1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 2970-2016 English PDF (GB/T2970-2016)

GB/T 2970-2016 English PDF (GB/T2970-2016)

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 2970-2016: Method for ultrasonic testing of thicker steel plates

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 2970-2016 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 2970-2016

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 2970-2016

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.20

H 26

Replacing GB/T 2970-2004

Method for ultrasonic testing of thicker steel plates

ISSUED ON. FEBRUARY 24, 2016

IMPLEMENTED ON. SEPTEMBER 1, 2016

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 General requirements ... 4

4 Contrast samples ... 5

5 Testing instruments and equipment ... 8

6 Test conditions and methods ... 9

7 Defect determination and assessment ... 10

8 Quality grading of steel plates ... 12

9 Testing report ... 12

Appendix A (Normative) Methods for transverse wave testing of steel plates 13

Appendix B (Normative) Property requirements of dual-crystal probes ... 17

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 2970-2004 Thicker steel plates - Method for

ultrasonic inspection. Compared with GB/T 2970-2004, the major technical

changes are as follows.

— MODIFY the debugging method for sensitivity of dual-crystal straight

beam probes. For the steel plates with the thicknesses of greater than

60mm, the debugging method for testing sensitivity of dual-crystal

straight beam probes is consistent with that of single-crystal straight

beam probes.

— STIPULATE similar acoustic properties, which is “the acoustic attenuation

bias shall be within the range of ± 25%”.

— ADD the provisions on the contrast samples of the single-crystal straight

beam probes for the steel plates with the thicknesses of greater than

200mm.

— ADD “rectangular groove” to the “dynamic samples”.

— MODIFY the test method of defect boundaries and lengths.

— ADD Appendix A (Normative).

This Standard was proposed by China Iron and Steel Association.

This Standard shall be under the jurisdiction of the National Technical

Committee for Standardization of Steels (SAC/TC 183).

Drafting organizations of this Standard. Central Iron and Steel Research

Institute, Eddysun (Xiamen) Electronic Co., Ltd, China Metallurgical Information

and Standardization Institute, Sichuan Xingtianyuan Material Testing

Technology Co., Ltd, and NCS Testing Technology Co., Ltd.

Main drafters of this Standard. Zhang Jianwei, Fan Hong, Lin Junming, Dong

Li, Liu Changqing, Zhang Ke, Shen Haihong, Jia Huiming, Yuan Gangqiang and

Zhang Weixu.

The previous released editions replaced by this Standard are as follows.

— GB/T 2970-1982, GB/T 2970-1991 and GB/T 2970-2004.

Method for ultrasonic testing of thicker steel plates

1 Scope

This Standard specifies the general requirements, contrast samples, testing

instruments and equipment, test conditions and methods, defect determination

and assessment, quality grading of steel plates, and testing report of the

ultrasonic testing of thicker steel plates.

This Standard is applicable to the ultrasonic testing of the steel plates with the

thicknesses of not less than 6mm and used in pressure elements, bridges,

buildings, shipbuilding, steel structures, pipelines, moulds, etc. The austenitic

stainless steel plates can also make reference to this Standard.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 8651 Flaw detection method by the ultrasonic plate wave for metal

plates

JB/T 10061 Commonly used specification for A-mode ultrasonic flaw

detector using pulse echo technique

3 General requirements

3.1 The surfaces of the tested plates shall be flat and smooth along with

uniform thickness. There shall be no droplets, oil stains, corrosions and other

dirt.

3.2 During testing, the internal constitutions of the tested plates shall not

generate interference echoes affecting the testing.

3.3 The detection sites shall avoid the following factors that affect the stability

of ultrasonic flaw detectors and the reliable observation of detection personnel,

such as strong light, strong magnetic fields, strong vibration, corrosive gases,

severe dust, etc.

3.4 The personnel engaged in ultrasonic testing of steel plates shall be trained,

and obtained Level 1 qualification certificate and above of professional

ultrasonic flaw detection issued by certification authorities. The personnel

issuing the flaw detection reports shall obtain Level 2 qualification certificate

and above of professional ultrasonic flaw detection issued by certification

authorities.

