indicated by N.

Note 2: Q + The specified minimum upper yield strength value + delivery status

code, abbreviated as “steel-grade”.

Example: Q355ND, where:

Q - The initials of the Chinese Pinyin “Qu” of the yield strength of steel;

355 - The minimum value of the specified upper yield strength, in megapascal

(MPa);

N - The delivery status is normalizing or normalizing rolling;

D - The quality-grade is D.

4.2 When the purchaser requires the steel plate to have thickness-direction

performance, a symbol representing the thickness direction (Z-direction)

performance level, such as Q355NDZ25, is added after the above-mentioned

specified designation.

5 Ordering content

5.1 Contracts or orders placed under this Standard shall include the following:

a) This Standard number;

6.2 The size, shape, weight and allowable deviation of hot-rolled steel sections

shall comply with the provisions of GB/T 706, the specific group shall be

specified in the contract.

6.3 The size, shape, weight and allowable deviation of hot-rolled steel sheets

and strips shall comply with the provisions of GB/T 709, the specific accuracy

categories shall be indicated in the contract.

6.4 The size, shape, weight and allowable deviation of hot-rolled H-section steel

and split T-section steel shall comply with the provisions of GB/T 11263.

6.5 Steels of other sizes, shapes and allowable deviations may be supplied

upon agreement between the supplier and the purchaser.

7 Technical requirements

7.1 Steel designations and chemical composition

7.1.1 The designation and chemical composition of the hot-rolled steel (melting

analysis) shall comply with the requirements of Table 1, the carbon equivalent

value shall comply with the requirements of Table 2.

7.1.2 The designation and chemical composition of the normalized and

normalized rolled steel (melting analysis) shall comply with the requirements of

Table 3, the carbon equivalent value shall comply with the requirements of Table

4.

7.1.3 The designation and chemical composition of the thermomechanical

processed steel (melting analysis) shall comply with the requirements of Table

5, the carbon equivalent value shall comply with the provisions of Table 6. When

the carbon content of the thermomechanical processed steel is not greater than

0.12%, it should use the weld crack sensitivity index (Pcm) instead of the carbon

equivalent to evaluate the weldability of the steel. The Pcm value shall meet the

requirements of Table 6. After consultation between the supplier and the buyer,

it may specify using the carbon equivalent or weld crack sensitivity index to

evaluate the weldability of the steel; when it is not specified, the supplier may

choose either one.

