1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB/T 35528-2017 English PDF (GBT35528-2017)

GB/T 35528-2017 English PDF (GBT35528-2017)

Regular price

$700.00 USD

Regular price

Sale price

$700.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 35528-2017

Historical versions: GB/T 35528-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 35528-2017: Safety guidelines for cryogenic liquefied gases

GB/T 35528-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.100.20

G 86

Safety guidelines for cryogenic liquefied gases

ISSUED ON: DECEMBER 29, 2017

IMPLEMENTED ON: JULY 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of China.

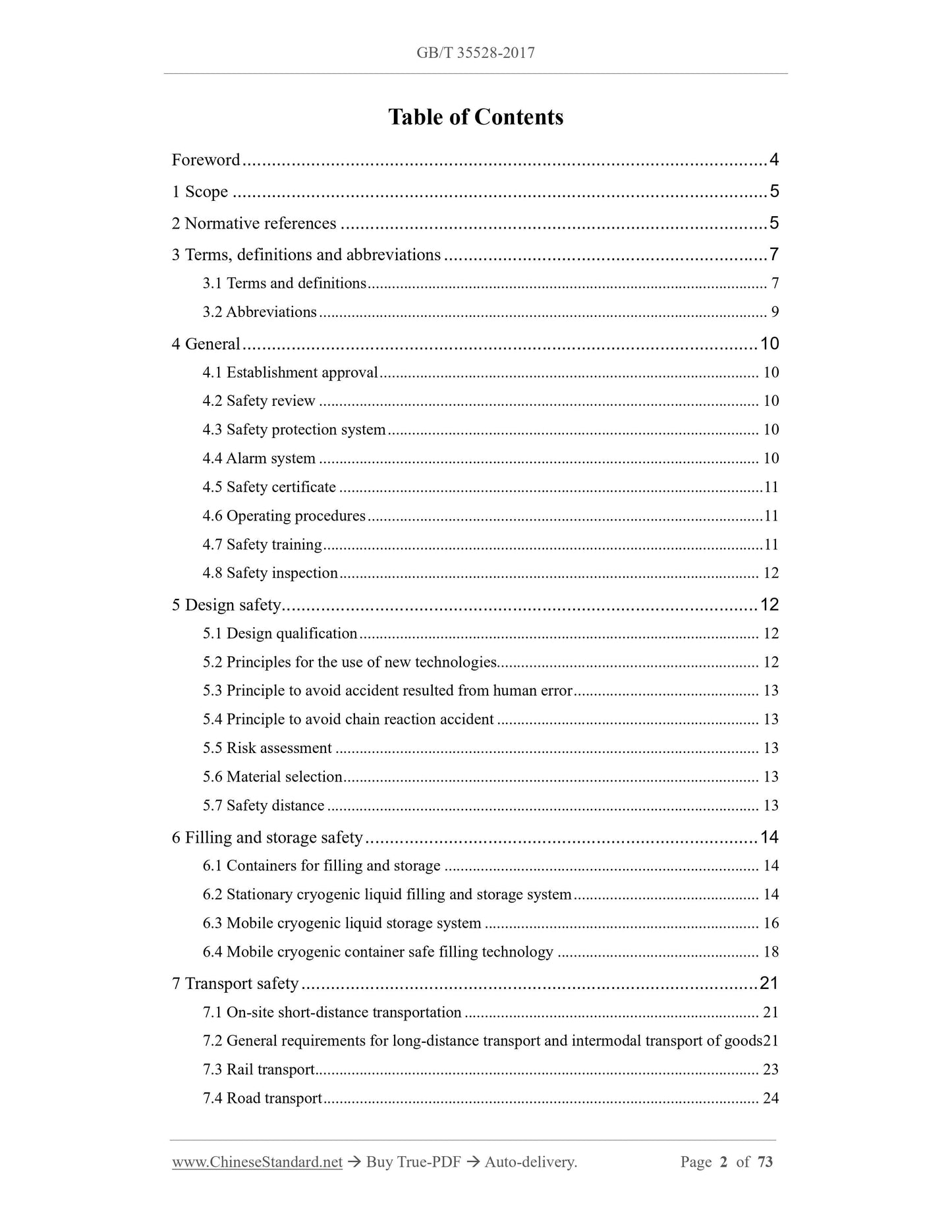

Table of Contents

Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Terms, definitions and abbreviations ... 7

