1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 22930.1-2021 English PDF (GB/T22930.1-2021)

GB/T 22930.1-2021 English PDF (GB/T22930.1-2021)

Regular price

$320.00 USD

Regular price

Sale price

$320.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click GB/T 22930.1-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 22930.1-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 22930.1-2021: Leather and fur - Chemical determination of metal content - Part 1:Extractable metals

GB/T 22930.1-2021

(Leather and furs. Chemical determination of metal content. Part 1.Extractable metals)

ICS 59.140.30

CCSY46

National Standards of People's Republic of China

Partially replaces GB/T 22930-2008

Chemical Determination of Metal Content of Leather and Furs

Part 1.Extractable Metals

(ISO 17072-1.2019Leather-Chemicaldeterminationofmetalcontent-

Published on 2021-10-11

2022-05-01 Implementation

State Administration for Market Regulation

Released by the National Standardization Administration

Chemical Determination of Metal Content of Leather and Furs

Part 1.Extractable Metals

Warning. The concentrated acids used in this document are all highly corrosive and/or oxidizing liquids.

Possibility of burning or explosion, acute or chronic health hazard to human body, and harm to water body, necessary measures should be taken during the test.

security measures.

1 Scope

This document describes aluminium (Al), arsenic (As), barium (Ba), calcium (Ca), cadmium (Cd), cobalt (Co), chromium (Cr), copper (Cu), iron in leather and fur

(Fe), Potassium (K), Magnesium (Mg), Lead (Pb), Manganese (Mn), Molybdenum (Mo), Nickel (Ni), Mercury (Hg), Antimony (Sb), Selenium (Se), Tin (Sn), Titanium (Ti), Zinc

Test method for the content of 22 extractable metals (Zn) and zirconium (Zr).

This document is applicable to the determination of 22 extractable metals in various types of leather and furs, as well as extractable chromium in chrome-tanned leather

Determination of content.

2 Normative references

The contents of the following documents constitute essential provisions of this document through normative references in the text. Among them, dated citations

documents, only the version corresponding to that date applies to this document; for undated references, the latest edition (including all amendments) applies to

this document.

GB/T 3922 Textiles Color fastness test Color fastness to perspiration (GB/T 3922-2013, ISO 105-E04.2013,

MOD)

GB/T 6682 Analysis Laboratory Water Specifications and Test Methods (GB/T 6682-2008, ISO 3696.1987, MOD)

GB/T 39364 Leather chemical, physical, mechanical and color fastness test sampling site (GB/T 39364-2020, ISO 2418.

2017, MOD)

QB/T 1267 Fur chemical, physical and mechanical, color fastness test sampling site (QB/T 1267-2012, ISO 2418.

2002, MOD)

QB/T 1272 Preparation of fur chemical test samples (QB/T 1272-2012, ISO 4044.2008, MOD)

QB/T 1273 Determination of volatile matter in chemical test of fur (QB/T 1273-2012, ISO 4684.2005, MOD)

QB/T 1276 Determination of carbon tetrachloride extracts in chemical tests of fur (QB/T 1276-2012, ISO 4048.2008,

MOD)

QB/T 2716 Preparation of leather chemical test samples (QB/T 2716-2018, ISO 4044.2008, MOD)

QB/T 2717 Determination of leather chemical test volatiles (QB/T 2717-2018, ISO 4684.2005, MOD)

QB/T 2718 Leather chemical test Determination of dichloromethane extract (QB/T 2718-2018, ISO 4048.2008,

MOD)

3 Terms and Definitions

There are no terms and definitions that need to be defined in this document.

4 Principles

The leather samples were extracted with acidic artificial sweat, and the extract was filtered and acidified and then passed through an inductively coupled plasma emission spectrometer (ICP-

OES), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Atomic Absorption Spectrometry (AAS), or Atomic Fluorescence Spectrometry (AFS) to measure extraction

Calculate the metal concentration in the liquid and calculate the extractable metal content in the sample.