3.5 It is allowed to scan manually and automatically. It is allowed to use the

piezoelectric (contact and immersion methods) and electromagnetic ultrasonic

testing methods.

3.6 The adopted ultrasonic wave shapes can be longitudinal waves,

transverse waves and plate waves. When using transverse waves as the

supplement of the longitudinal wave testing, it shall be agreed upon by the

supply and requisitioning parties when ordering goods.

4 Contrast samples

4.1 The materials and acoustic properties of the contrast samples shall be the

same or similar with those of the tested steel plates (the acoustic attenuation

bias shall be within the range of ± 25%). Furthermore, ENSURE that there are

no defects affecting the testing inside.

4.2 When using a dual-crystal straight beam probe to test the steel plates with

the thicknesses of not greater than 60mm, the contrast samples being used are

shown in Figure 1. When using a dual-crystal straight beam probe to test the

steel plates with the thicknesses of greater than 60mm, the contrast samples

shall conform to the provisions of Figure 2 as well as Tables 1 and 2. For the

test block in Figure 2, the variation of its perpendicularity a along with the test

block thickness shall meet the requirements of Table 2.

4.3 When using a single-crystal straight beam probe for testing, the contrast

samples shall conform to the provisions of Figure 2 as well as Tables 1 and 2.

4.4 When using the piezoelectric or electromagnetic automatic ultrasonic

testing method, the long side of the dynamic contrast sample shall be parallel

to the calendaring direction. In the meantime, the end surface shall be straight.

It is allowed to make reference to Figure 3 for the preparation of the dynamic

contrast sample.

4.5 For the form of using plate waves for contrast sample testing, SEE GB/T

8651. For the contrast samples tested by using transverse waves, SEE

Appendix A of this Standard.

Note 2. The dimensions of 1#, 2# and 3# manual defects are 50mm × 10mm (length × width).

Note 3. 4# manual defect refers to rectangular notch groove. The groove is 3mm in width. PROCESS the

depth as required.

Note 4. According to different requirements for flaw detection, it is allowed to add appropriate number of

the flat-bottomed holes with the equivalent diameter of 5mm or other equivalents in appropriate

positions (the distance between tested surface and flat-bottomed hole shall be in accordance

with Table 1).

Figure 3 Dynamic Contrast Sample for Automatic Ultrasonic Testing

5 Testing instruments and equipment

5.1 Flaw detector

The properties of the flaw detector being used shall conform to the relevant

provisions of JB/T 10061.