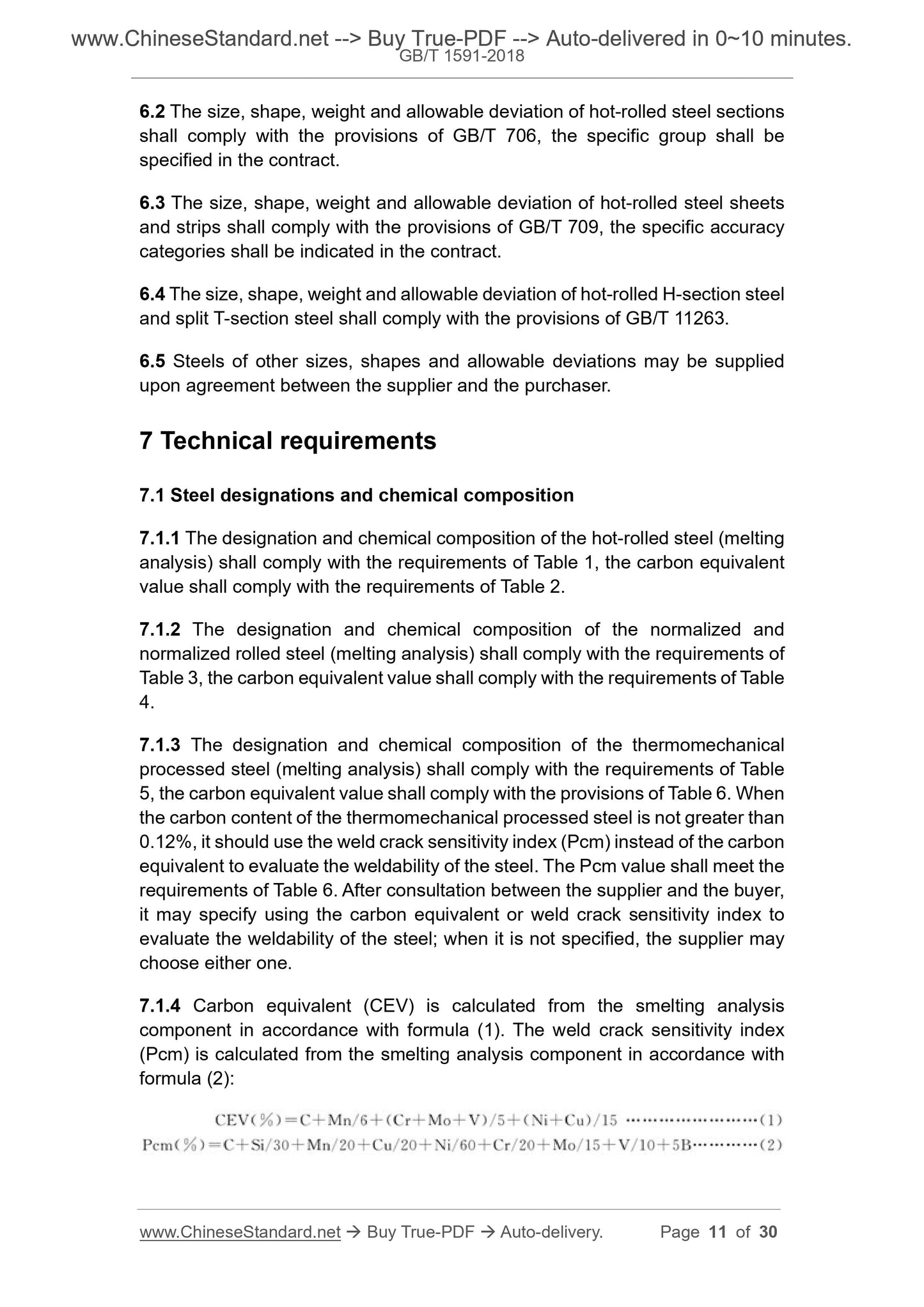

7.1.4 Carbon equivalent (CEV) is calculated from the smelting analysis

component in accordance with formula (1). The weld crack sensitivity index

(Pcm) is calculated from the smelting analysis component in accordance with

formula (2):

d) Heat treatment shall be carried out again after welding repair of heat

treated steel plate.

7.5.1.5 After consultation between the supplier and the purchaser, the surface

quality of the steel plate may also meet the requirements of GB/T 14977.

7.5.2 Steel strip and its cut steel plate

7.5.2.1 The surface of the steel strip shall be free of defects such as crusting,

cracks, folding, inclusions, blisters and iron oxide indentation which are harmful

to use. The steel strip shall not have visible delamination.

7.5.2.2 The surface of the steel strip is allowed to have a thin layer of iron oxide

scale, rust and slight pitting, scratches and other partial defects. The depth or

height shall not exceed half of the thickness tolerance of the steel strip, and it

shall ensure the allowable minimum thickness of the steel strip.

7.5.2.3 The steel is allowed to be delivered with partial defects, but the defective

portion shall not exceed 6% of the total length of each steel strip.

7.5.2.4 After consultation between the supplier and the purchaser, the surface

quality of the steel strip may also meet the requirements of GB/T 14977.

7.5.3 Steel sections

7.5.3.1 The surface quality of steel sections shall comply with the provisions of

relevant standards.

7.5.3.2 The surface quality of the steel sections may also follow the provisions

of YB/T 4427 after consultation between the supplier and the purchaser.

7.5.4 Steel bars

7.5.4.1 The surface quality of steel bars should comply with the provisions of

relevant standards.