Note. This method measures the content of extractable metals, not the content of a specific metal compound or metal oxide.

5 Reagents and Materials

5.1 Unless otherwise specified, the reagents used should be of analytical grade, and the test solutions should be aqueous solutions.

5.2 Nitric acid, the mass fraction is 60%~70%.

5.3 L-histidine hydrochloride-hydrate, C6H9O2N3·HCI·H2O.

5.4 Sodium chloride.

5.5 Sodium dihydrogen phosphate dihydrate, NaH2PO4 · 2H2O.

5.6 Sodium hydroxide solution, 0.1mol/L.

5.7 Metal element standard stock solution, the mass concentration of each metal element is 1000mg/L.

Note 1.Both the standard stock solution of single metal elements and the standard stock solution of multi-metal elements can be used in the market.

The procedure is fully explained. The shelf life of commercially available standard stock solutions is at least 1 year, but in order to ensure the stability of the solutions used, the manufacturer's

suggestion.

Note 2.Standard stock solutions of metal elements with other suitable concentrations (such as 100mg/L) can also be used, which are indicated in the test report.

5.8 The water shall comply with the provisions of secondary water in GB/T 6682.

5.9 Gold element (Au) solution, dissolved in hydrochloric acid or potassium permanganate, 1000μg/L.

5.10 Hydrochloric acid, the mass fraction is 37%.

6 Instruments and equipment

6.1 The glassware, analytical equipment and materials (including filters) used shall meet the requirements for trace metal element analysis.

6.2 Oven, controllable temperature to (102±2)℃.

6.3 Analytical balance with an accuracy of 0.1 mg.

6.4 Conventional balance, accuracy 0.01g.

6.5 Filter membrane and support, water system, pore size is 0.45μm.

6.6 Filtration device, glass fiber (GFC) or membrane filter.

6.7 Volumetric flask, 50mL, 100mL, 1000mL.

6.8 Conical flask with stopper, 250mL.

6.9 Conical flask, various specifications.

6.10 Water bath, temperature controllable to (37±2)℃, with horizontal oscillator [oscillation frequency is (60±5) r/min] or orbital oscillator [oscillation frequency

is (100±10)r/min].

6.11 Inductively coupled plasma optical emission spectrometer (ICP-OES), with a hydride generator, the purity of the gas used should not be less than 99.99%.

6.12 Flame or graphite furnace atomic absorption spectrometer (AAS) with hydride generator, hollow cathode lamp, nitrous oxide burner head or high solid

For bulk nitrous oxide burner heads, the purity of the gas used should not be less than 99.99%.

6.13 For inductively coupled plasma mass spectrometer (ICP-MS), the purity of the gas used shall not be less than 99.99%.

6.14 Atomic fluorescence spectrometer (AFS) for the determination of mercury content.

7 Sampling and sample preparation

7.1 Sampling

Leather according to the provisions of GB/T 39364.

The fur is carried out according to the regulations of QB/T 1267.

If it is not possible to take samples from standard parts (such as directly from shoes and clothing), samples should be taken from any part of the usable area, and the samples should be

Be representative, and indicate the sampling process in the test report.

7.2 Preparation of test specimens

Leather is carried out according to the regulations of QB/T 2716.

The fur is carried out according to the regulations of QB/T 1272.During the shearing process, damage to the quilt should be avoided and the quilt should be kept intact.

For samples with high moisture content (greater than 30%), it should be pre-dried for more than 12 hours at a temperature not exceeding (50 ± 2) °C.

The selection should take into account the possible effect of high temperature on the properties of the analyte.

7.3 Determination of volatiles

Leather according to the provisions of QB/T 2717.The fur is carried out according to the regulations of QB/T 1273.Specimens prepared from the same batch may be used in 8.2

extraction in.

