1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 32095.1-2015 English PDF (GBT32095.1-2015)

GB/T 32095.1-2015 English PDF (GBT32095.1-2015)

Regular price

$70.00 USD

Regular price

Sale price

$70.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 32095.1-2015

Historical versions: GB/T 32095.1-2015

Preview True-PDF (Reload/Scroll if blank)

GB/T 32095.1-2015: Performance and test methods of non-stick surface of domestic metal cooking utensils for household food -- Part 1: General requirement of performance

GB/T 32095.1-2015

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 97.040.60

Y 73

Performance and test methods of non-stick surface of

domestic metal cooking utensils for household food -

Part 1. General requirement of performance

ISSUED ON. OCTOBER 09, 2015

IMPLEMENTED ON. MAY 01, 2016

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the PRC.

Table of contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Classification ... 6

5 Requirements ... 6

6 Test method ... 8

Foreword

GB/T 32095 “Performance and test methods of non-stick surface of domestic

metal cooking utensils for household food” is divided into four parts.

- Part 1. General requirements of performance;

- Part 2. Test specification of non-stick performance and abrasion resistance;

- Part 3. Test specification of corrosion resistance;

- Part 4. Test specification of simulative test and evaluation methods;

This part is part 1 of GB/T 32095.

This part was drafted in accordance with the rules given in GB/T 1.1-2009.

This part was proposed by China Light Industry Federation.

This part shall be under the jurisdiction of the National Metallic Food and

Cooking Appliance Standardization Committee (S AC/TC 410).

The responsible drafting organizations of this part. Zhejiang Supor Co., Ltd.,

ASD Electric Co., Ltd.

The participating drafting organizations of this part. National Daily Metallic

Product Quality Supervision and Inspection Center (Shenyang), China

Standardization Research Institute, Zhejiang Cooking King Cookware Co., Ltd.,

Nanlong Group Co., Ltd., Daikin Fluorine Coatings (Shanghai) Co., Ltd., Tianxi

Holding Co., Ltd. Guangdong Media Electric Appliance Manufacturing Co., Ltd.,

Jiuyang Co., Ltd., Hangzhou Jihua Polymer Materials Co., Ltd., Zhejiang Sanhe

Kitchenware Co., Ltd., Huafu Paint (Jiangmen) Co., Ltd., Guangdong Yangchen

Kitchenware Co., Ltd., Zhejiang PFLUON Technology Co., Ltd., Foshan Polima

High-tech Materials Co., Ltd., Foshan Nanfang Cookware Co., Ltd.

The main drafters of this part. Zhang Tianfu, Cai Changshou, Chen Helin, Chen

Meirong, Shan Zhihua, Ma Aijin, Zhang Xueling, Wang Peng, Xu Chongyi, Guo

Xingpeng, Yuan Jun, Huang Liangguang, Han Run, Liu Haibing, Cheng Qiang,

Cao Junfeng, Yao Zhongwo, Shi Hang, Liang Wenbo, Li Guozhong.

Performance and test methods of non-stick surface of

domestic metal cooking utensils for household food -

Part 1. General requirement of performance

1 Scope

This part of the GB/T 32095 specifies the terms and definitions, classification,

requirements and test methods for general requirements of performance and

test methods of non-stick surface of domestic metal cooking utensils for

household food (hereinafter referred to as cooking utensils).

This part applies to metal-based household food cooking utensils for which the

food contact surface is subjected to non-stick coating treatment, including frying,

cooking, rice cookers, baking appliances and so on.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this document.

GB/T 6739 Color paint and varnish - Determination of film hardness by pencil

test

GB/T 32095.2-2015 Performance and test methods of non-stick surface of

domestic metal cooking utensils for household food - Test specification of

non-stick performance and abrasion resistance

GB/T 32095.3-2015 Performance and test methods of non-stick surface of

domestic metal cooking utensils for household food - Test specification of

corrosion resistance

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

R - Cooking utensils inner bottom plane radius.

Figure 1 Coating thickness measurement point diagram

6.2.4 Hardness test

The test is carried out in accordance with GB/T 6739.