7.5.4.2 After consultation between the supplier and the purchaser, the surface

quality of the steel bar can be as specified in GB/T 28300.

7.6 Non-destructive testing

After consultation between the supplier and the purchaser, the internal quality

of the steel may be inspected by non-destructive testing. The testing criteria

and requirements shall be as specified in the contract.

8 Test methods

8.1 The inspection items and test methods for each inspection of steel shall

comply with the requirements of Table 13.

8.2 The chemical composition test of steel is generally carried out in accordance

with GB/T 4336, GB/T 20123, GB/T 20124, GB/T 20125 or general chemical

analysis methods. During arbitration, it is carried out in accordance with GB/T

223.3, GB/T 223.9, GB/T 223.11, GB/T 223.14, GB/T 223.17, GB/T 223.18,

GB/T 223.23, GB/T 223.26, GB/T 223.37, GB/T 223.40, GB/T 223.60, GB/T

223.63 , GB/T 223.68, GB/T 223.69, GB/T 223.76, GB/T 223.78, GB/T 223.84

and GB/T 20125.

8.3 When the purchaser has no special requirement, the sampling position of

the impact test shall be as follows:

a) For steel sections, it shall be in accordance with the provisions of Figure

A.3 of GB/T 2975-2018;

b) For round steel, when the nominal diameter d ≤ 25 mm, 25 mm < d ≤ 50

mm and d > 50 mm, it shall be respectively in accordance with the

provisions of a), b), d) of Figure A.5 of GB/T 2975-2018;

c) For square steel, when the side length is not greater than 50 mm, it shall

be in accordance with the provisions of a) of Figure A.9 of GB/T 2975-

2018; when the side length is greater than 50 mm, it shall be in accordance

with the provisions of b) in Figure A.9 of GB/T 2975-2018;

d) For steel plates, when the nominal thickness is not greater than 40 mm, it

shall be in accordance with the provisions of a) in Figure A.11 of GB/T

2975-2018; when the nominal thickness is greater than 40 mm, it shall be

in accordance with b) of Figure A.11 of GB/T 2975-2018.

9 Inspection rules

9.1 Inspection and acceptance

The inspection and acceptance of steel materials shall be carried out by the

technical supervision department of the supplier.

9.2 Batching rules

9.2.1 Steel shall be accepted in batches. Each batch shall be composed of steel

of the same designation, the same furnace-number, the same specification and

the same delivery status. The weight of each batch shall not be greater than 60

t, however, two rolling coils of steel strip and continuous rolling sheet of volume-

weight greater than 30 t may form a batch; for the steel sections smelted by

converter with a volume greater than 200 t, the weight per batch shall be not

greater than 80 t. Through negotiation between the supplier and the purchaser,

GB/T 1591-2018

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.01

H 40

GB/T 1591-2008

High strength low alloy structural steels

ISSUED ON: MAY 14, 2018

IMPLEMENTED ON: FEBRUARY 01, 2019

Issued by: State Market Regulatory Administration;

Standardization Administration of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 8

4 Designation representation ... 9

5 Ordering content ... 9

6 Size, shape, weight ... 10

7 Technical requirements ... 11

8 Test methods ... 25

9 Inspection rules ... 26

10 Packaging, marking and quality certificate ... 28

Appendix A (Informative) Domestic and international standards’ designation

comparison ... 29

High strength low alloy structural steels

1 Scope

This Standard specifies the designation representation method, ordering

content, size, shape, weight, technical requirements, test methods, inspection

rules, packaging, marking, and quality certificate of high strength low alloy

structural steel.

This Standard is applicable to high strength low alloy structural steel plates,

steel strips, steel sections, steel bars, etc. for general structural and engineering

purposes. Its chemical composition is also applicable to steel billets.

