1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 33366-2016 English PDF (GBT33366-2016)

GB/T 33366-2016 English PDF (GBT33366-2016)

Regular price

$150.00 USD

Regular price

Sale price

$150.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 33366-2016

Historical versions: GB/T 33366-2016

Preview True-PDF (Reload/Scroll if blank)

GB/T 33366-2016: Wrought aluminium alloy extruded rods and bars for electron enginery-tank

GB/T 33366-2016

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.10

H 61

Wrought Aluminium Alloy Extruded Rods

and Bars for Electron Enginery-tank

ISSUED ON: DECEMBER 30, 2016

IMPLEMENTED ON: JULY 01, 2017

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Requirements ... 5

4 Test method ... 8

5 Test rules ... 10

6 Marking, packaging, transportation, storage and quality certificate ... 13

7 Order form (or contract) contents ... 14

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard was proposed by the China Nonferrous Metals Industry

Association.

This Standard shall be under the jurisdiction of National Technical Committee

243 on Nonferrous Metals of Standardization Administration of China (SAC/TC

243).

The drafting organizations of this Standard: Southwest Aluminum (Group) Co.,

Ltd., China Nonferrous Metals Techno-Economic Research Institute,

Guangdong Haomei Aluminum Co., Ltd., Liaoning Zhongwang Group Co., Ltd.,

Northeast Light Alloy Co., Ltd., National Nonferrous Metals Quality Supervision

and Inspection Center, Shandong Yancon Light Alloy Co., Ltd., Fujian Nanping

Aluminum Co., Ltd., Guangdong Huachang Aluminum Factory Co., Ltd.

The drafters of this Standard: Wang Xiaogang, Peng Zhujun, Ge Lixin, Xiang

Shengqian, Gai Hongtao, Wang Guojun, Li Pu, Wang Zhibo, Luo Taotao, Gao

Xinyu, Chen Jingchun, Tang Xingyu.

Wrought Aluminium Alloy Extruded Rods

and Bars for Electron Enginery-tank

1 Scope

This Standard specifies the requirements, test methods, inspection rules and

marking, packaging, transportation, storage, quality certificate and order form

(or contract) contents of wrought aluminium alloy extruded rods and bars for

electron enginery-tank.

This Standard applies to aluminum alloy extruded round bars (hereinafter

referred to as bars) which are used for processing conductive parts in electronic

equipment control cabinets.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 231.1, Metallic materials. Brinell hardness test. Part 1: Test method