5.2 Transducer

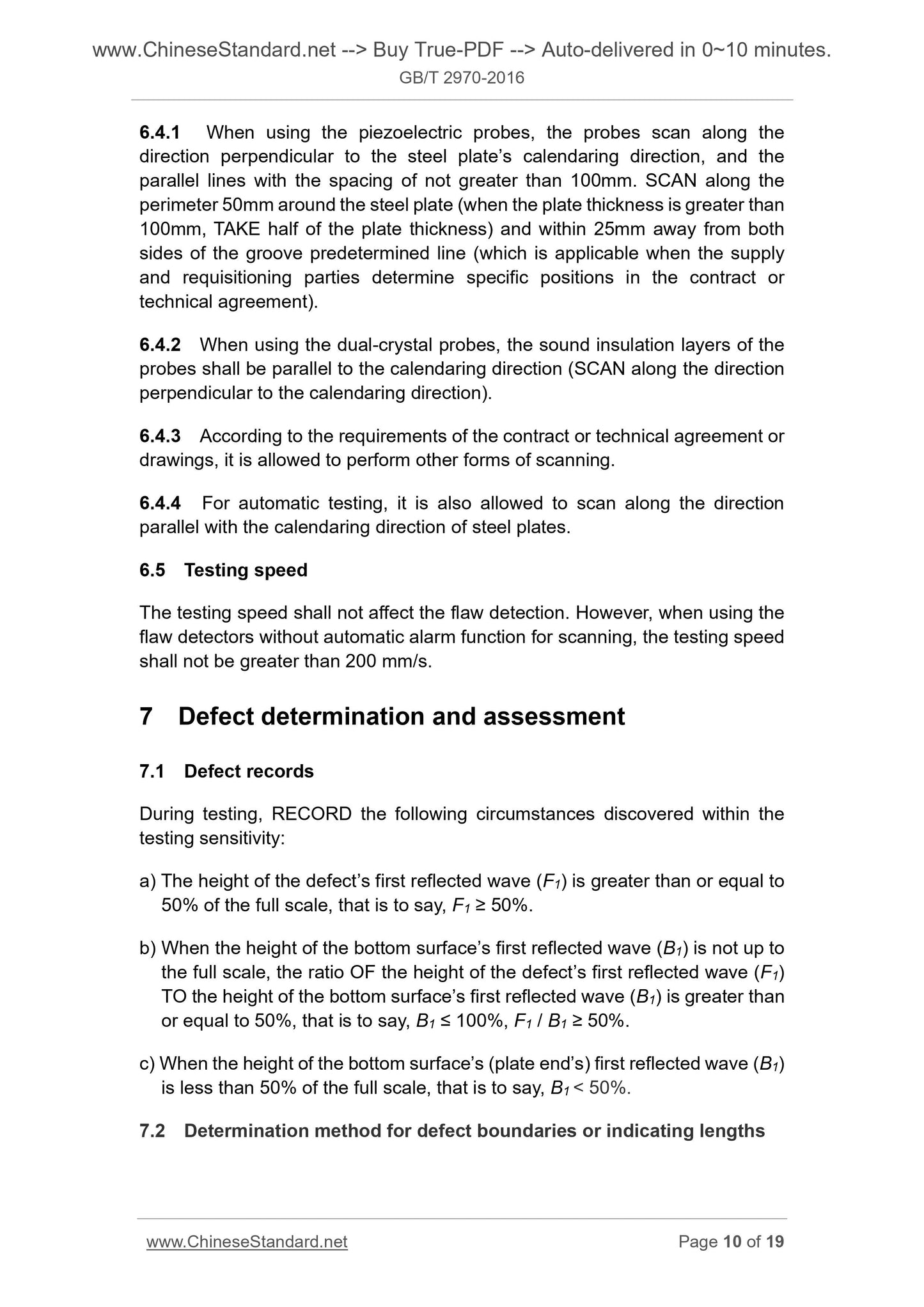

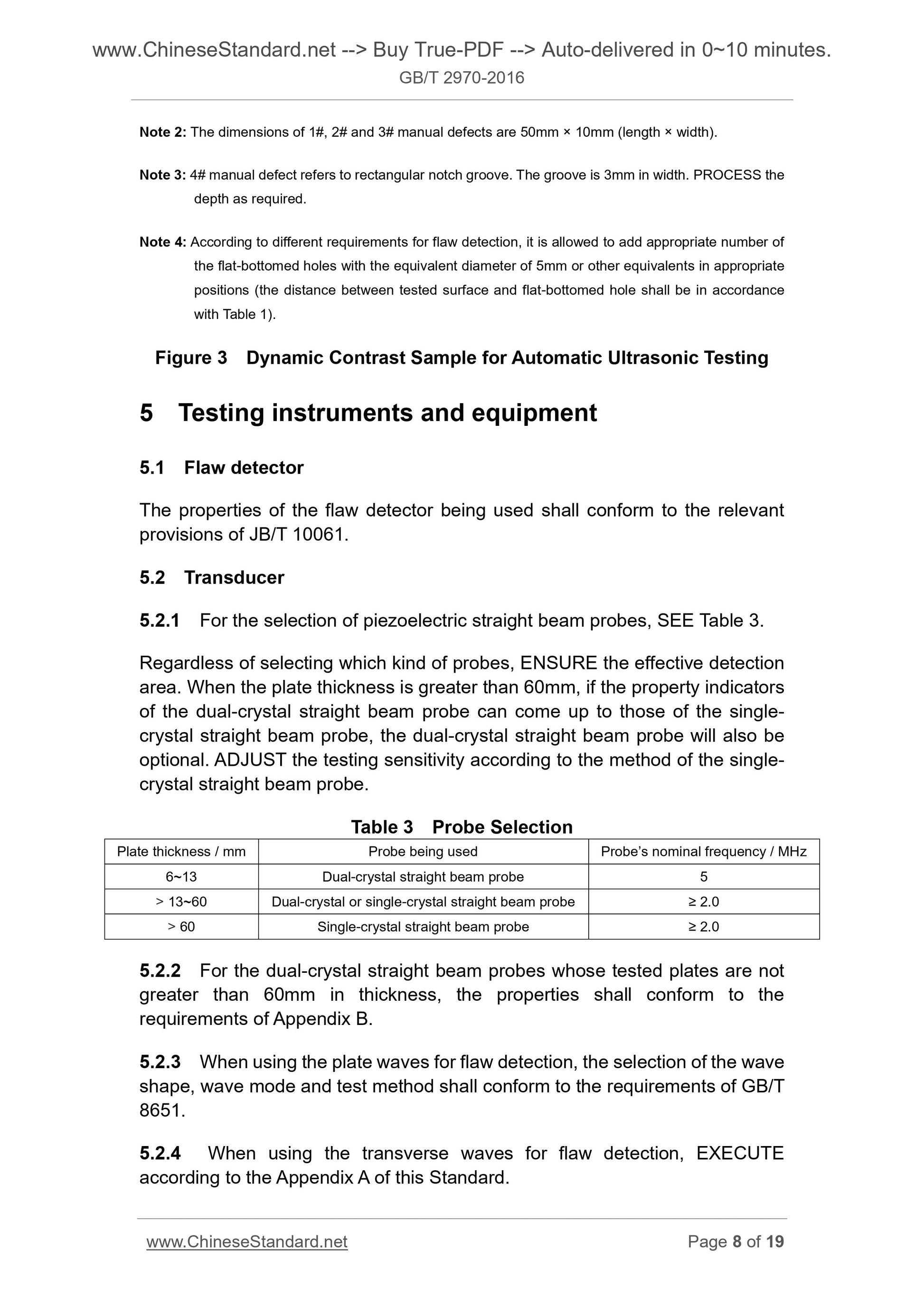

5.2.1 For the selection of piezoelectric straight beam probes, SEE Table 3.

Regardless of selecting which kind of probes, ENSURE the effective detection

area. When the plate thickness is greater than 60mm, if the property indicators

of the dual-crystal straight beam probe can come up to those of the single-

crystal straight beam probe, the dual-crystal straight beam probe will also be

optional. ADJUST the testing sensitivity according to the method of the single-

crystal straight beam probe.

Table 3 Probe Selection

Plate thickness / mm Probe being used Probe’s nominal frequency / MHz

6~13 Dual-crystal straight beam probe 5

> 13~60 Dual-crystal or single-crystal straight beam probe ≥ 2.0

> 60 Single-crystal straight beam probe ≥ 2.0

5.2.2 For the dual-crystal straight beam probes whose tested plates are not

greater than 60mm in thickness, the properties shall conform to the

requirements of Appendix B.

5.2.3 When using the plate waves for flaw detection, the selection of the wave

shape, wave mode and test method shall conform to the requirements of GB/T

8651.

5.2.4 When using the transverse waves for flaw detection, EXECUTE

according to the Appendix A of this Standard.

6.4.1 When using the piezoelectric probes, the probes scan along the

direction perpendicular to the steel plate’s calendaring direction, and the

parallel lines with the spacing of not greater than 100mm. SCAN along the

perimeter 50mm around the steel plate (when the plate thickness is greater than

100mm, TAKE h...

