1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 17394.3-2022 English PDF (GB/T17394.3-2022)

GB/T 17394.3-2022 English PDF (GB/T17394.3-2022)

Regular price

$380.00

Regular price

Sale price

$380.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 17394.3-2022: Metallic materials - Leeb hardness test - Part 3: Calibration of reference test blocks

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 17394.3-2022 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 17394.3-2022

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 17394.3-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 19.060; 77.040.10

CCS N 71

Replacing GB/T 17394.3-2012

Metallic Materials – Leeb Hardness Test – Part 3:

Calibration of Reference Test Blocks

(ISO 16859-3:2015, MOD)

ISSUED ON: JULY 11, 2022

IMPLEMENTED ON: FEBRUARY 01, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative References ... 6

3 Terms and Definitions ... 6

4 Manufacture of Reference Test Blocks ... 7

5 Calibration Machine ... 7

5.1 General ... 7

5.2 Traceability ... 8

5.3 Requirements on calibration machines ... 8

5.4 Calibration of calibration machines ... 8

6 Calibration Method ... 10

7 Number of Test Indentations ... 10

8 Uniformity of Hardness ... 11

9 Marking ... 12

10 Validity ... 13

Annex A (Informative) Examples of reference Test Block ... 14

Annex B (Normative) Requirements for Leeb Hardness Calibration Machines ... 15

Annex C (Informative) Measurement Uncertainty of Hardness Value of Standard Block

... 16

Annex D (Normative) Method for Calibrating Standard Block Using Standard Machine

Based on Non-Leeb Hardness Test Principle ... 20

Annex E (Informative) Conversion Table of Vickers Hardness Value/Brinell Hardness

Value and Leeb Hardness Value Calibrated by the Standard Block ... 26

Bibliography ... 32

Foreword

This Document was drafted as per the rules specified in GB/T 1.1-2020 Directives for

Standardization – Part 1: Rules for the Structure and Drafting of Standardizing Documents.

This Document is Part 3 of GB/T 17394 Metallic Materials – Leeb Hardness Test. GB/T 17394

consists of the following parts:

--- Part 1: Test Method;

--- Part 2: Verification and Calibration of Hardness Tester;

--- Part 3: Calibration of Reference Blocks;

--- Part 4: Tables of Hardness Values Conversation.

This Document replaced GB/T 17394.3-2012 Metallic Materials – Leeb Hardness Test – Part

3: Calibration of Reference Blocks. Compared with GB/T 173294.3-2012, the major technical

changes are as follows:

--- Modify the calculation formula and technical indicators of the hardness range and

hardness uniformity of standard Leeb hardness blocks (see 4.2, 8.2 of this Edition; 3.3

and 7.1 of the 2012 Edition);

--- Modify the technical indicators, such as geometric dimensions, flatness, parallelism and

surface roughness of standard Leeb hardness block; and add minimum quality

requirements (see 4.3, 4.5 and 4.6 of this Edition; 3.2, 3.3 and 7.1 of the 2012 Edition);

--- Modify the requirements for the standard machine used to calibrate standard Leeb

hardness blocks (see Clause 5 and Annex B of this Edition; Clause 4 of the 2012 Edition);

--- Modify the requirements for calibration method, number of indentations and validity (see

Clauses 6, 7, and 10 of this Edition; Clauses 5, 6, and 9 of the 2012 Edition);

--- Modify the geometric dimensions and technical requirements of the standard block; and

change it to an informative annex (see Annex A of this Edition; 3.2 of the 2012 Edition);

--- Add the requirements for standard machine performance parameters based on the

principle of Leeb hardness speed measurement (see Annex B of this Edition);

--- Modify the measurement uncertainty of the hardness value of the standard block (see

Annex C of this Edition; Annex A of the 2012 Edition);

--- Add the method of calibrating the standard block using a standard machine based on the

non-Leeb hardness test principle (see Annex D of this Edition).

