1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 3094-2012 English PDF (GB/T3094-2012)

GB/T 3094-2012 English PDF (GB/T3094-2012)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click GB/T 3094-2012 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 3094-2012

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 3094-2012: Cold drawn shaped steel tubes

GB/T 3094-2012

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

H48

Replacing GB/T 3094-2000

Cold Drawn Shaped Steel Tubes

ISSUED ON. MAY 11, 2012

IMPLEMENTED ON. FEBRUARY 1, 2013

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (AQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Classification and Designation ... 6

4 Ordering Information ... 6

5 Shape, Dimension and Weight ... 7

6 Technical Requirements ... 9

7 Test Methods ... 12

8 Inspection Rules ... 13

9 Packaging, Marking and Quality Certificate ... 13

Appendix A (Normative) Shape and Dimension of Steel Tube ... 14

Appendix B (Normative) Determination Method for Twist Value of Shaped Steel

Tube ... 32

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

This Standard is revised by reference to ASTM A 500-07 "Standard Specification for

Cold-formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and

Shapes".

This Standard replace GB/T 3094-2000 "Cold Drawn Shaped Steel Tubes" (GB/T

3094-2000). Compared with GB/T 3094-2000, the main changes of this Standard are

as follows.

- Quality grades of steel designations Q215, Q235, Q345 and Q390 are added;

Q295 is deleted;

- Ordering information is added;

- Curvature and twist value requirements are modified;

- Marking example is deleted;

- General length is modified;

- Mechanical performance of steel tube is modified;

- Requirements for impact test of steel tube are added;

- Size and dimension of steel tube in Appendix A are modified.

This Standard was proposed by China Iron and Steel Association.

This Standard shall be under the jurisdiction of the National Technical Committee on

Iron and Steel of Standardization Administration of China (SAC/TC 183).

Drafting organizations of this Standard. Shanghai Shaped Steel Tube Co., Ltd. AND

Jiangsu Jieda Specific New Material Co., Ltd.

Chief drafting staffs of this Standard. Gao Zhijian, Chen Hongqi, Zhu Sujian, Xue

Jianliang, Wang Wei, Hu Hongwei, Yang Wenyi and Lei Liangliang.

The previous editions replaced by this Standard are as follows.

- GB 3094-1982;

- GB/T 3094-2000.

Cold Drawn Shaped Steel Tubes

1 Scope

This Standard specifies the classification, designation, ordering information, shape,

dimension, technical requirements, test method, inspection rule, packaging, marking

and quality certificate of cold drawn shaped steel tubes.

This Standard is applicable to cold-drawn simple-section shaped tube (hereinafter

referred to as steel tube).

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated

references, the latest edition of the normative document (including any amendments)

applies.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel Products

GB/T 223.5 Steel and Iron - Determination of Acid-soluble Silicon and Total

Silicon Content - Reduced Molybdosilicate Spectrophotometric Method

GB/T 223.9 Iron, Steel and Alloy - Determination of Aluminum Content - Chrom

Azurol S Photometric Method

GB/T 223.12 GB/T 223.62 Methods for Chemical Analysis of Iron, Steel and Alloy

- The Sodium Carbonate Separation - Diphenyl Carbazide Photometric Method for

the Determination of Chromium Content

GB/T 223.14 Methods for Chemical Analysis of Iron, Steel and Alloy - The

N-benzoy-N-phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.17 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Photometric Method for the Determination of Titanium Content

GB/T 223.19 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Neocuproine - Chloroform Extraction Photometric Method for the Determination of

Copper Content

GB/T 223.23 Iron Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.40 Iron Steel and Alloy - Determination of Niobium Content by the

Sulphochlorophenol S Spectrophotometric Method

GB/T 223.59 Iron Steel and Alloy - Determination of Phosphorus Content -

Bismuth Phosphomolybdate Blue Spectrophotometric Method and Antimony

Phosphomolybdate Blue Spectrophotometric Method

GB/T 223.60 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Perchloric Acid Dehydration Gravimetric Method for the Determination of Silicon

Content

GB/T 223.62 Methods for Chemical Analysis of Iron, Steel and Alloy - The Butyl

Acetate Extraction Photometric Method for the Determination of Phosphorus

Content

GB/T 223.63 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium (Potassium) Periodate Photometric Method for the Determination of

Manganese Content

GB/T 223.64 Iron Steel and Alloy - Determination of Manganese Content - Flame

Atomic Absorption Spectrometric Method

GB/T 223.68 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Potassium Iodate Titration Method after Combustion in the Pipe Furnace for the

Determination of Sulfur Content

GB/T 223.69 Iron Steel and Alloy - Determination of Carbon Contents -

Gas-volumetric Method after Combustion in the Pipe Furnace

GB/T 223.71 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Gravimetric Method after Combustion in the Pipe Furnace for the Determination of

Carbon Content

GB/T 223.72 Iron Steel and Alloy - Determination of Sulfur Content - Gravimetric

Method

GB/T 228.1 Metallic Materials - Tensile Testing - Part 1. Method of Test at Room

Temperature

GB/T 229 Metallic Materials - Charpy Pendulum Impact Test Method

GB/T 699 Quality Carbon Structural Steels

GB/T 700 Carbon Structural Steels

GB/T 1591 High Strength Low Alloy Structural Steels

GB/T 2102 Acceptance, Packing, Marking and Certification of Pipe

GB/T 2975 Steel and Steel Products - Location and Preparation of Test Pieces for

Mechanical Testing

GB/T 3077 Alloy Structure Steels

GB/T 4336 Standard Test Method for Spark Discharge Atomic Emission

Spectrometric Analysis of Carbon and Low-alloy Steel (Routine Method)

GB/T 20066 Steel and Iron - Sampling and Preparation of Samples for the

Determination of Chemical Composition

GB/T 20123 Steel and Iron - Determination of Total Carbon and Sulfur Content

Infrared Absorption Method after Combustion in an Induction Furnace (Routine

Method)