GB/T 2970-2016

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.20

H 26

Replacing GB/T 2970-2004

Method for ultrasonic testing of thicker steel plates

ISSUED ON. FEBRUARY 24, 2016

IMPLEMENTED ON. SEPTEMBER 1, 2016

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 General requirements ... 4

4 Contrast samples ... 5

5 Testing instruments and equipment ... 8

6 Test conditions and methods ... 9

7 Defect determination and assessment ... 10

8 Quality grading of steel plates ... 12

9 Testing report ... 12

Appendix A (Normative) Methods for transverse wave testing of steel plates 13

Appendix B (Normative) Property requirements of dual-crystal probes ... 17

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 2970-2004 Thicker steel plates - Method for

ultrasonic inspection. Compared with GB/T 2970-2004, the major technical

changes are as follows.

— MODIFY the debugging method for sensitivity of dual-crystal straight

beam probes. For the steel plates with the thicknesses of greater than

60mm, the debugging method for testing sensitivity of dual-crystal

straight beam probes is consistent with that of single-crystal straight

beam probes.

— STIPULATE similar acoustic properties, which is “the acoustic attenuation

bias shall be within the range of ± 25%”.

— ADD the provisions on the contrast samples of the single-crystal straight

beam probes for the steel plates with the thicknesses of greater than

200mm.

— ADD “rectangular groove” to the “dynamic samples”.

— MODIFY the test method of defect boundaries and lengths.

— ADD Appendix A (Normative).

This Standard was proposed by China Iron and Steel Association.

This Standard shall be under the jurisdiction of the National Technical

Committee for Standardization of Steels (SAC/TC 183).

Drafting organizations of this Standard. Central Iron and Steel Research

Institute, Eddysun (Xiamen) Electronic Co., Ltd, China Metallurgical Information

and Standardization Institute, Sichuan Xingtianyuan Material Testing

Technology Co., Ltd, and NCS Testing Technology Co., Ltd.

Main drafters of this Standard. Zhang Jianwei, Fan Hong, Lin Junming, Dong

Li, Liu Changqing, Zhang Ke, Shen Haihong, Jia Huiming, Yuan Gangqiang and

Zhang Weixu.

The previous released editions replaced by this Standard are as follows.

— GB/T 2970-1982, GB/T 2970-1991 and GB/T 2970-2004.

Method for ultrasonic testing of thicker steel plates

1 Scope

This Standard specifies the general requirements, contrast samples, testing

instruments and equipment, test conditions and methods, defect determination

and assessment, quality grading of steel plates, and testing report of the

ultrasonic testing of thicker steel plates.

This Standard is applicable to the ultrasonic testing of the steel plates with the

thicknesses of not less than 6mm and used in pressure elements, bridges,

buildings, shipbuilding, steel structures, pipelines, moulds, etc. The austenitic

stainless steel plates can also make reference to this Standard.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 8651 Flaw detection method by the ultrasonic plate wave for metal

plates

JB/T 10061 Commonly used specification for A-mode ultrasonic flaw

detector using pulse echo technique

3 General requirements

3.1 The surfaces of the tested plates shall be flat and smooth along with

uniform thickness. There shall be no droplets, oil stains, corrosions and other

dirt.

3.2 During testing, the internal constitutions of the tested plates shall not

generate interference echoes affecting the testing.

3.3 The detection sites shall avoid the following factors that affect the stability

of ultrasonic flaw detectors and the reliable observation of detection personnel,

such as strong light, strong magnetic fields, strong vibration, corrosive gases,

severe dust, etc.

3.4 The personnel engaged in ultrasonic testing of steel plates shall be trained,

and obtained Level 1 qualification certificate and above of professional

ultrasonic flaw detection issued by certification authorities. The personnel

issuing the flaw detection reports shall obtain Level 2 qualification certificate

and above of professional ultrasonic flaw detection issued by certification

authorities.