8 Test steps

8.1 Preparation of Acidic Artificial Sweat

Should be carried out in accordance with the provisions of GB/T 3922.The solution should be prepared and used immediately, and the components of the solution are shown in Table 1.

8.2 Extraction of the sample

Use an analytical balance (6.3) to accurately weigh 2g of the sample (accurate to 0.001g) into a 250mL conical flask with a stopper (6.8), and remove it with a pipette

Put 100mL of acidic artificial sweat (8.1) into a conical flask, and then place it in a water bath (6.10) at (37±2) °C and shake for (240±5) min. will be extracted

The liquid is filtered first with the filter device (6.6), and then the filtrate is filtered through the filter membrane (6.5).

Note 1.In order to avoid incomplete extraction, weigh 1g of sample into a 150mL conical flask, add 50mL of acidic artificial sweat for extraction.

Note 2.For the determination of Sn, Sb and Pb, check the filtering operation to prevent the loss of elements.

Note 3.Strictly control the extraction conditions of the sample to avoid any deviations that may lead to erroneous test results.

Note 4.When measuring the content of Hg element, add 10 μL of gold element (Au) solution (5.9) and extract the sample at the same time with acidic artificial sweat.

8.3 Blank test

In order to control the effect of reagent contamination on the results, it is necessary to carry out a blank test. Replace the sample with an equal amount of acidic artificial sweat,

Add to the Erlenmeyer flask and proceed according to 8.2.

8.4 Instrumental Analysis

8.4.1 General

If the content of metal elements in the extract obtained in 8.2 is within the range of the standard curve, pipette a quantitative extract, add the extract

Accumulate 5% nitric acid (5.2) for acidification. After mixing evenly, it can be directly used for analysis and testing. The dilution of the extract by nitric acid during acidification should be included in the results.

calculate. Otherwise, the extract should be properly diluted and tested, and the dilution ratio should be recorded.

The preparation of the metal standard solution to be tested and its standard working solution shall be carried out according to the provisions of Appendix C.