GB/T 3190, Wrought aluminum and aluminum alloy. Chemical composition

GB/T 3199, Wrought aluminium and aluminium alloy products. Packing,

marking, transporting and storing

GB/T 3048.2, Test methods for electrical properties of electric cables and

wires. Part 2: Test of electrical resistivity of metallic materials

GB/T 3246.1, Inspection method for structure of wrought aluminum and

aluminum alloy products. Part 1: Inspection method for microstructure

GB/T 3246.2, Inspection method for structure of wrought aluminum and

aluminum alloy products. Part 2: Inspection method for macrostructure

GB/T 7999, Optical emission spectrometric analysis method of aluminum

and aluminum alloys

GB/T 8170, Rules of rounding off for numerical values and expression and

judgment of limiting values

GB/T 12966, The method for determining aluminum alloys conductivity using

eddy current

GB/T 16865, Test pieces and method for tensile test for wrought aluminium

and magnesium alloys products

GB/T 17432, Methods of sampling for analyzing the chemical composition of

wrought aluminum and aluminum alloys

GB/T 20975, Methods for chemical analysis of aluminium and aluminium

alloys

3 Requirements

3.1 Product categories

3.1.1 Grade, status and dimensions

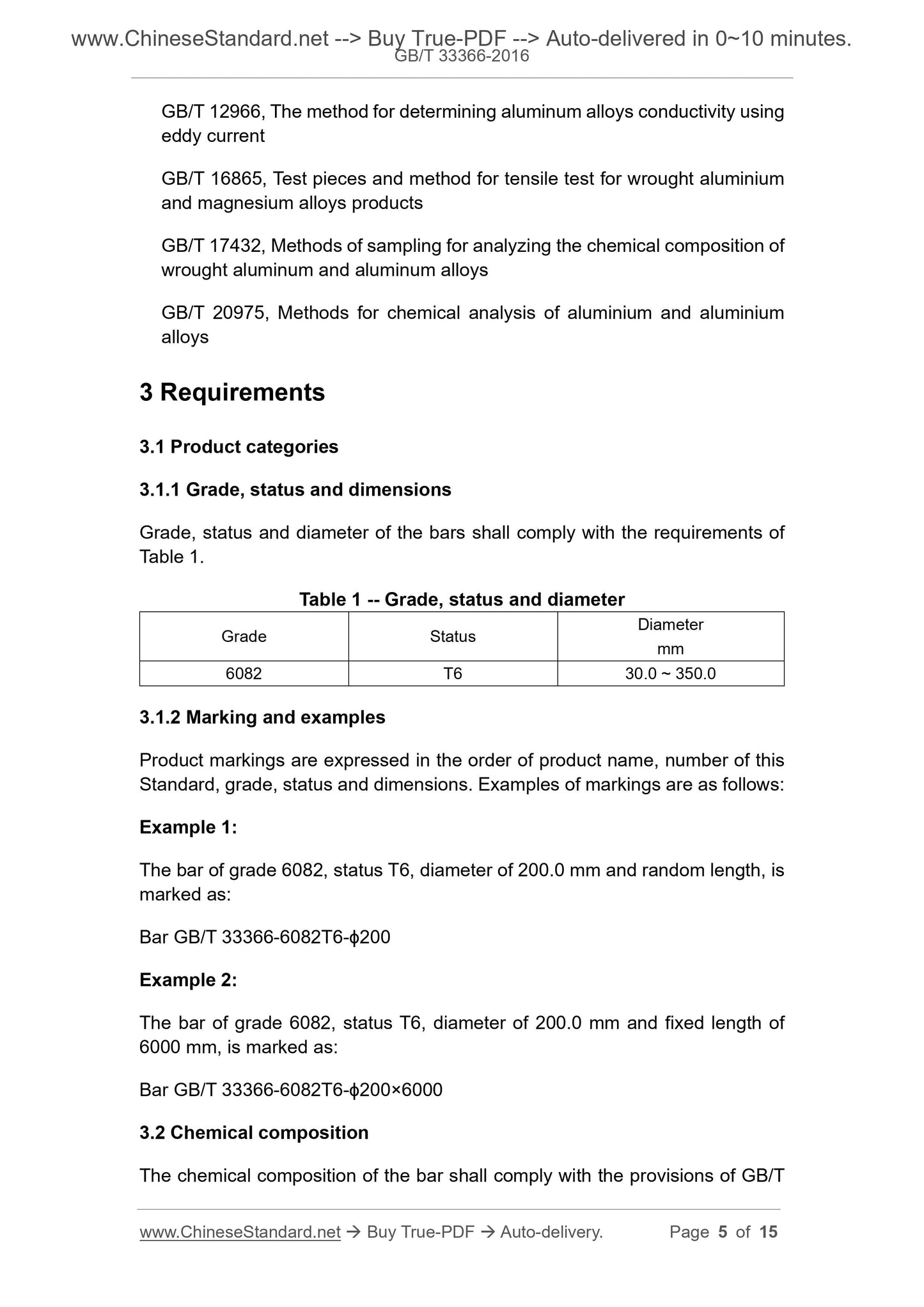

Grade, status and diameter of the bars shall comply with the requirements of

Table 1.

Table 1 -- Grade, status and diameter

Grade Status Diameter mm

6082 T6 30.0 ~ 350.0

3.1.2 Marking and examples

Product markings are expressed in the order of product name, number of this

Standard, grade, status and dimensions. Examples of markings are as follows:

Example 1:

The bar of grade 6082, status T6, diameter of 200.0 mm and random length, is

marked as:

Bar GB/T 33366-6082T6-ϕ200

Example 2:

The bar of grade 6082, status T6, diameter of 200.0 mm and fixed length of

6000 mm, is marked as:

Bar GB/T 33366-6082T6-ϕ200×6000

3.2 Chemical composition

The chemical composition of the bar shall comply with the provisions of GB/T

3190.

