1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 222-2006 English PDF (GBT222-2006)

GB/T 222-2006 English PDF (GBT222-2006)

Regular price

$70.00 USD

Regular price

Sale price

$70.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 222-2006

Historical versions: GB/T 222-2006

Preview True-PDF (Reload/Scroll if blank)

GB/T 222-2006: Permissible tolerances for chemical composition of steel products

GB/T 222-2006

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.080.20

H 40

Partially replacing GB/T 222-1984

Permissible Tolerances for Chemical

Composition of Steel Products

Issue date. February 5, 2006 Implementation date. August 1, 2006

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1. Scope ... 4

2. Terms and Definitions ... 4

3. Sampling and Sample-making Methods for Product Analysis ... 5

4. Chemical Analysis Method ... 5

5. Permissible Tolerance for Product Analysis ... 5

Foreword

This Standard is formulated based on the relevant parts about permissible

variations for chemical composition in GB/T 222-1984 “Method of Sampling

Steel for Determination of Chemical Composition and Permissible Variations

for Product Analysis”.

This Standard replaces the relevant parts of “permissible tolerances for

chemical composition of steel products” in GB/T 222-1984; method of

sampling steel for determination of chemical composition of steel will be

specified in separate independent standard.

Compared the content of permissible tolerances of finished chemical

composition in this Standard and in GB/T 222-1984, the main changes are as

follows.

- Applicable scope of Table 1 is changed from common straight carbon

steel and low alloy steel to unalloyed steel and low alloy steel; applicable

scope of Table 2 is changed to alloy steel (see 6.1 in 1984 version, and

5.1 in this Standard).

- It is clarified that permissible tolerance values in Table 1 and Table 2 are

applicable to steel products of which the cross-sectional area is not larger

than 65000mm2 (5.1 in this Standard).

- It is supplemented that analysis on finished products replace heat

analysis (5.4 in this Standard).

- Permissible tolerance values of carbon and manganese elements in

Table 1 and Table 2 are adjusted; and provisions on elements, such as

aluminium, cobalt, nitrogen gas and calcium, are added.

This Standard was proposed by State Bureau of Metallurgical Industry.

This Standard shall be under the jurisdiction of National Technical Committee

of Standardization for Steel.

Drafting organization of this Standard. China Metallurgical Information and

Standardization Research Institute.

Main drafters of this Standard. Wu Qiansi, Luan Yan, Liu Baoshi and Dai

Qiang.

The first edition of this Standard was issued in August 1984.

Permissible Tolerances for Chemical Composition of

Steel Products

1. Scope

This Standard specifies the permissible tolerances of chemical composition of

finished unalloyed steel (excluding boiling steel), low alloy steel and alloy steel

products that are relative to the threshold value of melted chemical

composition; and it provides the relevant terms and definitions.

2. Terms and Definitions

This following terms and definitions are applicable to this Standard.

2.1 Heat (or cast/ladle) analysis

It refers to a procedure that adopts ingot sample during molten steel casting to

make test sample, and then carrying out chemical analysis. The analytic result

refers to average chemical composition of molten steel of the same batch.

2.2 Product analysis

Product analysis refers to take sample from processed finished steel product

(including steel feed), and then to analyze its chemical composition. Product

analysis is mainly used to check chemical composition, and it is also called

check analysis. Due to the fact that molten steel is distributed unevenly

(segregation) during crystallization, composition value of product analysis is

different from composition value of heat analysis sometimes.

2.3 Permissible tolerances for product analysis

It refers to that - although composition value of heat analysis is within the

exceed composition threshold value specified in standards, however, because

of segregation of steel composition, a permissible value of product analysis is

possible to exceed the threshold value that is specified by the standard. The

permissible value is the permissible tolerance for product analysis.

of threshold value of chemical composition as specified in the standard, or

shall not exceed the result of lower limit of threshold value of chemical

composition specified in the standards, subtracting lower deviation. In product

analysis of the same batch, one element is only allowed to have one time

deflected, and upper deviation and lower deviation shall not appear

simultaneously.