8.4.2 ICP method

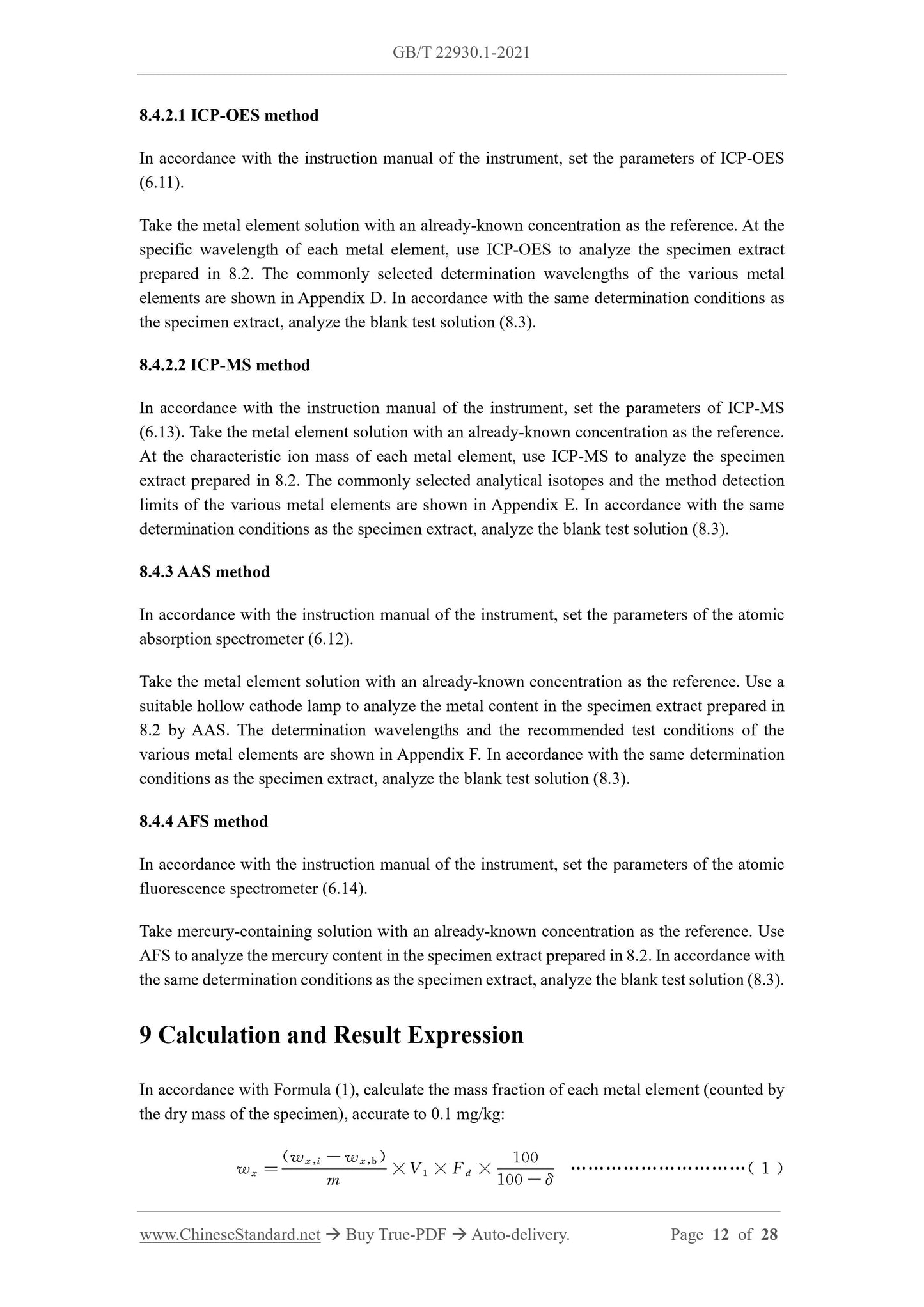

8.4.2.1 ICP-OES method

According to the instrument manual, set the parameters of ICP-OES (6.11).

The samples prepared in 8.2 were tested by ICP-OES at the specific wavelength of each metal element using a solution of metal elements of known concentration as a reference.

The extraction liquid is analyzed, and the measurement wavelengths often selected for each metal element are shown in Appendix D. Analyze the empty space under the same measurement conditions as the sample extract

White test solution (8.3).

8.4.2.2 ICP-MS method

According to the instrument manual, set the parameters of ICP-MS (6.13), with the metal element solution of known concentration as the reference, in each metal

ICP-MS is used to analyze the sample extract prepared in 8.2 at the characteristic ion mass of the element, and the analytical isotope of each metal element is often selected.

See Appendix E for elements and their method detection limits. Analyze the blank test solution (8.3) under the same measurement conditions as the sample extract.

8.4.3 AAS method

According to the instrument manual, set the parameters of the atomic absorption spectrometer (6.12).

Using a metal element solution of known concentration as a reference, use a suitable hollow cathode lamp to analyze the concentration of the sample extract prepared in 8.2 by AAS.

The metal content is analyzed, and the determination wavelength and recommended test conditions of each metal element are shown in Appendix F. According to the same determination as the sample extract

Condition Analysis Blank Test Solution (8.3).

8.4.4 AFS method

According to the instrument manual, set the parameters of the atomic fluorescence spectrometer (6.14).

The mercury content in the sample extract prepared in 8.2 is analyzed by AFS with a mercury-containing solution of known concentration as a reference. follow and try

Analyze the blank test solution (8.3) under the same measurement conditions as the sample extract.

10 Test report

The test report should contain the following.

a) the document number;

b) The detailed information of the sample, the situation in which the sampling is inconsistent with GB/T 39364 or QB/T 1267;

c) the specific instrumental analysis method used;

d) the content of volatiles in the sample (if necessary, the oil content in the sample);

e) the content of extractable metals in the sample (based on the dry weight of the sample);

f) any deviation from the methods specified in this document.