3.3 Dimension deviation

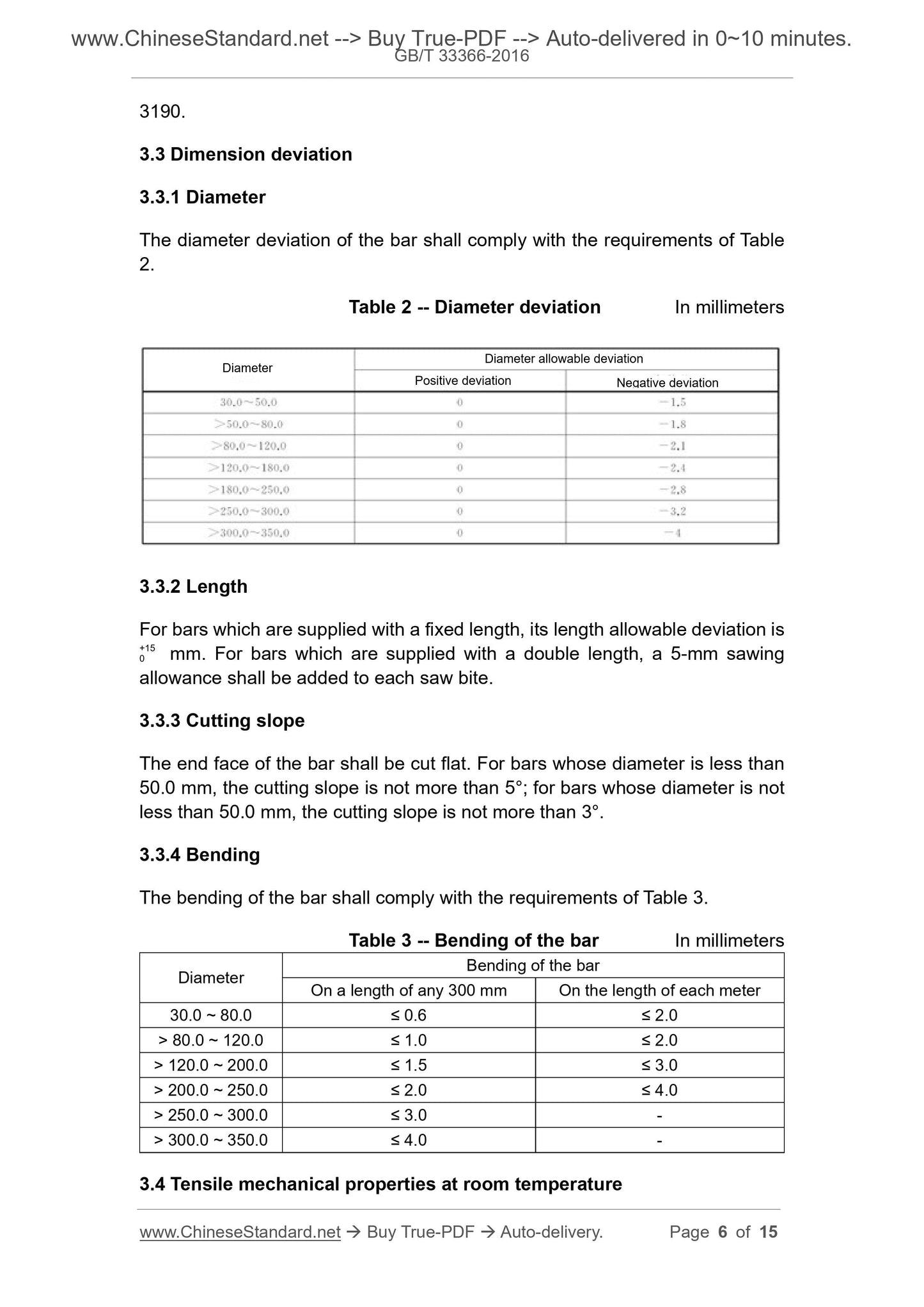

3.3.1 Diameter

The diameter deviation of the bar shall comply with the requirements of Table

2.

Table 2 -- Diameter deviation In millimeters

3.3.2 Length

For bars which are supplied with a fixed length, its length allowable deviation is

+15

0 mm. For bars which are supplied with a double length, a 5-mm sawing

allowance shall be added to each saw bite.

3.3.3 Cutting slope

The end face of the bar shall be cut flat. For bars whose diameter is less than

50.0 mm, the cutting slope is not more than 5°; for bars whose diameter is not

less than 50.0 mm, the cutting slope is not more than 3°.