3.5 It is allowed to scan manually and automatically. It is allowed to use the

piezoelectric (contact and immersion methods) and el...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 2970-2016 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 2970-2016

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 2970-2016

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.20

H 26

Replacing GB/T 2970-2004

Method for ultrasonic testing of thicker steel plates

ISSUED ON. FEBRUARY 24, 2016

IMPLEMENTED ON. SEPTEMBER 1, 2016

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 General requirements ... 4

4 Contrast samples ... 5

5 Testing instruments and equipment ... 8

6 Test conditions and methods ... 9

7 Defect determination and assessment ... 10

8 Quality grading of steel plates ... 12

9 Testing report ... 12

Appendix A (Normative) Methods for transverse wave testing of steel plates 13

Appendix B (Normative) Property requirements of dual-crystal probes ... 17

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 2970-2004 Thicker steel plates - Method for

ultrasonic inspection. Compared with GB/T 2970-2004, the major technical

changes are as follows.

— MODIFY the debugging method for sensitivity of dual-crystal straight

beam probes. For the steel plates with the thicknesses of greater than

60mm, the debugging method for testing sensitivity of dual-crystal

straight beam probes is consistent with that of single-crystal straight

beam probes.

— STIPULATE similar acoustic properties, which is “the acoustic attenuation

bias shall be within the range of ± 25%”.

— ADD the provisions on the contrast samples of the single-crystal straight

beam probes for the steel plates with the thicknesses of greater than

200mm.

— ADD “rectangular groove” to the “dynamic samples”.

— MODIFY the test method of defect boundaries and lengths.

— ADD Appendix A (Normative).

This Standard was proposed by China Iron and Steel Association.

This Standard shall be under the jurisdiction of the National Technical

Committee for Standardization of Steels (SAC/TC 183).

Drafting organizations of this Standard. Central Iron and Steel Research

Institute, Eddysun (Xiamen) Electronic Co., Ltd, China Metallurgical Information

and Standardization Institute, Sichuan Xingtianyuan Material Testing

Technology Co., Ltd, and NCS Testing Technology Co., Ltd.

Main drafters of this Standard. Zhang Jianwei, Fan Hong, Lin Junming, Dong

Li, Liu Changqing, Zhang Ke, Shen Haihong, Jia Huiming, Yuan Gangqiang and

Zhang Weixu.

The previous released editions replaced by this Standard are as follows.

— GB/T 2970-1982, GB/T 2970-1991 and GB/T 2970-2004.

Method for ultrasonic testing of thicker steel plates

1 Scope

This Standard specifies the general requirements, contrast samples, testing

instruments and equipment, test conditions and methods, defect determination

and assessment, quality grading of steel plates, and testing report of the

ultrasonic testing of thicker steel plates.

This Standard is applicable to the ultrasonic testing of the steel plates with the

thicknesses of not less than 6mm and used in pressure elements, bridges,

buildings, shipbuilding, steel structures, pipelines, moulds, etc. The austenitic

stainless steel plates can also make reference to this Standard.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 8651 Flaw detection method by the ultrasonic plate wave for metal

plates

JB/T 10061 Commonly used specification for A-mode ultrasonic flaw

detector using pulse echo technique

3 General requirements

3.1 The surfaces of the tested plates shall be flat and smooth along with

uniform thickness. There shall be no droplets, oil stains, corrosions and other

dirt.

3.2 During testing, the internal constitutions of the tested plates shall not

generate interference echoes affecting the testing.

3.3 The detection sites shall avoid the following factors that affect the stability

of ultrasonic flaw detectors and the reliable observation of detection personnel,

such as strong light, strong magnetic fields, strong vibration, corrosive gases,

severe dust, etc.

3.4 The personnel engaged in ultrasonic testing of steel plates shall be trained,

and obtained Level 1 qualification certificate and above of professional

ultrasonic flaw detection issued by certification authorities. The personnel

issuing the flaw detection reports shall obtain Level 2 qualification certificate

and above of professional ultrasonic flaw detection issued by certification

authorities.

