1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 27800-2021 English PDF (GBT27800-2021)

GB/T 27800-2021 English PDF (GBT27800-2021)

Regular price

$200.00 USD

Regular price

Sale price

$200.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 27800-2021

Historical versions: GB/T 27800-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 27800-2021: Determination of the life for static sealing rubber products

GB/T 27800-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.140.50

CCS G 43

Replacing GB/T 27800-2011

Determination of the life for static sealing rubber

products

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Principle ... 6

5 Specimen ... 6

6 Test instruments ... 7

7 Test conditions ... 7

8 Test steps ... 8

9 Result processing ... 9

10 Test report ... 14

Annex A (informative) Suggestions on the upper limit of temperature for

accelerated aging test of different kinds of rubber materials ... 15

Annex B (informative) Derivation of the relationship between the aging

coefficient y and the aging time t and the test temperature T ... 16

Determination of the life for static sealing rubber

products

1 Scope

This Standard specifies the fast-forecasting method to determine the service

life of static sealing rubber products.

This Standard is applicable to determine the service life of static sealing rubber

products in the state of compression (radial compression is 12%-25%, axial

compression is 15%-40%) when in contact with various media and air. It is also

applicable to determine the storage period of rubber products in free state.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 528, Rubber, vulcanized or thermoplastic - Determination of tensile

stress-strain properties

GB/T 1683, Rubber, vulcanized - Determination of compression set at

constant strain

GB/T 1685, Rubber, vulcanized or thermoplastic - Determination of stress

relaxation in compression at ambient and at elevated temperatures

GB/T 1690, Rubber vulcanized or thermoplastic - Determination of the effect

of liquids

GB/T 3512, Rubber, vulcanized or thermoplastic - Accelerated ageing and

heat resistance tests - Air-oven method

GB/T 5720, Test methods for rubber O-rings

GB/T 7759.1, Rubber, vulcanized or thermoplastic - Determination of

compression set - Part 1: At ambient or elevated temperatures

GB/T 15905, Rubber, vulcanized - Test method of damp heat aging

6 Test instruments

6.1 Hot air aging box

The hot air aging box shall meet the requirements of GB/T 3512.

6.2 Humidity test chamber

The humidity test chamber shall meet the requirements of GB/T 15905.

6.3 Tensile testing machine

The tensile testing machine shall meet the requirements of GB/T 528.

6.4 Compressive stress relaxation instrument

The compressive stress relaxation instrument shall meet the requirements of

GB/T 1685.

7 Test conditions

7.1 Test temperature

7.1.1 The number of aging test temperature shall not be less than 5. The interval

between adjacent temperatures is not less than 10°C.

7.1.2 The upper limit of the test temperature varies with the raw rubber and

vulcanization system. Refer to Table A.1 in Annex A for the recommended upper

limit of test temperature. When the test time allows, lower the test temperature

to improve the accuracy of prediction.

7.2 Test humidity

Consider the accelerated aging test under the influence of relative humidity. The

relative humidity during the test is consistent with the relative humidity in the

use environment.

7.3 Test time

7.3.1 There shall be no less than 10 test data at each test temperature. The

time interval can be determined according to the performance changes. For

compression set, the difference between the two test results is controlled within

10%. For stress relaxation and elongation at break, the difference between the

two test results shall be controlled within 10% of the original value.

7.3.2 At the first performance test at each test temperature, the change in

8.2.2 Determination of compression set

8.2.2.1 The compression set is determined in accordance with GB/T 7759.1.

After compressing the specimen to the specified compression rate, place in a

standard laboratory environment for 3d. Then open the fixture. Place for another

1d. Determine the height and it shall be the initial height. After the specimen

has been subjected to the accelerated aging test (see 8.1), remove the fixture

from the aging box and remove the load. Place for 1d under standard laboratory

conditions. Measure and record the height of the specimen. Calculate its

compression set.

8.2.2.2 Put the specimen back into the fixture and return it to the aging box for

the next cycle of aging. Measure, record and calculate the compression set

again. Repeat this for many times.