Get Quotation: Click GB/T 22930.1-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 22930.1-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 22930.1-2021: Leather and fur - Chemical determination of metal content - Part 1:Extractable metals

GB/T 22930.1-2021

(Leather and furs. Chemical determination of metal content. Part 1.Extractable metals)

ICS 59.140.30

CCSY46

National Standards of People's Republic of China

Partially replaces GB/T 22930-2008

Chemical Determination of Metal Content of Leather and Furs

Part 1.Extractable Metals

(ISO 17072-1.2019Leather-Chemicaldeterminationofmetalcontent-

Published on 2021-10-11

2022-05-01 Implementation

State Administration for Market Regulation

Released by the National Standardization Administration

Chemical Determination of Metal Content of Leather and Furs

Part 1.Extractable Metals

Warning. The concentrated acids used in this document are all highly corrosive and/or oxidizing liquids.

Possibility of burning or explosion, acute or chronic health hazard to human body, and harm to water body, necessary measures should be taken during the test.

security measures.

1 Scope

This document describes aluminium (Al), arsenic (As), barium (Ba), calcium (Ca), cadmium (Cd), cobalt (Co), chromium (Cr), copper (Cu), iron in leather and fur

(Fe), Potassium (K), Magnesium (Mg), Lead (Pb), Manganese (Mn), Molybdenum (Mo), Nickel (Ni), Mercury (Hg), Antimony (Sb), Selenium (Se), Tin (Sn), Titanium (Ti), Zinc

Test method for the content of 22 extractable metals (Zn) and zirconium (Zr).

This document is applicable to the determination of 22 extractable metals in various types of leather and furs, as well as extractable chromium in chrome-tanned leather

Determination of content.

2 Normative references

The contents of the following documents constitute essential provisions of this document through normative references in the text. Among them, dated citations

documents, only the version corresponding to that date applies to this document; for undated references, the latest edition (including all amendments) applies to

this document.

GB/T 3922 Textiles Color fastness test Color fastness to perspiration (GB/T 3922-2013, ISO 105-E04.2013,

MOD)

GB/T 6682 Analysis Laboratory Water Specifications and Test Methods (GB/T 6682-2008, ISO 3696.1987, MOD)

GB/T 39364 Leather chemical, physical, mechanical and color fastness test sampling site (GB/T 39364-2020, ISO 2418.

2017, MOD)

QB/T 1267 Fur chemical, physical and mechanical, color fastness test sampling site (QB/T 1267-2012, ISO 2418.

2002, MOD)

QB/T 1272 Preparation of fur chemical test samples (QB/T 1272-2012, ISO 4044.2008, MOD)

QB/T 1273 Determination of volatile matter in chemical test of fur (QB/T 1273-2012, ISO 4684.2005, MOD)

QB/T 1276 Determination of carbon tetrachloride extracts in chemical tests of fur (QB/T 1276-2012, ISO 4048.2008,

MOD)

QB/T 2716 Preparation of leather chemical test samples (QB/T 2716-2018, ISO 4044.2008, MOD)

QB/T 2717 Determination of leather chemical test volatiles (QB/T 2717-2018, ISO 4684.2005, MOD)

QB/T 2718 Leather chemical test Determination of dichloromethane extract (QB/T 2718-2018, ISO 4048.2008,

MOD)

3 Terms and Definitions

There are no terms and definitions that need to be defined in this document.

4 Principles

The leather samples were extracted with acidic artificial sweat, and the extract was filtered and acidified and then passed through an inductively coupled plasma emission spectrometer (ICP-

OES), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Atomic Absorption Spectrometry (AAS), or Atomic Fluorescence Spectrometry (AFS) to measure extraction

Calculate the metal concentration in the liquid and calculate the extractable metal content in the sample.

Note. This method measures the content of extractable metals, not the content of a specific metal compound or metal oxide.

