1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 35749-2017 English PDF (GBT35749-2017)

GB/T 35749-2017 English PDF (GBT35749-2017)

Regular price

$230.00 USD

Regular price

Sale price

$230.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 35749-2017

Historical versions: GB/T 35749-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 35749-2017: Polyamide 66 draw textured yarn

GB/T 35749-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.060.20

W 52

Polyamide 66 draw textured yarn

锦纶 66弹力丝

ISSUED ON. DECEMBER 29, 2017

IMPLEMENTED ON. JULY 01, 2018

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

National Standardization Administration.

Table of Contents

Foreword... 3

1 Scope... 4

2 Normative references... 4

3 Terms and definitions... 5

4 Classification and identification... 5

5 Technical requirements... 5

6 Test methods... 7

7 Inspection rules... 8

8 Marking, packaging, transportation, storage... 10

Appendix A (Normative) Appearance requirements, inspection, evaluation... 12

Appendix B (Informative) Recommended method for rapid humidity conditioning of

specimens... 14

Polyamide 66 draw textured yarn

1 Scope

This standard specifies the terms and definitions, classification and identification,

technical requirements, test methods, inspection rules, marking, packaging,

transportation, storage requirements of polyamide 66 draw textured yarn products.

This standard applies to elastic yarn made of polyhexamethylene adipamide as raw

material, as well as round cross-section glossy, semi-dull and full-dull yarns, which

have a nominal linear density range of 7 dtex ~ 150 dtex (plied yarn refers to the

nominal linear density before plying) and a single yarn linear density of 0.8 dtex ~ 5.0

dtex.

2 Normative references

The following documents are essential for the application of this document. For all

dated references, only the dated version applies to this document. For all undated

references, the latest version (including all amendments) applies to this document.

GB/T 250 Textiles - Tests for color fastness - Grey scale for assessing change in

color

GB/T 2828.1-2012 Sampling procedures for inspection by attributes - Part 1.

Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot

inspection

GB/T 3291.1 Textiles - Terms of textile material properties and test - Part 1.Fiber

and yarn

GB/T 3291.3 Textiles - Terms of textile material properties and test - Part 3.General

GB/T 4146 (all parts) Textiles - Man-made fibres

GB/T 6502 Sampling method of man-made filament yarns

GB/T 6503 Man-made fibres - Test method of moisture regain

GB/T 6504 Man-made fiber - Test method for oil content

GB/T 6506 Synthetic fiber - Test method for crimp contraction properties of textured

filament yarns

GB/T 6529 Textiles - Standard atmospheres for conditioning and testing

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 14343 Testing method for linear density of man-made filament yarns

GB/T 14344 Man-made fiber - Test method for tensile properties of filament yarns

FZ/T 50008 Test method for dyeing uniformity of polyamide filament yarns

FZ/T 50001 Test method for interlacing degree of synthetic filament yarns

FZ/T 51011 Fiber grade polyhexamethylene adipamide (PA66) chip

3 Terms and definitions

The terms and definitions as defined in GB/T 3291.1, GB/T 3291.3, GB/T 4146 (all

parts), FZ/T 51011, apply to this document.

4 Classification and identification

4.1 According to the different TiO2 content, it can be divided into glossy yarn, semi-

matte yarn, full-matte yarn.

4.2 Product specifications are identified by fiber thickness (TEX system, in dtex) and

number of roots (number of spinneret holes, represented by f).

Example 1.78 dtex/52f.

Example 2.Ply yarn representation. 78 dtex/52f×2.

5 Technical requirements

5.1 Product classification

Polyamide 66 draw textured yarn product are divided into three grades. superior, first-

grade, qualified. Products lower than qualified are substandard.

5.2 Performance items and indicators

Physical and mechanical properties and dyeing performance items and indicators are as

shown in Table 1.

5.4 Appearance items and index values

Negotiation between the supplier and the purchaser or implemented in accordance with

the requirements of Appendix A.

6 Test methods

6.1 General

6.1.1 Pre-humidification, humidity conditioning standard atmosphere for testing

6.1.1.1 Pre-humidification

6.1.1.1.1 Pre-humidification is required when the sample meets one of the following

conditions.

- When the moisture regain of the specimen exceeds the official moisture regain;

- The sample is in an atmosphere with a relative humidity higher than the upper limit

of the relative humidity in the laboratory;

- The sample temperature is 5 °C lower than the laboratory temperature.

