1

/

of

4

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 3207-2008 English PDF (GB/T3207-2008)

GB/T 3207-2008 English PDF (GB/T3207-2008)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 3207-2008: Bright steel

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 3207-2008 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 3207-2008

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 3207-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.60

H 44

Replacing GB/T 3207-1988

Bright steel

ISSUED ON: AUGUST 05, 2008

IMPLEMENTED ON: APRIL 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification code ... 6

5 Size, shape, weight and allowable deviation ... 6

6 Technical requirements ... 10

7 Test method ... 11

8 Inspection rules ... 12

9 Marking and quality certificate ... 12

10 Packaging, transportation and storage ... 12

Bright steel

1 Scope

This standard specifies the terms and definitions, classification code, size,

shape, weight and allowable deviations, technical requirements, test methods,

inspection rules, marks and quality certificates, packaging, transportation and

storage requirements of bright steel.

This standard is applicable to stripped, ground and polished round steel with

high requirements for surface quality.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 2101 General requirement of acceptance packaging marking and

certification for section steel

GB/T 2103 General requirements for acceptance, packing, marking and

quality certification of steel wire

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

Bright steel

A bright-surface round steel with no rolling defects and decarburized layer

on the surface. It can be subdivided into flake steel, polish steel, buff steel.

3.2

Flake steel

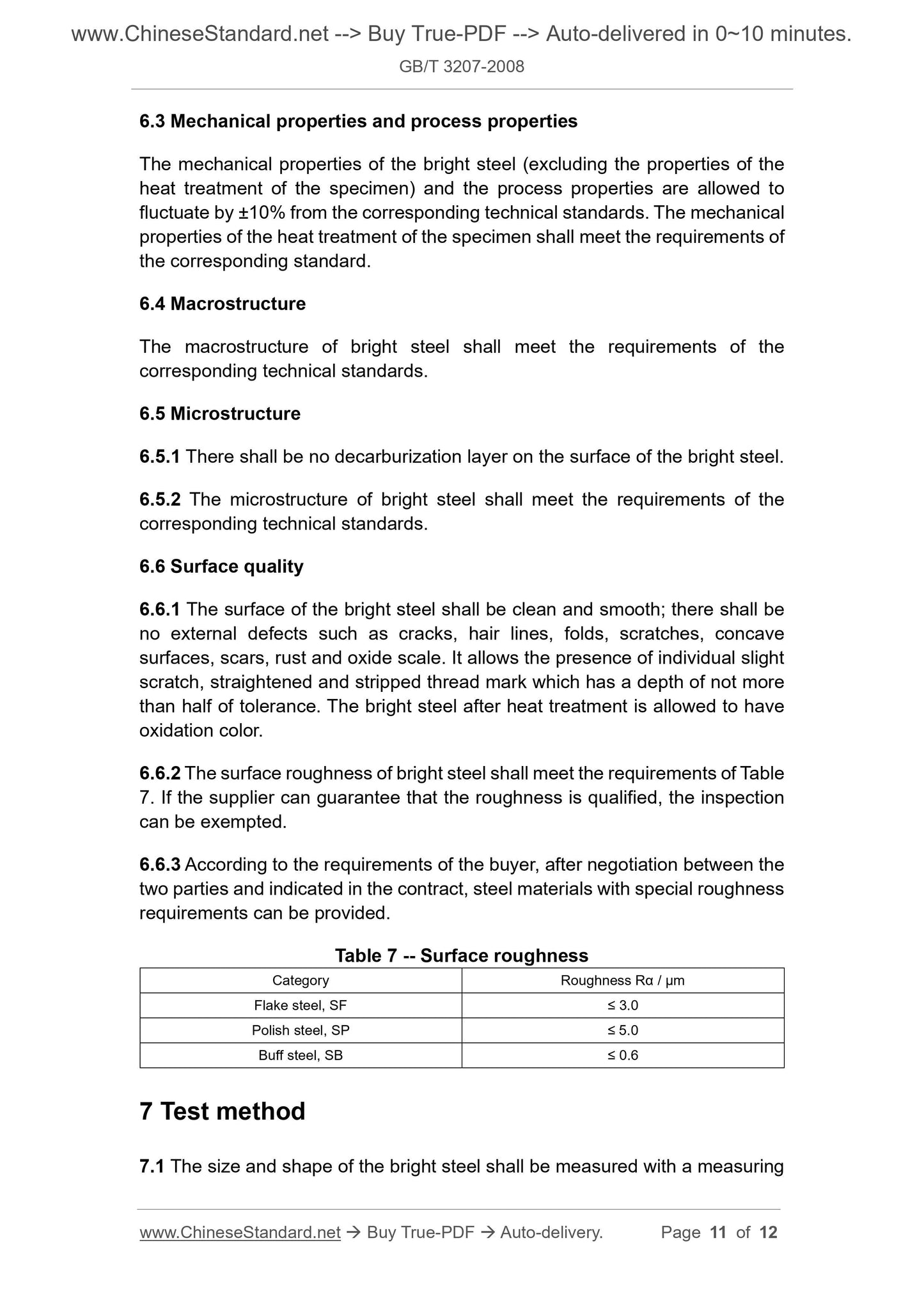

6.3 Mechanical properties and process properties

The mechanical properties of the bright steel (excluding the properties of the

heat treatment of the specimen) and the process properties are allowed to

fluctuate by ±10% from the corresponding technical standards. The mechanical

properties of the heat treatment of the specimen shall meet the requirements of

the corresponding standard.