GB/T 20125 Low-alloy Steel - Determination of Multi-element Contents -

Inductively Coupled Plasma Atomic Emission Spectrometric Method

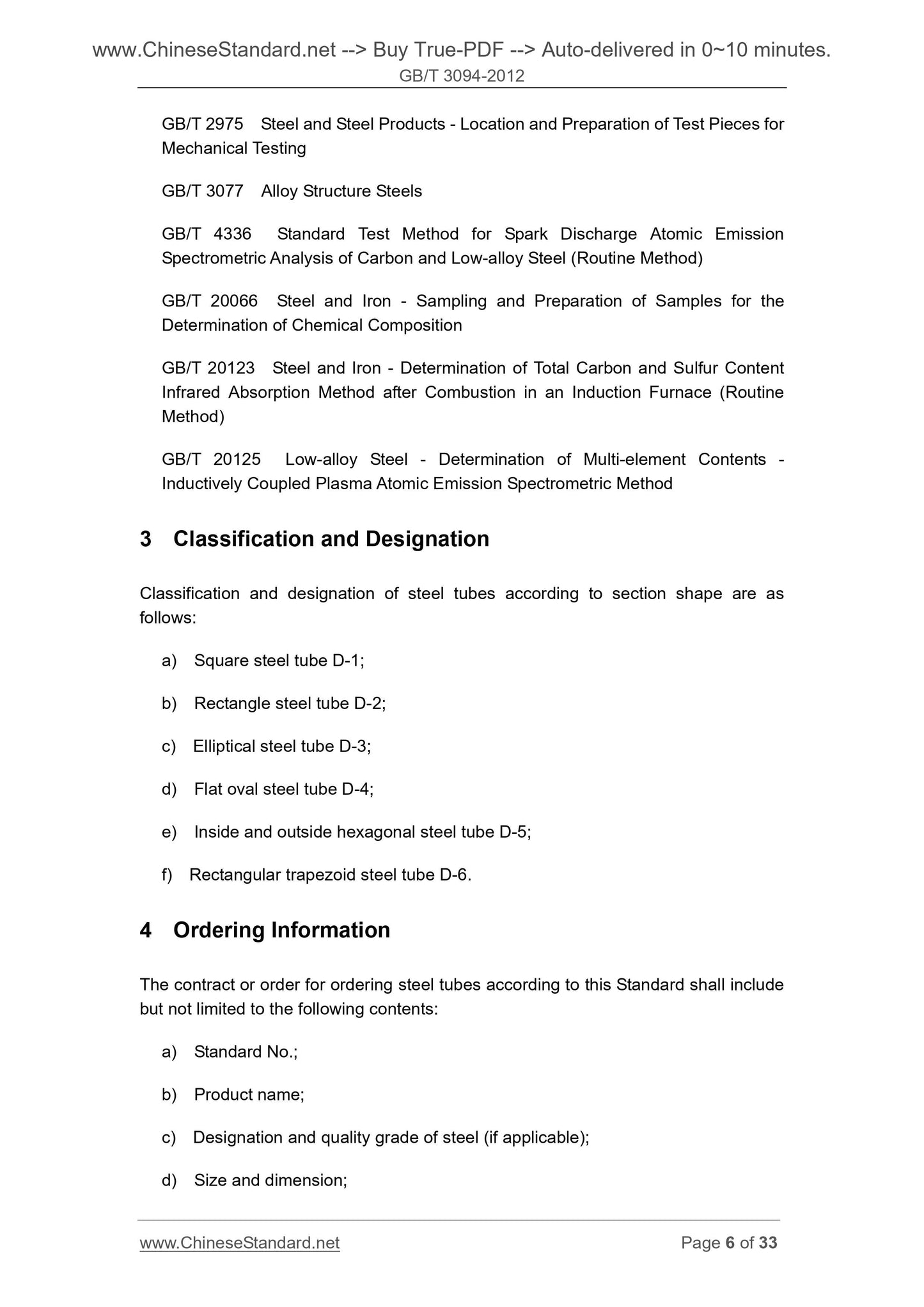

3 Classification and Designation

Classification and designation of steel tubes according to section shape are as

follows.

a) Square steel tube D-1;

b) Rectangle steel tube D-2;

c) Elliptical steel tube D-3;

d) Flat oval steel tube D-4;

e) Inside and outside hexagonal steel tube D-5;

f) Rectangular trapezoid steel tube D-6.

4 Ordering Information

The contract or order for ordering steel tubes according to this Standard shall include

but not limited to the following contents.

a) Standard No.;

b) Product name;

c) Designation and quality grade of steel (if applicable);

d) Size and dimension;

e) Ordering quantity (total weight or total length);

f) Delivery state;

g) Special requirements.

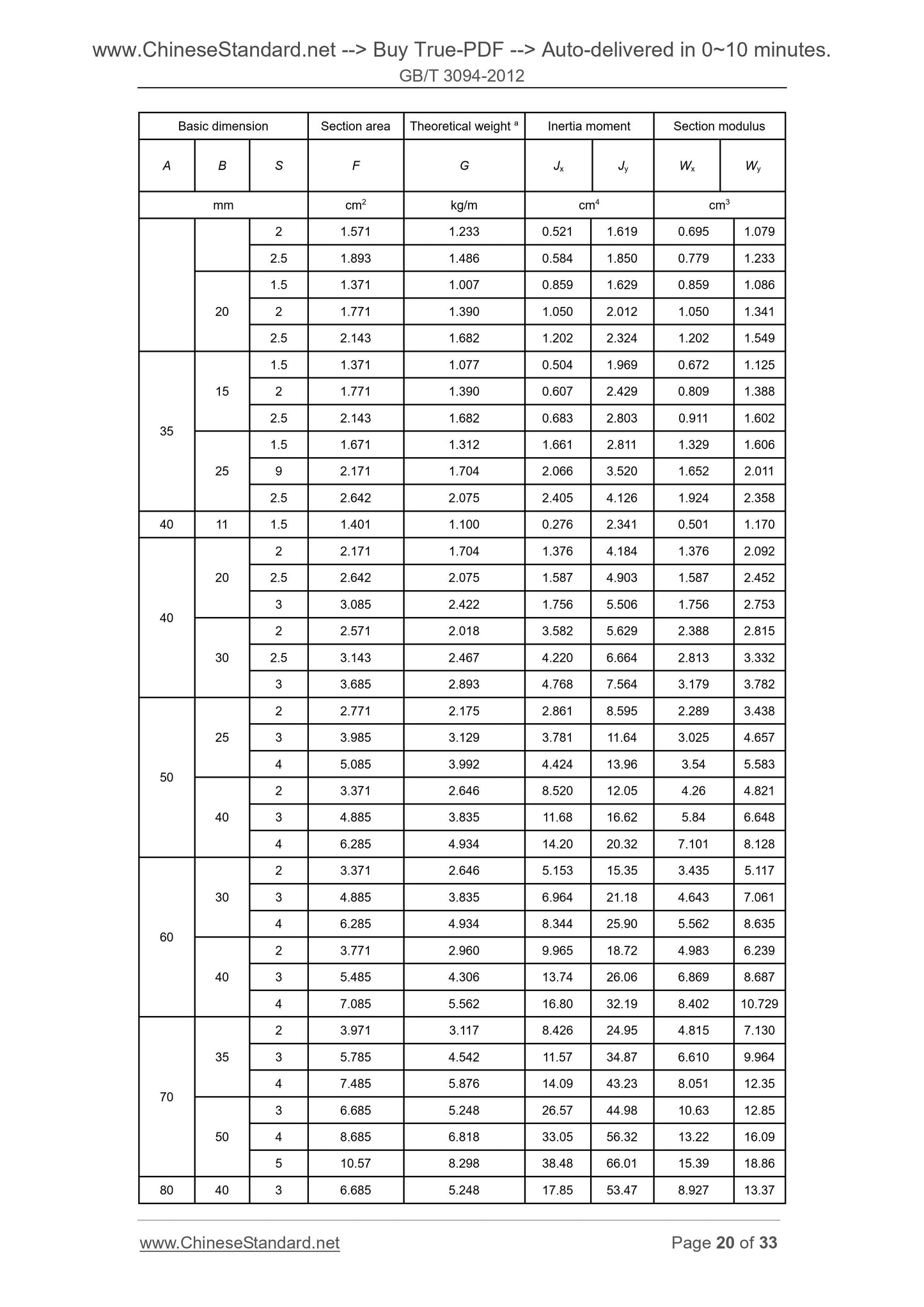

5 Shape, Dimension and Weight

5.1 Shape and dimension

The shape and dimension of steel tube shall respectively meet the requirements of

Figures A.1~A.6 and Tables A.1~A.6 in Appendix A. As negotiated by the supplier and

the purchaser, steel tube with shape and/or size beyond those specified in Figures

A.1~A.6 and Tables A.1~A.6 in Appendix A may be supplied.