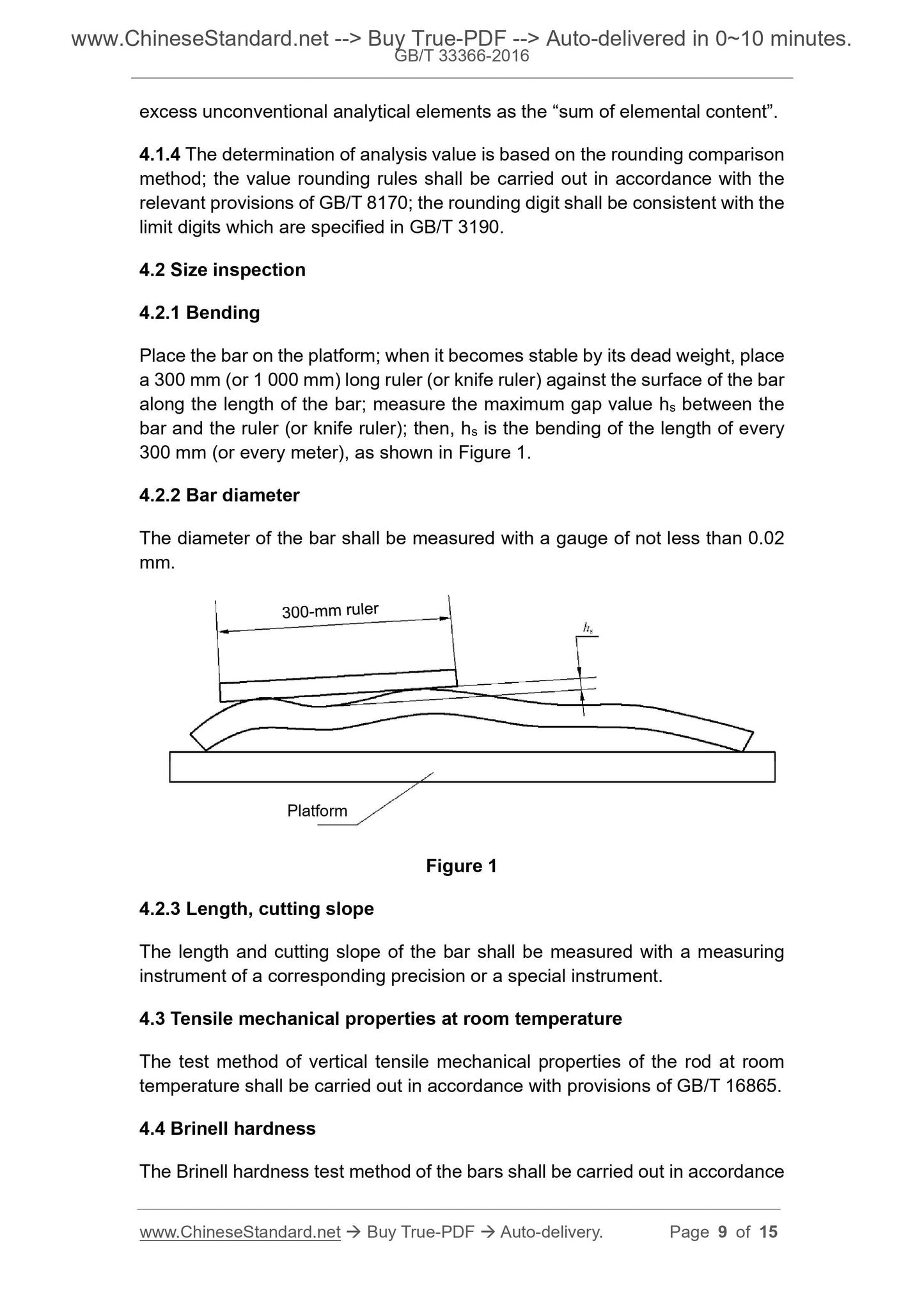

3.3.4 Bending

The bending of the bar shall comply with the requirements of Table 3.

Table 3 -- Bending of the bar In millimeters

Diameter Bending of the bar On a length of any 300 mm On the length of each meter

30.0 ~ 80.0 ≤ 0.6 ≤ 2.0

> 80.0 ~ 120.0 ≤ 1.0 ≤ 2.0

> 120.0 ~ 200.0 ≤ 1.5 ≤ 3.0

> 200.0 ~ 250.0 ≤ 2.0 ≤ 4.0

> 250.0 ~ 300.0 ≤ 3.0 -

> 300.0 ~ 350.0 ≤ 4.0 -

3.4 Tensile mechanical properties at room temperature

Diameter allowable deviation Diameter Positive deviation Negative deviation

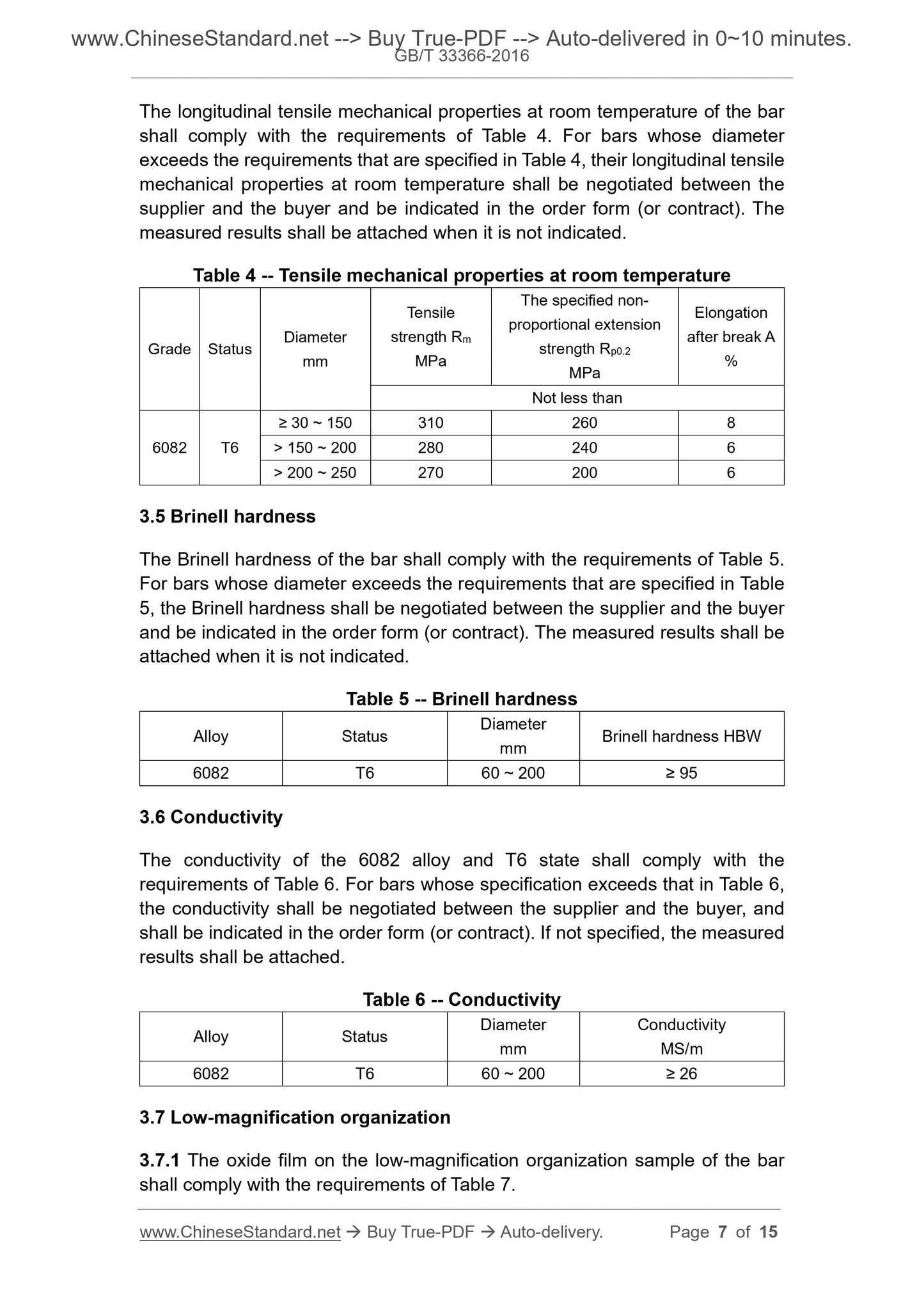

The longitudinal tensile mechanical properties at room temperature of the bar

shall comply with the requirements of Table 4. For bars whose diameter

exceeds the requirements that are specified in Table 4, their longitudinal tensile

mechanical properties at room temperature shall be negotiated between the

supplier and the buyer and be indicated in the order form (or contract). The

measured results shall be attached when it is not indicated.