2 Normative references

The following documents are essential to the application of this...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 1591-2018 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 1591-2018

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 1591-2018

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.01

H 40

GB/T 1591-2008

High strength low alloy structural steels

ISSUED ON: MAY 14, 2018

IMPLEMENTED ON: FEBRUARY 01, 2019

Issued by: State Market Regulatory Administration;

Standardization Administration of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 8

4 Designation representation ... 9

5 Ordering content ... 9

6 Size, shape, weight ... 10

7 Technical requirements ... 11

8 Test methods ... 25

9 Inspection rules ... 26

10 Packaging, marking and quality certificate ... 28

Appendix A (Informative) Domestic and international standards’ designation

comparison ... 29

High strength low alloy structural steels

1 Scope

This Standard specifies the designation representation method, ordering

content, size, shape, weight, technical requirements, test methods, inspection

rules, packaging, marking, and quality certificate of high strength low alloy

structural steel.

This Standard is applicable to high strength low alloy structural steel plates,

steel strips, steel sections, steel bars, etc. for general structural and engineering

purposes. Its chemical composition is also applicable to steel billets.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this Standard.

GB/T 222 Permissible tolerances for chemical composition of steel products

GB/T 223.3 Methods for chemical analysis of steels and alloys -

Determination of phosphorus content by diantipyryl methane

phosphomolybdate gravimetric method

GB/T 223.9 Iron steel and alloy - Determination of aluminum content -

Chrome azurol S photometric method

GB/T 223.11 Iron, steel and alloy - Determination of chromium content -

Visual titration or potentiometric titration method

GB/T 223.14 Methods for chemical analysis of iron, steel and alloy - The N-

Benzoyl-N-Phenylhydroxylamine extraction photometric method for the

determination of vanadium content

GB/T 223.17 Methods for chemical analysis of steels and alloys – Diantipyryl

methane photometric method for the determination of titanium content

GB/T 223.18 Methods for chemical analysis of iron, steel and alloy - The

sodium thiosulfate separation iodometric method for the determination of

copper content

GB/T 247 General rule of package mark and certification for steel plates

(sheets) and strips

GB/T 702 Hot-rolled round and square steel bars - Dimension, shape, weight

and tolerance

GB/T 706 Hot-rolled section steel

GB/T 709 Dimension, shape, weight and tolerances for hot-rolled sheets and

strip

GB/T 2101 General requirement of acceptance packaging marking and

certification for section steel

GB/T 2975-2018 Steel and steel products - Location and preparation of

samples and test pieces for mechanical testing

GB/T 4336 Carbon and low-alloy steel - Determination of multi-element

contents - Spark discharge atomic emission spectrometric method (Routine

method)

GB/T 5313 Steel plates with through-thickness characteristics

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 11263 Hot-rolled H and cut T section steel

GB/T 14977 General requirement for surface condition of hot-rolled steel

plates

GB/T 17505 Steel and steel products General technical delivery

requirements

GB/T 20066 Steel and iron - Sampling and preparation of samples for the

determination of chemical composition

GB/T 20123 Steel and iron - Determination of total carbon and sulfur content

Infrared absorption method after combustion in an induction furnace (routine

method)

GB/T 20124 Steel and iron - Determination of nitrogen content - Thermal

conductimetric method after fusion in a current of inert gas

GB/T 20125 Low-alloy steel - Determination of multi-element contents -

Inductively coupled plasma atomic emission spectrometric method

GB/T 28300 Surface quality classes for hot-rolled bars and rods technical

delivery conditions

Note 1: Thermoforming that may reduce the steel strength value or steel

post-weld heat treatment at temperatures above 580 °C may not be suitable.

In accordance with the relevant technical specifications, flame straightening

is allowed.

Note 2: Thermomechanical processing may include a process of increasing

the cooling rate in a tempered or non-tempered state, the tempering includes

self-tempering but not includes direct quenching and quenching and tempering.

Note 3: Also known as TMCP (thermomechanical controlled process), also

referred to as “controlled rolling” in some publications.

4 Designation representation

4.1 The steel designation consists of four parts: the initial Pinyin Q of the yield

strength “Qu”, the specified minimum upper yield strength value, the delivery

status code, and the quality-grade symbol (B, C, D, E, F).