This Document modifies and adopts ISO 16895-3:2015 Metallic Materials – Leeb Hardness

Test – Part 3: Calibration of Reference Test Blocks.

Compared with ISO 16895-3:2015, this Document has the following technical differences; the

terms to which these differences relate are indicated by a single vertical line (│) in their outer

margins. The specific technical differences and their causes are as follows:

--- Replace ISO16859-1:2015 with GB/T 17394.1 (see Clause 1, 6.1);

--- Replace ISO 16859-2:2015 with GB/T 17394.2-2022 that adopts the revises international

standard (see Clause 1, 5.1);

--- Replace ISO/IEC 17025:2005 with GB/T 27025-2008 that adopts the revises

international standard (see 5.2.1);

--- Replace the example of the standard block listed in Annex C of ISO16859-3:2015 by the

conventional standard block of China (see Annex A);

--- Add Annex D (normative) "Conversion Table between Vickers Hardness Value/Brinell

Hardness Value and Leeb Hardness Value Calibrated by Standard Block".

Please note some contents of this Document may involve patents. The issuing agency of this

Document shall not assume the responsibility to identify these patents.

This Document was proposed by China Machinery Industry Federation.

This Document shall be under the jurisdiction of National Technical Committee on Tester of

Standardization Administration of China (SAC/TC 122).

Drafting organizations of this Document: Quanzhou Fengze Donghai Instrument Hardness

Block Factory; AVIC Changcheng Institute of Metrology and Measurement; Sinotest Equipment

Co., Ltd.; Beijing Times Peak Technology Co., Ltd.; Shenyang TX Testing Instrument Co., Ltd.;

Laizhou Huayin Testing Instrument Co., Ltd.; and Metrology and Measurement Institute of

Hubei Space Academy.

Chief drafting staffs of this Document: Chen Junxin, Shi Wei, Zhang Jinwei, Zhou Cheng,

Zhang Luming, Wang Jingtao, and Huang Yongchang.

The historical editions replaced by this Document are as follows:

--- GB/T 17394.3-2012 was first-time published in 2012;

--- It is the first-time revised.

Metallic Materials – Leeb Hardness Test – Part 3:

Calibration of Reference Test Blocks

1 Scope

This Document specifies a method for the calibration of Leeb hardness standard blocks that are

used for the indirect verification of Leeb hardness testers according to GB/T 17394.2 and for

the periodic checking according to GB/T 17394.1.

This Document is applicable to the calibration of Leeb hardness standard block (hereinafter

referred to as reference block).

2 Normative References

The provisions in following documents become the essential provisions of this Document

through reference in this Document. For the dated documents, only the versions with the dates

indicated are applicable to this Document; for the undated documents, only the latest version

(including all the amendments) is applicable to this Document.

GB/T 231.3-2012 Metallic materials - Brinell hardness test - Part 3: Calibration of

reference blocks (ISO 6506-3:2005, MOD)

GB/T 4340.3-2012 Metallic Vickers hardness test - Part 3: Calibration of hardness (ISO

6507-3:2005, MOD)

GB/T 17394.1 Metallic materials - Leeb hardness test - Part 1: Test method

GB/T 17394.2-2022 Metallic materials - Leeb hardness test - Part 2: Verification and

calibration of hardness testers (ISO 16859-2:2015, MOD)

GB/T 27025 General requirements for the competence of testing and calibration

laboratories (GB/T 27025-2008, ISO/IEC 17025:2005, IDT)

3 Terms and Definitions

For the purposes of this Document, there are no terms and definitions apply.

5.2 Traceability

5.2.1 Leeb primary hardness standard machines owned by national level institutions are used

to calibrate primary reference test blocks in Leeb hardness for accredited Leeb hardness

calibration laboratories according to GB/T 27025.

5.2.2 The instruments used for the verification and calibration of the Leeb hardness calibration

machine shall be traceable to national standards.