6.2.5 Adhesion test

PROCEED as follows.

a) USE a shape single blade tip and special purpose grid template to make

11 parallel scratches at the spacing of 2.4 mm and length of 38 mm;

REPEAT the above operation perpendicular to the above scratches

(totally 100 grids); AND the tip must penetrate through the coating (as for

the product which cannot be subjected to grid cutting test, such as the full

pattern product, it may use the sample piece for detection);

b) ADD an appropriate amount of purified water to the cooking utensil (make

sure that the grid area is completely soaked during the test); MAKE it

boiling for 15 min; TAKE it out and LET it cool down naturally to room

temperature; USE soft cloth to wipe it dry;

c) ATTACH a single faced transparent pressure sensitive adhesive tape (3M

- 898) to the scratching area, in a direction parallel with one group of

scratching lines. USE external force to expel the air from the adhesive

portion, and MAKE sure the maximum degree of adhesion with the coating;

d) PULL one end of the tape quickly up at an angle of 90° for continuously 3

times; USE new tape for each pull-up;

e) ROTATE the scratch for 90° and REPEAT the aforementioned steps c)

and d).

6.2.6 Peeling resistance test

PROCEED as follows.

a) PREPARE the cooking utensils in accordance with 6.2.5 b);

b) USE a sharp knife (SEE Figure 2) to remove the coating along the

direction 90° to the blade, to generate a cutting of width 1.5 mm ~ 3 mm

AND length 30 mm ~ 50 mm. USE thumb nail to try to peel the coating

along the direction perpendicular to the cutting.

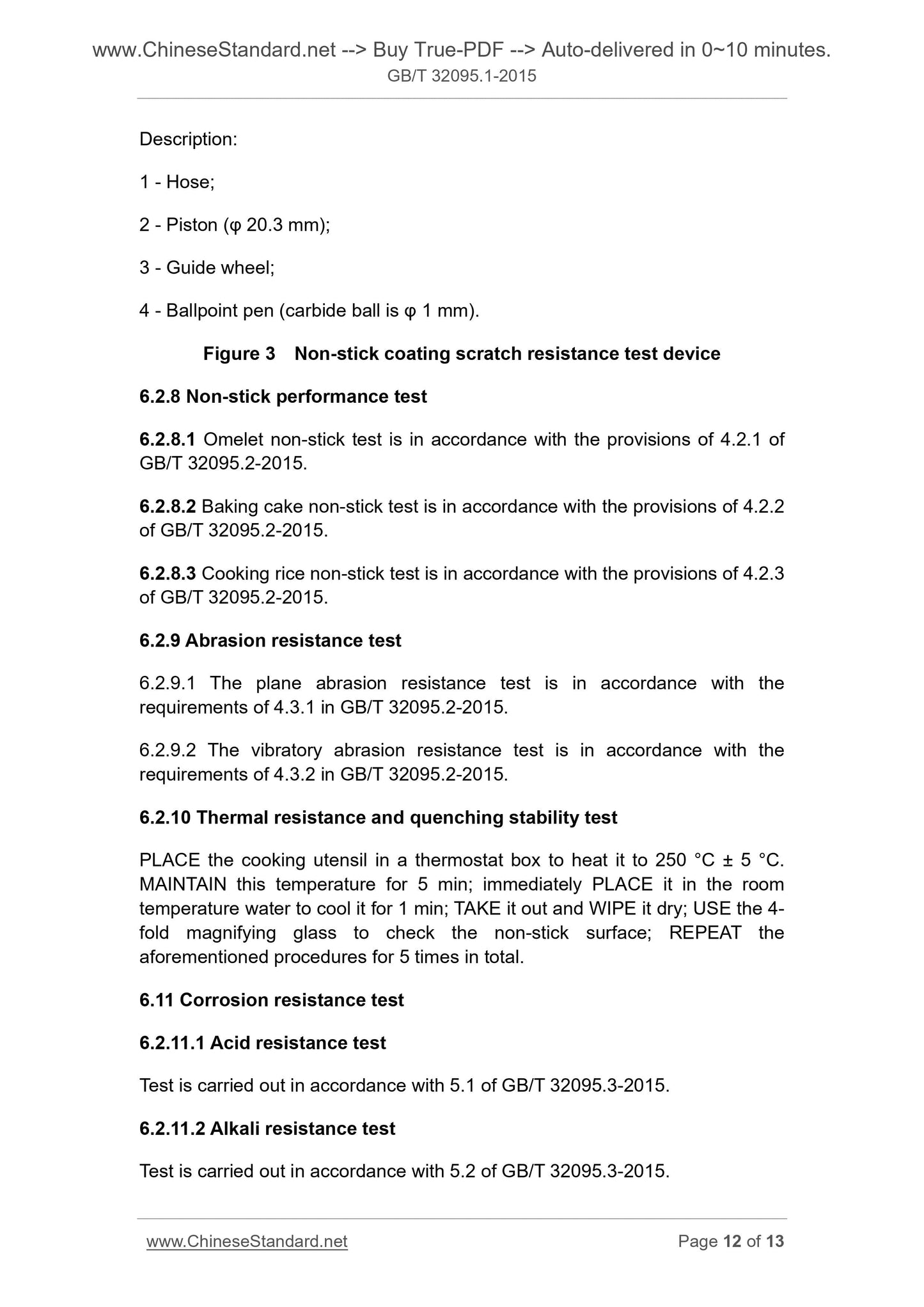

Description.

