1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 16777-2008 English PDF (GB/T16777-2008)

GB/T 16777-2008 English PDF (GB/T16777-2008)

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 16777-2008: Test methods for building waterproofing coatings

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 16777-2008 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 16777-2008

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 16777-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 91.120.30

Q 17

Replacing GB/T 16777-1997

Test methods for building waterproofing coatings

ISSUED ON: JUNE 30, 2008

IMPLEMENTED ON: APRIL 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Standard test conditions ... 5

4 Coating film preparation ... 6

5 Solid content ... 8

6 Heat resistance ... 9

7 Bond strength ... 10

8 Bond strength on wet substrate ... 16

9 Tensile properties ... 17

10 Tear strength ... 21

11 Aging at elongation ... 22

12 Heating stretch rate ... 23

13 Low temperature flexibility ... 25

14 Low temperature bendability ... 27

15 Impermeability ... 29

16 Drying time ... 30

Test methods for building waterproofing coatings

1 Scope

This document specifies the standard test conditions, coating film preparation, solid

content, heat resistance, bond strength, bond strength of wet substrate, tensile properties,

tear strength, aging at constant elongation, heating expansion rate of architectural

waterproof coatings , low temperature flexibility, impermeability, drying time and other

performance test methods.

This Standard applies to building waterproof coatings.

2 Normative references

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments (excluding

corrigendum) or revisions do not apply to this Standard, however, parties who reach an

agreement based on this Standard are encouraged to study if the latest versions of these

documents are applicable. For undated references, the latest edition of the referenced

document applies.

GB/T 328.10-2007, Test methods for building sheets for waterproofing - Part 10:

Bitumen, plastic and rubber sheets for waterproofing - Water tightness

GB/T 528, Rubber, vulcanized or thermoplastic - Determination of tensile stress-

strain properties (GB/T 528-1998, ISO 37:1994 eqv)

GB/T 529-1999, Rubber, vulcanized or thermoplastic - Determination of tear

strength (Trouser, angle and crescent test pieces) (ISO 34-1:1994 eqv)

GB/T 18244, Test methods for weathering resistance of building waterproof

materials

3 Standard test conditions

Laboratory standard test conditions: temperature is (23±2)℃; relative humidity is

(50±10)%.

Strict conditions: temperature is (23±2)℃; relative humidity is (50±5)%.

6.2 Test steps

After stirring the sample evenly, apply the sample in 2~3 times according to the

requirements of the manufacturer (the interval between each time shall not exceed 24h)

on the cleaned aluminum plate. The coating area is 100mm×50mm. The total thickness

is 1.5mm. Scrape the surface one last time. Carry out maintenance according to the

conditions in Table 1. Demolding is not required. Then hang the aluminum plate

vertically in an electric blast drying oven that has been adjusted to the specified

temperature. The distance between the test piece and the wall of the drying box is not

less than 50mm. The center of the test piece shall be at the same position as the probe

of the thermometer. After standing at the specified temperature for 5h, take it out.

Observe surface phenomena. Test 3 test pieces in total.

6.3 Result evaluation

After the test, all test pieces shall not flow, slide, or drip. There are no dense bubbles on

the surface of the test piece.

6.4 Test report

The test report shall contain the following information:

a) Chapter numbers of this Standard;

b) Determination of all necessary details of the test product;

c) Information about preparation of test piece;

d) Test temperature and time;

e) Test results;

f) Differences in methods used or abnormalities encountered during the test;

g) Test date.

7 Bond strength

7.1 Method A

7.1.1 Test apparatus

7.1.1.1 Tensile testing machine: the measured value is between (15-85)% of the range;

the indication accuracy is not less than 1%; the tensile speed is (5±1)mm/min.

7.1.1.2 Electric blast oven: temperature control accuracy is ±2℃.

7.1.1.3 Special metal clamps for stretching: upper clamps, lower clamps and backing

the prepared coating to the section of the mortar block. Conduct butt joint of the cross

sections of the two mortar blocks. Press them tightly. The thickness of the coating

between the mortar blocks shall not exceed 0.5mm. Place under standard test conditions

for 4h. Cure the prepared test pieces. The condition is at the temperature of (20±1)℃.

The relative humidity is not less than 90%. Cure for 168h. Prepare five test pieces.

Place the cured test pieces under standard test conditions for 2h. Install the test piece

on the testing machine. Keep the center line of the vertical direction of the test piece

surface and the center of the fixture of the testing machine on the same line. Stretch at

a speed of (5±1)mm/min until the test piece fails. Record the maximum tensile force of

the test piece. The test temperature is (23±2)°C.