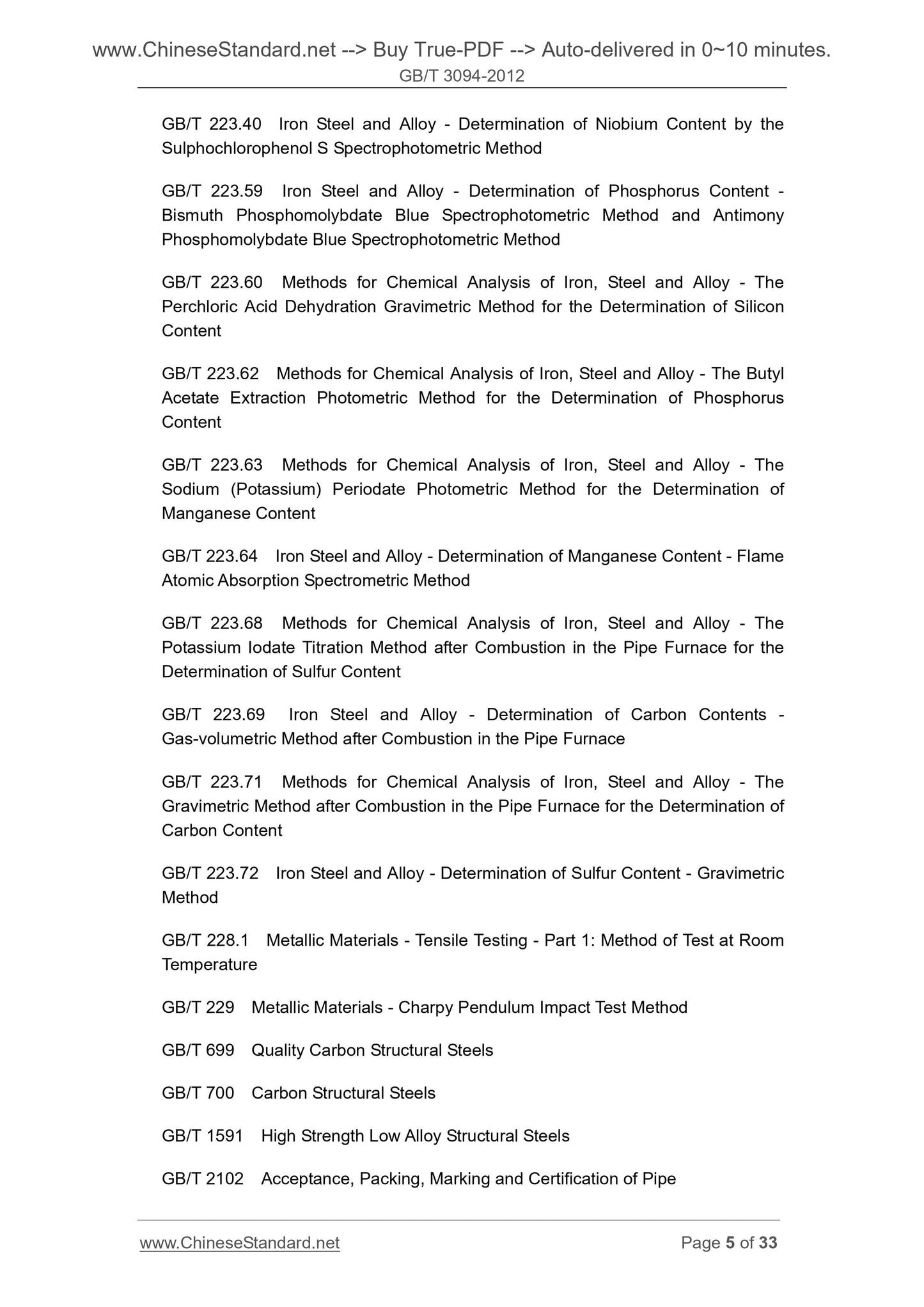

5.2 Permissible deviations in dimensions

The permissible dimension deviation of steel tube shall meet those specified in Table

1.

When the permissible dimension deviation grade is not indicated in the contract by the

purchaser, the permissible dimension deviation of steel tube shall meet the

requirements of ordinary grade dimensional precision. High grade dimensional

precision, when required by the purchaser, shall be indicated in the contract.

As required by the purchaser, steel tube with permissible dimension deviation beyond

those specified in Table 1 may be supplied upon negotiation between the supplier and

the purchaser.

Table 1 Permissible Dimension Deviation of Steel Tube In mm

Dimension

Permissible deviation

Ordinary grade High grade

Side lengths

A and B

≤30 ±0.30 ±0.20

>30~50 ±0.40 ±0.30

>50~75 ±0.80%A and ±0.80%B ±0.7%A and ±0.7%B

>75 ±1%A and ±1%B ±0.8%A and ±0.8%B

Wall thickness

≤1.0 ±0.18 ±0.12

>1.0~3.0 +15%S -10%S

+12.5%S

-10%S

>3.0 +12.5%S -10%S ±10%S

5.3 Side unevenness

Side unevenness of steel tube shall meet those specified in Table 2.