3.5 It is allowed to scan manually and automatically. It is allowed to use the

piezoelectric (contact and immersion methods) and electromagnetic ultrasonic

testing methods.

3.6 The adopted ultrasonic wave shapes can be longitudinal waves,

transverse waves and plate waves. When using transverse waves as the

supplement of the longitudinal wave testing, it shall be agreed upon by the

supply and requisitioning parties when ordering goods.

4 Contrast samples

4.1 The materials and acoustic properties of the contrast samples shall be the

same or similar with those of the tested steel plates (the acoustic attenuation

bias shall be within the range of ± 25%). Furthermore, ENSURE that there are

no defects affecting the testing inside.

4.2 When using a dual-crystal straight beam probe to test the steel plates with

the thicknesses of not greater than 60mm, the contrast samples being used are

shown in Figure 1. When using a dual-crystal straight beam probe to test the

steel plates with the thicknesses of greater than 60mm, the contrast samples

shall conform to the provisions of Figure 2 as well as Tables 1 and 2. For the

test block in Figure 2, the variation of its perpendicularity a along with the test

block thickness shall meet the requirements of Table 2.

4.3 When using a single-crystal straight beam probe for testing, the contrast

samples shall conform to the provisions of Figure 2 as well as Tables 1 and 2.

4.4 When using the piezoelectric or electromagnetic automatic ultrasonic

testing method, the long side of the dynamic contrast sample shall be parallel

to the calendaring direction. In the meantime, the end surface shall be straight.

It is allowed to make reference to Figure 3 for the preparation of the dynamic

contrast sample.

4.5 For the form of using plate waves for contrast sample testing, SEE GB/T

8651. For the contrast samples tested by using transverse waves, SEE

Appendix A of this Standard.

Note 2. The dimensions of 1#, 2# and 3# manual defects are 50mm × 10mm (length × width).

Note 3. 4# manual defect refers to rectangular notch groove. The groove is 3mm in width. PROCESS the

depth as required.

Note 4. According to different requirements for flaw detection, it is allowed to add appropriate number of

the flat-bottomed holes with the equivalent diameter of 5mm or other equivalents in appropriate

positions (the distance between tested surface and flat-bottomed hole shall be in accordance

with Table 1).

Figure 3 Dynamic Contrast Sample for Automatic Ultrasonic Testing

5 Testing instruments and equipment

5.1 Flaw detector

The properties of the flaw detector being used shall conform to the relevant

provisions of JB/T 10061.

5.2 Transducer

5.2.1 For the selection of piezoelectric straight beam probes, SEE Table 3.

Regardless of selecting which kind of probes, ENSURE the effective detection

area. When the plate thickness is greater than 60mm, if the property indicators

of the dual-crystal straight beam probe can come up to those of the single-

crystal straight beam probe, the dual-crystal straight beam probe will also be

optional. ADJUST the testing sensitivity according to the method of the single-

crystal straight beam probe.

Table 3 Probe Selection

Plate thickness / mm Probe being used Probe’s nominal frequency / MHz

6~13 Dual-crystal straight beam probe 5

> 13~60 Dual-crystal or single-crystal straight beam probe ≥ 2.0

> 60 Single-crystal straight beam probe ≥ 2.0

5.2.2 For the dual-crystal straight beam probes whose tested plates are not

greater than 60mm in thickness, the properties shall conform to the

requirements of Appendix B.

5.2.3 When using the plate waves for flaw detection, the selection of the wave

shape, wave mode and test method shall conform to the requirements of GB/T

8651.

5.2.4 When using the transverse waves for flaw detection, EXECUTE

according to the Appendix A of this Standard.

6.4.1 When using the piezoelectric probes, the probes scan along the

direction perpendicular to the steel plate’s calendaring direction, and the

parallel lines with the spacing of not greater than 100mm. SCAN along the

perimeter 50mm around the steel plate (when the plate thickness is greater than

100mm, TAKE h...