NOTE: The structure diagram of the three-level metrology chain required to define and reproduce the

hardness value of each scale of Leeb hardness is shown in Figure C.1 of GB/T 17394.1-2014. The

measurement chain of the Leeb hardness value is obtained by the Leeb method defined in this figure.

5.3 Requirements on calibration machines

5.3.1 Requirements on Leeb hardness calibration machines are given in Annex B.

5.3.2 The resolution of Leeb hardness calibration machines shall be equal to or better than 1.0

HL.

5.3.3 Measuring instruments such as the standard Vickers hardness machine and the standard

Brinell hardness machine that use the indirect method to calibrate the Leeb standard block shall

be traceable to the national standard.

5.4 Calibration of calibration machines

5.4.1 Leeb hardness calibration machines shall be calibrated at an interval of < 12 months.

5.4.2 Leeb hardness calibration machines shall comply with the requirements defined in Annex

B.

5.4.3 After direct calibration, the standard machine shall be calibrated indirectly using at least

three reference blocks covering the full range of the Leeb hardness scale specified in Table 2.

The Leeb hardness range, minimum repeatability and limit error of the calibration machine are

shown in Table 2.

Indirect calibration comprises at least 10 readings on each reference test block.

Annex C

(Informative)

Measurement Uncertainty of Hardness Value of Standard Block

NOTE: The measurement chain diagram for defining and reproducing the hardness value of each scale

of Leeb hardness is shown in GB/T 17394.1.

C.1 Direct inspection and calibration of standard Leeb hardness machines

C.1.1 Testing of geometrical parameters of impact body and support ring

C.1.1.1 The geometrical parameters of impact body shall be tested according to 5.3.1 and 5.3.3

in GB/T 17394.2-2022.

C.1.1.2 The geometrical parameters of support ring shall be tested according to 5.5 in GB/T

17394.2-2022.

C.1.2 Testing of signal of electronic unit

The signal of electronic unit shall be tested according to 5.3.2 of GB/T 17394.2-2022.

C.2 Indirect inspection and calibration of standard Leeb hardness machine

NOTE: In this annex, the standard block is referred to as "Certified Reference Material (CRM)".

The comprehensive performance of the standard machine can be tested by indirect inspection

of the standard Leeb hardness machine by using the reference Leeb hardness block. Moreover,

indirect inspection can also be used to measure the repeatability and indication error of the

hardness indication displayed by the standard machine.