Result calculation and test report are according to Chapter 7.

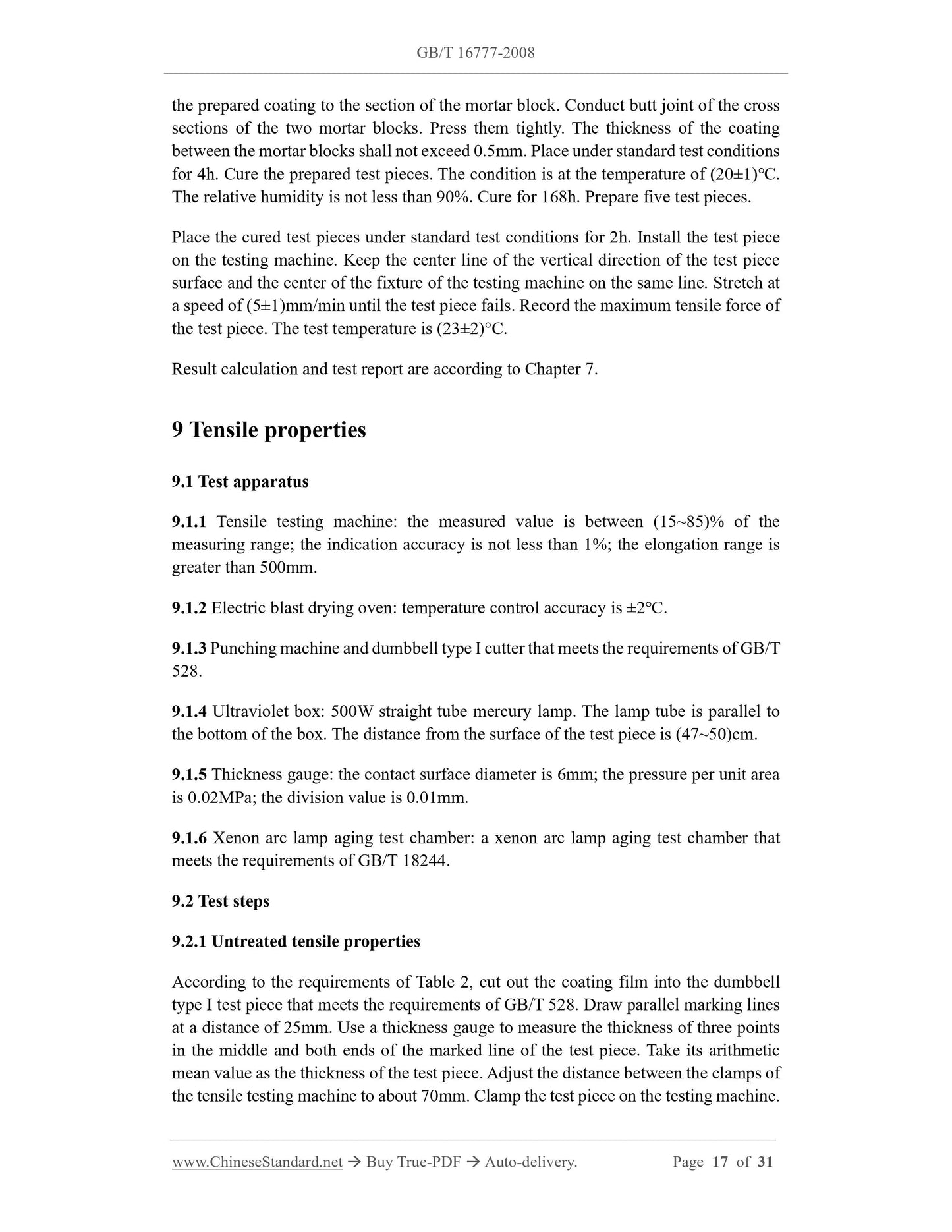

9 Tensile properties

9.1 Test apparatus

9.1.1 Tensile testing machine: the measured value is between (15~85)% of the

measuring range; the indication accuracy is not less than 1%; the elongation range is

greater than 500mm.

9.1.2 Electric blast drying oven: temperature control accuracy is ±2℃.

9.1.3 Punching machine and dumbbell type I cutter that meets the requirements of GB/T

528.

9.1.4 Ultraviolet box: 500W straight tube mercury lamp. The lamp tube is parallel to

the bottom of the box. The distance from the surface of the test piece is (47~50)cm.

9.1.5 Thickness gauge: the contact surface diameter is 6mm; the pressure per unit area

is 0.02MPa; the division value is 0.01mm.

9.1.6 Xenon arc lamp aging test chamber: a xenon arc lamp aging test chamber that

meets the requirements of GB/T 18244.