1 - Hose;

2 - Piston (φ 20.3 mm);

3 - Guide wheel;

4 - Ballpoint pen (carbide ball is φ 1 mm).

Figure 3 Non-stick coating scratch resistance test device

6.2.8 Non-stick performance test

6.2.8.1 Omelet non-stick test is in accordance with the provisions of 4.2.1 of

GB/T 32095.2-2015.

6.2.8.2 Baking cake non-stick test is in accordance with the provisions of 4.2.2

of GB/T 32095.2-2015.

6.2.8.3 Cooking rice non-stick test is in accordance with the provisions of 4.2.3

of GB/T 32095.2-2015.

6.2.9 Abrasion resistance test

6.2.9.1 The plane abrasion resistance test is in accordance with the

requirements of 4.3.1 in GB/T 32095.2-2015.

6.2.9.2 The vibratory abrasion resistance test is in accordance with the

requirements of 4.3.2 in GB/T 32095.2-2015.

6.2.10 Thermal resistance and quenching stability test

PLACE the cooking utensil in a thermostat box to heat it to 250 °C ± 5 °C.

MAINTAIN this temperature for 5 min; immediately PLACE it in the room

temperature water to cool it for 1 min; TAKE it out and WIPE it dry; USE the 4-

fold magnifying glass to check the non-stick surface; REPEAT the

aforementioned procedures for 5 times in total.

6.11 Corrosion resistance test

6.2.11.1 Acid resistance test

Test is carried out in accordance with 5.1 of GB/T 32095.3-2015.

6.2.11.2 Alkali resistance test

Test is carried out in accordance with 5.2 of GB/T 32095.3-2015.

Get QUOTATION in 1-minute: Click GB/T 32095.1-2015

Historical versions: GB/T 32095.1-2015

Preview True-PDF (Reload/Scroll if blank)

GB/T 32095.1-2015: Performance and test methods of non-stick surface of domestic metal cooking utensils for household food -- Part 1: General requirement of performance

GB/T 32095.1-2015

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 97.040.60

Y 73

Performance and test methods of non-stick surface of

domestic metal cooking utensils for household food -

Part 1. General requirement of performance

ISSUED ON. OCTOBER 09, 2015

IMPLEMENTED ON. MAY 01, 2016

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the PRC.

Table of contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Classification ... 6

5 Requirements ... 6

6 Test method ... 8

Foreword

GB/T 32095 “Performance and test methods of non-stick surface of domestic

metal cooking utensils for household food” is divided into four parts.

- Part 1. General requirements of performance;

- Part 2. Test specification of non-stick performance and abrasion resistance;

- Part 3. Test specification of corrosion resistance;

- Part 4. Test specification of simulative test and evaluation methods;

This part is part 1 of GB/T 32095.

This part was drafted in accordance with the rules given in GB/T 1.1-2009.

This part was proposed by China Light Industry Federation.

This part shall be under the jurisdiction of the National Metallic Food and

Cooking Appliance Standardization Committee (S AC/TC 410).

The responsible drafting organizations of this part. Zhejiang Supor Co., Ltd.,

ASD Electric Co., Ltd.

The participating drafting organizations of this part. National Daily Metallic

Product Quality Supervision and Inspection Center (Shenyang), China

Standardization Research Institute, Zhejiang Cooking King Cookware Co., Ltd.,

Nanlong Group Co., Ltd., Daikin Fluorine Coatings (Shanghai) Co., Ltd., Tianxi

Holding Co., Ltd. Guangdong Media Electric Appliance Manufacturing Co., Ltd.,

Jiuyang Co., Ltd., Hangzhou Jihua Polymer Materials Co., Ltd., Zhejiang Sanhe

Kitchenware Co., Ltd., Huafu Paint (Jiangmen) Co., Ltd., Guangdong Yangchen

Kitchenware Co., Ltd., Zhejiang PFLUON Technology Co., Ltd., Foshan Polima

High-tech Materials Co., Ltd., Foshan Nanfang Cookware Co., Ltd.