Table 4 -- Tensile mechanical properties at room temperature

Grade Status Diameter mm

Tensile

strength Rm

MPa

The specified non-

proportional extension

strength Rp0.2

MPa

Elongation

after break A

Not less than

6082 T6

≥ 30 ~ 150 310 260 8

> 150 ~ 200 280 240 6

> 200 ~ 250 270 200 6

3.5 Brinell hardness

The Brinell hardness of the bar shall comply with the requirements of Table 5.

For bars whose diameter exceeds the requirements that are specified in Table

5, the Brinell hardness shall be negotiated between the supplier and the buyer

and be indicated in the order form (or contract). The measured results shall be

attached when it is not indicated.

Table 5 -- Brinell hardness

Alloy Status Diameter mm Brinell hardness HBW

6082 T6 60 ~ 200 ≥ 95

3.6 Conductivity

The conductivity of the 6082 alloy and T6 state shall comply with the

requirements of Table 6. For bars whose specification exceeds that in Table 6,

the conductivity shall be negotiated between the supplier and the buyer, and

shall be indicated in the order form (or contract). If not specified, the measured

results shall be attached.

Table 6 -- Conductivity

Alloy Status Diameter mm

Conductivity

MS/m

6082 T6 60 ~ 200 ≥ 26

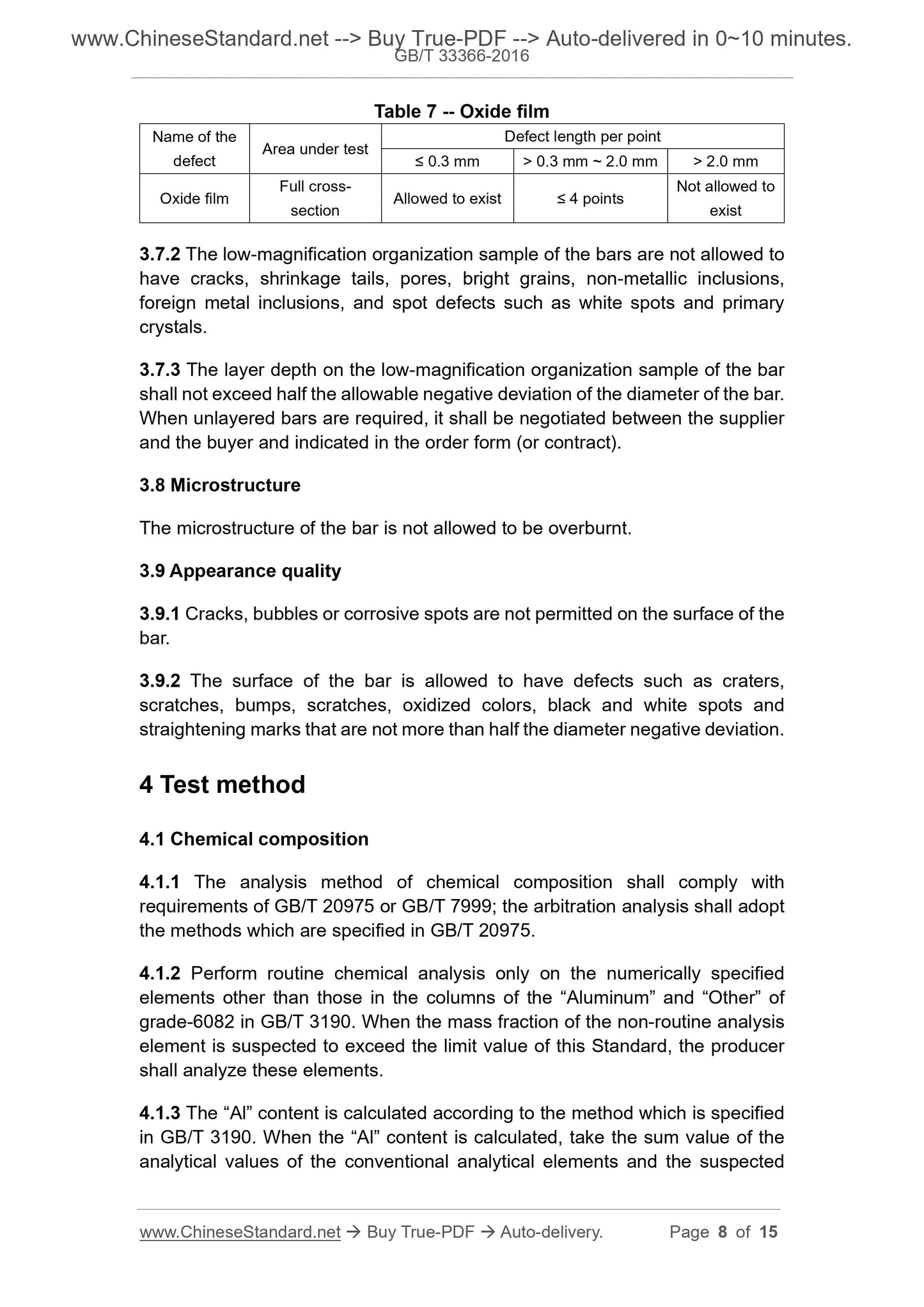

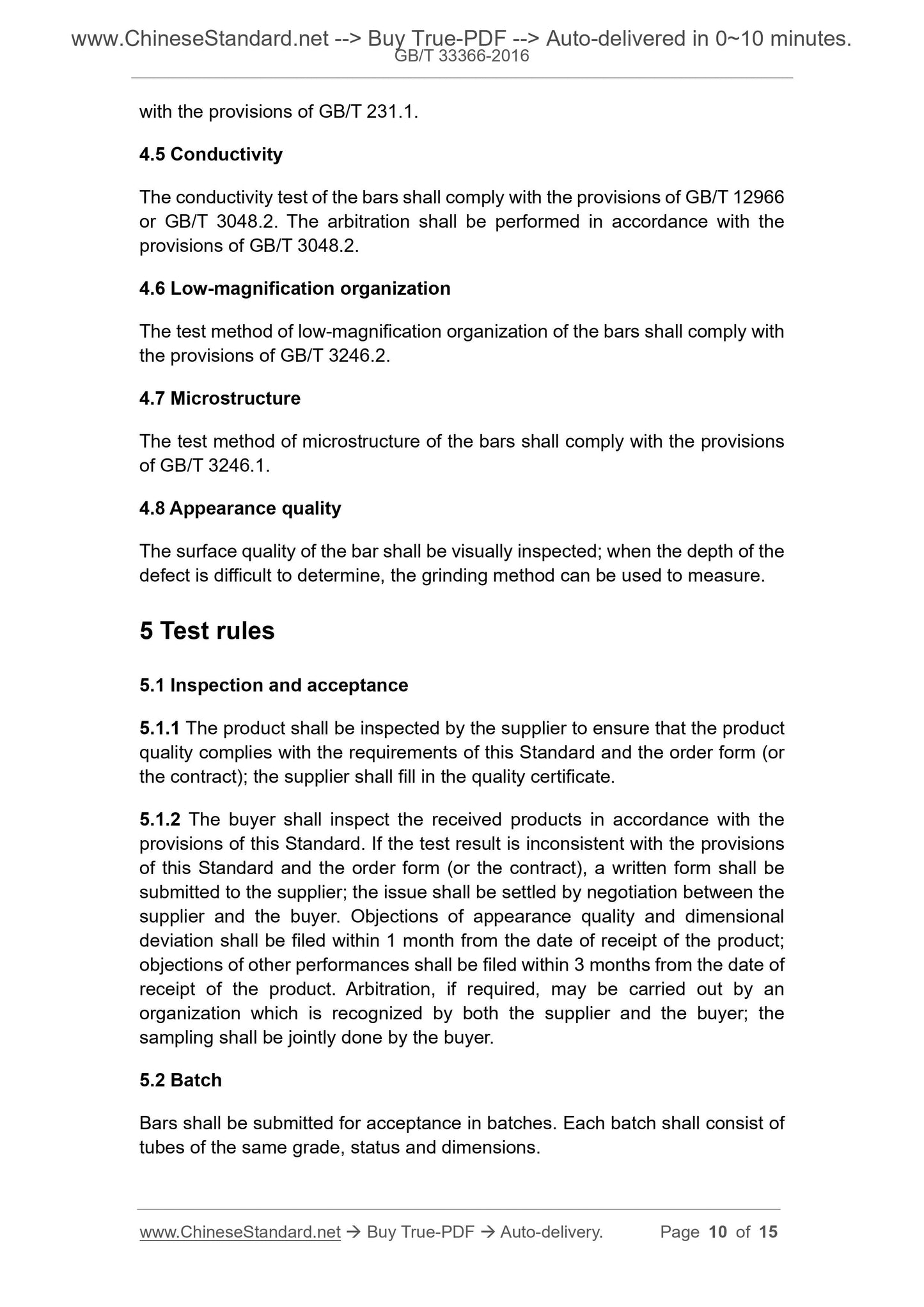

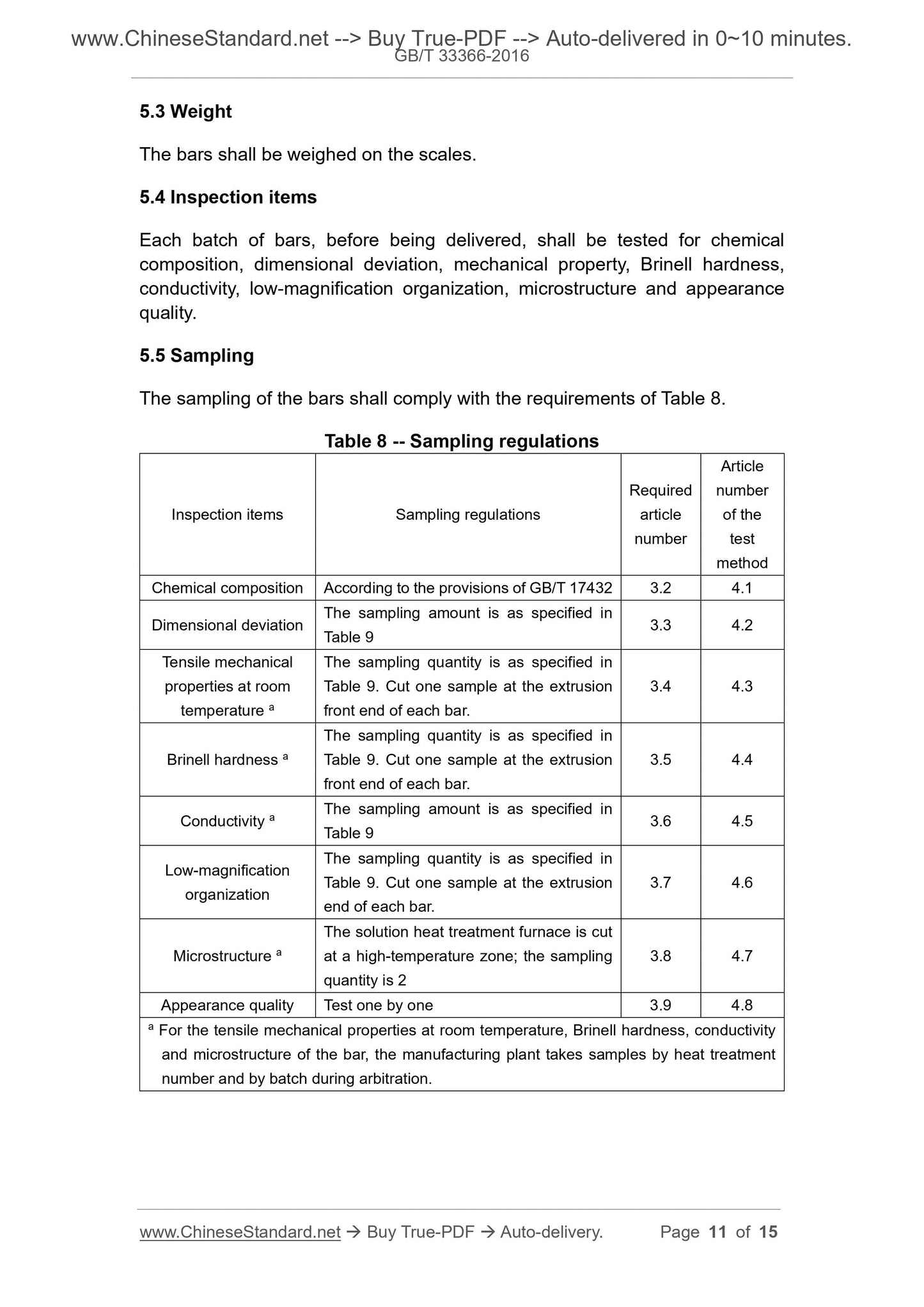

3.7 Low-magnificat...

Get QUOTATION in 1-minute: Click GB/T 33366-2016

Historical versions: GB/T 33366-2016

Preview True-PDF (Reload/Scroll if blank)

GB/T 33366-2016: Wrought aluminium alloy extruded rods and bars for electron enginery-tank

GB/T 33366-2016

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.10

H 61

Wrought Aluminium Alloy Extruded Rods

and Bars for Electron Enginery-tank

ISSUED ON: DECEMBER 30, 2016

IMPLEMENTED ON: JULY 01, 2017

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Requirements ... 5

4 Test method ... 8

5 Test rules ... 10

6 Marking, packaging, transportation, storage and quality certificate ... 13

7 Order form (or contract) contents ... 14

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard was proposed by the China Nonferrous Metals Industry

Association.