Example. For high-quality carbon structure #20 steel, limit carbon content of

smelting chemical composition specified in the standard is. upper limit 0.23%,

lower limit 0.17%; if carbon content is 0.25% when adding steel with the same

smelting number, it refers to that the value is 0.02% higher than the upper limit

specified in standards; if carbon content of steel with another smelting number is

0.15%, it refers to that the value is 0.02% lower than the lower limit specified in

standards; these two values of carbon content are deemed as qualified according

to provisions of Table 1.

5.4 If test sample for heat analysis is not available or reliable result of

smelting composition can not be obtained due to incorrect sample for heat

analysis, then product analysis can replace heat analysis, however, the

composition value of product analysis shall comply with provisions of smelting

composition, and permissible tolerances for product analysis specified in

Tables 1, 2 and 3 must NOT be adopted.

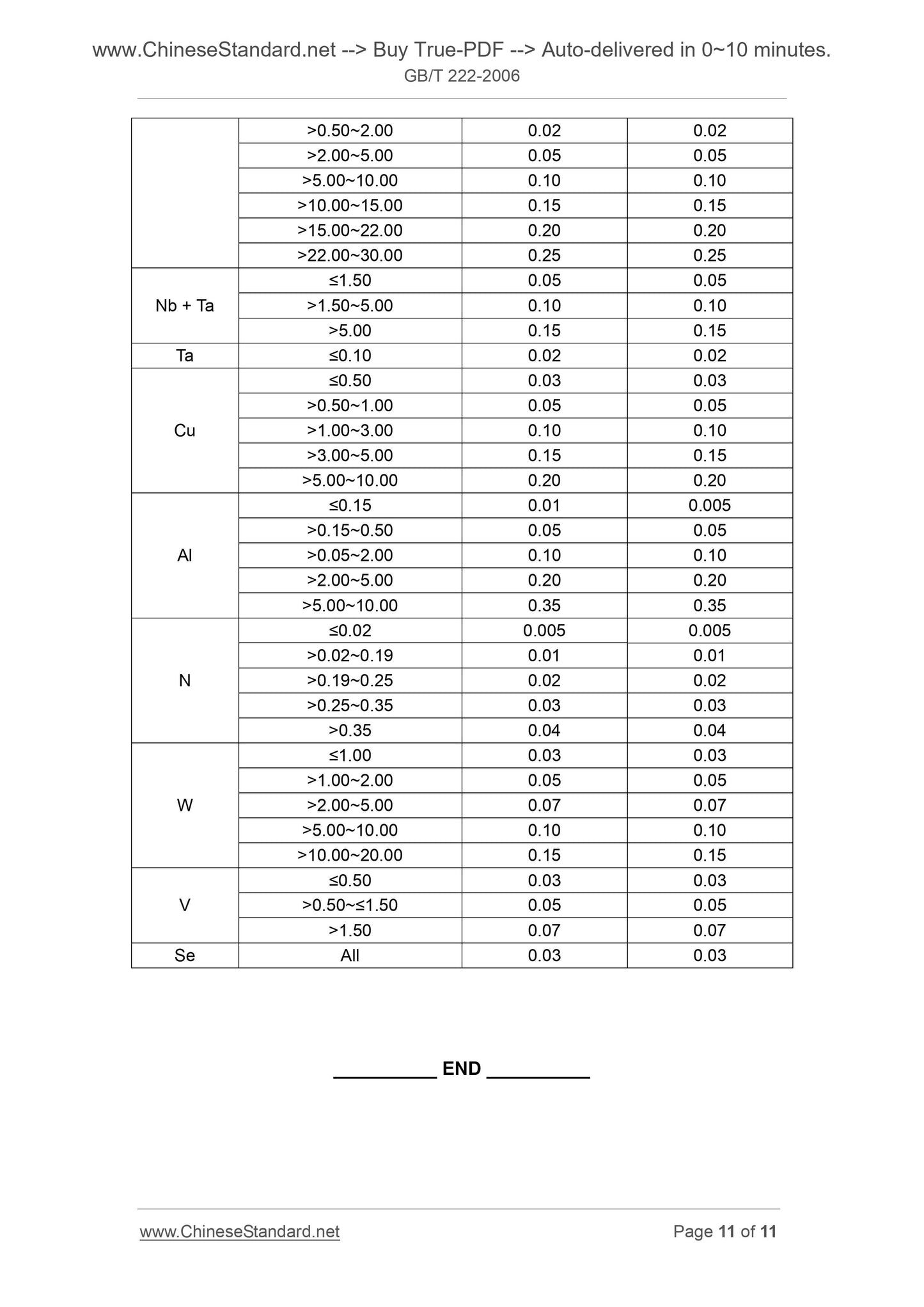

>0.50~2.00 0.02 0.02

>2.00~5.00 0.05 0.05

>5.00~10.00 0.10 0.10

>10.00~15.00 0.15 0.15

>15.00~22.00 0.20 0.20

>22.00~30.00 0.25 0.25

Nb + Ta

≤1.50 0.05 0.05

>1.50~5.00 0.10 0.10

>5.00 0.15 0.15

Ta ≤0.10 0.02 0.02

Cu

≤0.50 0.03 0.03

>0.50~1.00 0.05 0.05

>1.00~3.00 0.10 0.10

>3.00~5.00 0.15 0.15

>5.00~10.00 0.20 0.20

Al

≤0.15 0.01 0.005

>0.15~0.50 0.05 0.05

>0.05~2.00 0.10 0.10

>2.00~5.00 0.20 0.20

>5.00~10.00 0.35 0.35

≤0.02 0.005 0.005

>0.02~0.19 0.01 0.01

>0.19~0.25 0.02 0.02

>0.25~0.35 0.03 0.03

>0.35 0.04 0.04

≤1.00 0.03 0.03

>1.00~2.00 0.05 0.05

>2.00~5.00 0.07 0.07

>5.00~10.00 0.10 0.10

>10.00~20.00 0.15 0.15

≤0.50 0.03 0.03

>0.50~≤1.50 0.05 0.05

>1.50 0.07 0.07

Se All 0.03 0.03

Get QUOTATION in 1-minute: Click GB/T 222-2006

Historical versions: GB/T 222-2006

Preview True-PDF (Reload/Scroll if blank)

GB/T 222-2006: Permissible tolerances for chemical composition of steel products

GB/T 222-2006

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.080.20