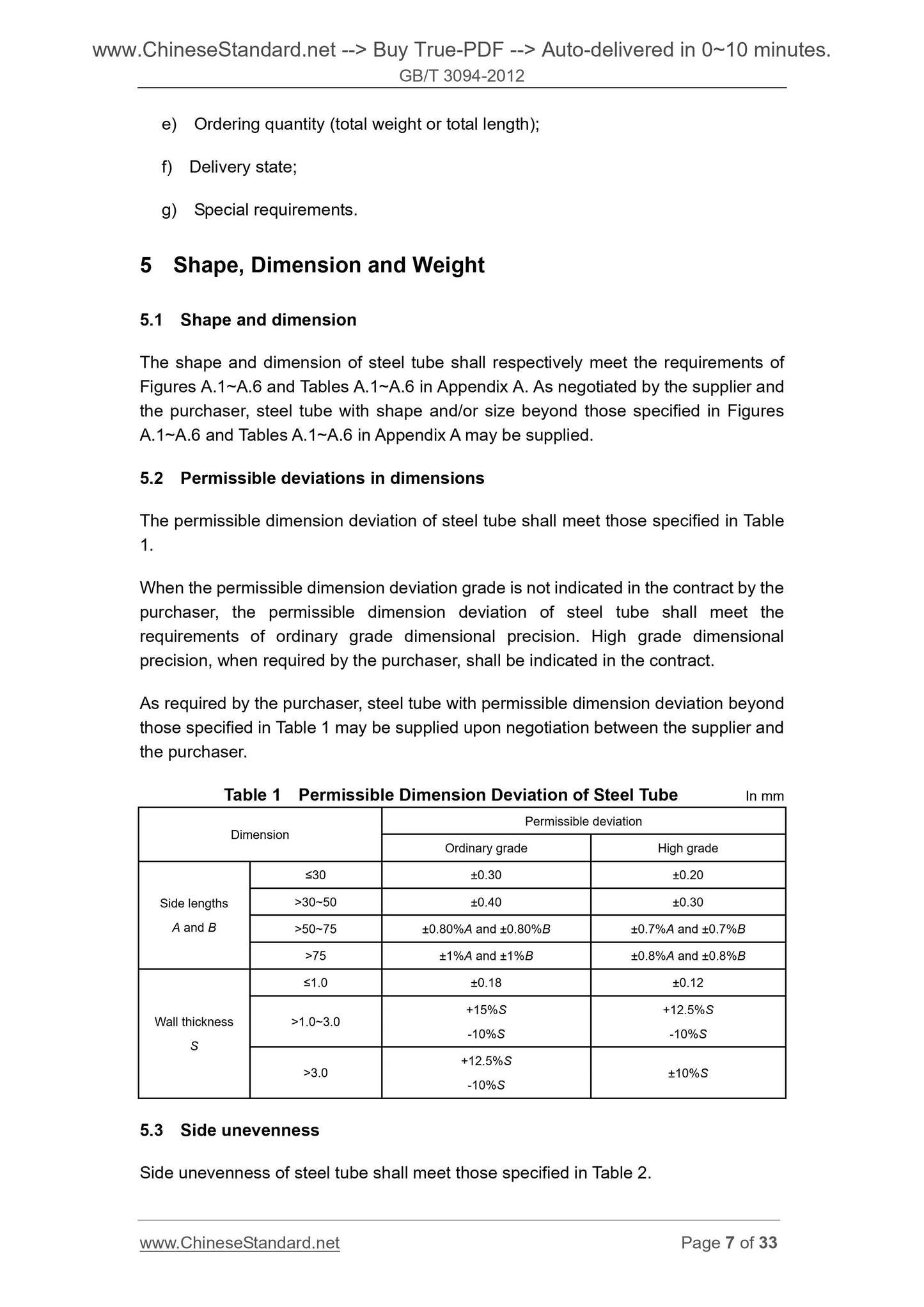

Table 5 Twist Value of Steel Tube

Side length of steel tube/mm Permissible twist value/(mm/m)

≤30 ≤1.5

>30~75 ≤2.0

>75 ≤2.5

5.7 Length

5.7.1 General length

The general length of steel tube is 2000~9000mm.

As required by the purchaser, steel tube with length beyond those specified may be

supplied upon negotiation between the supplier and the purchaser and when

indicated in the contract.

5.7.2 Specified length and multiple length

5.7.2.1 As required by the purchaser, steel tube may be delivered with specified

length or multiple length upon negotiation between the supplier and the purchaser and

when indicated in the contract

5.7.2.2 The specified length and multiple length shall be within the range of general

length. The permissible deviation of the specified length is 15

mm; while that of the

total multiple length is 10

mm; each multiple length shall be remained with a notch

allowance of 5~10mm.

5.8 End shape

End faces on both ends of steel tube shall be vertical to the axis of steel tube, and the

burr on notch shall be removed.

5.9 Weight

The steel tube is delivered according to actual weight. When indicated in the contract,

it may also be delivered according to the theoretical weight. See Appendix A for the

calculation formula of theoretical weight (with steel density of 7.85 kg/dm3).

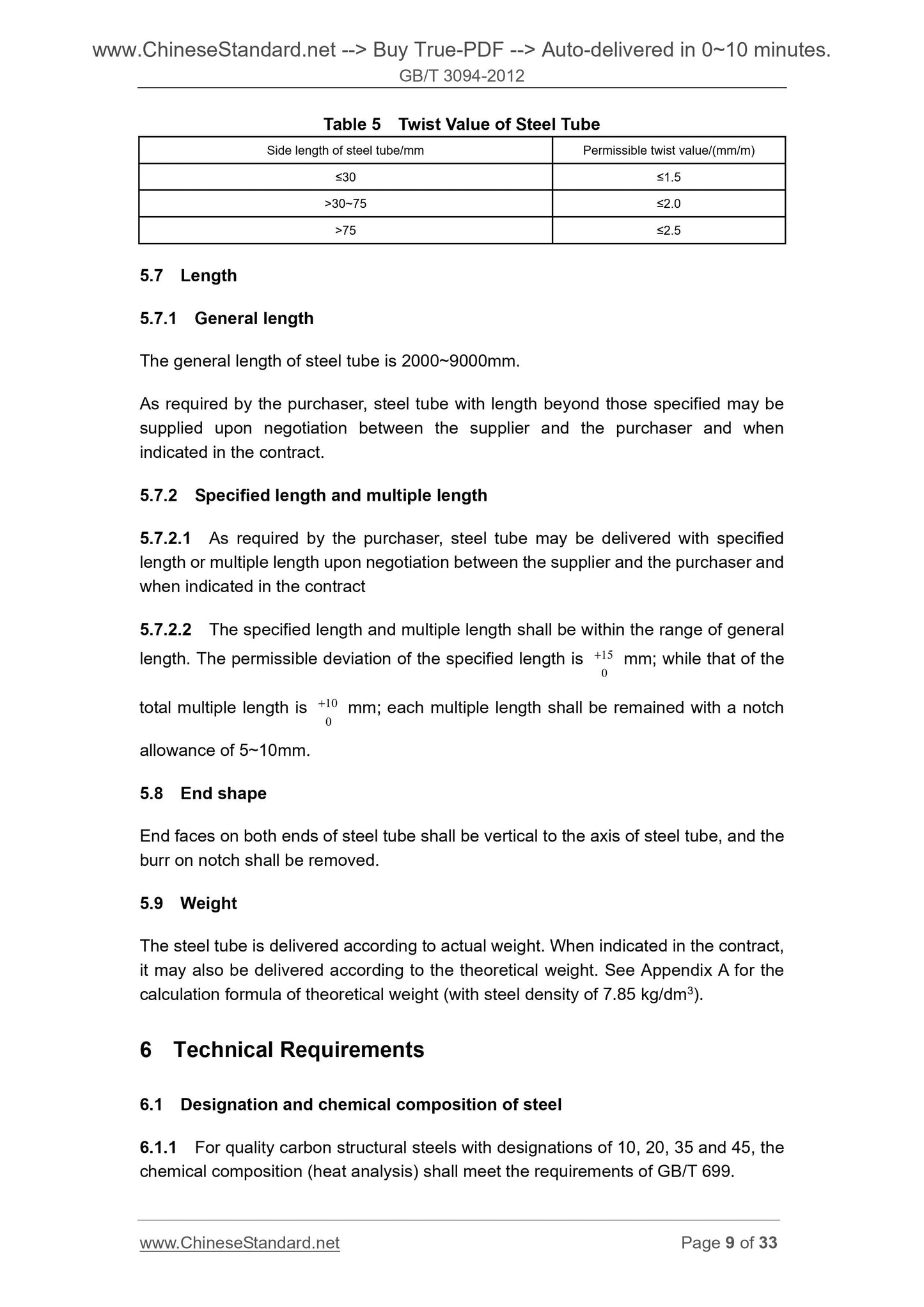

6 Technical Requirements

6.1 Designation and chemical composition of steel

6.1.1 For quality carbon structural steels with designations of 10, 20, 35 and 45, the

chemical composition (heat analysis) shall meet the requirements of GB/T 699.