5 Reagents and Materials

5.1 Unless otherwise specified, the reagents used should be of analytical grade, and the test solutions should be aqueous solutions.

5.2 Nitric acid, the mass fraction is 60%~70%.

5.3 L-histidine hydrochloride-hydrate, C6H9O2N3·HCI·H2O.

5.4 Sodium chloride.

5.5 Sodium dihydrogen phosphate dihydrate, NaH2PO4 · 2H2O.

5.6 Sodium hydroxide solution, 0.1mol/L.

5.7 Metal element standard stock solution, the mass concentration of each metal element is 1000mg/L.

Note 1.Both the standard stock solution of single metal elements and the standard stock solution of multi-metal elements can be used in the market.

The procedure is fully explained. The shelf life of commercially available standard stock solutions is at least 1 year, but in order to ensure the stability of the solutions used, the manufacturer's

suggestion.

Note 2.Standard stock solutions of metal elements with other suitable concentrations (such as 100mg/L) can also be used, which are indicated in the test report.

5.8 The water shall comply with the provisions of secondary water in GB/T 6682.

5.9 Gold element (Au) solution, dissolved in hydrochloric acid or potassium permanganate, 1000μg/L.

5.10 Hydrochloric acid, the mass fraction is 37%.

6 Instruments and equipment

6.1 The glassware, analytical equipment and materials (including filters) used shall meet the requirements for trace metal element analysis.

6.2 Oven, controllable temperature to (102±2)℃.

6.3 Analytical balance with an accuracy of 0.1 mg.

6.4 Conventional balance, accuracy 0.01g.

6.5 Filter membrane and support, water system, pore size is 0.45μm.

6.6 Filtration device, glass fiber (GFC) or membrane filter.

6.7 Volumetric flask, 50mL, 100mL, 1000mL.

6.8 Conical flask with stopper, 250mL.

6.9 Conical flask, various specifications.

6.10 Water bath, temperature controllable to (37±2)℃, with horizontal oscillator [oscillation frequency is (60±5) r/min] or orbital oscillator [oscillation frequency

is (100±10)r/min].

6.11 Inductively coupled plasma optical emission spectrometer (ICP-OES), with a hydride generator, the purity of the gas used should not be less than 99.99%.

6.12 Flame or graphite furnace atomic absorption spectrometer (AAS) with hydride generator, hollow cathode lamp, nitrous oxide burner head or high solid

For bulk nitrous oxide burner heads, the purity of the gas used should not be less than 99.99%.

6.13 For inductively coupled plasma mass spectrometer (ICP-MS), the purity of the gas used shall not be less than 99.99%.

6.14 Atomic fluorescence spectrometer (AFS) for the determination of mercury content.

7 Sampling and sample preparation

7.1 Sampling

Leather according to the provisions of GB/T 39364.

The fur is carried out according to the regulations of QB/T 1267.

If it is not possible to take samples from standard parts (such as directly from shoes and clothing), samples should be taken from any part of the usable area, and the samples should be

Be representative, and indicate the sampling process in the test report.

7.2 Preparation of test specimens

Leather is carried out according to the regulations of QB/T 2716.

The fur is carried out according to the regulations of QB/T 1272.During the shearing process, damage to the quilt should be avoided and the quilt should be kept intact.

For samples with high moisture content (greater than 30%), it should be pre-dried for more than 12 hours at a temperature not exceeding (50 ± 2) °C.

The selection should take into account the possible effect of high temperature on the properties of the analyte.

7.3 Determination of volatiles

Leather according to the provisions of QB/T 2717.The fur is carried out according to the regulations of QB/T 1273.Specimens prepared from the same batch may be used in 8.2

extraction in.

8 Test steps

8.1 Preparation of Acidic Artificial Sweat

Should be carried out in accordance with the provisions of GB/T 3922.The solution should be prepared and used immediately, and the components of the solution are shown in Table 1.