This Standard shall be under the jurisdiction of National Technical Committee

243 on Nonferrous Metals of Standardization Administration of China (SAC/TC

243).

The drafting organizations of this Standard: Southwest Aluminum (Group) Co.,

Ltd., China Nonferrous Metals Techno-Economic Research Institute,

Guangdong Haomei Aluminum Co., Ltd., Liaoning Zhongwang Group Co., Ltd.,

Northeast Light Alloy Co., Ltd., National Nonferrous Metals Quality Supervision

and Inspection Center, Shandong Yancon Light Alloy Co., Ltd., Fujian Nanping

Aluminum Co., Ltd., Guangdong Huachang Aluminum Factory Co., Ltd.

The drafters of this Standard: Wang Xiaogang, Peng Zhujun, Ge Lixin, Xiang

Shengqian, Gai Hongtao, Wang Guojun, Li Pu, Wang Zhibo, Luo Taotao, Gao

Xinyu, Chen Jingchun, Tang Xingyu.

Wrought Aluminium Alloy Extruded Rods

and Bars for Electron Enginery-tank

1 Scope

This Standard specifies the requirements, test methods, inspection rules and

marking, packaging, transportation, storage, quality certificate and order form

(or contract) contents of wrought aluminium alloy extruded rods and bars for

electron enginery-tank.