6.1.1.1.2 The conditions for pre-humidification are.

- Temperature not exceeding 50 °C;

- Relative humidity 5% ~ 25%;

- Time greater than 30 min.

6.1.1.2 Humidity conditioning and standard atmosphere for testing

6.1.1.2.1 The conditions for humidity conditioning are.

- Temperature (20 ± 2) °C;

- Relative humidity (65 ± 3)%;

- Recommended humidity adjustment time 16 h.

6.1.1.2.2 Test conditions are.

- Temperature (20 ± 2) °C;

- Relative humidity (65 ± 3)%.

6.1.1.3 Others

supplier and the buyer or according to the requirements specified in Appendix A.

7.1.2 Group-batching rules

Periodic sampling is used to form inspection lots within a certain range. A production

lot can be composed of one inspection lot or several inspection lots.

7.1.3 Sampling requirements

7.1.3.1 All appearance items and dyeing uniformity items are inspected.

7.1.3.2 Laboratory samples of physical performance items are subject to sampling

inspection according to GB/T 6502.The appearance, tube weight, dyeing uniformity of

the sampled laboratory samples shall meet the corresponding grades.

7.1.4 Judgment rules

7.1.4.1 The calculated values of each performance item are compared with the limit

values of the performance item indicators in Table 1 according to GB/T 8170, to

determine the grade of each item. The dyeing uniformity item is evaluated roll by roll

and graded according to the grayscale sample for color change evaluation in GB/T 250.

7.1.4.2 The appearance inspection items are evaluated, graded, recorded for each roll

according to the provisions of Appendix A or agreed upon by the supplier and purchaser.

7.1.4.3 The lowest grade of the performance items and appearance items in the

inspection lot is finally determined as the grade of the batch of products.

7.2 Re-inspection rules

7.2.1 General rules

Within 3 months after a batch of products arrives at the consignee, a re-inspection may

be requested as acceptance or if there is any objection to the quality. If more than one-

third of the batch of products has been used, re-inspection shall not be requested. If the

quality of the batch of products affects the quality of the post-processing products and

causes serious losses, the supplier and purchaser shall analyze the reasons, clarify the

responsibilities, negotiate to deal with it.

7.2.2 Inspection items

Same as 7.1.1.

7.2.3 Group-batching rules

Group-batch it according to the original production lot.