For carbon structural steels with designations of Q195, Q215 and Q235, the chemical

composition (heat analysis) shall meet the requirements of GB/T 700.

For high strength low alloy structural steels with designations of Q345 and Q390, the

chemical composition (heat analysis) shall meet the requirements of GB/T 1591.

As required by the purchaser, structural alloy steel tube may be supplied upon

negotiation between the supplier and the purchaser, and its designation and chemical

composition (heat analysis) shall meet the requirements of GB/T 3077.

6.1.2 Chemical analysis for finished product, when required by the purchaser, shall

be indicated in the contract. The permissible deviation for chemical composition of

finished steel tube shall meet the requirements of GB/T 222.

6.1.3 As required by the purchaser, steel tube of other designation may be supplied

upon negotiation between the supplier and the purchaser.

6.2 Manufacturing method

6.2.1 Steel tube shall be manufactured of seamless steel tube through cold-drawn

forming.

6.2.2 As required by the purchaser, steel tube may be manufactured of welded steel

tube through cold-drawn forming upon negotiation between the supplier and the

purchaser and when indicated in the contract. The weld of cold-drawn welded steel

tube shall be kept away from round corner.

6.3 Delivery state

The steel tube shall be delivered in cold-drawn state. As required by the purchaser,

the steel tube may be delivered in heat treatment state upon negotiation between the

supplier and the purchaser and when indicated in the contract.

6.4 Mechanical performance

6.4.1 Steel tube delivered in cold-drawn state is not subject to mechanical

performance test. When the steel tube is delivered in heat treatment state, the

longitudinal mechanical performance of steel tube shall meet those specified in Table

6 while that of the structural alloy steel tube shall meet those specified in GB/T 3077.

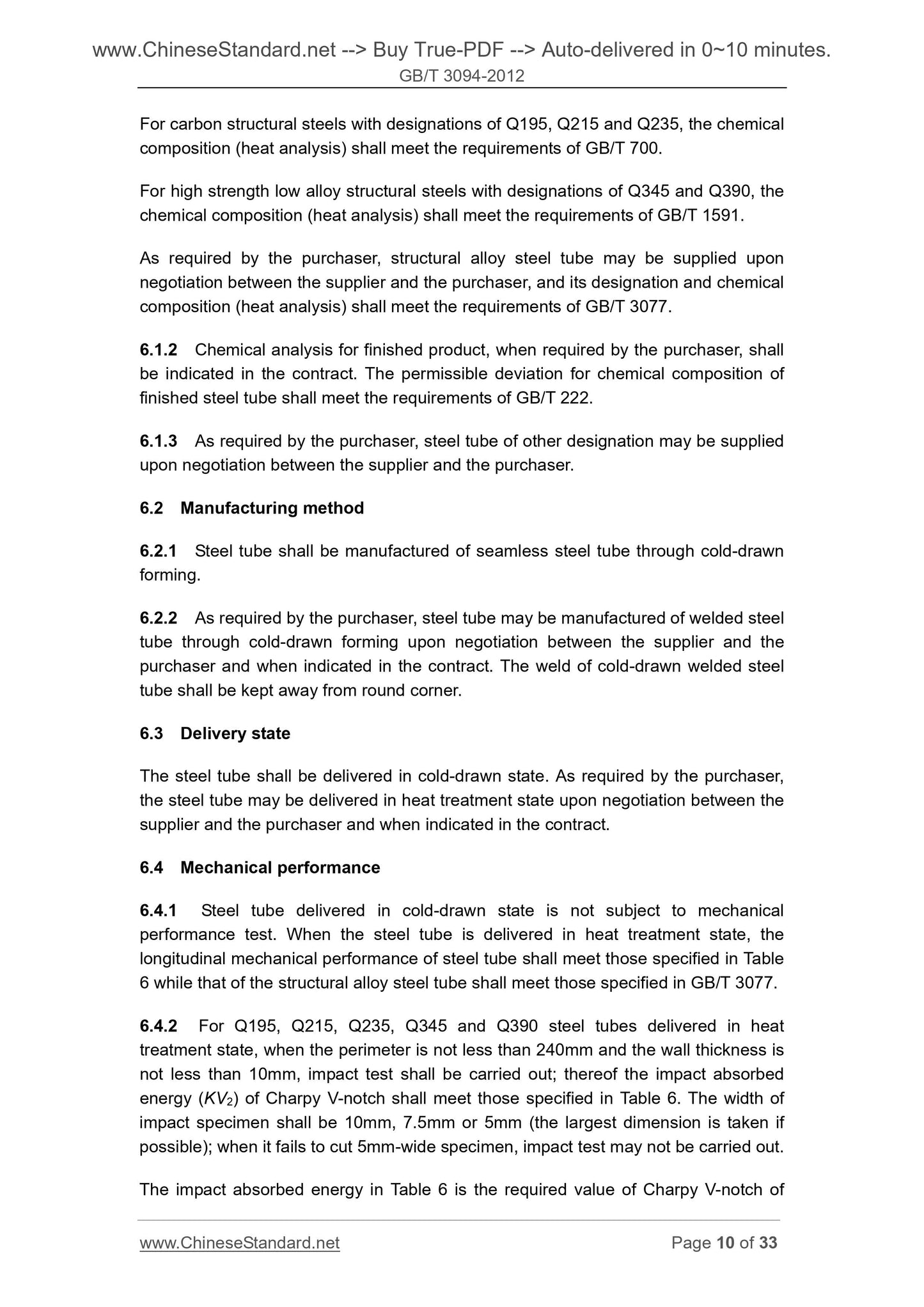

6.4.2 For Q195, Q215, Q235, Q345 and Q390 steel tubes delivered in heat

treatment state, when the perimeter is not less than 240mm and the wall thickness is

not less than 10mm, impact test shall be carried out; thereof the impact absorbed

energy (KV2) of Charpy V-notch shall meet those specified in Table 6. The width of

impact specimen shall be 10mm, 7.5mm or 5mm (the largest dimension is taken if

possible); when it fails to cut 5mm-wide specimen, impact test may not be carried out.