3.1 Terms and definitions ... 7

3.2 Abbreviations ... 9

4 General ... 10

4.1 Establishment approval ... 10

4.2 Safety review ... 10

4.3 Safety protection system ... 10

4.4 Alarm system ... 10

4.5 Safety certificate ... 11

4.6 Operating procedures ... 11

4.7 Safety training ... 11

4.8 Safety inspection ... 12

5 Design safety ... 12

5.1 Design qualification ... 12

5.2 Principles for the use of new technologies... 12

5.3 Principle to avoid accident resulted from human error ... 13

5.4 Principle to avoid chain reaction accident ... 13

5.5 Risk assessment ... 13

5.6 Material selection ... 13

5.7 Safety distance ... 13

6 Filling and storage safety ... 14

6.1 Containers for filling and storage ... 14

6.2 Stationary cryogenic liquid filling and storage system ... 14

6.3 Mobile cryogenic liquid storage system ... 16

6.4 Mobile cryogenic container safe filling technology ... 18

7 Transport safety ... 21

7.1 On-site short-distance transportation ... 21

7.2 General requirements for long-distance transport and intermodal transport of goods 21

7.3 Rail transport ... 23

7.4 Road transport ... 24

7.5 Waterway transportation ... 25

7.6 Air freight ... 26

8 Safety on use ... 30

8.1 Code for safe operation of liquid flammable gases ... 30

8.2 Specification for safe operation of liquid oxygen ... 32

8.3 Specifications for safe operation of liquid inert gases ... 35

9 Fire safety ... 38

9.1 General ... 38

9.2 General firefighting measures ... 40

9.3 Firefighting measures for hydrogen fires ... 42

9.4 Fire-fighting measures for methane fires ... 43

9.5 Firefighting measures for oxygen fire ... 43

9.6 Firefighting measures for inert cryogenic liquid fires ... 44

10 Personal safety protection ... 45

10.1 Labor protection articles ... 45

10.2 Occupational injury prevention ... 46

10.3 On-site first aid ... 47

Annex A (informative) Safety characteristics of cryogenic liquefied gas commonly used

in industry ... 50

A.1 Main physical and thermophysical properties of cryogenic liquefied gases commonly

used in industry ... 50

A.2 Hazard classification of common industrial liquefied gases ... 52

A.3 Product name number of gas dangerous goods ... 53

A.4 Safety hazards of cryogenic liquefied gas ... 53

Annex B (informative) International chemical safety card (ICSC) ... 56

B.1 Liquid hydrogen ... 56

B.2 Liquid oxygen ... 58

B.3 Liquid nitrogen ... 60

B.4 Liquid methane ... 61

B.5 Liquid helium ... 64

B.6 Liquid neon ... 65

B.7 Liquid argon ... 67

B.8 Liquid krypton ... 69

Annex C (informative) Low temperature properties of materials ... 71

Bibliography ... 73

Safety guidelines for cryogenic liquefied gases

1 Scope

This Standard specifies the basic requirements closely related to safety in the process

of (device) design, filling, storage, transportation and use of commonly used cryogenic

liquefied gases.

This Standard applies to common industrial gases that are transported and stored in

cryogenic liquid form, that is, cryogenic liquefaction products of hydrogen, oxygen,

nitrogen, helium, neon, argon, krypton and methane.

This Standard does not apply to the production process of various common industrial

gases and their liquefied products.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 150.1, Pressure Containers - Part 1: General Requirements

GB/T 191, Packaging and storage marks

GB/T 4387, Safety regulation for railway and road transportation in plants of

industrial enterprises

GB/T 5458, Liquid nitrogen biological container

GB 7258, Technical specifications for safety of power-driven vehicles operating on

roads

GB 8958, Safety regulation for working under hazardous condition of the oxygen

deficiency

GB 8965.1, Protective clothing - Flame retardant protective clothing

GB/T 10478, Railway tank car for liquefied gases

GB 12014, Protective clothing - Static protective clothing

GB 12158, General guideline for preventing electrostatic accidents

3.1.8 risk assessment

At the beginning of the design, an evaluation of the expected use of the device and

equipment after a certain period of time and the possible failure modes under various

operating conditions.

3.1.9 loss of vacuum

A failure that for different cryogenic liquid containers adopting vacuum jacket

insulation, the leakage rate of vacuum interlayer is greater than the requirements of

GB/T 18442 or GB/T 24159, so that the degree of vacuum gradually decreases, and the

thermal insulation performance gradually deteriorates.

