1

/

of

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 36162-2018 English PDF (GBT36162-2018)

GB/T 36162-2018 English PDF (GBT36162-2018)

Regular price

$160.00 USD

Regular price

Sale price

$160.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 36162-2018

Historical versions: GB/T 36162-2018

Preview True-PDF (Reload/Scroll if blank)

GB/T 36162-2018: Copper-steel composite sheet and strip

GB/T 36162-2018

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.99

H 62

Copper-steel composite sheet and strip

ISSUED ON. MAY 14, 2018

IMPLEMENTED ON. FEBRUARY 01, 2019

Issued by. State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Requirements... 8

5 Test methods ... 20

6 Inspection rules ... 24

7 Marking, packaging, transportation, storage and quality certificate ... 26

8 Order form (or contract) content ... 26

Copper-steel composite sheet and strip

1 Scope

This Standard specifies the requirements, test methods, inspection rules,

marking, packaging, transportation, storage, quality certificate and order forms

(or contracts) for copper-steel composite sheets and strips.

This Standard applies to copper-steel composite sheets and strips (hereinafter

referred to as CSC sheets and strips) for general industrial use.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 223 (all parts) Iron, steel and alloy

GB/T 228.1-2010 Metallic materials - Tensile testing - Part 1. Method of test

at room temperature

GB/T 232 Metallic materials - Bend test

GB/T 235 Metallic materials - Sheet and strip - Reverse bend test

GB/T 351 Metallic materials - Resistivity measurement method

GB/T 700 Carbon structural steels

GB/T 1591 High strength low alloy structural steels

GB/T 4156 Metallic materials - Sheet and strip - Erichsen cupping test

GB/T 5121 (all parts) Methods for chemical analysis of copper and copper

alloys

GB/T 5213 Cold rolled low carbon steel sheet and strip

GB/T 5231 Designation and chemical composition of wrought copper and

copper alloys

GB/T 6394 Determination of estimating the average grain size of metal

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 8888 Wrought heavy non-ferrous metal products - Packing, marking,

transportation, storing and certificate of quality

GB/T 10561-2005 Steel - Determination of content of nonmetallic inclusions

- Micrographic method using standards diagrams

GB/T 13298 Inspection methods of microstructure for metals

GB/T 26303.3 Measuring methods for dimensions and shapes of wrought

copper and copper alloys - Part 3. Sheets and strips

GB/T 33948.1 Method for chemical analysis of copper-steel composite metal

- Part 1. Determination of copper content- Iodine titration method

GB/T 33948.2 Method for chemical analysis of copper-steel composite metal

- Part 2. Determination of zinc content - Na2 EDTA titration method

GJB 1458B Specification for high quality carbon steel sheets and strips for

copper cladding

WJ 643-1994 Copper-clad steel sheets for bullets

YS/T 668 The sampling method of physical and chemical testing for copper

and copper alloys

YS/T 815 Preparation method of test pieces for mechanical and

technological properties of copper and copper alloys

YS/T 1045-2015 Copper-steel composite sheet and strip for decoration

YS/T 1104-2016 Copper-steel composite sheet and strip for deep drawing

3 Terms and definitions

For the purpose of this document, the following terms and definitions apply.