The impact absorbed energy in Table 6 is the required value of Charpy V-notch of

Table 7 Decline Factor for Impact Absorbed Energy of Small-dimension Specimen

Size of specimen Dimension of specimen (high × width)/(mm×mm) Decline factor

Standard specimen 10×10 1

Small specimen 10×7.5 0.75

Small specimen 10×5 0.50

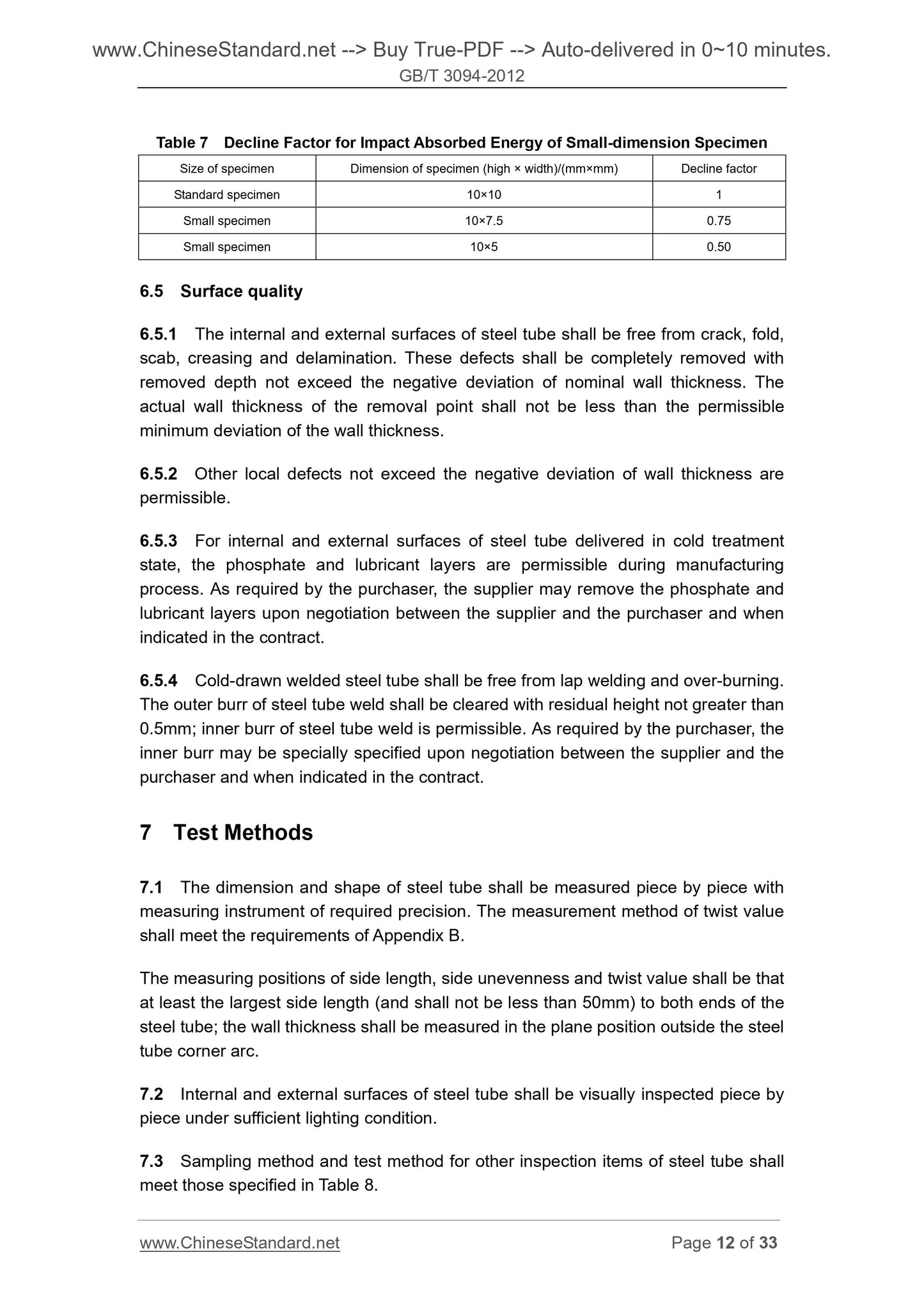

6.5 Surface quality

6.5.1 The internal and external surfaces of steel tube shall be free from crack, fold,

scab, creasing and delamination. These defects shall be completely removed with

removed depth not exceed the negative deviation of nominal wall thickness. The

actual wall thickness of the removal point shall not be less than the permissible

minimum deviation of the wall thickness.

6.5.2 Other local defects not exceed the negative deviation of wall thickness are

permissible.

6.5.3 For internal and external surfaces of steel tube delivered in cold treatment

state, the phosphate and lubricant layers are permissible during manufacturing

process. As required by the purchaser, the supplier may rem...

Get Quotation: Click GB/T 3094-2012 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 3094-2012

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 3094-2012: Cold drawn shaped steel tubes

GB/T 3094-2012

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

H48

Replacing GB/T 3094-2000

Cold Drawn Shaped Steel Tubes

ISSUED ON. MAY 11, 2012

IMPLEMENTED ON. FEBRUARY 1, 2013

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine (AQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Classification and Designation ... 6

4 Ordering Information ... 6

5 Shape, Dimension and Weight ... 7

6 Technical Requirements ... 9

7 Test Methods ... 12

8 Inspection Rules ... 13

9 Packaging, Marking and Quality Certificate ... 13

Appendix A (Normative) Shape and Dimension of Steel Tube ... 14

Appendix B (Normative) Determination Method for Twist Value of Shaped Steel

Tube ... 32

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

This Standard is revised by reference to ASTM A 500-07 "Standard Specification for

Cold-formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and

Shapes".

This Standard replace GB/T 3094-2000 "Cold Drawn Shaped Steel Tubes" (GB/T

3094-2000). Compared with GB/T 3094-2000, the main changes of this Standard are

as follows.

- Quality grades of steel designations Q215, Q235, Q345 and Q390 are added;

Q295 is deleted;

- Ordering information is added;

- Curvature and twist value requirements are modified;

- Marking example is deleted;

- General length is modified;

- Mechanical performance of steel tube is modified;

- Requirements for impact test of steel tube are added;

- Size and dimension of steel tube in Appendix A are modified.

This Standard was proposed by China Iron and Steel Association.

This Standard shall be under the jurisdiction of the National Technical Committee on

Iron and Steel of Standardization Administration of China (SAC/TC 183).

Drafting organizations of this Standard. Shanghai Shaped Steel Tube Co., Ltd. AND

Jiangsu Jieda Specific New Material Co., Ltd.

Chief drafting staffs of this Standard. Gao Zhijian, Chen Hongqi, Zhu Sujian, Xue

Jianliang, Wang Wei, Hu Hongwei, Yang Wenyi and Lei Liangliang.

The previous editions replaced by this Standard are as follows.

- GB 3094-1982;

- GB/T 3094-2000.

Cold Drawn Shaped Steel Tubes

1 Scope

This Standard specifies the classification, designation, ordering information, shape,

dimension, technical requirements, test method, inspection rule, packaging, marking

and quality certificate of cold drawn shaped steel tubes.

This Standard is applicable to cold-drawn simple-section shaped tube (hereinafter

referred to as steel tube).