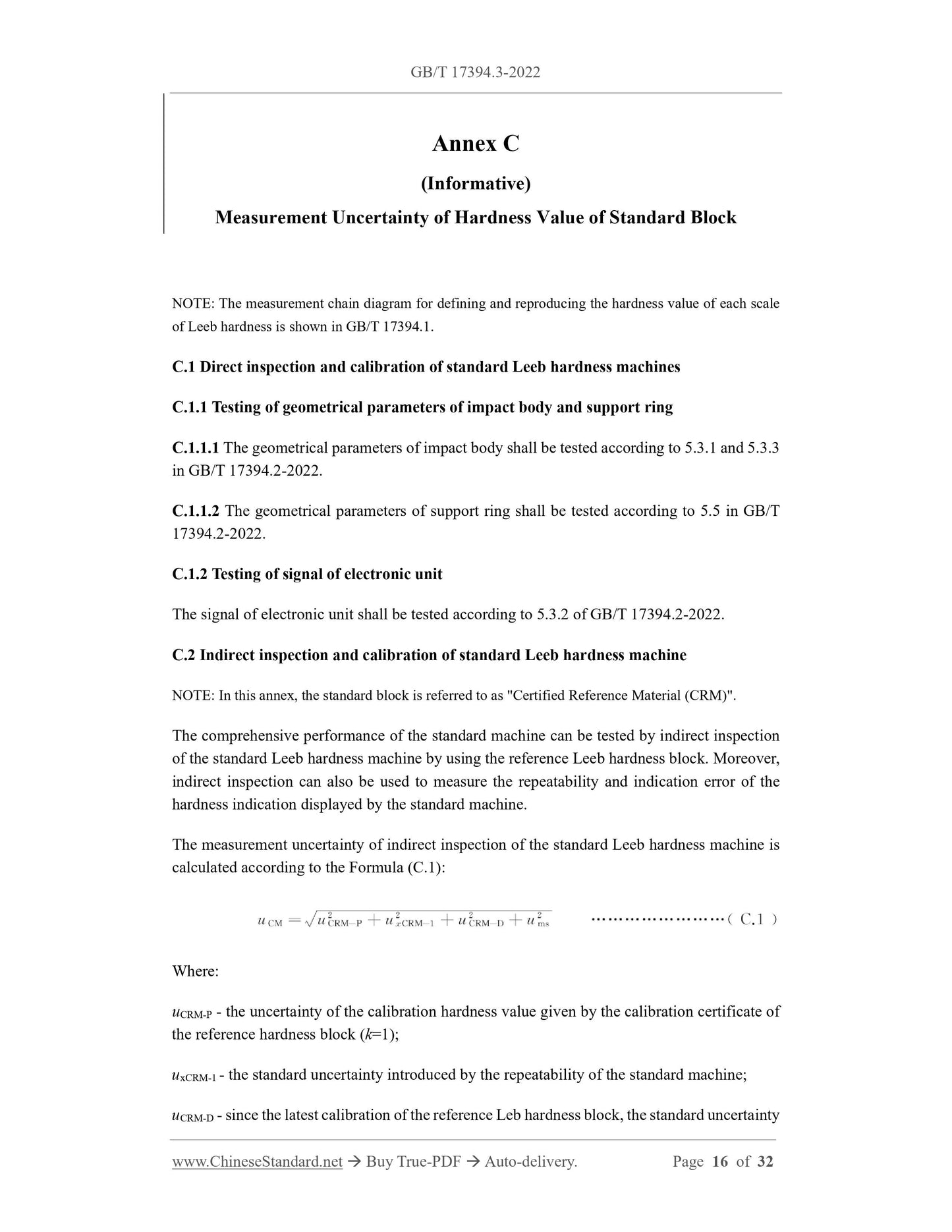

The measurement uncertainty of indirect inspection of the standard Leeb hardness machine is

calculated according to the Formula (C.1):

Where:

uCRM-P - the uncertainty of the calibration hardness value given by the calibration certificate of

the reference hardness block (k=1);

uxCRM-1 - the standard uncertainty introduced by the repeatability of the standard machine;

uCRM-D - since the latest calibration of the reference Leb hardness block, the standard uncertainty

GB/T 17394.3-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 19.060; 77.040.10

CCS N 71

Replacing GB/T 17394.3-2012

Metallic Materials – Leeb Hardness Test – Part 3:

Calibration of Reference Test Blocks

(ISO 16859-3:2015, MOD)

ISSUED ON: JULY 11, 2022

IMPLEMENTED ON: FEBRUARY 01, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative References ... 6

3 Terms and Definitions ... 6

4 Manufacture of Reference Test Blocks ... 7

5 Calibration Machine ... 7

5.1 General ... 7

5.2 Traceability ... 8

5.3 Requirements on calibration machines ... 8

5.4 Calibration of calibration machines ... 8

6 Calibration Method ... 10

7 Number of Test Indentations ... 10

8 Uniformity of Hardness ... 11

9 Marking ... 12

10 Validity ... 13

Annex A (Informative) Examples of reference Test Block ... 14

Annex B (Normative) Requirements for Leeb Hardness Calibration Machines ... 15

Annex C (Informative) Measurement Uncertainty of Hardness Value of Standard Block

... 16

Annex D (Normative) Method for Calibrating Standard Block Using Standard Machine

Based on Non-Leeb Hardness Test Principle ... 20

Annex E (Informative) Conversion Table of Vickers Hardness Value/Brinell Hardness

Value and Leeb Hardness Value Calibrated by the Standard Block ... 26

Bibliography ... 32

Foreword

This Document was drafted as per the rules specified in GB/T 1.1-2020 Directives for

Standardization – Part 1: Rules for the Structure and Drafting of Standardizing Documents.