Note 1: When the delivery status is as-rolled, the delivery status code AR or

WAR can be omitted; when the delivery status is normalized or normalizing

rolling, the delivery status code is indicated by N.

Note 2: Q + The specified minimum upper yield strength value + delivery status

code, abbreviated as “steel-grade”.

Example: Q355ND, where:

Q - The initials of the Chinese Pinyin “Qu” of the yield strength of steel;

355 - The minimum value of the specified upper yield strength, in megapascal

(MPa);

N - The delivery status is normalizing or normalizing rolling;

D - The quality-grade is D.

4.2 When the purchaser requires the steel plate to have thickness-direction

performance, a symbol representing the thickness direction (Z-direction)

performance level, such as Q355NDZ25, is added after the above-mentioned

specified designation.

5 Ordering content

5.1 Contracts or orders placed under this Standard shall include the following:

a) This Standard number;

6.2 The size, shape, weight and allowable deviation of hot-rolled steel sections

shall comply with the provisions of GB/T 706, the specific group shall be

specified in the contract.

6.3 The size, shape, weight and allowable deviation of hot-rolled steel sheets

and strips shall comply with the provisions of GB/T 709, the specific accuracy

categories shall be indicated in the contract.

6.4 The size, shape, weight and allowable deviation of hot-rolled H-section steel

and split T-section steel shall comply with the provisions of GB/T 11263.

6.5 Steels of other sizes, shapes and allowable deviations may be supplied

upon agreement between the supplier and the purchaser.

7 Technical requirements

7.1 Steel designations and chemical composition

7.1.1 The designation and chemical composition of the hot-rolled steel (melting

analysis) shall comply with the requirements of Table 1, the carbon equivalent

value shall comply with the requirements of Table 2.

7.1.2 The designation and chemical composition of the normalized and

normalized rolled steel (melting analysis) shall comply with the requirements of

Table 3, the carbon equivalent value shall comply with the requirements of Table

4.

7.1.3 The designation and chemical composition of the thermomechanical

processed steel (melting analysis) shall comply with the requirements of Table

5, the carbon equivalent value shall comply with the provisions of Table 6. When

the carbon content of the thermomechanical processed steel is not greater than

0.12%, it should use the weld crack sensitivity index (Pcm) instead of the carbon

equivalent to evaluate the weldability of the steel. The Pcm value shall meet the

requirements of Table 6. After consultation between the supplier and the buyer,

it may specify using the carbon equivalent or weld crack sensitivity index to

evaluate the weldability of the steel; when it is not specified, the supplier may

choose either one.

7.1.4 Carbon equivalent (CEV) is calculated from the smelting analysis

component in accordance with formula (1). The weld crack sensitivity index

(Pcm) is calculated from the smelting analysis component in accordance with

formula (2):

d) Heat treatment shall be carried out again after welding repair of heat

treated steel plate.

7.5.1.5 After consultation between the supplier and the purchaser, the surface

quality of the steel plate may also meet the requirements of GB/T 14977.

7.5.2 Steel strip and its cut steel plate

7.5.2.1 The surface of the steel strip shall be free of defects such as crusting,

cracks, folding, inclusions, blisters and iron oxide indentation which are harmful

to use. The steel strip shall not have visible delamination.

7.5.2.2 The surface of the steel strip is allowed to have a thin layer of iron oxide

scale, rust and slight pitting, scratches and other partial defects. The depth or

height shall not exceed half of the thickness tolerance of the steel strip, and it

shall ensure the allowable minimum thickness of the steel strip.

7.5.2.3 The steel is allowed to be delivered with partial defects, but the defective

portion shall not exceed 6% of the total length of each steel strip.

7.5.2.4 After consultation between the supplier and the purchaser, the surface

quality of the steel strip may also meet the requirements of GB/T 14977.

7.5.3 Steel sections

7.5.3.1 The surface quality of steel sections shall comply with the provisions of

relevant standards.

7.5.3.2 The surface quality of the steel sections may also follow the provisions

of YB/T 4427 after consultation between the supplier and the purchaser.