9.2 Test steps

9.2.1 Untreated tensile properties

According to the requirements of Table 2, cut out the coating film into the dumbbell

type I test piece that meets the requirements of GB/T 528. Draw parallel marking lines

at a distance of 25mm. Use a thickness gauge to measure the thickness of three points

in the middle and both ends of the marked line of the test piece. Take its arithmetic

mean value as the thickness of the test piece. Adjust the distance between the clamps of

the tensile testing machine to about 70mm. Clamp the test piece on the testing machine.

GB/T 528. Carry out the tensile test according to 9.2.1.

For water-based coatings, after soaking, take them out and wipe them dry. Then place

them in an electric blast oven at (60±2)°C for 6h±15min. Take out and place under

standard test conditions for (18±2)h. Cut out the dumbbell type I test piece that meets

the requirements of GB/T 528. Carry out the tensile test according to 9.2.1.

9.2.5 Tensile properties after UV treatment

Place six (120×25mm rectangular test pieces) cut according to Table 2 flat on the glazed

tile. To prevent sticking, talcum powder can be sprinkled on the surface of the glazed

tile. Put the test piece into the UV box. The temperature of the space about 50mm away

from the surface of the test piece is (45±2)℃. Conduct constant temperature irradiation

for 240h. Take out and place under standard test conditions for 4h. Cut out the dumbbell

type I test piece that meets the requirements of GB/T 528. Carry out the tensile test

according to 9.2.1.

9.2.6 Tensile properties of artificially weathered materials

Place six (120×25)mm rectangular specimens cut according to Table 2 in a xenon arc

lamp aging test chamber that meets the requirements of GB/T 18244. Take out after the

cumulative irradiation energy of the test is 1500 MJ2/m2 (about 720h). Wipe dry. Place

under standard test conditions for 4h. Cut out dumbbell type I test pieces that meet the

requirements of GB/T 528. Carry out the tensile test according to 9.2.1.

For water-based coating, take out and wipe dry. Then place in an electric blast oven at

(60±2)°C for 6h±15min. Take out and place under standard test conditions for (18±2)h.

Cut out the dumbbell type I test piece that meets the requirements of GB/T 528. Carry

out the tensile test according to 9.2.1.