8.2.2.3 For the test of 3 higher temperatures among 5 temperatures, when the

compression set reaches the critical value (see 9.6.1) or greater than 70%,

terminate the test. For the other two lower temperature tests, when the

compression set is greater than 50%, terminate the test.

8.2.3 Determination of elongation at break

8.2.3.1 The elongation at break is measured in accordance with GB/T 528. The

elongation at break before aging is the average of the results of 10 dumbbell-

shaped specimens. After the specimen has been subjected to the accelerated

aging test (see 8.1), the elongation at break is the average of the results of 5

dumbbell-shaped specimens. Record the elongation at break for all aging

cycles.

8.2.3.2 For the test of 3 higher temperatures among 5 temperatures, when the

elongation at break reaches the critical value (see 9.6.1) or less than 30% of

the original value, terminate the test. For the other two lower temperature tests,

when the elongation at break should be less than 50% of the original value,

terminate the test.

9 Result processing

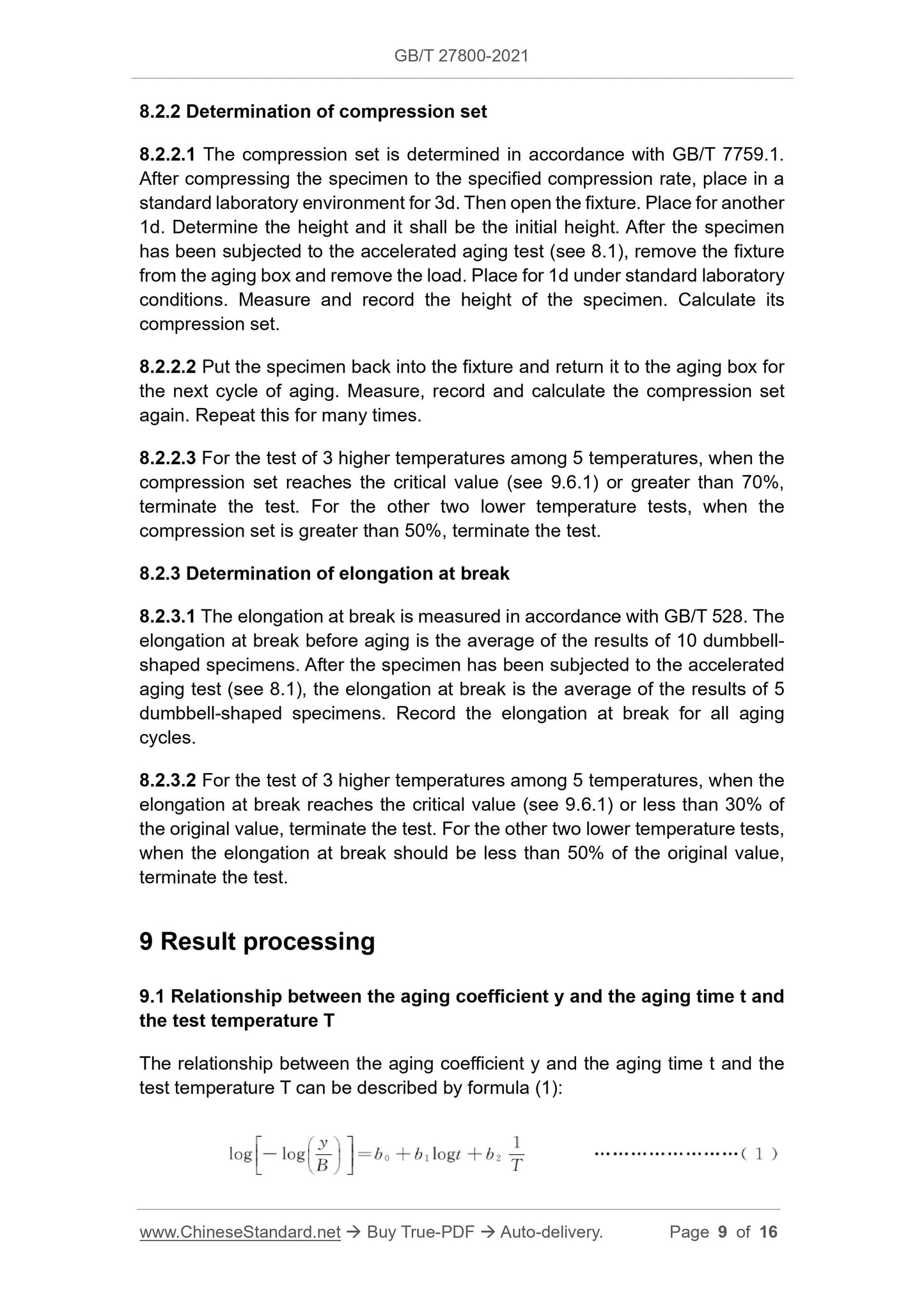

9.1 Relationship between the aging coefficient y and the aging time t and

the test temperature T

The relationship between the aging coefficient y and the aging time t and the

test temperature T can be described by formula (1):