This Standard applies to aluminum alloy extruded round bars (hereinafter

referred to as bars) which are used for processing conductive parts in electronic

equipment control cabinets.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 231.1, Metallic materials. Brinell hardness test. Part 1: Test method

GB/T 3190, Wrought aluminum and aluminum alloy. Chemical composition

GB/T 3199, Wrought aluminium and aluminium alloy products. Packing,

marking, transporting and storing

GB/T 3048.2, Test methods for electrical properties of electric cables and

wires. Part 2: Test of electrical resistivity of metallic materials

GB/T 3246.1, Inspection method for structure of wrought aluminum and

aluminum alloy products. Part 1: Inspection method for microstructure

GB/T 3246.2, Inspection method for structure of wrought aluminum and

aluminum alloy products. Part 2: Inspection method for macrostructure

GB/T 7999, Optical emission spectrometric analysis method of aluminum

and aluminum alloys

GB/T 8170, Rules of rounding off for numerical values and expression and

judgment of limiting values

GB/T 12966, The method for determining aluminum alloys conductivity using

eddy current

GB/T 16865, Test pieces and method for tensile test for wrought aluminium

and magnesium alloys products

GB/T 17432, Methods of sampling for analyzing the chemical composition of

wrought aluminum and aluminum alloys

GB/T 20975, Methods for chemical analysis of aluminium and aluminium

alloys

3 Requirements

3.1 Product categories

3.1.1 Grade, status and dimensions

Grade, status and diameter of the bars shall comply with the requirements of

Table 1.

Table 1 -- Grade, status and diameter

Grade Status Diameter mm

6082 T6 30.0 ~ 350.0

3.1.2 Marking and examples

Product markings are expressed in the order of product name, number of this

Standard, grade, status and dimensions. Examples of markings are as follows:

Example 1:

The bar of grade 6082, status T6, diameter of 200.0 mm and random length, is

marked as:

Bar GB/T 33366-6082T6-ϕ200

Example 2:

The bar of grade 6082, status T6, diameter of 200.0 mm and fixed length of

6000 mm, is marked as:

Bar GB/T 33366-6082T6-ϕ200×6000

3.2 Chemical composition

The chemical composition of the bar shall comply with the provisions of GB/T

3190.

3.3 Dimension deviation

3.3.1 Diameter

The diameter deviation of the bar shall comply with the requirements of Table

2.

Table 2 -- Diameter deviation In millimeters

3.3.2 Length

For bars which are supplied with a fixed length, its length allowable deviation is

+15

0 mm. For bars which are supplied with a double length, a 5-mm sawing

allowance shall be added to each saw bite.

3.3.3 Cutting slope

The end face of the bar shall be cut flat. For bars whose diameter is less than

50.0 mm, the cutting slope is not more than 5°; for bars whose diameter is not

less than 50.0 mm, the cutting slope is not more than 3°.

3.3.4 Bending

The bending of the bar shall comply with the requirements of Table 3.

Table 3 -- Bending of the bar In millimeters

Diameter Bending of the bar On a length of any 300 mm On the length of each meter

30.0 ~ 80.0 ≤ 0.6 ≤ 2.0

> 80.0 ~ 120.0 ≤ 1.0 ≤ 2.0

> 120.0 ~ 200.0 ≤ 1.5 ≤ 3.0

> 200.0 ~ 250.0 ≤ 2.0 ≤ 4.0

> 250.0 ~ 300.0 ≤ 3.0 -

> 300.0 ~ 350.0 ≤ 4.0 -

3.4 Tensile mechanical properties at room temperature

Diameter allowable deviation Diameter Positive deviation Negative deviation

The longitudinal tensile mechanical properties at room temperature of the bar

shall comply with the requirements of Table 4. For bars whose diameter

exceeds the requirements that are specified in Table 4, their longitudinal tensile

mechanical properties at room temperature shall be negotiated between the

supplier and the buyer and be indicated in the order form (or contract). The

measured results shall be attached when it is not indicated.

Table 4 -- Tensile mechanical properties at room temperature

Grade Status Diameter mm

Tensile

strength Rm

MPa

The specified non-

proportional extension

strength Rp0.2

MPa

Elongation

after break A

Not less than

6082 T6

≥ 30 ~ 150 310 260 8

> 150 ~ 200 280 240 6

> 200 ~ 250 270 200 6

3.5 Brinell hardness

The Brinell hardness of the bar shall comply with the requirements of Table 5.

For bars whose diameter exceeds the requirements that are specified in Table

5, the Brinell hardness shall be negotiated between the supplier and the buyer

and be indicated in the order form (or contract). The measured results shall be

attached when it is not indicated.

Table 5 -- Brinell hardness

Alloy Status Diameter mm Brinell hardness HBW

6082 T6 60 ~ 200 ≥ 95

3.6 Conductivity

The conductivity of the 6082 alloy and T6 state shall comply with the

requirements of Table 6. For bars whose specification exceeds that in Table 6,

the conductivity shall be negotiated between the supplier and the buyer, and

shall be indicated in the order form (or contract). If not specified, the measured

results shall be attached.

Table 6 -- Conductivity

Alloy Status Diameter mm

Conductivity

MS/m

6082 T6 60 ~ 200 ≥ 26

3.7 Low-magnificat...

Share