9.3 Result calculation

9.3.1 Tensile strength

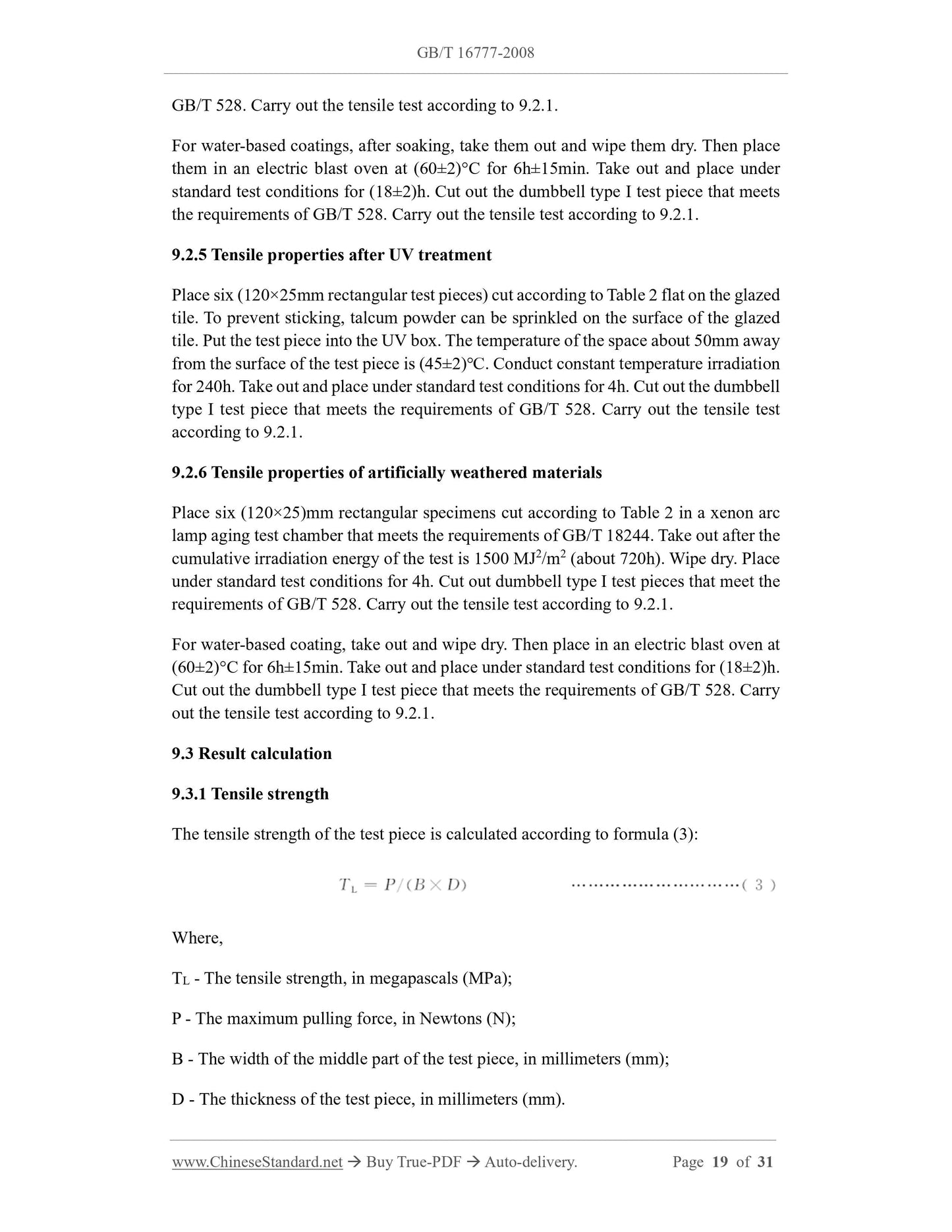

The tensile strength of the test piece is calculated according to formula (3):

Where,

TL - The tensile strength, in megapascals (MPa);

P - The maximum pulling force, in Newtons (N);

B - The width of the middle part of the test piece, in millimeters (mm);

D - The thickness of the test piece, in millimeters (mm).

e) Tensile speed;

f) Test results;

g) Differences in methods used or abnormalities encountered during the test;

h) Test date.

10 Tear strength

10.1 Test apparatus

10.1.1 Tensile testing machine: the measured value is between (15~85)% of the

measuring range; the indication accuracy is not less than 1%; the elongation range is

greater than 500mm.

10.1.2 Electric blast drying oven: temperature control accuracy is ±2℃.

10.1.3 Punching machine and right-angle tearing cutter that meets the requirements in

5.1.2 of GB/T 529-1999.

10.1.4 Thickness gauge: the contact surface diameter is 6mm; the pressure per unit area

is 0.02MPa; the division value is 0.01mm.

10.2 Test steps

Cut the coating film, according to the requirements in Table 2, into right-angle tear test

pieces without a cut that meet the requirements of GB/T 529-1999. Use a thickness

gauge to measure the thickness of three points in the right-angle tear area of the test

piece. Take the arithmetic mean value as the thickness of the test piece. Clamp the test

piece on the testing machine. Keep the centerline of the length direction of the test piece

on the same line as the center of the fixture of the testing machine. Stretch to break

according to the tensile speed in Table 4. Record the maximum load when the test piece

breaks (P). Test five test pieces.