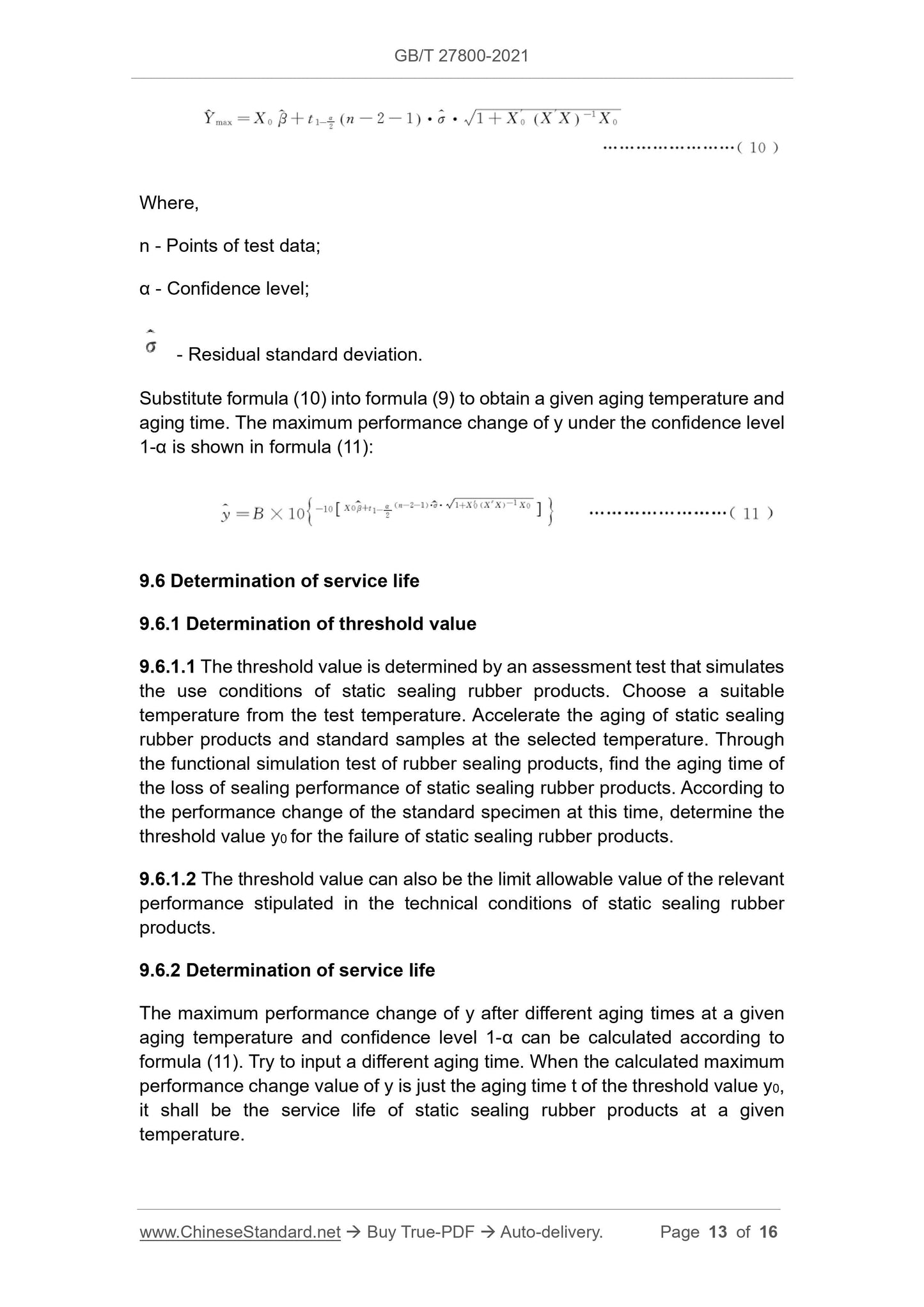

Where,

n - Points of test data;

α - Confidence level;

- Residual standard deviation.

Substitute formula (10) into formula (9) to obtain a given aging temperature and

aging time. The maximum performance change of y under the confidence level

1-α is shown in formula (11):

9.6 Determination of service life

9.6.1 Determination of threshold value

9.6.1.1 The threshold value is determined by an assessment test that simulates

the use conditions of static sealing rubber products. Choose a suitable

temperature from the test temperature. Accelerate the aging of static sealing

rubber products and standard samples at the selected temperature. Through

the functional simulation test of rubber sealing products, find the aging time of

the loss of sealing performance of static sealing rubber products. According to

the performance change of the standard specimen at this time, determine the

threshold value y0 for the failure of static sealing rubber products.

9.6.1.2 The threshold value can also be the limit allowable value of the relevant

performance stipulated in the technical conditions of static sealing rubber

products.

9.6.2 Determination of service life

The maximum performance change of y after different ag...

Get QUOTATION in 1-minute: Click GB/T 27800-2021

Historical versions: GB/T 27800-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 27800-2021: Determination of the life for static sealing rubber products

GB/T 27800-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.140.50

CCS G 43

Replacing GB/T 27800-2011

Determination of the life for static sealing rubber

products

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Principle ... 6

5 Specimen ... 6

6 Test instruments ... 7

7 Test conditions ... 7