3.1

copper-steel composite sheet and strip

Material using carbon steel as the base metal, with copper and copper alloy of

a certain thickness integrally and continuously cladded on one or both sides by

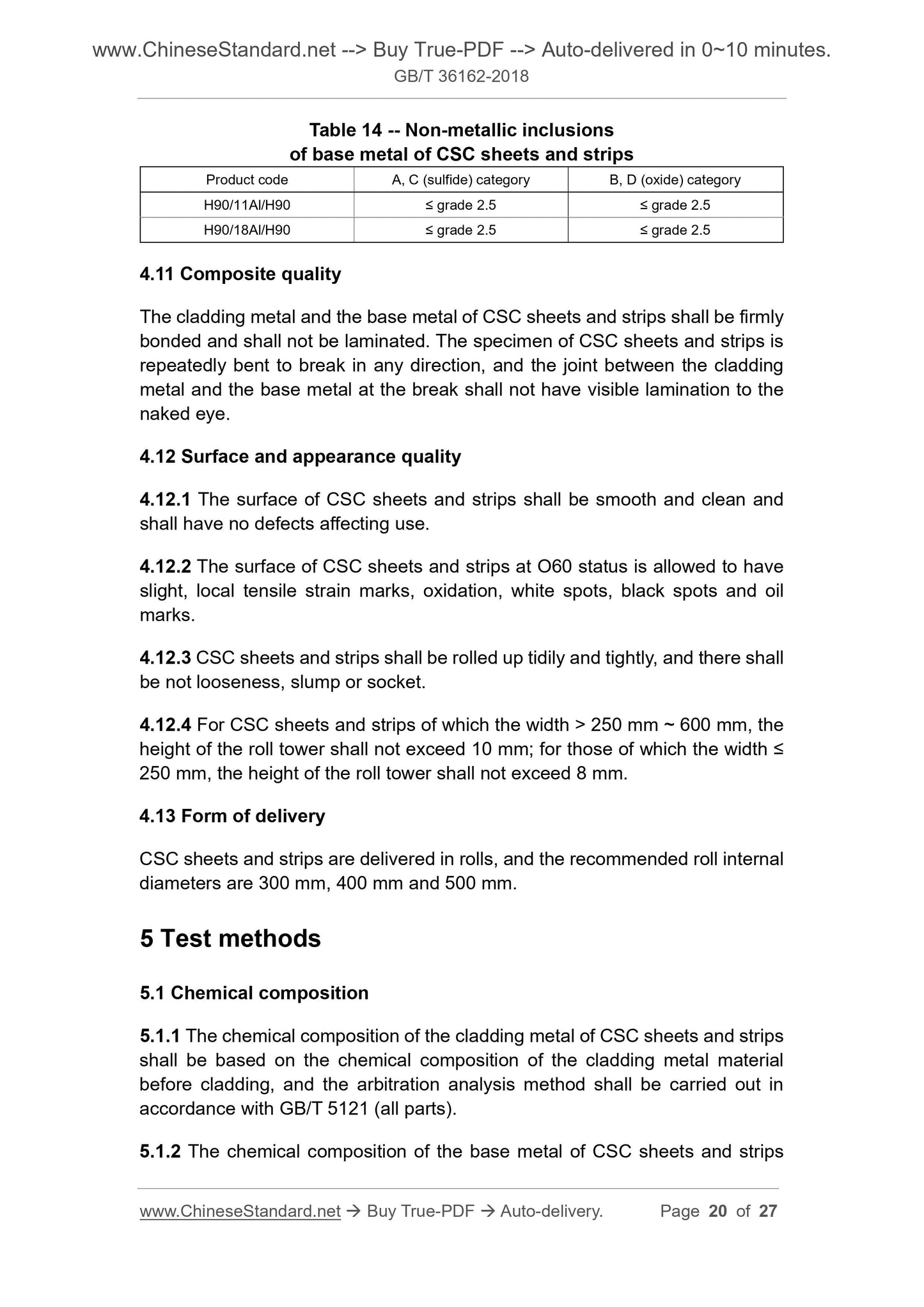

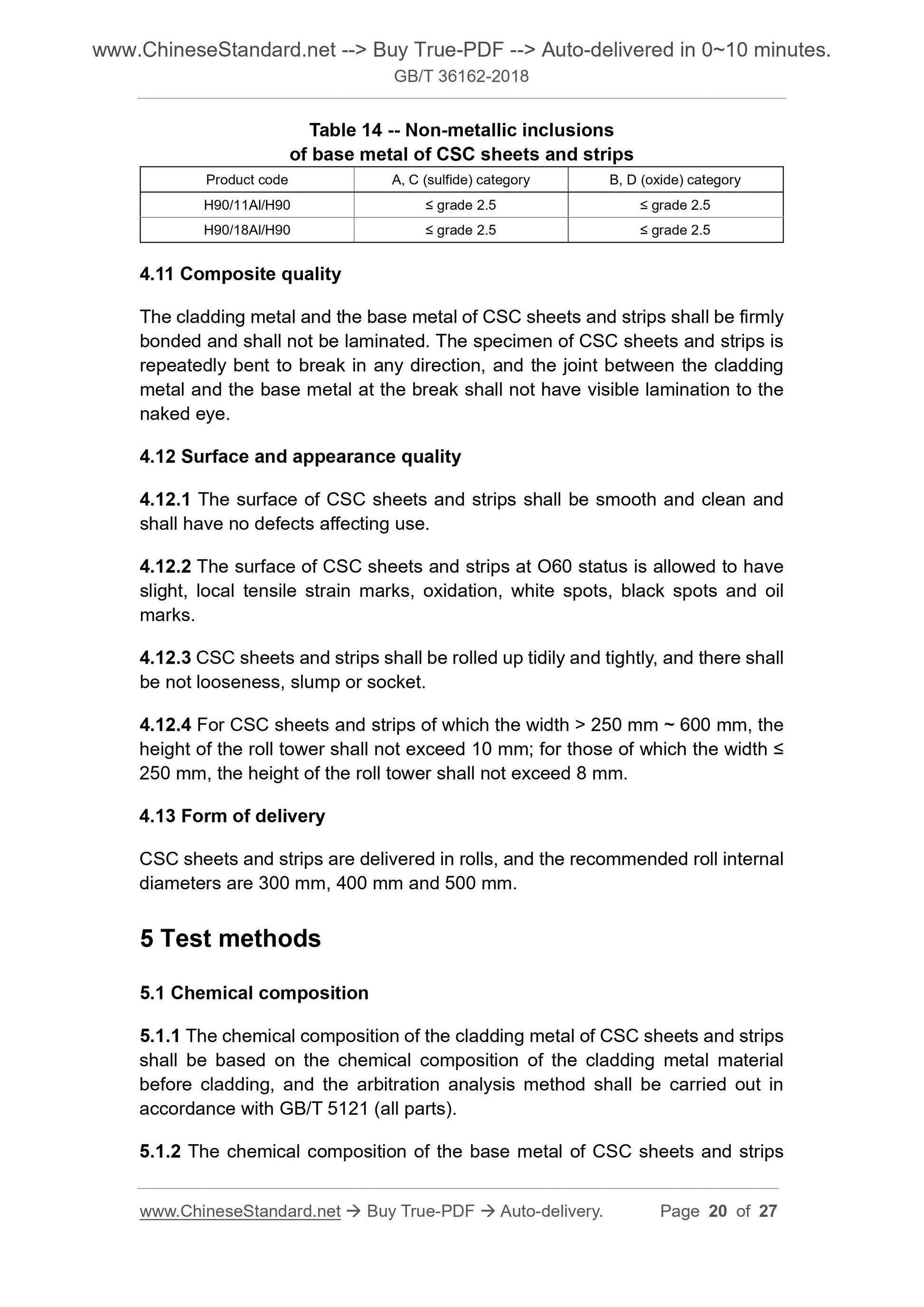

Table 14 -- Non-metallic inclusions

of base metal of CSC sheets and strips

Product code A, C (sulfide) category B, D (oxide) category

H90/11Al/H90 ≤ grade 2.5 ≤ grade 2.5

H90/18Al/H90 ≤ grade 2.5 ≤ grade 2.5

4.11 Composite quality

The cladding metal and the base metal of CSC sheets and strips shall be firmly

bonded and shall not be laminated. The specimen of CSC sheets and strips is

repeatedly bent to break in any direction, and the joint between the cladding

metal and the base metal at the break shall not have visible lamination to the

naked eye.

4.12 Surface and appearance quality

4.12.1 The surface of CSC sheets and strips shall be smooth and clean and

shall have no defects affecting use.

4.12.2 The surface of CSC sheets and strips at O60 status is allowed to have

slight, local tensile strain marks, oxidation, white spots, black spots and oil

marks.

4.12.3 CSC sheets and strips shall be rolled up tidily and tightly, and there shall

be not looseness, slump or socket.

4.12.4 For CSC sheets and strips of which the width > 250 mm ~ 600 mm, the

height of the roll tower shall not exceed 10 mm; for those of which the width ≤

250 mm, the height of the roll tower shall not exceed 8 mm.

4.13 Form of delivery

CSC sheets and strips are delivered in rolls, and the recommended roll internal

diameters are 300 mm, 400 mm and 500 mm.

5 Test methods

5.1 Chemical composition

5.1.1 The chemical composition of the cladding metal of CSC sheets and strips

shall be based on the chemical composition of the cladding metal material

before cladding, and the arbitration analysis method shall be carried out in

accordance with GB/T 5121 (all parts).