8.2 Extraction of the sample

Use an analytical balance (6.3) to accurately weigh 2g of the sample (accurate to 0.001g) into a 250mL conical flask with a stopper (6.8), and remove it with a pipette

Put 100mL of acidic artificial sweat (8.1) into a conical flask, and then place it in a water bath (6.10) at (37±2) °C and shake for (240±5) min. will be extracted

The liquid is filtered first with the filter device (6.6), and then the filtrate is filtered through the filter membrane (6.5).

Note 1.In order to avoid incomplete extraction, weigh 1g of sample into a 150mL conical flask, add 50mL of acidic artificial sweat for extraction.

Note 2.For the determination of Sn, Sb and Pb, check the filtering operation to prevent the loss of elements.

Note 3.Strictly control the extraction conditions of the sample to avoid any deviations that may lead to erroneous test results.

Note 4.When measuring the content of Hg element, add 10 μL of gold element (Au) solution (5.9) and extract the sample at the same time with acidic artificial sweat.

8.3 Blank test

In order to control the effect of reagent contamination on the results, it is necessary to carry out a blank test. Replace the sample with an equal amount of acidic artificial sweat,

Add to the Erlenmeyer flask and proceed according to 8.2.

8.4 Instrumental Analysis

8.4.1 General

If the content of metal elements in the extract obtained in 8.2 is within the range of the standard curve, pipette a quantitative extract, add the extract

Accumulate 5% nitric acid (5.2) for acidification. After mixing evenly, it can be directly used for analysis and testing. The dilution of the extract by nitric acid during acidification should be included in the results.

calculate. Otherwise, the extract should be properly diluted and tested, and the dilution ratio should be recorded.