7.5.4 Steel bars

7.5.4.1 The surface quality of steel bars should comply with the provisions of

relevant standards.

7.5.4.2 After consultation between the supplier and the purchaser, the surface

quality of the steel bar can be as specified in GB/T 28300.

7.6 Non-destructive testing

After consultation between the supplier and the purchaser, the internal quality

of the steel may be inspected by non-destructive testing. The testing criteria

and requirements shall be as specified in the contract.

8 Test methods

8.1 The inspection items and test methods for each inspection of steel shall

comply with the requirements of Table 13.

8.2 The chemical composition test of steel is generally carried out in accordance

with GB/T 4336, GB/T 20123, GB/T 20124, GB/T 20125 or general chemical

analysis methods. During arbitration, it is carried out in accordance with GB/T

223.3, GB/T 223.9, GB/T 223.11, GB/T 223.14, GB/T 223.17, GB/T 223.18,

GB/T 223.23, GB/T 223.26, GB/T 223.37, GB/T 223.40, GB/T 223.60, GB/T

223.63 , GB/T 223.68, GB/T 223.69, GB/T 223.76, GB/T 223.78, GB/T 223.84

and GB/T 20125.

8.3 When the purchaser has no special requirement, the sampling position of

the impact test shall be as follows:

a) For steel sections, it shall be in accordance with the provisions of Figure

A.3 of GB/T 2975-2018;

b) For round steel, when the nominal diameter d ≤ 25 mm, 25 mm < d ≤ 50

mm and d > 50 mm, it shall be respectively in accordance with the

provisions of a), b), d) of Figure A.5 of GB/T 2975-2018;

c) For square steel, when the side length is not greater than 50 mm, it shall

be in accordance with the provisions of a) of Figure A.9 of GB/T 2975-

2018; when the side length is greater than 50 mm, it shall be in accordance

with the provisions of b) in Figure A.9 of GB/T 2975-2018;

d) For steel plates, when the nominal thickness is not greater than 40 mm, it

shall be in accordance with the provisions of a) in Figure A.11 of GB/T

2975-2018; when the nominal thickness is greater than 40 mm, it shall be

in accordance with b) of Figure A.11 of GB/T 2975-2018.

9 Inspection rules

9.1 Inspection and acceptance

The inspection and acceptance of steel materials shall be carried out by the

technical supervision department of the supplier.

9.2 Batching rules

9.2.1 Steel shall be accepted in batches. Each batch shall be composed of steel

of the same designation, the same furnace-number, the same specification and

the same delivery status. The weight of each batch shall not be greater than 60

t, however, two rolling coils of steel strip and continuous rolling sheet of volume-

weight greater than 30 t may form a batch; for the steel sections smelted by

converter with a volume greater than 200 t, the weight per batch shall be not

greater than 80 t. Through negotiation between the supplier and the purchaser,

GB/T 1591-2018

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.01

H 40

GB/T 1591-2008

High strength low alloy structural steels

ISSUED ON: MAY 14, 2018

IMPLEMENTED ON: FEBRUARY 01, 2019

Issued by: State Market Regulatory Administration;

Standardization Administration of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 8

4 Designation representation ... 9

5 Ordering content ... 9

6 Size, shape, weight ... 10

7 Technical requirements ... 11

8 Test methods ... 25

9 Inspection rules ... 26

10 Packaging, marking and quality certificate ... 28

Appendix A (Informative) Domestic and international standards’ designation

comparison ... 29

High strength low alloy structural steels

1 Scope

This Standard specifies the designation representation method, ordering

content, size, shape, weight, technical requirements, test methods, inspection

rules, packaging, marking, and quality certificate of high strength low alloy

structural steel.

This Standard is applicable to high strength low alloy structural steel plates,

steel strips, steel sections, steel bars, etc. for general structural and engineering

purposes. Its chemical composition is also applicable to steel billets.

2 Normative references

The following documents are essential to the application of this...

Share