3.1.10 violent boiling

Sudden violent boiling of a frozen liquid with splashing of the liquid.

3.1.11 maximum allowable filling volume

That is, the design storage capacity of the stationary pressure container and the

maximum allowable filling capacity of the mobile pressure container.

3.1.12 vent pipe

A pipeline with a certain height that can directly discharge gas into the atmosphere.

3.1.13 flame arrester

A safety device to prevent flashback of flammable gases.

3.1.14 confined space

Confined space with known or potentially hazardous and limited access structures.

3.1.15 buddy system

A safety measure in which one person performs necessary tasks in a dangerous

operating environment, while another person observes and monitors in a safe area and

is ready to carry out timely rescue at any time.

3.1.16 backflow

Specifically refers to the phenomenon of air diffusion into cryogenic liquefied gas

containers or equipment.

3.1.17 detonation

An exothermic chemical reaction accompanied by a shock wave in which an explosive

mixture or medium travels at supersonic speeds.

3.1.18 sensitivity to impact

The degree of susceptibility to detonation of an explosive mixture or medium by

mechanical shock.

3.1.19 cryogenic contact injury

Cold burns similar to thermal burns to skin tissue or eyes due to exposure to cryogenic

liquids or cold vapors on exposed parts of the body.

3.1.20 oxygen deficiency atmosphere

A state where the oxygen content in the workplace air is less than 19.5%.

3.1.21 asphyxia caused by inhalation of hypoxic air

A pathological state that due to the lack of oxygen in the air, the breathing process of

the human body is blocked or abnormal, resulting in tissue and cell metabolism

disorders, functional disorders and morphological and structural damage caused by

oxygen deficiency and carbon dioxide retention in various organs and tissues

throughout the body.

3.1.22 respiratory protective equipment

Protective equipment to prevent oxygen-deficient air and air pollutants from entering

t...

Get QUOTATION in 1-minute: Click GB/T 35528-2017

Historical versions: GB/T 35528-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 35528-2017: Safety guidelines for cryogenic liquefied gases

GB/T 35528-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.100.20

G 86

Safety guidelines for cryogenic liquefied gases

ISSUED ON: DECEMBER 29, 2017

IMPLEMENTED ON: JULY 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of China.

Table of Contents

Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Terms, definitions and abbreviations ... 7

3.1 Terms and definitions ... 7

3.2 Abbreviations ... 9

4 General ... 10

4.1 Establishment approval ... 10

4.2 Safety review ... 10

4.3 Safety protection system ... 10

4.4 Alarm system ... 10

4.5 Safety certificate ... 11

4.6 Operating procedures ... 11

4.7 Safety training ... 11

4.8 Safety inspection ... 12

5 Design safety ... 12

5.1 Design qualification ... 12

5.2 Principles for the use of new technologies... 12

5.3 Principle to avoid accident resulted from human error ... 13

5.4 Principle to avoid chain reaction accident ... 13

5.5 Risk assessment ... 13

5.6 Material selection ... 13

5.7 Safety distance ... 13

6 Filling and storage safety ... 14

6.1 Containers for filling and storage ... 14

6.2 Stationary cryogenic liquid filling and storage system ... 14

6.3 Mobile cryogenic liquid storage system ... 16

6.4 Mobile cryogenic container safe filling technology ... 18

7 Transport safety ... 21

7.1 On-site short-distance transportation ... 21

7.2 General requirements for long-distance transport and intermodal transport of goods 21

7.3 Rail transport ... 23

7.4 Road transport ... 24

7.5 Waterway transportation ... 25

7.6 Air freight ... 26

8 Safety on use ... 30

8.1 Code for safe operation of liquid flammable gases ... 30

8.2 Specification for safe operation of liquid oxygen ... 32

8.3 Specifications for safe operation of liquid inert gases ... 35

9 Fire safety ... 38

9.1 General ... 38

9.2 General firefighting measures ... 40

9.3 Firefighting measures for hydrogen fires ... 42

9.4 Fire-fighting measures for methane fires ... 43

9.5 Firefighting measures for oxygen fire ... 43

9.6 Firefighting measures for inert cryogenic liquid fires ... 44

10 Personal safety protection ... 45

10.1 Labor protection articles ... 45

10.2 Occupational injury prevention ... 46

10.3 On-site first aid ... 47

Annex A (informative) Safety characteristics of cryogenic liquefied gas commonly used

