1

/

of

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 1689-2014 English PDF (GBT1689-2014)

GB/T 1689-2014 English PDF (GBT1689-2014)

Regular price

$70.00 USD

Regular price

Sale price

$70.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 1689-2014

Historical versions: GB/T 1689-2014

Preview True-PDF (Reload/Scroll if blank)

GB/T 1689-2014: Rubber vulcanized -- Determination of abrasion resistance (Akron machine)

GB/T 1689-2014

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.060

G 40

Partially replacing GB/T 1689-1998

Rubber vulcanized - Determination of abrasion

resistance (Akron machine)

ISSUED ON: SEPTEMBER 22, 2014

IMPLEMENTED ON: JUNE 01, 2015

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Principle ... 5

4 Instruments ... 5

5 Instrument calibration ... 6

6 Specimen ... 6

7 Environment conditioning ... 7

8 Procedures ... 7

9 Test results ... 7

10 Test report ... 8

Appendix A (Normative) Standard rubber formula ... 9

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces GB/T 1689-1998 Rubber vulcanized - Determination of

abrasion resistance (Akron machine). As compared with GB/T 1689-1998, the

main technical changes are as follows:

- DELETE the age number of the normative references (see Chapter 2;

Chapter 2 of the 1998 edition);

- DELETE the normative reference GB/T 9865.1-1996 (see Chapter 2 of the

1998 edition);

- ADD relevant content in the principle (see Chapter 3);

- ADD Akron machine (see 4.1);

- ADD content related to the balance (see 4.2);

- ADD recommendations for regular calibration of grinding wheels (see note

in Chapter 5);

- ADD the use of different sample preparation methods (see note in Chapter

6);

- CORRECT the unit of density in the calculation formula (see 9.1; 9.1 of

1998 edition).

This standard was proposed by the China Petroleum and Chemical Industry

Federation.

This standard shall be under the jurisdiction of the National Rubber and Rubber

Product Standardization Technical Committee General Test Method

Subcommittee (SAC/TC 35/SC 2).

Drafting organizations of this standard: Zhongce Rubber Group Co., Ltd.,

Triangle Tire Co., Ltd., Fengshen Tire Co., Ltd., Qingdao Rubber Conveyor Belt

Co., Ltd., Qingdao Yikesi New Materials Co., Ltd., Shandong Bayi Tire

Manufacturing Co., Ltd., Qingdao Double Star Group Technology Development

Center, Beijing Rubber Industry Research and Design Institute, Guizhou Tire

Co., Ltd., Jiangsu Xinzhengwei Testing Machinery Co., Ltd., Jiangsu Mingzhu

Testing Machinery Co., Ltd.

The main drafters of this standard: Xiang Chan, Xu Qiuhuan, Yan Fujiang, Ren

Shaowen, Liu Yuwan, Zhang Feng, Yao Feng, Lin Qingju, Wang Daiqiang, Liu

Qiang, Zhao Jianlin, Sha Shufen, Xie Junfang, Li Jing, Feng Ping, Shen Kehui,

Rubber vulcanized - Determination of abrasion

resistance (Akron machine)

1 Scope

This standard specifies the method for determining the abrasion resistance of

vulcanized rubber.

This standard is applicable to the determination of the abrasion resistance of

vulcanized rubber by the Akron machine.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest version (including all amendments) applies to

this document.

GB/T 533 Rubber vulcanized or thermoplastic - Determination of density

(GB/T 533-2008, ISO 2781:2007, IDT)

GB/T 2941 Rubber - General procedures for preparing and conditioning test

pieces for physical test methods (GB/T 2941-2006, ISO 23529:2004, IDT)

3 Principle

In this test, the specimen and the grinding wheel are rubbed under a certain

inclination angle and a certain load, to determine the wear volume or wear index

of a certain mileage of the specimen.

4 Instruments

4.1 Akron machine

4.1.1 The rotation speed of the rubber wheel shaft is 76 r/min ± 2 r/min. The

rotation speed of the grinding wheel shaft is 34 r/min ± 1 r/min.

4.1.2 When the angle between the rubber wheel shaft and the grinding wheel

shaft is zero degrees, the two shafts shall remain parallel and horizontal.

is the circumference ratio.

6.2 The surface of the specimen shall be flat and shall be free from cracks and

impurities.

6.3 After the two sides of the specimen are polished, they are glued to the

rubber wheel. The specimen shall not be subjected to tension when bonding.

The joint shall be smoothly transitioned during binding. The bonded sample

wheel shall be conditioned for at least 16 h.

6.4 The rubber wheel has a diameter of 68 mm, a thickness of 12.7 mm ±

0.2 mm, a hardness of 75 to 80 degrees (Shore A). The diameter of the center

hole shall correspond to the diameter of the rotary shaft of the rubber wheel.

Note: The sample preparation method of vulcanizing the rubber to be tested or

directly vulcanizing the rubber to be tested on the metal mold wheel can also

be used. The test results obtained by different sample preparation methods are

not comparable and shall be noted in the test report.

7 Environment conditioning

The environment conditioning of the sample shall be carried out in accordance

with the provisions of GB/T 2941.