H 40

Partially replacing GB/T 222-1984

Permissible Tolerances for Chemical

Composition of Steel Products

Issue date. February 5, 2006 Implementation date. August 1, 2006

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1. Scope ... 4

2. Terms and Definitions ... 4

3. Sampling and Sample-making Methods for Product Analysis ... 5

4. Chemical Analysis Method ... 5

5. Permissible Tolerance for Product Analysis ... 5

Foreword

This Standard is formulated based on the relevant parts about permissible

variations for chemical composition in GB/T 222-1984 “Method of Sampling

Steel for Determination of Chemical Composition and Permissible Variations

for Product Analysis”.

This Standard replaces the relevant parts of “permissible tolerances for

chemical composition of steel products” in GB/T 222-1984; method of

sampling steel for determination of chemical composition of steel will be

specified in separate independent standard.

Compared the content of permissible tolerances of finished chemical

composition in this Standard and in GB/T 222-1984, the main changes are as

follows.

- Applicable scope of Table 1 is changed from common straight carbon

steel and low alloy steel to unalloyed steel and low alloy steel; applicable

scope of Table 2 is changed to alloy steel (see 6.1 in 1984 version, and

5.1 in this Standard).

- It is clarified that permissible tolerance values in Table 1 and Table 2 are

applicable to steel products of which the cross-sectional area is not larger

than 65000mm2 (5.1 in this Standard).

- It is supplemented that analysis on finished products replace heat

analysis (5.4 in this Standard).

- Permissible tolerance values of carbon and manganese elements in

Table 1 and Table 2 are adjusted; and provisions on elements, such as

aluminium, cobalt, nitrogen gas and calcium, are added.

This Standard was proposed by State Bureau of Metallurgical Industry.

This Standard shall be under the jurisdiction of National Technical Committee

of Standardization for Steel.