6.4 Macrostructure

The macrostructure of bright steel shall meet the requirements of the

corresponding technical standards.

6.5 Microstructure

6.5.1 There shall be no decarburization layer on the surface of the bright steel.

6.5.2 The microstructure of bright steel shall meet the requirements of the

corresponding technical standards.

6.6 Surface quality

6.6.1 The surface of the bright steel shall be clean and smooth; there shall be

no external defects such as cracks, hair lines, folds, scratches, concave

surfaces, scars, rust and oxide scale. It allows the presence of individual slight

scratch, straightened and stripped thread mark which has a depth of not more

than half of tolerance. The bright steel after heat treatment is allowed to have

oxidation color.

6.6.2 The surface roughness of bright steel shall meet the requirements of Table

7. If the supplier can guarantee that the roughness is qualified, the inspection

can be exempted.

6.6.3 According to the requirements of the buyer, after negotiation between the

two parties and indicated in the contract, steel materials with special roughness

requirements can be provided.

Table 7 -- Surface roughness

Category Roughness Rα / µm

Flake steel, SF ≤ 3.0

Polish steel, SP ≤ 5.0

Buff steel, SB ≤ 0.6

7 Test method

7.1 The size and shape of the bright steel shall be measured with a measuring

GB/T 3207-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.60

H 44

Replacing GB/T 3207-1988

Bright steel

ISSUED ON: AUGUST 05, 2008

IMPLEMENTED ON: APRIL 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification code ... 6

5 Size, shape, weight and allowable deviation ... 6

6 Technical requirements ... 10

7 Test method ... 11

8 Inspection rules ... 12

9 Marking and quality certificate ... 12

10 Packaging, transportation and storage ... 12

Bright steel

1 Scope

This standard specifies the terms and definitions, classification code, size,

shape, weight and allowable deviations, technical requirements, test methods,

inspection rules, marks and quality certificates, packaging, transportation and

storage requirements of bright steel.

This standard is applicable to stripped, ground and polished round steel with

high requirements for surface quality.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 2101 General requirement of acceptance packaging marking and

certification for section steel

GB/T 2103 General requirements for acceptance, packing, marking and

quality certification of steel wire

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

Bright steel

A bright-surface round steel with no rolling defects and decarburized layer

on the surface. It can be subdivided into flake steel, polish steel, buff steel.

3.2

Flake steel

6.3 Mechanical properties and process properties

The mechanical properties of the bright steel (excluding the properties of the

heat treatment of the specimen) and the process properties are allowed to

fluctuate by ±10% from the corresponding technical standards. The mechanical

properties of the heat treatment of the specimen shall meet the requirements of

the corresponding standard.

6.4 Macrostructure

The macrostructure of bright steel shall meet the requirements of the

corresponding technical standards.

6.5 Microstructure

6.5.1 There shall be no decarburization layer on the surface of the bright steel.

6.5.2 The microstructure of bright steel shall meet the requirements of the

corresponding technical standards.

6.6 Surface quality

6.6.1 The surface of the bright steel shall be clean and smooth; there shall be

no external defects such as cracks, hair lines, folds, scratches, concave

surfaces, scars, rust and oxide scale. It allows the presence of individual slight

scratch, straightened and stripped thread mark which has a depth of not more

than half of tolerance. The bright steel after heat treatment is allowed to have

oxidation color.

6.6.2 The surface roughness of bright steel shall meet the requirements of Table

7. If the supplier can guarantee that the roughness is qualified, the inspection

can be exempted.

6.6.3 According to the requirements of the buyer, after negotiation between the

two parties and indicated in the contract, steel materials with special roughness

requirements can be provided.

Table 7 -- Surface roughness

Category Roughness Rα / µm

Flake steel, SF ≤ 3.0

Polish steel, SP ≤ 5.0

Buff steel, SB ≤ 0.6

7 Test method

7.1 The size and shape of the bright steel shall be measured with a measuring

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 3207-2008 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 3207-2008

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 3207-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.60

H 44

Replacing GB/T 3207-1988

Bright steel

ISSUED ON: AUGUST 05, 2008

IMPLEMENTED ON: APRIL 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification code ... 6

5 Size, shape, weight and allowable deviation ... 6

6 Technical requirements ... 10

7 Test method ... 11

8 Inspection rules ... 12

9 Marking and quality certificate ... 12

10 Packaging, transportation and storage ... 12

Bright steel

1 Scope

This standard specifies the terms and definitions, classification code, size,

shape, weight and allowable deviations, technical requirements, test methods,

inspection rules, marks and quality certificates, packaging, transportation and

storage requirements of bright steel.