This Document is Part 3 of GB/T 17394 Metallic Materials – Leeb Hardness Test. GB/T 17394

consists of the following parts:

--- Part 1: Test Method;

--- Part 2: Verification and Calibration of Hardness Tester;

--- Part 3: Calibration of Reference Blocks;

--- Part 4: Tables of Hardness Values Conversation.

This Document replaced GB/T 17394.3-2012 Metallic Materials – Leeb Hardness Test – Part

3: Calibration of Reference Blocks. Compared with GB/T 173294.3-2012, the major technical

changes are as follows:

--- Modify the calculation formula and technical indicators of the hardness range and

hardness uniformity of standard Leeb hardness blocks (see 4.2, 8.2 of this Edition; 3.3

and 7.1 of the 2012 Edition);

--- Modify the technical indicators, such as geometric dimensions, flatness, parallelism and

surface roughness of standard Leeb hardness block; and add minimum quality

requirements (see 4.3, 4.5 and 4.6 of this Edition; 3.2, 3.3 and 7.1 of the 2012 Edition);

--- Modify the requirements for the standard machine used to calibrate standard Leeb

hardness blocks (see Clause 5 and Annex B of this Edition; Clause 4 of the 2012 Edition);

--- Modify the requirements for calibration method, number of indentations and validity (see

Clauses 6, 7, and 10 of this Edition; Clauses 5, 6, and 9 of the 2012 Edition);

--- Modify the geometric dimensions and technical requirements of the standard block; and

change it to an informative annex (see Annex A of this Edition; 3.2 of the 2012 Edition);

--- Add the requirements for standard machine performance parameters based on the

principle of Leeb hardness speed measurement (see Annex B of this Ed...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 17394.3-2022 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 17394.3-2022

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 17394.3-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 19.060; 77.040.10

CCS N 71

Replacing GB/T 17394.3-2012

Metallic Materials – Leeb Hardness Test – Part 3:

Calibration of Reference Test Blocks

(ISO 16859-3:2015, MOD)

ISSUED ON: JULY 11, 2022

IMPLEMENTED ON: FEBRUARY 01, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative References ... 6

3 Terms and Definitions ... 6

4 Manufacture of Reference Test Blocks ... 7

5 Calibration Machine ... 7

5.1 General ... 7

5.2 Traceability ... 8

5.3 Requirements on calibration machines ... 8

5.4 Calibration of calibration machines ... 8

6 Calibration Method ... 10

7 Number of Test Indentations ... 10

8 Uniformity of Hardness ... 11

9 Marking ... 12

10 Validity ... 13

Annex A (Informative) Examples of reference Test Block ... 14

Annex B (Normative) Requirements for Leeb Hardness Calibration Machines ... 15

Annex C (Informative) Measurement Uncertainty of Hardness Value of Standard Block

... 16

Annex D (Normative) Method for Calibrating Standard Block Using Standard Machine

Based on Non-Leeb Hardness Test Principle ... 20

Annex E (Informative) Conversion Table of Vickers Hardness Value/Brinell Hardness

Value and Leeb Hardness Value Calibrated by the Standard Block ... 26

Bibliography ... 32

Foreword

This Document was drafted as per the rules specified in GB/T 1.1-2020 Directives for

Standardization – Part 1: Rules for the Structure and Drafting of Standardizing Documents.

This Document is Part 3 of GB/T 17394 Metallic Materials – Leeb Hardness Test. GB/T 17394

consists of the following parts:

--- Part 1: Test Method;

--- Part 2: Verification and Calibration of Hardness Tester;

--- Part 3: Calibration of Reference Blocks;

--- Part 4: Tables of Hardness Values Conversation.