GB/T 2970-2016

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.20

H 26

Replacing GB/T 2970-2004

Method for ultrasonic testing of thicker steel plates

ISSUED ON. FEBRUARY 24, 2016

IMPLEMENTED ON. SEPTEMBER 1, 2016

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 General requirements ... 4

4 Contrast samples ... 5

5 Testing instruments and equipment ... 8

6 Test conditions and methods ... 9

7 Defect determination and assessment ... 10

8 Quality grading of steel plates ... 12

9 Testing report ... 12

Appendix A (Normative) Methods for transverse wave testing of steel plates 13

Appendix B (Normative) Property requirements of dual-crystal probes ... 17

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 2970-2004 Thicker steel plates - Method for

ultrasonic inspection. Compared with GB/T 2970-2004, the major technical

changes are as follows.

— MODIFY the debugging method for sensitivity of dual-crystal straight

beam probes. For the steel plates with the thicknesses of greater than

60mm, the debugging method for testing sensitivity of dual-crystal

straight beam probes is consistent with that of single-crystal straight

beam probes.

— STIPULATE similar acoustic properties, which is “the acoustic attenuation

bias shall be within the range of ± 25%”.

— ADD the provisions on the contrast samples of the single-crystal straight

beam probes for the steel plates with the thicknesses of greater than

200mm.

— ADD “rectangular groove” to the “dynamic samples”.

— MODIFY the test method of defect boundaries and lengths.

— ADD Appendix A (Normative).

This Standard was proposed by China Iron and Steel Association.

This Standard shall be under the jurisdiction of the National Technical

Committee for Standardization of Steels (SAC/TC 183).

Drafting organizations of this Standard. Central Iron and Steel Research

Institute, Eddysun (Xiamen) Electronic Co., Ltd, China Metallurgical Information

and Standardization Institute, Sichuan Xingtianyuan Material Testing

Technology Co., Ltd, and NCS Testing Technology Co., Ltd.

Main drafters of this Standard. Zhang Jianwei, Fan Hong, Lin Junming, Dong

Li, Liu Changqing, Zhang Ke, Shen Haihong, Jia Huiming, Yuan Gangqiang and

Zhang Weixu.

The previous released editions replaced by this Standard are as follows.

— GB/T 2970-1982, GB/T 2970-1991 and GB/T 2970-2004.

Method for ultrasonic testing of thicker steel plates

1 Scope

This Standard specifies the general requirements, contrast samples, testing

instruments and equipment, test conditions and methods, defect determination

and assessment, quality grading of steel plates, and testing report of the

ultrasonic testing of thicker steel plates.

This Standard is applicable to the ultrasonic testing of the steel plates with the

thicknesses of not less than 6mm and used in pressure elements, bridges,

buildings, shipbuilding, steel structures, pipelines, moulds, etc. The austenitic

stainless steel plates can also make reference to this Standard.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 8651 Flaw detection method by the ultrasonic plate wave for metal

plates

JB/T 10061 Commonly used specification for A-mode ultrasonic flaw

detector using pulse echo technique

3 General requirements

3.1 The surfaces of the tested plates shall be flat and smooth along with

uniform thickness. There shall be no droplets, oil stains, corrosions and other

dirt.

3.2 During testing, the internal constitutions of the tested plates shall not

generate interference echoes affecting the testing.

3.3 The detection sites shall avoid the following factors that affect the stability

of ultrasonic flaw detectors and the reliable observation of detection personnel,

such as strong light, strong magnetic fields, strong vibration, corrosive gases,

severe dust, etc.

3.4 The personnel engaged in ultrasonic testing of steel plates shall be trained,

and obtained Level 1 qualification certificate and above of professional

ultrasonic flaw detection issued by certification authorities. The personnel

issuing the flaw detection reports shall obtain Level 2 qualification certificate

and above of professional ultrasonic flaw detection issued by certification

authorities.

3.5 It is allowed to scan manually and automatically. It is allowed to use the

piezoelectric (contact and immersion methods) and el...

Share