5.1.2 The chemical composition of the base metal of CSC sheets and strips

5.9.1 The microstructure specimen shall be taken along the longitudinal section

of CSC sheets and strips in the rolling direction, and the inspection method is

carried out in accordance with the specifications of GB/T 13298.

5.9.2 For the pearlite inspection of CSC sheets and strips, etch the inspection

surface of the specimen with 2 % ~ 4 % ethanol solution, magnify 400 times,

select a representative field of view, carry out grade determination according to

Annex A of WJ 643-1994.

5.9.3 For the grain size inspection of CSC sheets and strips, prepare two

specimens, deeply etch the inspection surface of the specimens with 2 % ~ 4 %

nitric acid solution, magnify 100 times, carry out according to the specifications

of GB/T 6394, to measure the average grain size.

5.9.4 For the non-metallic inclusion inspection of CSC sheets and strips, the

throwing surface of the specimen is magnified 100 times, select a square field

of view of 0.50 mm2, and comparatively evaluate according to Method A and

Annex A of GB/T 10561-2005.

a) For Class A and Class C inclusions present in the same field of view, they

shall be evaluated in combination, and the corresponding coarse and fine

rating pictures shall be selected according to the dominant inclusions and

their coarse and fine tendency, evaluate according to the most serious

ones;

b) For Class B inclusions and Class D inclusions of similar size to Class B

present in the same field of view, they shall also be evaluated in

combination and reported as Class B inclusions, evaluate according to the

most serious ones;

c) For dispersed oxides, it is also reported as Class B inclusions; for coarse

and large Class D inclusions, treat as appropriate.

5.10 Composite quality

The composite quality test method for CSC sheets and strips shall be carried

out in accordance with the specifications of GB/T 235.

5.11 Surface and appearance quality

5.11.1 The surface and appearance quality of CSC sheets an...

Get QUOTATION in 1-minute: Click GB/T 36162-2018

Historical versions: GB/T 36162-2018

Preview True-PDF (Reload/Scroll if blank)

GB/T 36162-2018: Copper-steel composite sheet and strip

GB/T 36162-2018

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.99

H 62

Copper-steel composite sheet and strip

ISSUED ON. MAY 14, 2018

IMPLEMENTED ON. FEBRUARY 01, 2019

Issued by. State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Requirements... 8

5 Test methods ... 20

6 Inspection rules ... 24

7 Marking, packaging, transportation, storage and quality certificate ... 26

8 Order form (or contract) content ... 26

Copper-steel composite sheet and strip

1 Scope

This Standard specifies the requirements, test methods, inspection rules,

marking, packaging, transportation, storage, quality certificate and order forms

(or contracts) for copper-steel composite sheets and strips.

This Standard applies to copper-steel composite sheets and strips (hereinafter

referred to as CSC sheets and strips) for general industrial use.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 223 (all parts) Iron, steel and alloy

GB/T 228.1-2010 Metallic materials - Tensile testing - Part 1. Method of test

at room temperature

GB/T 232 Metallic materials - Bend test

GB/T 235 Metallic materials - Sheet and strip - Reverse bend test

GB/T 351 Metallic materials - Resistivity measurement method

GB/T 700 Carbon structural steels

GB/T 1591 High strength low alloy structural steels

GB/T 4156 Metallic materials - Sheet and strip - Erichsen cupping test

GB/T 5121 (all parts) Methods for chemical analysis of copper and copper

alloys

GB/T 5213 Cold rolled low carbon steel sheet and strip

GB/T 5231 Designation and chemical composition of wrought copper and

copper alloys

GB/T 6394 Determination of estimating the average grain size of metal

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB/T 8888 Wrought heavy non-ferrous metal products - Packing, marking,

transportation, storing and certificate of quality

GB/T 10561-2005 Steel - Determination of content of nonmetallic inclusions

- Micrographic method using standards diagrams

GB/T 13298 Inspection methods of microstructure for metals

GB/T 26303.3 Measuring methods for dimensions and shapes of wrought

copper and copper alloys - Part 3. Sheets and strips

GB/T 33948.1 Method for chemical analysis of copper-steel composite metal

- Part 1. Determination of copper content- Iodine titration method

GB/T 33948.2 Method for chemical analysis of copper-steel composite metal

- Part 2. Determination of zinc content - Na2 EDTA titration method

GJB 1458B Specification for high quality carbon steel sheets and strips for

copper cladding

WJ 643-1994 Copper-clad steel sheets for bullets

YS/T 668 The sampling method of physical and chemical testing for copper

and copper alloys

YS/T 815 Preparation method of test pieces for mechanical and

technological properties of copper and copper alloys

YS/T 1045-2015 Copper-steel composite sheet and strip for decoration

YS/T 1104-2016 Copper-steel composite sheet and strip for deep drawing

3 Terms and definitions

For the purpose of this document, the following terms and definitions apply.