8 Test steps ... 8

9 Result processing ... 9

10 Test report ... 14

Annex A (informative) Suggestions on the upper limit of temperature for

accelerated aging test of different kinds of rubber materials ... 15

Annex B (informative) Derivation of the relationship between the aging

coefficient y and the aging time t and the test temperature T ... 16

Determination of the life for static sealing rubber

products

1 Scope

This Standard specifies the fast-forecasting method to determine the service

life of static sealing rubber products.

This Standard is applicable to determine the service life of static sealing rubber

products in the state of compression (radial compression is 12%-25%, axial

compression is 15%-40%) when in contact with various media and air. It is also

applicable to determine the storage period of rubber products in free state.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 528, Rubber, vulcanized or thermoplastic - Determination of tensile

stress-strain properties

GB/T 1683, Rubber, vulcanized - Determination of compression set at

constant strain

GB/T 1685, Rubber, vulcanized or thermoplastic - Determination of stress

relaxation in compression at ambient and at elevated temperatures

GB/T 1690, Rubber vulcanized or thermoplastic - Determination of the effect

of liquids

GB/T 3512, Rubber, vulcanized or thermoplastic - Accelerated ageing and

heat resistance tests - Air-oven method

GB/T 5720, Test methods for rubber O-rings

GB/T 7759.1, Rubber, vulcanized or thermoplastic - Determination of

compression set - Part 1: At ambient or elevated temperatures

GB/T 15905, Rubber, vulcanized - Test method of damp heat aging

6 Test instruments

6.1 Hot air aging box

The hot air aging box shall meet the requirements of GB/T 3512.