8 Procedures

8.1 Fix the glued specimen wheel on the rubber wheel shaft and start the motor

to rotate the specimen clockwise.

8.2 Pre-grind the specimen for 15 min ~ 20 min, remove the rubber scraps and

weigh the mass, accurate to 0.001 g.

8.3 Use pre-ground specimen for testing. After the specimen runs for 1.61 km,

turn off the motor, remove the specimen, brush off the chips, weigh it within 1

h, accurate to 0.001 g.

8.4 Determine the density of the specimen according to GB/T 533.

9 Test results

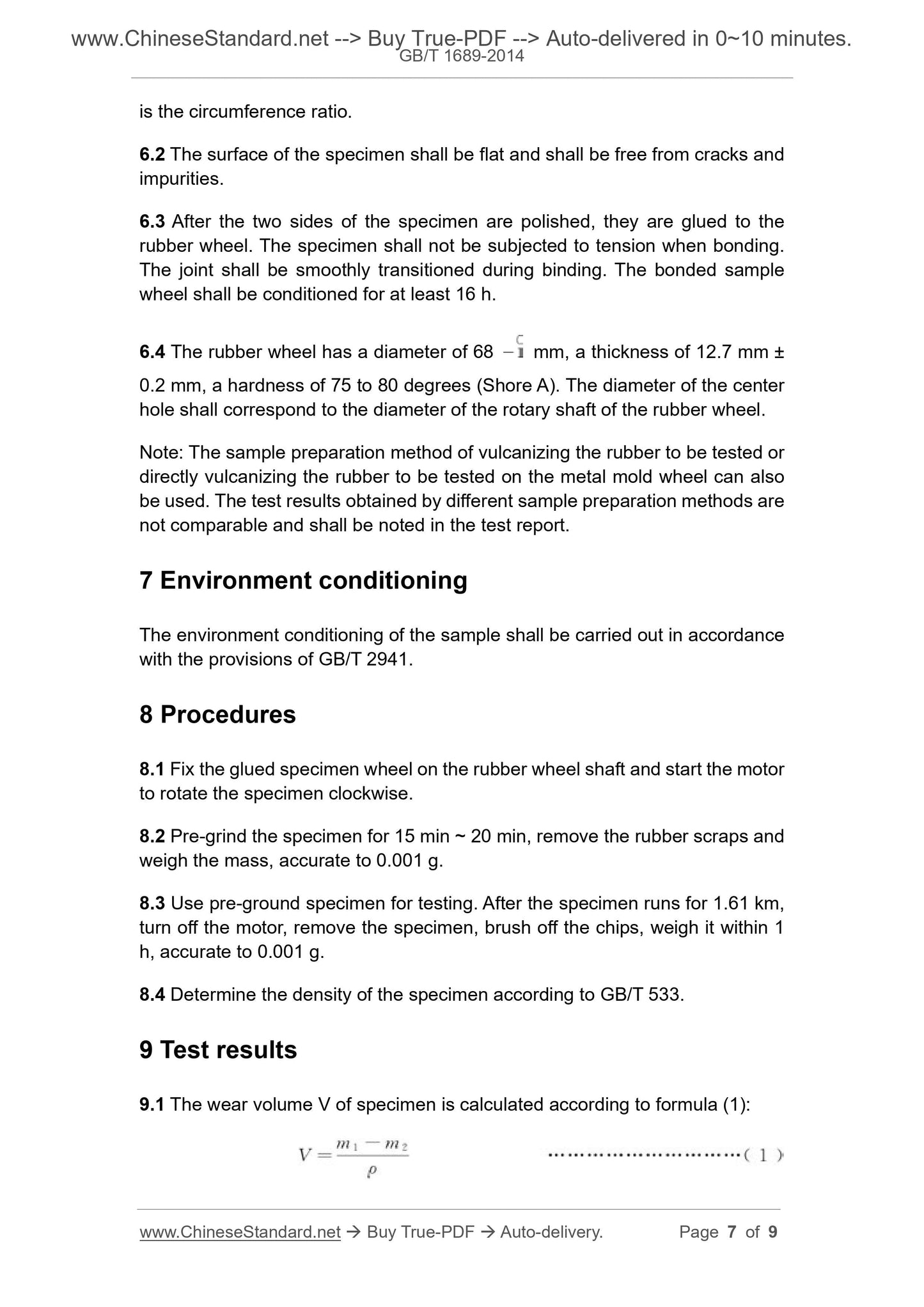

9.1 The wear volume V of specimen is calculated according to formula (1):

Get QUOTATION in 1-minute: Click GB/T 1689-2014

Historical versions: GB/T 1689-2014

Preview True-PDF (Reload/Scroll if blank)

GB/T 1689-2014: Rubber vulcanized -- Determination of abrasion resistance (Akron machine)

GB/T 1689-2014

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.060

G 40

Partially replacing GB/T 1689-1998

Rubber vulcanized - Determination of abrasion

resistance (Akron machine)