3.1

copper-steel composite sheet and strip

Material using carbon steel as the base metal, with copper and copper alloy of

a certain thickness integrally and continuously cladded on one or both sides by

Table 14 -- Non-metallic inclusions

of base metal of CSC sheets and strips

Product code A, C (sulfide) category B, D (oxide) category

H90/11Al/H90 ≤ grade 2.5 ≤ grade 2.5

H90/18Al/H90 ≤ grade 2.5 ≤ grade 2.5

4.11 Composite quality

The cladding metal and the base metal of CSC sheets and strips shall be firmly

bonded and shall not be laminated. The specimen of CSC sheets and strips is

repeatedly bent to break in any direction, and the joint between the cladding

metal and the base metal at the break shall not have visible lamination to the

naked eye.

4.12 Surface and appearance quality

4.12.1 The surface of CSC sheets and strips shall be smooth and clean and

shall have no defects affecting use.

4.12.2 The surface of CSC sheets and strips at O60 status is allowed to have

slight, local tensile strain marks, oxidation, white spots, black spots and oil

marks.

4.12.3 CSC sheets and strips shall be rolled up tidily and tightly, and there shall

be not looseness, slump or socket.

4.12.4 For CSC sheets and strips of which the width > 250 mm ~ 600 mm, the

height of the roll tower shall not exceed 10 mm; for those of which the width ≤

250 mm, the height of the roll tower shall not exceed 8 mm.

4.13 Form of delivery

CSC sheets and strips are delivered in rolls, and the recommended roll internal

diameters are 300 mm, 400 mm and 500 mm.

5 Test methods

5.1 Chemical composition

5.1.1 The chemical composition of the cladding metal of CSC sheets and strips

shall be based on the chemical composition of the cladding metal material

before cladding, and the arbitration analysis method shall be carried out in

accordance with GB/T 5121 (all parts).

5.1.2 The chemical composition of the base metal of CSC sheets and strips

5.9.1 The microstructure specimen shall be taken along the longitudinal section

of CSC sheets and strips in the rolling direction, and the inspection method is

carried out in accordance with the specifications of GB/T 13298.

5.9.2 For the pearlite inspection of CSC sheets and strips, etch the inspection

surface of the specimen with 2 % ~ 4 % ethanol solution, magnify 400 times,

select a representative field of view, carry out grade determination according to

Annex A of WJ 643-1994.

5.9.3 For the grain size inspection of CSC sheets and strips, prepare two

specimens, deeply etch the inspection surface of the specimens with 2 % ~ 4 %

nitric acid solution, magnify 100 times, carry out according to the specifications

of GB/T 6394, to measure the average grain size.

5.9.4 For the non-metallic inclusion inspection of CSC sheets and strips, the

throwing surface of the specimen is magnified 100 times, select a square field

of view of 0.50 mm2, and comparatively evaluate according to Method A and

Annex A of GB/T 10561-2005.

a) For Class A and Class C inclusions present in the same field of view, they

shall be evaluated in combination, and the corresponding coarse and fine

rating pictures shall be selected according to the dominant inclusions and

their coarse and fine tendency, evaluate according to the most serious

ones;

b) For Class B inclusions and Class D inclusions of similar size to Class B

present in the same field of view, they shall also be evaluated in

combination and reported as Class B inclusions, evaluate according to the

most serious ones;

c) For dispersed oxides, it is also reported as Class B inclusions; for coarse

and large Class D inclusions, treat as appropriate.

5.10 Composite quality

The composite quality test method for CSC sheets and strips shall be carried

out in accordance with the specifications of GB/T 235.

5.11 Surface and appearance quality

5.11.1 The surface and appearance quality of CSC sheets an...

Share