Drafting organization of this Standard. China Metallurgical Information and

Standardization Research Institute.

Main drafters of this Standard. Wu Qiansi, Luan Yan, Liu Baoshi and Dai

Qiang.

The first edition of this Standard was issued in August 1984.

Permissible Tolerances for Chemical Composition of

Steel Products

1. Scope

This Standard specifies the permissible tolerances of chemical composition of

finished unalloyed steel (excluding boiling steel), low alloy steel and alloy steel

products that are relative to the threshold value of melted chemical

composition; and it provides the relevant terms and definitions.

2. Terms and Definitions

This following terms and definitions are applicable to this Standard.

2.1 Heat (or cast/ladle) analysis

It refers to a procedure that adopts ingot sample during molten steel casting to

make test sample, and then carrying out chemical analysis. The analytic result

refers to average chemical composition of molten steel of the same batch.

2.2 Product analysis

Product analysis refers to take sample from processed finished steel product

(including steel feed), and then to analyze its chemical composition. Product

analysis is mainly used to check chemical composition, and it is also called

check analysis. Due to the fact that molten steel is distributed unevenly

(segregation) during crystallization, composition value of product analysis is

different from composition value of heat analysis sometimes.

2.3 Permissible tolerances for product analysis

It refers to that - although composition value of heat analysis is within the

exceed composition threshold value specified in standards, however, because

of segregation of steel composition, a permissible value of product analysis is

possible to exceed the threshold value that is specified by the standard. The

permissible value is the permissible tolerance for product analysis.

of threshold value of chemical composition as specified in the standard, or

shall not exceed the result of lower limit of threshold value of chemical

composition specified in the standards, subtracting lower deviation. In product

analysis of the same batch, one element is only allowed to have one time

deflected, and upper deviation and lower deviation shall not appear

simultaneously.

Example. For high-quality carbon structure #20 steel, limit carbon content of

smelting chemical composition specified in the standard is. upper limit 0.23%,

lower limit 0.17%; if carbon content is 0.25% when adding steel with the same

smelting number, it refers to that the value is 0.02% higher than the upper limit

specified in standards; if carbon content of steel with another smelting number is

0.15%, it refers to that the value is 0.02% lower than the lower limit specified in

standards; these two values of carbon content are deemed as qualified according

to provisions of Table 1.

5.4 If test sample for heat analysis is not available or reliable result of

smelting composition can not be obtained due to incorrect sample for heat

analysis, then product analysis can replace heat analysis, however, the

composition value of product analysis shall comply with provisions of smelting

composition, and permissible tolerances for product analysis specified in

Tables 1, 2 and 3 must NOT be adopted.

>0.50~2.00 0.02 0.02

>2.00~5.00 0.05 0.05

>5.00~10.00 0.10 0.10

>10.00~15.00 0.15 0.15

>15.00~22.00 0.20 0.20

>22.00~30.00 0.25 0.25

Nb + Ta

≤1.50 0.05 0.05

>1.50~5.00 0.10 0.10

>5.00 0.15 0.15

Ta ≤0.10 0.02 0.02

Cu

≤0.50 0.03 0.03

>0.50~1.00 0.05 0.05

>1.00~3.00 0.10 0.10

>3.00~5.00 0.15 0.15

>5.00~10.00 0.20 0.20

Al

≤0.15 0.01 0.005

>0.15~0.50 0.05 0.05

>0.05~2.00 0.10 0.10

>2.00~5.00 0.20 0.20

>5.00~10.00 0.35 0.35

≤0.02 0.005 0.005

>0.02~0.19 0.01 0.01

>0.19~0.25 0.02 0.02

>0.25~0.35 0.03 0.03

>0.35 0.04 0.04

≤1.00 0.03 0.03

>1.00~2.00 0.05 0.05

>2.00~5.00 0.07 0.07

>5.00~10.00 0.10 0.10

>10.00~20.00 0.15 0.15

≤0.50 0.03 0.03

>0.50~≤1.50 0.05 0.05

>1.50 0.07 0.07

Se All 0.03 0.03

Share