ISSUED ON: SEPTEMBER 22, 2014

IMPLEMENTED ON: JUNE 01, 2015

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Principle ... 5

4 Instruments ... 5

5 Instrument calibration ... 6

6 Specimen ... 6

7 Environment conditioning ... 7

8 Procedures ... 7

9 Test results ... 7

10 Test report ... 8

Appendix A (Normative) Standard rubber formula ... 9

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces GB/T 1689-1998 Rubber vulcanized - Determination of

abrasion resistance (Akron machine). As compared with GB/T 1689-1998, the

main technical changes are as follows:

- DELETE the age number of the normative references (see Chapter 2;

Chapter 2 of the 1998 edition);

- DELETE the normative reference GB/T 9865.1-1996 (see Chapter 2 of the

1998 edition);

- ADD relevant content in the principle (see Chapter 3);

- ADD Akron machine (see 4.1);

- ADD content related to the balance (see 4.2);

- ADD recommendations for regular calibration of grinding wheels (see note

in Chapter 5);

- ADD the use of different sample preparation methods (see note in Chapter

6);

- CORRECT the unit of density in the calculation formula (see 9.1; 9.1 of

1998 edition).

This standard was proposed by the China Petroleum and Chemical Industry

Federation.

This standard shall be under the jurisdiction of the National Rubber and Rubber

Product Standardization Technical Committee General Test Method

Subcommittee (SAC/TC 35/SC 2).

Drafting organizations of this standard: Zhongce Rubber Group Co., Ltd.,

Triangle Tire Co., Ltd., Fengshen Tire Co., Ltd., Qingdao Rubber Conveyor Belt

Co., Ltd., Qingdao Yikesi New Materials Co., Ltd., Shandong Bayi Tire

Manufacturing Co., Ltd., Qingdao Double Star Group Technology Development

Center, Beijing Rubber Industry Research and Design Institute, Guizhou Tire

Co., Ltd., Jiangsu Xinzhengwei Testing Machinery Co., Ltd., Jiangsu Mingzhu

Testing Machinery Co., Ltd.

The main drafters of this standard: Xiang Chan, Xu Qiuhuan, Yan Fujiang, Ren

Shaowen, Liu Yuwan, Zhang Feng, Yao Feng, Lin Qingju, Wang Daiqiang, Liu

Qiang, Zhao Jianlin, Sha Shufen, Xie Junfang, Li Jing, Feng Ping, Shen Kehui,

Rubber vulcanized - Determination of abrasion

resistance (Akron machine)

1 Scope

This standard specifies the method for determining the abrasion resistance of

vulcanized rubber.

This standard is applicable to the determination of the abrasion resistance of

vulcanized rubber by the Akron machine.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest version (including all amendments) applies to

this document.

GB/T 533 Rubber vulcanized or thermoplastic - Determination of density

(GB/T 533-2008, ISO 2781:2007, IDT)

GB/T 2941 Rubber - General procedures for preparing and conditioning test

pieces for physical test methods (GB/T 2941-2006, ISO 23529:2004, IDT)

3 Principle

In this test, the specimen and the grinding wheel are rubbed under a certain

inclination angle and a certain load, to determine the wear volume or wear index

of a certain mileage of the specimen.

4 Instruments

4.1 Akron machine

4.1.1 The rotation speed of the rubber wheel shaft is 76 r/min ± 2 r/min. The

rotation speed of the grinding wheel shaft is 34 r/min ± 1 r/min.

4.1.2 When the angle between the rubber wheel shaft and the grinding wheel

shaft is zero degrees, the two shafts shall remain parallel and horizontal.

is the circumference ratio.

6.2 The surface of the specimen shall be flat and shall be free from cracks and

impurities.

6.3 After the two sides of the specimen are polished, they are glued to the

rubber wheel. The specimen shall not be subjected to tension when bonding.

The joint shall be smoothly transitioned during binding. The bonded sample

wheel shall be conditioned for at least 16 h.

6.4 The rubber wheel has a diameter of 68 mm, a thickness of 12.7 mm ±

0.2 mm, a hardness of 75 to 80 degrees (Shore A). The diameter of the center

hole shall correspond to the diameter of the rotary shaft of the rubber wheel.

Note: The sample preparation method of vulcanizing the rubber to be tested or

directly vulcanizing the rubber to be tested on the metal mold wheel can also

be used. The test results obtained by different sample preparation methods are

not comparable and shall be noted in the test report.

7 Environment conditioning

The environment conditioning of the sample shall be carried out in accordance

with the provisions of GB/T 2941.

8 Procedures

8.1 Fix the glued specimen wheel on the rubber wheel shaft and start the motor

to rotate the specimen clockwise.

8.2 Pre-grind the specimen for 15 min ~ 20 min, remove the rubber scraps and

weigh the mass, accurate to 0.001 g.

8.3 Use pre-ground specimen for testing. After the specimen runs for 1.61 km,

turn off the motor, remove the specimen, brush off the chips, weigh it within 1

h, accurate to 0.001 g.

8.4 Determine the density of the specimen according to GB/T 533.

9 Test results

9.1 The wear volume V of specimen is calculated according to formula (1):

Share