in industry ... 50

A.1 Main physical and thermophysical properties of cryogenic liquefied gases commonly

used in industry ... 50

A.2 Hazard classification of common industrial liquefied gases ... 52

A.3 Product name number of gas dangerous goods ... 53

A.4 Safety hazards of cryogenic liquefied gas ... 53

Annex B (informative) International chemical safety card (ICSC) ... 56

B.1 Liquid hydrogen ... 56

B.2 Liquid oxygen ... 58

B.3 Liquid nitrogen ... 60

B.4 Liquid methane ... 61

B.5 Liquid helium ... 64

B.6 Liquid neon ... 65

B.7 Liquid argon ... 67

B.8 Liquid krypton ... 69

Annex C (informative) Low temperature properties of materials ... 71

Bibliography ... 73

Safety guidelines for cryogenic liquefied gases

1 Scope

This Standard specifies the basic requirements closely related to safety in the process

of (device) design, filling, storage, transportation and use of commonly used cryogenic

liquefied gases.

This Standard applies to common industrial gases that are transported and stored in

cryogenic liquid form, that is, cryogenic liquefaction products of hydrogen, oxygen,

nitrogen, helium, neon, argon, krypton and methane.

This Standard does not apply to the production process of various common industrial

gases and their liquefied products.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 150.1, Pressure Containers - Part 1: General Requirements

GB/T 191, Packaging and storage marks

GB/T 4387, Safety regulation for railway and road transportation in plants of

industrial enterprises

GB/T 5458, Liquid nitrogen biological container

GB 7258, Technical specifications for safety of power-driven vehicles operating on

roads

GB 8958, Safety regulation for working under hazardous condition of the oxygen

deficiency

GB 8965.1, Protective clothing - Flame retardant protective clothing

GB/T 10478, Railway tank car for liquefied gases

GB 12014, Protective clothing - Static protective clothing

GB 12158, General guideline for preventing electrostatic accidents

3.1.8 risk assessment

At the beginning of the design, an evaluation of the expected use of the device and

equipment after a certain period of time and the possible failure modes under various

operating conditions.

3.1.9 loss of vacuum

A failure that for different cryogenic liquid containers adopting vacuum jacket

insulation, the leakage rate of vacuum interlayer is greater than the requirements of

GB/T 18442 or GB/T 24159, so that the degree of vacuum gradually decreases, and the

thermal insulation performance gradually deteriorates.

3.1.10 violent boiling

Sudden violent boiling of a frozen liquid with splashing of the liquid.

3.1.11 maximum allowable filling volume

That is, the design storage capacity of the stationary pressure container and the

maximum allowable filling capacity of the mobile pressure container.

3.1.12 vent pipe

A pipeline with a certain height that can directly discharge gas into the atmosphere.

3.1.13 flame arrester

A safety device to prevent flashback of flammable gases.

3.1.14 confined space

Confined space with known or potentially hazardous and limited access structures.

3.1.15 buddy system

A safety measure in which one person performs necessary tasks in a dangerous

operating environment, while another person observes and monitors in a safe area and

is ready to carry out timely rescue at any time.

3.1.16 backflow

Specifically refers to the phenomenon of air diffusion into cryogenic liquefied gas

containers or equipment.

3.1.17 detonation

An exothermic chemical reaction accompanied by a shock wave in which an explosive

mixture or medium travels at supersonic speeds.

3.1.18 sensitivity to impact

The degree of susceptibility to detonation of an explosive mixture or medium by

mechanical shock.

3.1.19 cryogenic contact injury

Cold burns similar to thermal burns to skin tissue or eyes due to exposure to cryogenic

liquids or cold vapors on exposed parts of the body.

3.1.20 oxygen deficiency atmosphere

A state where the oxygen content in the workplace air is less than 19.5%.

3.1.21 asphyxia caused by inhalation of hypoxic air

A pathological state that due to the lack of oxygen in the air, the breathing process of

the human body is blocked or abnormal, resulting in tissue and cell metabolism

disorders, functional disorders and morphological and structural damage caused by

oxygen deficiency and carbon dioxide retention in various organs and tissues

throughout the body.

3.1.22 respiratory protective equipment

Protective equipment to prevent oxygen-deficient air and air pollutants from entering

t...

Share