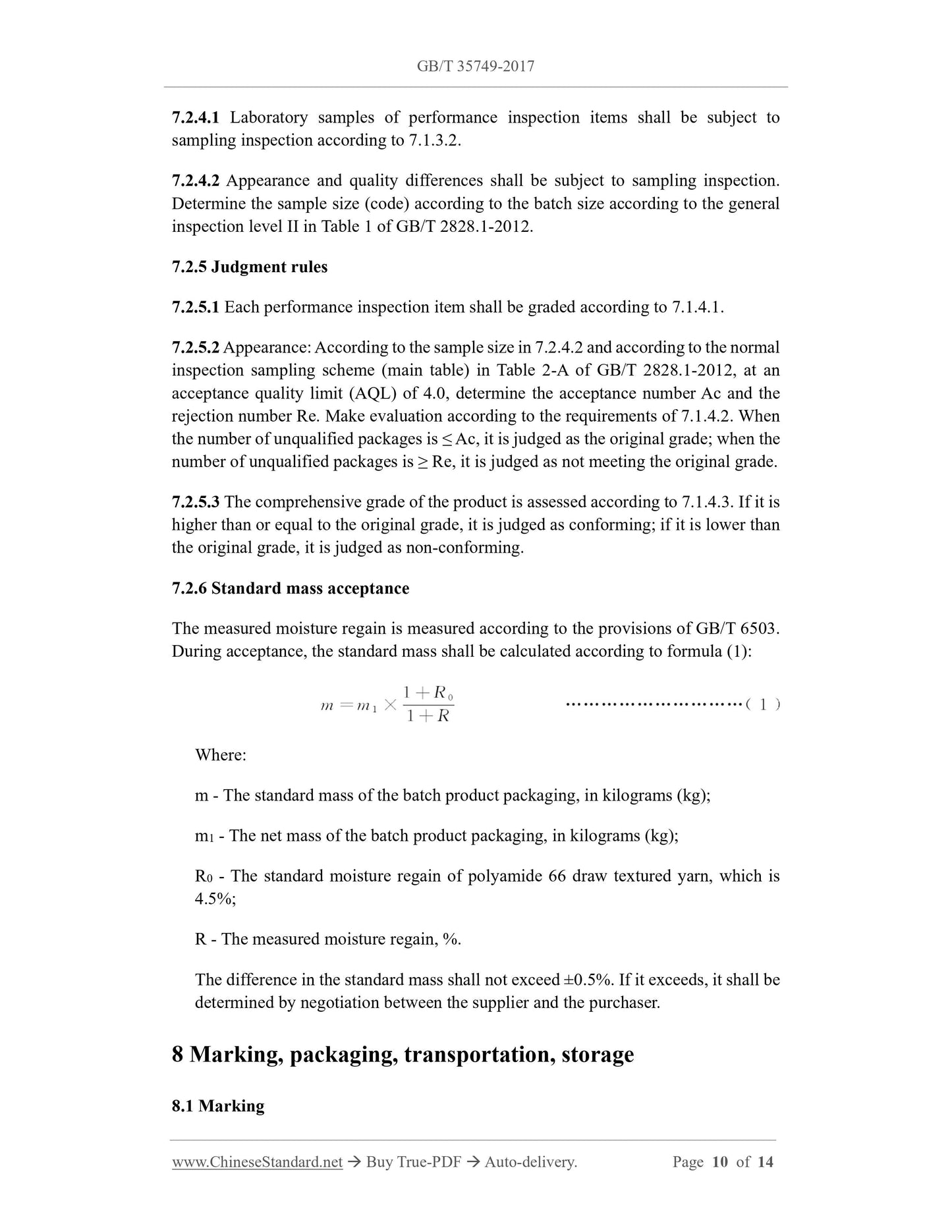

7.2.4 Sampling requirements

7.2.4.1 Laboratory samples of performance inspection items shall be subject to

sampling inspection according to 7.1.3.2.

7.2.4.2 Appearance and quality differences shall be subject to sampling inspection.

Determine the sample size (code) according to the batch size according to the general

inspection level II in Table 1 of GB/T 2828.1-2012.

7.2.5 Judgment rules

Get QUOTATION in 1-minute: Click GB/T 35749-2017

Historical versions: GB/T 35749-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 35749-2017: Polyamide 66 draw textured yarn

GB/T 35749-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.060.20

W 52

Polyamide 66 draw textured yarn

锦纶 66弹力丝

ISSUED ON. DECEMBER 29, 2017

IMPLEMENTED ON. JULY 01, 2018

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

National Standardization Administration.

Table of Contents

Foreword... 3

1 Scope... 4

2 Normative references... 4

3 Terms and definitions... 5

4 Classification and identification... 5

5 Technical requirements... 5

6 Test methods... 7

7 Inspection rules... 8

8 Marking, packaging, transportation, storage... 10

Appendix A (Normative) Appearance requirements, inspection, evaluation... 12

Appendix B (Informative) Recommended method for rapid humidity conditioning of

specimens... 14

Polyamide 66 draw textured yarn

1 Scope

This standard specifies the terms and definitions, classification and identification,

technical requirements, test methods, inspection rules, marking, packaging,

transportation, storage requirements of polyamide 66 draw textured yarn products.

This standard applies to elastic yarn made of polyhexamethylene adipamide as raw

material, as well as round cross-section glossy, semi-dull and full-dull yarns, which

have a nominal linear density range of 7 dtex ~ 150 dtex (plied yarn refers to the

nominal linear density before plying) and a single yarn linear density of 0.8 dtex ~ 5.0

dtex.

2 Normative references

The following documents are essential for the application of this document. For all

dated references, only the dated version applies to this document. For all undated

references, the latest version (including all amendments) applies to this document.

GB/T 250 Textiles - Tests for color fastness - Grey scale for assessing change in

color

GB/T 2828.1-2012 Sampling procedures for inspection by attributes - Part 1.

Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot

inspection

GB/T 3291.1 Textiles - Terms of textile material properties and test - Part 1.Fiber

and yarn

GB/T 3291.3 Textiles - Terms of textile material properties and test - Part 3.General

GB/T 4146 (all parts) Textiles - Man-made fibres

GB/T 6502 Sampling method of man-made filament yarns

GB/T 6503 Man-made fibres - Test method of moisture regain

GB/T 6504 Man-made fiber - Test method for oil content

GB/T 6506 Synthetic fiber - Test method for crimp contraction properties of textured

filament yarns

GB/T 6529 Textiles - Standard atmospheres for conditioning and testing

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 14343 Testing method for linear density of man-made filament yarns

GB/T 14344 Man-made fiber - Test method for tensile properties of filament yarns

FZ/T 50008 Test method for dyeing uniformity of polyamide filament yarns

FZ/T 50001 Test method for interlacing degree of synthetic filament yarns

FZ/T 51011 Fiber grade polyhexamethylene adipamide (PA66) chip

3 Terms and definitions

The terms and definitions as defined in GB/T 3291.1, GB/T 3291.3, GB/T 4146 (all

parts), FZ/T 51011, apply to this document.