10.3 Result calculation

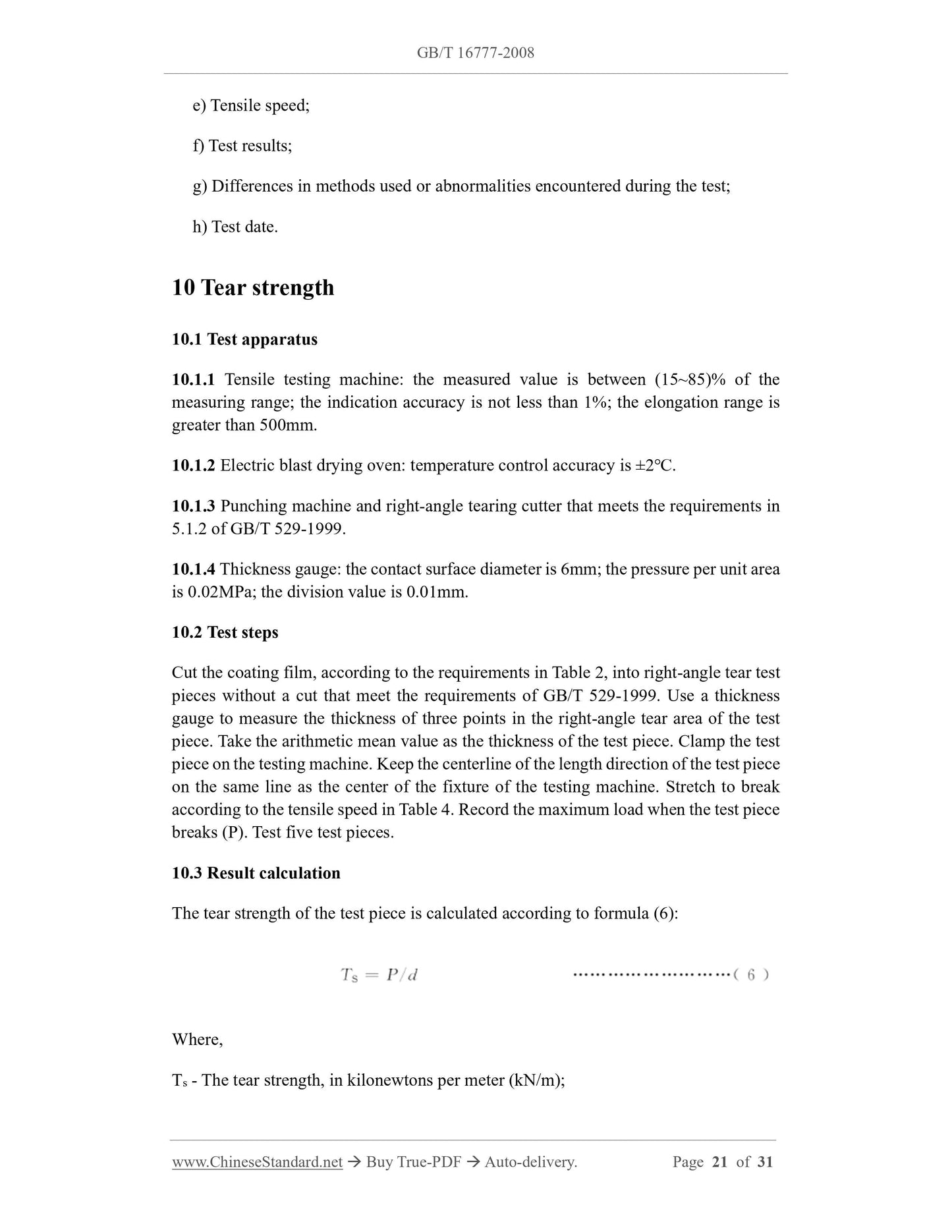

The tear strength of the test piece is calculated according to formula (6):

Where,

Ts - The tear strength, in kilonewtons per meter (kN/m);

P - The maximum pulling force, in Newtons (N);

d - The thickness of the test piece, in millimeters (mm).

Take the arithmetic mean value of five test pieces as the test result. The result is accurate

to 0.1kN/m.

10.4 Test report

The test report shall contain the following information:

a) Chapter numbers of this Standard;

b) Determination of all necessary details of the test product;

c) Information about preparation of test piece;

d) Tensile speed;

e) Test results;

f) Differences in methods used or abnormalities encountered during the test;

g) Test date.

11 Aging at elongation

11.1 Test apparatus

11.1.1 Electric blast drying oven: temperature control accuracy is ±2℃.

11.1.2 Xenon arc lamp aging test chamber: a xenon arc lamp aging test chamber that

meets the requirements of GB/T 18244.

11.1.3 Punching machine and dumbbell type I cutter that meets the requirements of

GB/T 528.

11.1.4 Constant extension retainer: it can stretch the distance between marking lines by

more than 100%.

11.2 Test steps

11.2.1 Heat aging

Cut the coating film, according to the requirements in Table 2, into dumbbell type I test

pieces that meet the requirements of GB/T 528. Draw parallel marking lines at a

distance of 25mm. Stretch the distance between the marking lines of the test piece from

25mm to 50mm. Place for 24hs under standard test conditions. Then put the constant

13 Low temperature flexibility

13.1 Test apparatus

13.1.1 Low-temperature freezer: temperature control accuracy is ±2°C.

13.1.2 Round bar or bent plate: diameter is 10mm, 20mm, 30mm.

13.2 Test steps

13.2.1 Without treatment

Cut the coating film, according to the requirements in Table 2, into three (100×25)mm

test pieces for testing. Put the test piece and the bent plate or round bar into the freezing

liquid of the low temperature freezer that has been adjusted to the specified temperature.

The thermometer probe shall be at the same level as the test piece. Keep at the specified

temperature for 1h. Then the test piece is bent 180° around a round rod or a bent plate

in 3s in the freezing liquid. Bend three test pieces (without distinction between upper

and lower surfaces). Immediately take out the test pieces. Observe with the naked eye

whether there are cracks or breaks on the surface of the test piece.