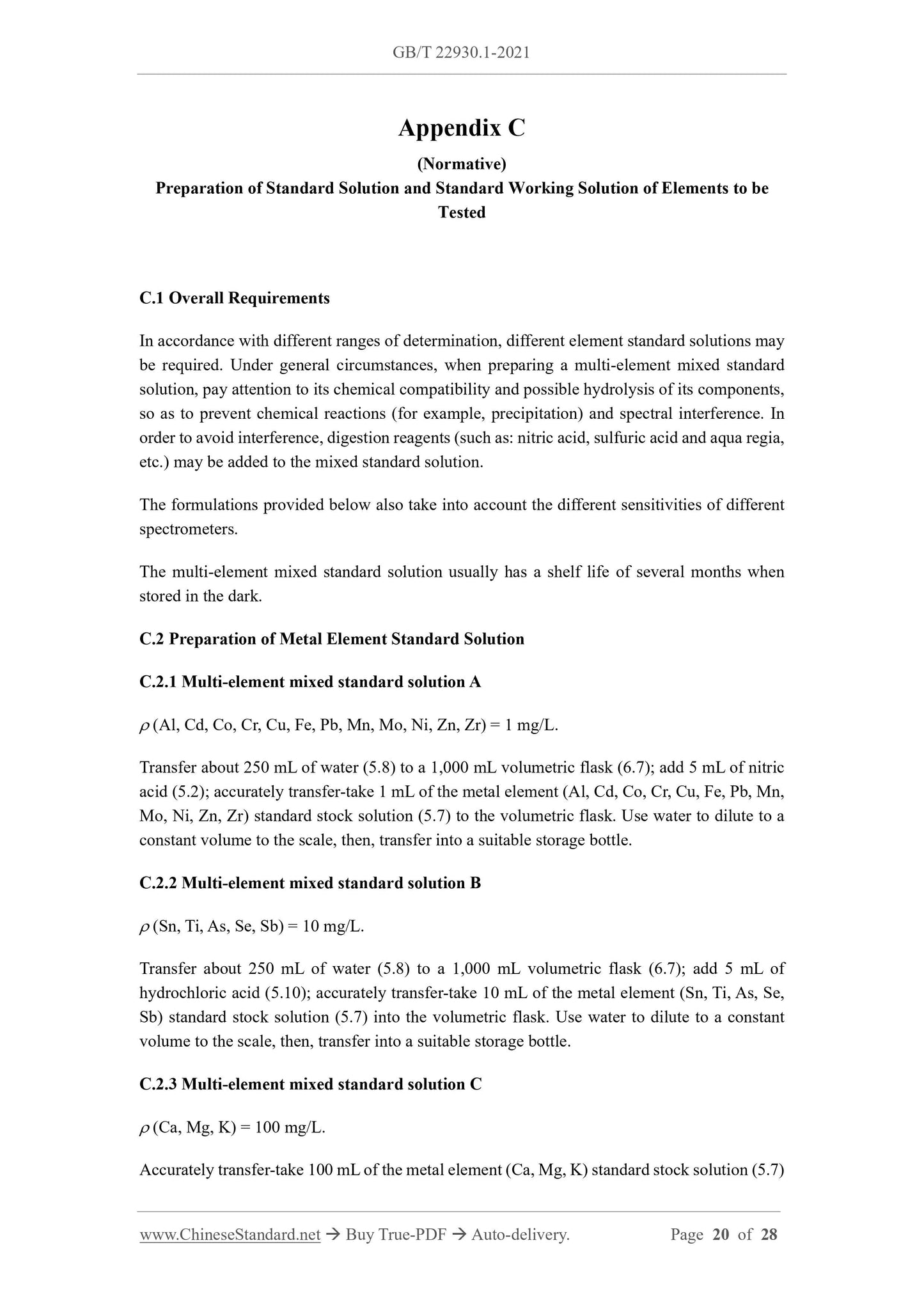

The preparation of the metal standard solution to be tested and its standard working solution shall be carried out according to the provisions of Appendix C.

8.4.2 ICP method

8.4.2.1 ICP-OES method

According to the instrument manual, set the parameters of ICP-OES (6.11).

The samples prepared in 8.2 were tested by ICP-OES at the specific wavelength of each metal element using a solution of metal elements of known concentration as a reference.

The extraction liquid is analyzed, and the measurement wavelengths often selected for each metal element are shown in Appendix D. Analyze the empty space under the same measurement conditions as the sample extract

White test solution (8.3).

8.4.2.2 ICP-MS method

According to the instrument manual, set the parameters of ICP-MS (6.13), with the metal element solution of known concentration as the reference, in each metal

ICP-MS is used to analyze the sample extract prepared in 8.2 at the characteristic ion mass of the element, and the analytical isotope of each metal element is often selected.

See Appendix E for elements and their method detection limits. Analyze the blank test solution (8.3) under the same measurement conditions as the sample extract.

8.4.3 AAS method

According to the instrument manual, set the parameters of the atomic absorption spectrometer (6.12).

Using a metal element solution of known concentration as a reference, use a suitable hollow cathode lamp to analyze the concentration of the sample extract prepared in 8.2 by AAS.

The metal content is analyzed, and the determination wavelength and recommended test conditions of each metal element are shown in Appendix F. According to the same determination as the sample extract

Condition Analysis Blank Test Solution (8.3).

8.4.4 AFS method

According to the instrument manual, set the parameters of the atomic fluorescence spectrometer (6.14).

The mercury content in the sample extract prepared in 8.2 is analyzed by AFS with a mercury-containing solution of known concentration as a reference. follow and try

Analyze the blank test solution (8.3) under the same measurement conditions as the sample extract.

10 Test report

The test report should contain the following.

a) the document number;

b) The detailed information of the sample, the situation in which the sampling is inconsistent with GB/T 39364 or QB/T 1267;

c) the specific instrumental analysis method used;

d) the content of volatiles in the sample (if necessary, the oil content in the sample);

e) the content of extractable metals in the sample (based on the dry weight of the sample);

f) any deviation from the methods specified in this document.

Share