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated

references, the latest edition of the normative document (including any amendments)

applies.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel Products

GB/T 223.5 Steel and Iron - Determination of Acid-soluble Silicon and Total

Silicon Content - Reduced Molybdosilicate Spectrophotometric Method

GB/T 223.9 Iron, Steel and Alloy - Determination of Aluminum Content - Chrom

Azurol S Photometric Method

GB/T 223.12 GB/T 223.62 Methods for Chemical Analysis of Iron, Steel and Alloy

- The Sodium Carbonate Separation - Diphenyl Carbazide Photometric Method for

the Determination of Chromium Content

GB/T 223.14 Methods for Chemical Analysis of Iron, Steel and Alloy - The

N-benzoy-N-phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.17 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Photometric Method for the Determination of Titanium Content

GB/T 223.19 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Neocuproine - Chloroform Extraction Photometric Method for the Determination of

Copper Content

GB/T 223.23 Iron Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.40 Iron Steel and Alloy - Determination of Niobium Content by the

Sulphochlorophenol S Spectrophotometric Method

GB/T 223.59 Iron Steel and Alloy - Determination of Phosphorus Content -

Bismuth Phosphomolybdate Blue Spectrophotometric Method and Antimony

Phosphomolybdate Blue Spectrophotometric Method

GB/T 223.60 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Perchloric Acid Dehydration Gravimetric Method for the Determination of Silicon

Content

GB/T 223.62 Methods for Chemical Analysis of Iron, Steel and Alloy - The Butyl

Acetate Extraction Photometric Method for the Determination of Phosphorus

Content

GB/T 223.63 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium (Potassium) Periodate Photometric Method for the Determination of

Manganese Content

GB/T 223.64 Iron Steel and Alloy - Determination of Manganese Content - Flame

Atomic Absorption Spectrometric Method

GB/T 223.68 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Potassium Iodate Titration Method after Combustion in the Pipe Furnace for the

Determination of Sulfur Content

GB/T 223.69 Iron Steel and Alloy - Determination of Carbon Contents -

Gas-volumetric Method after Combustion in the Pipe Furnace

GB/T 223.71 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Gravimetric Method after Combustion in the Pipe Furnace for the Determination of

Carbon Content

GB/T 223.72 Iron Steel and Alloy - Determination of Sulfur Content - Gravimetric

Method

GB/T 228.1 Metallic Materials - Tensile Testing - Part 1. Method of Test at Room

Temperature

GB/T 229 Metallic Materials - Charpy Pendulum Impact Test Method

GB/T 699 Quality Carbon Structural Steels

GB/T 700 Carbon Structural Steels

GB/T 1591 High Strength Low Alloy Structural Steels

GB/T 2102 Acceptance, Packing, Marking and Certification of Pipe

GB/T 2975 Steel and Steel Products - Location and Preparation of Test Pieces for

Mechanical Testing

GB/T 3077 Alloy Structure Steels

GB/T 4336 Standard Test Method for Spark Discharge Atomic Emission

Spectrometric Analysis of Carbon and Low-alloy Steel (Routine Method)

GB/T 20066 Steel and Iron - Sampling and Preparation of Samples for the

Determination of Chemical Composition

GB/T 20123 Steel and Iron - Determination of Total Carbon and Sulfur Content

Infrared Absorption Method after Combustion in an Induction Furnace (Routine

Method)

GB/T 20125 Low-alloy Steel - Determination of Multi-element Contents -

Inductively Coupled Plasma Atomic Emission Spectrometric Method

3 Classification and Designation

Classification and designation of steel tubes according to section shape are as

follows.

a) Square steel tube D-1;

b) Rectangle steel tube D-2;

c) Elliptical steel tube D-3;

d) Flat oval steel tube D-4;

e) Inside and outside hexagonal steel tube D-5;

f) Rectangular trapezoid steel tube D-6.

4 Ordering Information

The contract or order for ordering steel tubes according to this Standard shall include

but not limited to the following contents.

a) Standard No.;

b) Product name;

c) Designation and quality grade of steel (if applicable);

d) Size and dimension;

e) Ordering quantity (total weight or total length);

f) Delivery state;

g) Special requirements.

5 Shape, Dimension and Weight

5.1 Shape and dimension

The shape and dimension of steel tube shall respectively meet the requirements of

Figures A.1~A.6 and Tables A.1~A.6 in Appendix A. As negotiated by the supplier and

the purchaser, steel tube with shape and/or size beyond those specified in Figures

A.1~A.6 and Tables A.1~A.6 in Appendix A may be supplied.

5.2 Permissible deviations in dimensions

The permissible dimension deviation of steel tube shall meet those specified in Table

1.

When the permissible dimension deviation grade is not indicated in the contract by the

purchaser, the permissible dimension deviation of steel tube shall meet the

requirements of ordinary grade dimensional precision. High grade dimensional

precision, when required by the purchaser, shall be indicated in the contract.

As required by the purchaser, steel tube with permissible dimension deviation beyond

those specified in Table 1 may be supplied upon negotiation between the supplier and

the purchaser.

Table 1 Permissible Dimension Deviation of Steel Tube In mm

Dimension

Permissible deviation

Ordinary grade High grade

Side lengths

A and B

≤30 ±0.30 ±0.20

>30~50 ±0.40 ±0.30

>50~75 ±0.80%A and ±0.80%B ±0.7%A and ±0.7%B

>75 ±1%A and ±1%B ±0.8%A and ±0.8%B

Wall thickness

≤1.0 ±0.18 ±0.12

>1.0~3.0 +15%S -10%S

+12.5%S

-10%S

>3.0 +12.5%S -10%S ±10%S

5.3 Side unevenness

Side unevenness of steel tube shall meet those specified in Table 2.

Table 5 Twist Value of Steel Tube

Side length of steel tube/mm Permissible twist value/(mm/m)

≤30 ≤1.5

>30~75 ≤2.0

>75 ≤2.5

5.7 Length

5.7.1 General length

The general length of steel tube is 2000~9000mm.

As required by the purchaser, steel tube with length beyond those specified may be

supplied upon negotiation between the supplier and the purchaser and when

indicated in the contract.

5.7.2 Specified length and multiple length

5.7.2.1 As required by the purchaser, steel tube may be delivered with specified

length or multiple length upon negotiation between the supplier and the purchaser and

when indicated in the contract

5.7.2.2 The specified length and multiple length shall be within the range of general

length. The permissible deviation of the specified length is 15

mm; while that of the

total multiple length is 10

mm; each multiple length shall be remained with a notch

allowance of 5~10mm.

5.8 End shape

End faces on both ends of steel tube shall be vertical to the axis of steel tube, and the

burr on notch shall be removed.

5.9 Weight

The steel tube is delivered according to actual weight. When indicated in the contract,

it may also be delivered according to the theoretical weight. See Appendix A for the

calculation formula of theoretical weight (with steel density of 7.85 kg/dm3).

6 Technical Requirements

6.1 Designation and chemical composition of steel

6.1.1 For quality carbon structural steels with designations of 10, 20, 35 and 45, the

chemical composition (heat analysis) shall meet the requirements of GB/T 699.