13.2.2 Heat treatment

Cut the coating film, according to the requirements in Table 2, into three (100×25)mm

rectangular test pieces. Place them on the isolation material. Put them horizontally into

an electric blast oven that has reached the specified temperature. The heating

temperature for bituminous coatings is (70±2)°C. The heating temperature for other

coatings is (80±2)°C. The distance between the test piece and the box wall shall not be

less than 50mm. The test piece shall be at the same level as the probe of the thermometer.

Keep the constant temperature (168±1)h in the electric blast oven at the specified

temperature and take out. Then place under standard test conditions for 4h. Test

according to 13.2.1.

13.2.3 Alkali treatment

At (23±2)°C, in 0.1% chemically pure NaOH solution, add Ca(OH)2 reagent, and reach

supersaturated state.

Put three (100×25)mm test pieces cut according to Table 2 into 400mL of this solution.

The liquid level shall be more than 10mm above the surface of the test piece. After

continuous soaking (168±1)h, take out. Rinse well with water. Wipe dry. Place under

standard test conditions for 4h. Test according to 13.2.1.

For water-based coating, soak, take out and wipe dry. Then place it in an electric blast

oven at (60±2)°C for 6h±15min. Take it out and place it under standard test conditions

for (18±2)h. Test accordin...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 16777-2008 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 16777-2008

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 16777-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 91.120.30

Q 17

Replacing GB/T 16777-1997

Test methods for building waterproofing coatings

ISSUED ON: JUNE 30, 2008

IMPLEMENTED ON: APRIL 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Standard test conditions ... 5

4 Coating film preparation ... 6

5 Solid content ... 8

6 Heat resistance ... 9

7 Bond strength ... 10

8 Bond strength on wet substrate ... 16

9 Tensile properties ... 17

10 Tear strength ... 21

11 Aging at elongation ... 22

12 Heating stretch rate ... 23

13 Low temperature flexibility ... 25

14 Low temperature bendability ... 27

15 Impermeability ... 29

16 Drying time ... 30

Test methods for building waterproofing coatings

1 Scope

This document specifies the standard test conditions, coating film preparation, solid

content, heat resistance, bond strength, bond strength of wet substrate, tensile properties,

tear strength, aging at constant elongation, heating expansion rate of architectural

waterproof coatings , low temperature flexibility, impermeability, drying time and other

performance test methods.

This Standard applies to building waterproof coatings.

2 Normative references

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments (excluding

corrigendum) or revisions do not apply to this Standard, however, parties who reach an

agreement based on this Standard are encouraged to study if the latest versions of these

documents are applicable. For undated references, the latest edition of the referenced

document applies.

GB/T 328.10-2007, Test methods for building sheets for waterproofing - Part 10:

Bitumen, plastic and rubber sheets for waterproofing - Water tightness

GB/T 528, Rubber, vulcanized or thermoplastic - Determination of tensile stress-

strain properties (GB/T 528-1998, ISO 37:1994 eqv)

GB/T 529-1999, Rubber, vulcanized or thermoplastic - Determination of tear

strength (Trouser, angle and crescent test pieces) (ISO 34-1:1994 eqv)

GB/T 18244, Test methods for weathering resistance of building waterproof

materials

3 Standard test conditions

Laboratory standard test conditions: temperature is (23±2)℃; relative humidity is

(50±10)%.

Strict conditions: temperature is (23±2)℃; relative humidity is (50±5)%.

6.2 Test steps

After stirring the sample evenly, apply the sample in 2~3 times according to the

requirements of the manufacturer (the interval between each time shall not exceed 24h)

on the cleaned aluminum plate. The coating area is 100mm×50mm. The total thickness

is 1.5mm. Scrape the surface one last time. Carry out maintenance according to the

conditions in Table 1. Demolding is not required. Then hang the aluminum plate

vertically in an electric blast drying oven that has been adjusted to the specified

temperature. The distance between the test piece and the wall of the drying box is not

less than 50mm. The center of the test piece shall be at the same position as the probe

of the thermometer. After standing at the specified temperature for 5h, take it out.

Observe surface phenomena. Test 3 test pieces in total.

6.3 Result evaluation

After the test, all test pieces shall not flow, slide, or drip. There are no dense bubbles on

the surface of the test piece.

6.4 Test report

The test report shall contain the following information:

a) Chapter numbers of this Standard;

b) Determination of all necessary details of the test product;

c) Information about preparation of test piece;

d) Test temperature and time;

e) Test results;

f) Differences in methods used or abnormalities encountered during the test;

g) Test date.

7 Bond strength

7.1 Method A

7.1.1 Test apparatus

7.1.1.1 Tensile testing machine: the measured value is between (15-85)% of the range;

the indication accuracy is not less than 1%; the tensile speed is (5±1)mm/min.