6.2 Humidity test chamber

The humidity test chamber shall meet the requirements of GB/T 15905.

6.3 Tensile testing machine

The tensile testing machine shall meet the requirements of GB/T 528.

6.4 Compressive stress relaxation instrument

The compressive stress relaxation instrument shall meet the requirements of

GB/T 1685.

7 Test conditions

7.1 Test temperature

7.1.1 The number of aging test temperature shall not be less than 5. The interval

between adjacent temperatures is not less than 10°C.

7.1.2 The upper limit of the test temperature varies with the raw rubber and

vulcanization system. Refer to Table A.1 in Annex A for the recommended upper

limit of test temperature. When the test time allows, lower the test temperature

to improve the accuracy of prediction.

7.2 Test humidity

Consider the accelerated aging test under the influence of relative humidity. The

relative humidity during the test is consistent with the relative humidity in the

use environment.

7.3 Test time

7.3.1 There shall be no less than 10 test data at each test temperature. The

time interval can be determined according to the performance changes. For

compression set, the difference between the two test results is controlled within

10%. For stress relaxation and elongation at break, the difference between the

two test results shall be controlled within 10% of the original value.

7.3.2 At the first performance test at each test temperature, the change in

8.2.2 Determination of compression set

8.2.2.1 The compression set is determined in accordance with GB/T 7759.1.

After compressing the specimen to the specified compression rate, place in a

standard laboratory environment for 3d. Then open the fixture. Place for another

1d. Determine the height and it shall be the initial height. After the specimen

has been subjected to the accelerated aging test (see 8.1), remove the fixture

from the aging box and remove the load. Place for 1d under standard laboratory

conditions. Measure and record the height of the specimen. Calculate its

compression set.

8.2.2.2 Put the specimen back into the fixture and return it to the aging box for

the next cycle of aging. Measure, record and calculate the compression set

again. Repeat this for many times.

8.2.2.3 For the test of 3 higher temperatures among 5 temperatures, when the

compression set reaches the critical value (see 9.6.1) or greater than 70%,

terminate the test. For the other two lower temperature tests, when the

compression set is greater than 50%, terminate the test.

8.2.3 Determination of elongation at break

8.2.3.1 The elongation at break is measured in accordance with GB/T 528. The

elongation at break before aging is the average of the results of 10 dumbbell-

shaped specimens. After the specimen has been subjected to the accelerated

aging test (see 8.1), the elongation at break is the average of the results of 5

dumbbell-shaped specimens. Record the elongation at break for all aging

cycles.

8.2.3.2 For the test of 3 higher temperatures among 5 temperatures, when the

elongation at break reaches the critical value (see 9.6.1) or less than 30% of

the original value, terminate the test. For the other two lower temperature tests,

when the elongation at break should be less than 50% of the original value,

terminate the test.

9 Result processing

9.1 Relationship between the aging coefficient y and the aging time t and

the test temperature T

The relationship between the aging coefficient y and the aging time t and the

test temperature T can be described by formula (1):

Where,

n - Points of test data;

α - Confidence level;

- Residual standard deviation.

Substitute formula (10) into formula (9) to obtain a given aging temperature and

aging time. The maximum performance change of y under the confidence level

1-α is shown in formula (11):

9.6 Determination of service life

9.6.1 Determination of threshold value

9.6.1.1 The threshold value is determined by an assessment test that simulates

the use conditions of static sealing rubber products. Choose a suitable

temperature from the test temperature. Accelerate the aging of static sealing

rubber products and standard samples at the selected temperature. Through

the functional simulation test of rubber sealing products, find the aging time of

the loss of sealing performance of static sealing rubber products. According to

the performance change of the standard specimen at this time, determine the

threshold value y0 for the failure of static sealing rubber products.

9.6.1.2 The threshold value can also be the limit allowable value of the relevant

performance stipulated in the technical conditions of static sealing rubber

products.

9.6.2 Determination of service life

The maximum performance change of y after different ag...

Share