The main drafters of this part. Zhang Tianfu, Cai Changshou, Chen Helin, Chen

Meirong, Shan Zhihua, Ma Aijin, Zhang Xueling, Wang Peng, Xu Chongyi, Guo

Xingpeng, Yuan Jun, Huang Liangguang, Han Run, Liu Haibing, Cheng Qiang,

Cao Junfeng, Yao Zhongwo, Shi Hang, Liang Wenbo, Li Guozhong.

Performance and test methods of non-stick surface of

domestic metal cooking utensils for household food -

Part 1. General requirement of performance

1 Scope

This part of the GB/T 32095 specifies the terms and definitions, classification,

requirements and test methods for general requirements of performance and

test methods of non-stick surface of domestic metal cooking utensils for

household food (hereinafter referred to as cooking utensils).

This part applies to metal-based household food cooking utensils for which the

food contact surface is subjected to non-stick coating treatment, including frying,

cooking, rice cookers, baking appliances and so on.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this document.

GB/T 6739 Color paint and varnish - Determination of film hardness by pencil

test

GB/T 32095.2-2015 Performance and test methods of non-stick surface of

domestic metal cooking utensils for household food - Test specification of

non-stick performance and abrasion resistance

GB/T 32095.3-2015 Performance and test methods of non-stick surface of

domestic metal cooking utensils for household food - Test specification of

corrosion resistance

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

R - Cooking utensils inner bottom plane radius.

Figure 1 Coating thickness measurement point diagram

6.2.4 Hardness test

The test is carried out in accordance with GB/T 6739.

6.2.5 Adhesion test

PROCEED as follows.

a) USE a shape single blade tip and special purpose grid template to make

11 parallel scratches at the spacing of 2.4 mm and length of 38 mm;

REPEAT the above operation perpendicular to the above scratches

(totally 100 grids); AND the tip must penetrate through the coating (as for

the product which cannot be subjected to grid cutting test, such as the full

pattern product, it may use the sample piece for detection);

b) ADD an appropriate amount of purified water to the cooking utensil (make

sure that the grid area is completely soaked during the test); MAKE it

boiling for 15 min; TAKE it out and LET it cool down naturally to room

temperature; USE soft cloth to wipe it dry;

c) ATTACH a single faced transparent pressure sensitive adhesive tape (3M

- 898) to the scratching area, in a direction parallel with one group of

scratching lines. USE external force to expel the air from the adhesive

portion, and MAKE sure the maximum degree of adhesion with the coating;

d) PULL one end of the tape quickly up at an angle of 90° for continuously 3

times; USE new tape for each pull-up;

e) ROTATE the scratch for 90° and REPEAT the aforementioned steps c)

and d).

6.2.6 Peeling resistance test

PROCEED as follows.

a) PREPARE the cooking utensils in accordance with 6.2.5 b);

b) USE a sharp knife (SEE Figure 2) to remove the coating along the

direction 90° to the blade, to generate a cutting of width 1.5 mm ~ 3 mm

AND length 30 mm ~ 50 mm. USE thumb nail to try to peel the coating

along the direction perpendicular to the cutting.

Description.

1 - Hose;

2 - Piston (φ 20.3 mm);

3 - Guide wheel;

4 - Ballpoint pen (carbide ball is φ 1 mm).

Figure 3 Non-stick coating scratch resistance test device

6.2.8 Non-stick performance test

6.2.8.1 Omelet non-stick test is in accordance with the provisions of 4.2.1 of

GB/T 32095.2-2015.

6.2.8.2 Baking cake non-stick test is in accordance with the provisions of 4.2.2

of GB/T 32095.2-2015.

6.2.8.3 Cooking rice non-stick test is in accordance with the provisions of 4.2.3

of GB/T 32095.2-2015.

6.2.9 Abrasion resistance test

6.2.9.1 The plane abrasion resistance test is in accordance with the

requirements of 4.3.1 in GB/T 32095.2-2015.

6.2.9.2 The vibratory abrasion resistance test is in accordance with the

requirements of 4.3.2 in GB/T 32095.2-2015.

6.2.10 Thermal resistance and quenching stability test

PLACE the cooking utensil in a thermostat box to heat it to 250 °C ± 5 °C.

MAINTAIN this temperature for 5 min; immediately PLACE it in the room

temperature water to cool it for 1 min; TAKE it out and WIPE it dry; USE the 4-

fold magnifying glass to check the non-stick surface; REPEAT the

aforementioned procedures for 5 times in total.

6.11 Corrosion resistance test

6.2.11.1 Acid resistance test

Test is carried out in accordance with 5.1 of GB/T 32095.3-2015.

6.2.11.2 Alkali resistance test

Test is carried out in accordance with 5.2 of GB/T 32095.3-2015.

Share