7.1.1.2 Electric blast oven: temperature control accuracy is ±2℃.

7.1.1.3 Special metal clamps for stretching: upper clamps, lower clamps and backing

the prepared coating to the section of the mortar block. Conduct butt joint of the cross

sections of the two mortar blocks. Press them tightly. The thickness of the coating

between the mortar blocks shall not exceed 0.5mm. Place under standard test conditions

for 4h. Cure the prepared test pieces. The condition is at the temperature of (20±1)℃.

The relative humidity is not less than 90%. Cure for 168h. Prepare five test pieces.

Place the cured test pieces under standard test conditions for 2h. Install the test piece

on the testing machine. Keep the center line of the vertical direction of the test piece

surface and the center of the fixture of the testing machine on the same line. Stretch at

a speed of (5±1)mm/min until the test piece fails. Record the maximum tensile force of

the test piece. The test temperature is (23±2)°C.

Result calculation and test report are according to Chapter 7.

9 Tensile properties

9.1 Test apparatus

9.1.1 Tensile testing machine: the measured value is between (15~85)% of the

measuring range; the indication accuracy is not less than 1%; the elongation range is

greater than 500mm.

9.1.2 Electric blast drying oven: temperature control accuracy is ±2℃.

9.1.3 Punching machine and dumbbell type I cutter that meets the requirements of GB/T

528.

9.1.4 Ultraviolet box: 500W straight tube mercury lamp. The lamp tube is parallel to

the bottom of the box. The distance from the surface of the test piece is (47~50)cm.

9.1.5 Thickness gauge: the contact surface diameter is 6mm; the pressure per unit area

is 0.02MPa; the division value is 0.01mm.

9.1.6 Xenon arc lamp aging test chamber: a xenon arc lamp aging test chamber that

meets the requirements of GB/T 18244.

9.2 Test steps

9.2.1 Untreated tensile properties

According to the requirements of Table 2, cut out the coating film into the dumbbell

type I test piece that meets the requirements of GB/T 528. Draw parallel marking lines

at a distance of 25mm. Use a thickness gauge to measure the thickness of three points

in the middle and both ends of the marked line of the test piece. Take its arithmetic

mean value as the thickness of the test piece. Adjust the distance between the clamps of

the tensile testing machine to about 70mm. Clamp the test piece on the testing machine.

GB/T 528. Carry out the tensile test according to 9.2.1.

For water-based coatings, after soaking, take them out and wipe them dry. Then place

them in an electric blast oven at (60±2)°C for 6h±15min. Take out and place under

standard test conditions for (18±2)h. Cut out the dumbbell type I test piece that meets

the requirements of GB/T 528. Carry out the tensile test according to 9.2.1.

9.2.5 Tensile properties after UV treatment

Place six (120×25mm rectangular test pieces) cut according to Table 2 flat on the glazed

tile. To prevent sticking, talcum powder can be sprinkled on the surface of the glazed

tile. Put the test piece into the UV box. The temperature of the space about 50mm away

from the surface of the test piece is (45±2)℃. Conduct constant temperature irradiation

for 240h. Take out and place under standard test conditions for 4h. Cut out the dumbbell

type I test piece that meets the requirements of GB/T 528. Carry out the tensile test

according to 9.2.1.

9.2.6 Tensile properties of artificially weathered materials

Place six (120×25)mm rectangular specimens cut according to Table 2 in a xenon arc

lamp aging test chamber that meets the requirements of GB/T 18244. Take out after the

cumulative irradiation energy of the test is 1500 MJ2/m2 (about 720h). Wipe dry. Place

under standard test conditions for 4h. Cut out dumbbell type I test pieces that meet the

requirements of GB/T 528. Carry out the tensile test according to 9.2.1.

For water-based coating, take out and wipe dry. Then place in an electric blast oven at

(60±2)°C for 6h±15min. Take out and place under standard test conditions for (18±2)h.

Cut out the dumbbell type I test piece that meets the requirements of GB/T 528. Carry

out the tensile test according to 9.2.1.

9.3 Result calculation

9.3.1 Tensile strength

The tensile strength of the test piece is calculated according to formula (3):

Where,

TL - The tensile strength, in megapascals (MPa);

P - The maximum pulling force, in Newtons (N);

B - The width of the middle part of the test piece, in millimeters (mm);

D - The thickness of the test piece, in millimeters (mm).

e) Tensile speed;

f) Test results;

g) Differences in methods used or abnormalities encountered during the test;

h) Test date.

10 Tear strength

10.1 Test apparatus

10.1.1 Tensile testing machine: the measured value is between (15~85)% of the

measuring range; the indication accuracy is not less than 1%; the elongation range is

greater than 500mm.