This Document replaced GB/T 17394.3-2012 Metallic Materials – Leeb Hardness Test – Part

3: Calibration of Reference Blocks. Compared with GB/T 173294.3-2012, the major technical

changes are as follows:

--- Modify the calculation formula and technical indicators of the hardness range and

hardness uniformity of standard Leeb hardness blocks (see 4.2, 8.2 of this Edition; 3.3

and 7.1 of the 2012 Edition);

--- Modify the technical indicators, such as geometric dimensions, flatness, parallelism and

surface roughness of standard Leeb hardness block; and add minimum quality

requirements (see 4.3, 4.5 and 4.6 of this Edition; 3.2, 3.3 and 7.1 of the 2012 Edition);

--- Modify the requirements for the standard machine used to calibrate standard Leeb

hardness blocks (see Clause 5 and Annex B of this Edition; Clause 4 of the 2012 Edition);

--- Modify the requirements for calibration method, number of indentations and validity (see

Clauses 6, 7, and 10 of this Edition; Clauses 5, 6, and 9 of the 2012 Edition);

--- Modify the geometric dimensions and technical requirements of the standard block; and

change it to an informative annex (see Annex A of this Edition; 3.2 of the 2012 Edition);

--- Add the requirements for standard machine performance parameters based on the

principle of Leeb hardness speed measurement (see Annex B of this Edition);

--- Modify the measurement uncertainty of the hardness value of the standard block (see

Annex C of this Edition; Annex A of the 2012 Edition);

--- Add the method of calibrating the standard block using a standard machine based on the

non-Leeb hardness test principle (see Annex D of this Edition).

This Document modifies and adopts ISO 16895-3:2015 Metallic Materials – Leeb Hardness

Test – Part 3: Calibration of Reference Test Blocks.

Compared with ISO 16895-3:2015, this Document has the following technical differences; the

terms to which these differences relate are indicated by a single vertical line (│) in their outer

margins. The specific technical differences and their causes are as follows:

--- Replace ISO16859-1:2015 with GB/T 17394.1 (see Clause 1, 6.1);

--- Replace ISO 16859-2:2015 with GB/T 17394.2-2022 that adopts the revises international

standard (see Clause 1, 5.1);

--- Replace ISO/IEC 17025:2005 with GB/T 27025-2008 that adopts the revises

international standard (see 5.2.1);

--- Replace the example of the standard block listed in Annex C of ISO16859-3:2015 by the

conventional standard block of China (see Annex A);

--- Add Annex D (normative) "Conversion Table between Vickers Hardness Value/Brinell

Hardness Value and Leeb Hardness Value Calibrated by Standard Block".

Please note some contents of this Document may involve patents. The issuing agency of this

Document shall not assume the responsibility to identify these patents.

This Document was proposed by China Machinery Industry Federation.

This Document shall be under the jurisdiction of National Technical Committee on Tester of

Standardization Administration of China (SAC/TC 122).

Drafting organizations of this Document: Quanzhou Fengze Donghai Instrument Hardness

Block Factory; AVIC Changcheng Institute of Metrology and Measurement; Sinotest Equipment

Co., Ltd.; Beijing Times Peak Technology Co., Ltd.; Shenyang TX Testing Instrument Co., Ltd.;

Laizhou Huayin Testing Instrument Co., Ltd.; and Metrology and Measurement Institute of

Hubei Space Academy.

Chief drafting staffs of this Document: Chen Junxin, Shi Wei, Zhang Jinwei, Zhou Cheng,

Zhang Luming, Wang Jingtao, and Huang Yongchang.

The historical editions replaced by this Document are as follows:

--- GB/T 17394.3-2012 was first-time published in 2012;

--- It is the first-time revised.