This standard is applicable to stripped, ground and polished round steel with

high requirements for surface quality.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 2101 General requirement of acceptance packaging marking and

certification for section steel

GB/T 2103 General requirements for acceptance, packing, marking and

quality certification of steel wire

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

Bright steel

A bright-surface round steel with no rolling defects and decarburized layer

on the surface. It can be subdivided into flake steel, polish steel, buff steel.

3.2

Flake steel

6.3 Mechanical properties and process properties

The mechanical properties of the bright steel (excluding the properties of the

heat treatment of the specimen) and the process properties are allowed to

fluctuate by ±10% from the corresponding technical standards. The mechanical

properties of the heat treatment of the specimen shall meet the requirements of

the corresponding standard.

6.4 Macrostructure

The macrostructure of bright steel shall meet the requirements of the

corresponding technical standards.

6.5 Microstructure

6.5.1 There shall be no decarburization layer on the surface of the bright steel.

6.5.2 The microstructure of bright steel shall meet the requirements of the

corresponding technical standards.

6.6 Surface quality

6.6.1 The surface of the bright steel shall be clean and smooth; there shall be

no external defects such as cracks, hair lines, folds, scratches, concave

surfaces, scars, rust and oxide scale. It allows the presence of individual slight

scratch, straightened and stripped thread mark which has a depth of not more

than half of tolerance. The bright steel after heat treatment is allowed to have

oxidation color.

6.6.2 The surface roughness of bright steel shall meet the requirements of Table

7. If the supplier can guarantee that the roughness is qualified, the inspection

can be exempted.

6.6.3 According to the requirements of the buyer, after negotiation between the

two parties and indicated in the contract, steel materials with special roughness

requirements can be provided.

Table 7 -- Surface roughness

Category Roughness Rα / µm

Flake steel, SF ≤ 3.0

Polish steel, SP ≤ 5.0

Buff steel, SB ≤ 0.6

7 Test method

7.1 The size and shape of the bright steel shall be measured with a measuring

GB/T 3207-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.60

H 44

Replacing GB/T 3207-1988

Bright steel

ISSUED ON: AUGUST 05, 2008

IMPLEMENTED ON: APRIL 01, 2009

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification code ... 6

5 Size, shape, weight and allowable deviation ... 6

6 Technical requirements ... 10

7 Test method ... 11

8 Inspection rules ... 12

9 Marking and quality certificate ... 12

10 Packaging, transportation and storage ... 12

Bright steel

1 Scope

This standard specifies the terms and definitions, classification code, size,

shape, weight and allowable deviations, technical requirements, test methods,

inspection rules, marks and quality certificates, packaging, transportation and

storage requirements of bright steel.

This standard is applicable to stripped, ground and polished round steel with

high requirements for surface quality.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 2101 General requirement of acceptance packaging marking and

certification for section steel

GB/T 2103 General requirements for acceptance, packing, marking and

quality certification of steel wire

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

Bright steel

A bright-surface round steel with no rolling defects and decarburized layer

on the surface. It can be subdivided into flake steel, polish steel, buff steel.

3.2

Flake steel

6.3 Mechanical properties and process properties

The mechanical properties of the bright steel (excluding the properties of the

heat treatment of the specimen) and the process properties are allowed to

fluctuate by ±10% from the corresponding technical standards. The mechanical

properties of the heat treatment of the specimen shall meet the requirements of

the corresponding standard.

6.4 Macrostructure

The macrostructure of bright steel shall meet the requirements of the

corresponding technical standards.

6.5 Microstructure

6.5.1 There shall be no decarburization layer on the surface of the bright steel.

6.5.2 The microstructure of bright steel shall meet the requirements of the

corresponding technical standards.

6.6 Surface quality

6.6.1 The surface of the bright steel shall be clean and smooth; there shall be

no external defects such as cracks, hair lines, folds, scratches, concave

surfaces, scars, rust and oxide scale. It allows the presence of individual slight

scratch, straightened and stripped thread mark which has a depth of not more

than half of tolerance. The bright steel after heat treatment is allowed to have

oxidation color.

6.6.2 The surface roughness of bright steel shall meet the requirements of Table

7. If the supplier can guarantee that the roughness is qualified, the inspection

can be exempted.

6.6.3 According to the requirements of the buyer, after negotiation between the

two parties and indicated in the contract, steel materials with special roughness

requirements can be provided.

Table 7 -- Surface roughness

Category Roughness Rα / µm

Flake steel, SF ≤ 3.0

Polish steel, SP ≤ 5.0

Buff steel, SB ≤ 0.6

7 Test method

7.1 The size and shape of the bright steel shall be measured with a measuring

Share