10.1.2 Electric blast drying oven: temperature control accuracy is ±2℃.

10.1.3 Punching machine and right-angle tearing cutter that meets the requirements in

5.1.2 of GB/T 529-1999.

10.1.4 Thickness gauge: the contact surface diameter is 6mm; the pressure per unit area

is 0.02MPa; the division value is 0.01mm.

10.2 Test steps

Cut the coating film, according to the requirements in Table 2, into right-angle tear test

pieces without a cut that meet the requirements of GB/T 529-1999. Use a thickness

gauge to measure the thickness of three points in the right-angle tear area of the test

piece. Take the arithmetic mean value as the thickness of the test piece. Clamp the test

piece on the testing machine. Keep the centerline of the length direction of the test piece

on the same line as the center of the fixture of the testing machine. Stretch to break

according to the tensile speed in Table 4. Record the maximum load when the test piece

breaks (P). Test five test pieces.

10.3 Result calculation

The tear strength of the test piece is calculated according to formula (6):

Where,

Ts - The tear strength, in kilonewtons per meter (kN/m);

P - The maximum pulling force, in Newtons (N);

d - The thickness of the test piece, in millimeters (mm).

Take the arithmetic mean value of five test pieces as the test result. The result is accurate

to 0.1kN/m.

10.4 Test report

The test report shall contain the following information:

a) Chapter numbers of this Standard;

b) Determination of all necessary details of the test product;

c) Information about preparation of test piece;

d) Tensile speed;

e) Test results;

f) Differences in methods used or abnormalities encountered during the test;

g) Test date.

11 Aging at elongation

11.1 Test apparatus

11.1.1 Electric blast drying oven: temperature control accuracy is ±2℃.

11.1.2 Xenon arc lamp aging test chamber: a xenon arc lamp aging test chamber that

meets the requirements of GB/T 18244.

11.1.3 Punching machine and dumbbell type I cutter that meets the requirements of

GB/T 528.

11.1.4 Constant extension retainer: it can stretch the distance between marking lines by

more than 100%.

11.2 Test steps

11.2.1 Heat aging

Cut the coating film, according to the requirements in Table 2, into dumbbell type I test

pieces that meet the requirements of GB/T 528. Draw parallel marking lines at a

distance of 25mm. Stretch the distance between the marking lines of the test piece from

25mm to 50mm. Place for 24hs under standard test conditions. Then put the constant

13 Low temperature flexibility

13.1 Test apparatus

13.1.1 Low-temperature freezer: temperature control accuracy is ±2°C.

13.1.2 Round bar or bent plate: diameter is 10mm, 20mm, 30mm.

13.2 Test steps

13.2.1 Without treatment

Cut the coating film, according to the requirements in Table 2, into three (100×25)mm

test pieces for testing. Put the test piece and the bent plate or round bar into the freezing

liquid of the low temperature freezer that has been adjusted to the specified temperature.

The thermometer probe shall be at the same level as the test piece. Keep at the specified

temperature for 1h. Then the test piece is bent 180° around a round rod or a bent plate

in 3s in the freezing liquid. Bend three test pieces (without distinction between upper

and lower surfaces). Immediately take out the test pieces. Observe with the naked eye

whether there are cracks or breaks on the surface of the test piece.

13.2.2 Heat treatment

Cut the coating film, according to the requirements in Table 2, into three (100×25)mm

rectangular test pieces. Place them on the isolation material. Put them horizontally into

an electric blast oven that has reached the specified temperature. The heating

temperature for bituminous coatings is (70±2)°C. The heating temperature for other

coatings is (80±2)°C. The distance between the test piece and the box wall shall not be

less than 50mm. The test piece shall be at the same level as the probe of the thermometer.

Keep the constant temperature (168±1)h in the electric blast oven at the specified

temperature and take out. Then place under standard test conditions for 4h. Test

according to 13.2.1.

13.2.3 Alkali treatment

At (23±2)°C, in 0.1% chemically pure NaOH solution, add Ca(OH)2 reagent, and reach

supersaturated state.

Put three (100×25)mm test pieces cut according to Table 2 into 400mL of this solution.

The liquid level shall be more than 10mm above the surface of the test piece. After

continuous soaking (168±1)h, take out. Rinse well with water. Wipe dry. Place under

standard test conditions for 4h. Test according to 13.2.1.

For water-based coating, soak, take out and wipe dry. Then place it in an electric blast

oven at (60±2)°C for 6h±15min. Take it out and place it under standard test conditions

for (18±2)h. Test accordin...

Share