Metallic Materials – Leeb Hardness Test – Part 3:

Calibration of Reference Test Blocks

1 Scope

This Document specifies a method for the calibration of Leeb hardness standard blocks that are

used for the indirect verification of Leeb hardness testers according to GB/T 17394.2 and for

the periodic checking according to GB/T 17394.1.

This Document is applicable to the calibration of Leeb hardness standard block (hereinafter

referred to as reference block).

2 Normative References

The provisions in following documents become the essential provisions of this Document

through reference in this Document. For the dated documents, only the versions with the dates

indicated are applicable to this Document; for the undated documents, only the latest version

(including all the amendments) is applicable to this Document.

GB/T 231.3-2012 Metallic materials - Brinell hardness test - Part 3: Calibration of

reference blocks (ISO 6506-3:2005, MOD)

GB/T 4340.3-2012 Metallic Vickers hardness test - Part 3: Calibration of hardness (ISO

6507-3:2005, MOD)

GB/T 17394.1 Metallic materials - Leeb hardness test - Part 1: Test method

GB/T 17394.2-2022 Metallic materials - Leeb hardness test - Part 2: Verification and

calibration of hardness testers (ISO 16859-2:2015, MOD)

GB/T 27025 General requirements for the competence of testing and calibration

laboratories (GB/T 27025-2008, ISO/IEC 17025:2005, IDT)

3 Terms and Definitions

For the purposes of this Document, there are no terms and definitions apply.

5.2 Traceability

5.2.1 Leeb primary hardness standard machines owned by national level institutions are used

to calibrate primary reference test blocks in Leeb hardness for accredited Leeb hardness

calibration laboratories according to GB/T 27025.

5.2.2 The instruments used for the verification and calibration of the Leeb hardness calibration

machine shall be traceable to national standards.

NOTE: The structure diagram of the three-level metrology chain required to define and reproduce the

hardness value of each scale of Leeb hardness is shown in Figure C.1 of GB/T 17394.1-2014. The

measurement chain of the Leeb hardness value is obtained by the Leeb method defined in this figure.

5.3 Requirements on calibration machines

5.3.1 Requirements on Leeb hardness calibration machines are given in Annex B.

5.3.2 The resolution of Leeb hardness calibration machines shall be equal to or better than 1.0

HL.

5.3.3 Measuring instruments such as the standard Vickers hardness machine and the standard

Brinell hardness machine that use the indirect method to calibrate the Leeb standard block shall

be traceable to the national standard.

5.4 Calibration of calibration machines

5.4.1 Leeb hardness calibration machines shall be calibrated at an interval of < 12 months.

5.4.2 Leeb hardness calibration machines shall comply with the requirements defined in Annex

B.

5.4.3 After direct calibration, the standard machine shall be calibrated indirectly using at least

three reference blocks covering the full range of the Leeb hardness scale specified in Table 2.

The Leeb hardness range, minimum repeatability and limit error of the calibration machine are

shown in Table 2.

Indirect calibration comprises at least 10 readings on each reference test block.

Annex C

(Informative)

Measurement Uncertainty of Hardness Value of Standard Block

NOTE: The measurement chain diagram for defining and reproducing the hardness value of each scale

of Leeb hardness is shown in GB/T 17394.1.

C.1 Direct inspection and calibration of standard Leeb hardness machines

C.1.1 Testing of geometrical parameters of impact body and support ring

C.1.1.1 The geometrical parameters of impact body shall be tested according to 5.3.1 and 5.3.3

in GB/T 17394.2-2022.

C.1.1.2 The geometrical parameters of support ring shall be tested according to 5.5 in GB/T

17394.2-2022.

C.1.2 Testing of signal of electronic unit

The signal of electronic unit shall be tested according to 5.3.2 of GB/T 17394.2-2022.

C.2 Indirect inspection and calibration of standard Leeb hardness machine

NOTE: In this annex, the standard block is referred to as "Certified Reference Material (CRM)".