4 Classification and identification

4.1 According to the different TiO2 content, it can be divided into glossy yarn, semi-

matte yarn, full-matte yarn.

4.2 Product specifications are identified by fiber thickness (TEX system, in dtex) and

number of roots (number of spinneret holes, represented by f).

Example 1.78 dtex/52f.

Example 2.Ply yarn representation. 78 dtex/52f×2.

5 Technical requirements

5.1 Product classification

Polyamide 66 draw textured yarn product are divided into three grades. superior, first-

grade, qualified. Products lower than qualified are substandard.

5.2 Performance items and indicators

Physical and mechanical properties and dyeing performance items and indicators are as

shown in Table 1.

5.4 Appearance items and index values

Negotiation between the supplier and the purchaser or implemented in accordance with

the requirements of Appendix A.

6 Test methods

6.1 General

6.1.1 Pre-humidification, humidity conditioning standard atmosphere for testing

6.1.1.1 Pre-humidification

6.1.1.1.1 Pre-humidification is required when the sample meets one of the following

conditions.

- When the moisture regain of the specimen exceeds the official moisture regain;

- The sample is in an atmosphere with a relative humidity higher than the upper limit

of the relative humidity in the laboratory;

- The sample temperature is 5 °C lower than the laboratory temperature.

6.1.1.1.2 The conditions for pre-humidification are.

- Temperature not exceeding 50 °C;

- Relative humidity 5% ~ 25%;

- Time greater than 30 min.

6.1.1.2 Humidity conditioning and standard atmosphere for testing

6.1.1.2.1 The conditions for humidity conditioning are.

- Temperature (20 ± 2) °C;

- Relative humidity (65 ± 3)%;

- Recommended humidity adjustment time 16 h.

6.1.1.2.2 Test conditions are.

- Temperature (20 ± 2) °C;

- Relative humidity (65 ± 3)%.

6.1.1.3 Others

supplier and the buyer or according to the requirements specified in Appendix A.

7.1.2 Group-batching rules

Periodic sampling is used to form inspection lots within a certain range. A production

lot can be composed of one inspection lot or several inspection lots.

7.1.3 Sampling requirements

7.1.3.1 All appearance items and dyeing uniformity items are inspected.

7.1.3.2 Laboratory samples of physical performance items are subject to sampling

inspection according to GB/T 6502.The appearance, tube weight, dyeing uniformity of

the sampled laboratory samples shall meet the corresponding grades.

7.1.4 Judgment rules

7.1.4.1 The calculated values of each performance item are compared with the limit

values of the performance item indicators in Table 1 according to GB/T 8170, to

determine the grade of each item. The dyeing uniformity item is evaluated roll by roll

and graded according to the grayscale sample for color change evaluation in GB/T 250.

7.1.4.2 The appearance inspection items are evaluated, graded, recorded for each roll

according to the provisions of Appendix A or agreed upon by the supplier and purchaser.

7.1.4.3 The lowest grade of the performance items and appearance items in the

inspection lot is finally determined as the grade of the batch of products.

7.2 Re-inspection rules

7.2.1 General rules

Within 3 months after a batch of products arrives at the consignee, a re-inspection may

be requested as acceptance or if there is any objection to the quality. If more than one-

third of the batch of products has been used, re-inspection shall not be requested. If the

quality of the batch of products affects the quality of the post-processing products and

causes serious losses, the supplier and purchaser shall analyze the reasons, clarify the

responsibilities, negotiate to deal with it.

7.2.2 Inspection items

Same as 7.1.1.

7.2.3 Group-batching rules

Group-batch it according to the original production lot.

7.2.4 Sampling requirements

7.2.4.1 Laboratory samples of performance inspection items shall be subject to

sampling inspection according to 7.1.3.2.

7.2.4.2 Appearance and quality differences shall be subject to sampling inspection.

Determine the sample size (code) according to the batch size according to the general

inspection level II in Table 1 of GB/T 2828.1-2012.

7.2.5 Judgment rules

Share