For carbon structural steels with designations of Q195, Q215 and Q235, the chemical

composition (heat analysis) shall meet the requirements of GB/T 700.

For high strength low alloy structural steels with designations of Q345 and Q390, the

chemical composition (heat analysis) shall meet the requirements of GB/T 1591.

As required by the purchaser, structural alloy steel tube may be supplied upon

negotiation between the supplier and the purchaser, and its designation and chemical

composition (heat analysis) shall meet the requirements of GB/T 3077.

6.1.2 Chemical analysis for finished product, when required by the purchaser, shall

be indicated in the contract. The permissible deviation for chemical composition of

finished steel tube shall meet the requirements of GB/T 222.

6.1.3 As required by the purchaser, steel tube of other designation may be supplied

upon negotiation between the supplier and the purchaser.

6.2 Manufacturing method

6.2.1 Steel tube shall be manufactured of seamless steel tube through cold-drawn

forming.

6.2.2 As required by the purchaser, steel tube may be manufactured of welded steel

tube through cold-drawn forming upon negotiation between the supplier and the

purchaser and when indicated in the contract. The weld of cold-drawn welded steel

tube shall be kept away from round corner.

6.3 Delivery state

The steel tube shall be delivered in cold-drawn state. As required by the purchaser,

the steel tube may be delivered in heat treatment state upon negotiation between the

supplier and the purchaser and when indicated in the contract.

6.4 Mechanical performance

6.4.1 Steel tube delivered in cold-drawn state is not subject to mechanical

performance test. When the steel tube is delivered in heat treatment state, the

longitudinal mechanical performance of steel tube shall meet those specified in Table

6 while that of the structural alloy steel tube shall meet those specified in GB/T 3077.

6.4.2 For Q195, Q215, Q235, Q345 and Q390 steel tubes delivered in heat

treatment state, when the perimeter is not less than 240mm and the wall thickness is

not less than 10mm, impact test shall be carried out; thereof the impact absorbed

energy (KV2) of Charpy V-notch shall meet those specified in Table 6. The width of

impact specimen shall be 10mm, 7.5mm or 5mm (the largest dimension is taken if

possible); when it fails to cut 5mm-wide specimen, impact test may not be carried out.

The impact absorbed energy in Table 6 is the required value of Charpy V-notch of

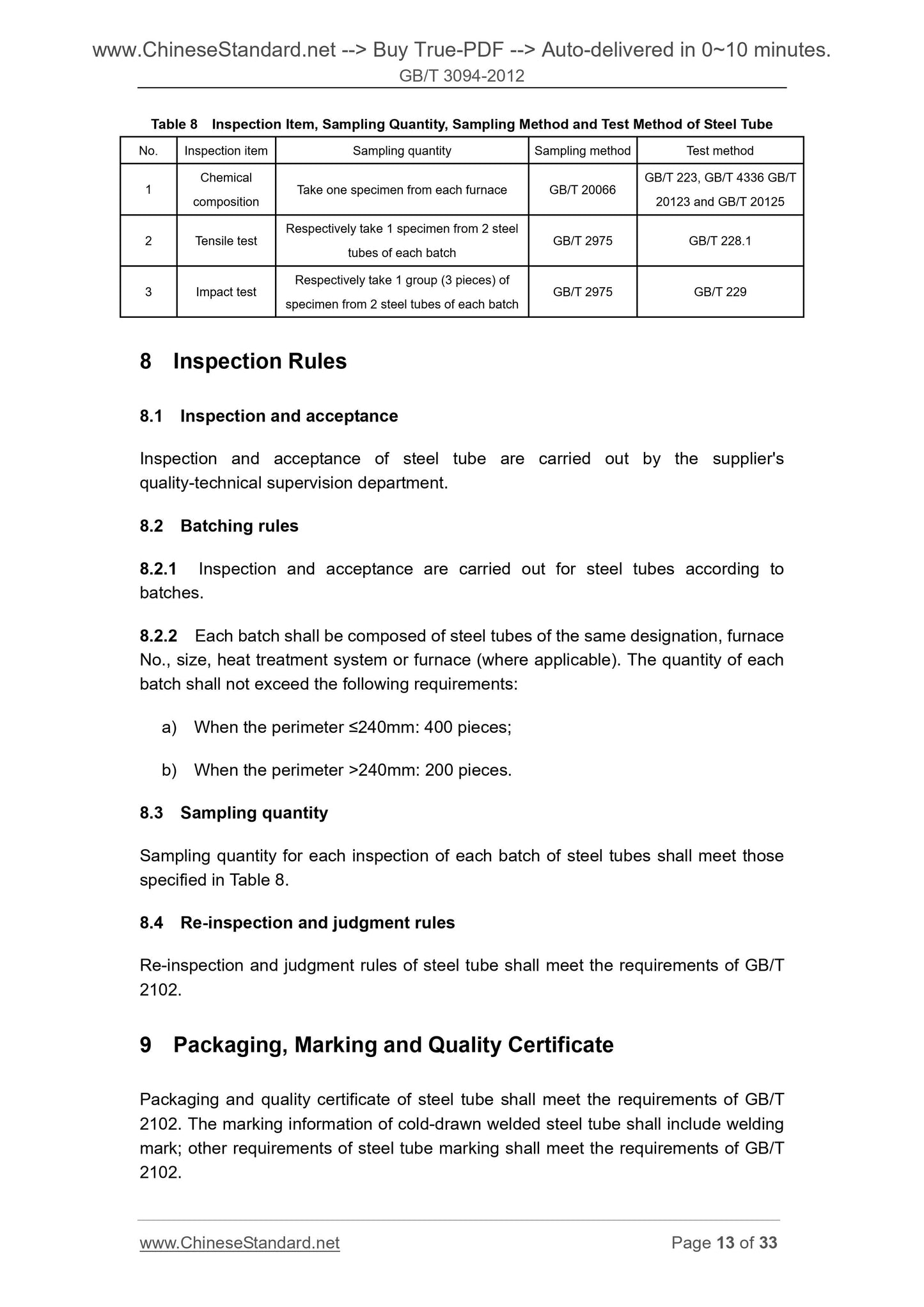

Table 7 Decline Factor for Impact Absorbed Energy of Small-dimension Specimen

Size of specimen Dimension of specimen (high × width)/(mm×mm) Decline factor

Standard specimen 10×10 1

Small specimen 10×7.5 0.75

Small specimen 10×5 0.50

6.5 Surface quality

6.5.1 The internal and external surfaces of steel tube shall be free from crack, fold,

scab, creasing and delamination. These defects shall be completely removed with

removed depth not exceed the negative deviation of nominal wall thickness. The

actual wall thickness of the removal point shall not be less than the permissible

minimum deviation of the wall thickness.

6.5.2 Other local defects not exceed the negative deviation of wall thickness are

permissible.

6.5.3 For internal and external surfaces of steel tube delivered in cold treatment

state, the phosphate and lubricant layers are permissible during manufacturing

process. As required by the purchaser, the supplier may rem...

Share