The comprehensive performance of the standard machine can be tested by indirect inspection

of the standard Leeb hardness machine by using the reference Leeb hardness block. Moreover,

indirect inspection can also be used to measure the repeatability and indication error of the

hardness indication displayed by the standard machine.

The measurement uncertainty of indirect inspection of the standard Leeb hardness machine is

calculated according to the Formula (C.1):

Where:

uCRM-P - the uncertainty of the calibration hardness value given by the calibration certificate of

the reference hardness block (k=1);

uxCRM-1 - the standard uncertainty introduced by the repeatability of the standard machine;

uCRM-D - since the latest calibration of the reference Leb hardness block, the standard uncertainty

GB/T 17394.3-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 19.060; 77.040.10

CCS N 71

Replacing GB/T 17394.3-2012

Metallic Materials – Leeb Hardness Test – Part 3:

Calibration of Reference Test Blocks

(ISO 16859-3:2015, MOD)

ISSUED ON: JULY 11, 2022

IMPLEMENTED ON: FEBRUARY 01, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative References ... 6

3 Terms and Definitions ... 6

4 Manufacture of Reference Test Blocks ... 7

5 Calibration Machine ... 7

5.1 General ... 7

5.2 Traceability ... 8

5.3 Requirements on calibration machines ... 8

5.4 Calibration of calibration machines ... 8

6 Calibration Method ... 10

7 Number of Test Indentations ... 10

8 Uniformity of Hardness ... 11

9 Marking ... 12

10 Validity ... 13

Annex A (Informative) Examples of reference Test Block ... 14

Annex B (Normative) Requirements for Leeb Hardness Calibration Machines ... 15

Annex C (Informative) Measurement Uncertainty of Hardness Value of Standard Block

... 16

Annex D (Normative) Method for Calibrating Standard Block Using Standard Machine

Based on Non-Leeb Hardness Test Principle ... 20

Annex E (Informative) Conversion Table of Vickers Hardness Value/Brinell Hardness

Value and Leeb Hardness Value Calibrated by the Standard Block ... 26

Bibliography ... 32

Foreword

This Document was drafted as per the rules specified in GB/T 1.1-2020 Directives for

Standardization – Part 1: Rules for the Structure and Drafting of Standardizing Documents.

This Document is Part 3 of GB/T 17394 Metallic Materials – Leeb Hardness Test. GB/T 17394

consists of the following parts:

--- Part 1: Test Method;

--- Part 2: Verification and Calibration of Hardness Tester;

--- Part 3: Calibration of Reference Blocks;

--- Part 4: Tables of Hardness Values Conversation.

This Document replaced GB/T 17394.3-2012 Metallic Materials – Leeb Hardness Test – Part

3: Calibration of Reference Blocks. Compared with GB/T 173294.3-2012, the major technical

changes are as follows:

--- Modify the calculation formula and technical indicators of the hardness range and

hardness uniformity of standard Leeb hardness blocks (see 4.2, 8.2 of this Edition; 3.3

and 7.1 of the 2012 Edition);

--- Modify the technical indicators, such as geometric dimensions, flatness, parallelism and

surface roughness of standard Leeb hardness block; and add minimum quality

requirements (see 4.3, 4.5 and 4.6 of this Edition; 3.2, 3.3 and 7.1 of the 2012 Edition);

--- Modify the requirements for the standard machine used to calibrate standard Leeb

hardness blocks (see Clause 5 and Annex B of this Edition; Clause 4 of the 2012 Edition);

--- Modify the requirements for calibration method, number of indentations and validity (see

Clauses 6, 7, and 10 of this Edition; Clauses 5, 6, and 9 of the 2012 Edition);

--- Modify the geometric dimensions and technical requirements of the standard block; and

change it to an informative annex (see Annex A of this Edition; 3.2 of the 2012 Edition);

--- Add the requirements for standard machine performance parameters based on the

principle of Leeb hardness speed measurement (see Annex B of this Ed...

Share