1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 36915-2019 English PDF (GB/T36915-2019)

GB/T 36915-2019 English PDF (GB/T36915-2019)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 36915-2019: Steel wire and wire products - General test methods

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 36915-2019 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 36915-2019

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 36915-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.65

H 22

Steel wire and wire products - General test methods

(ISO 22034-1:2007, Steel wire and wire products -

Part 1: General test methods, MOD)

ISSUED ON: MARCH 25, 2019

IMPLEMENTED ON: FEBRUARY 01, 2020

Issued by: State Market Regulatory Administration;

Standardization Administration of PRC.

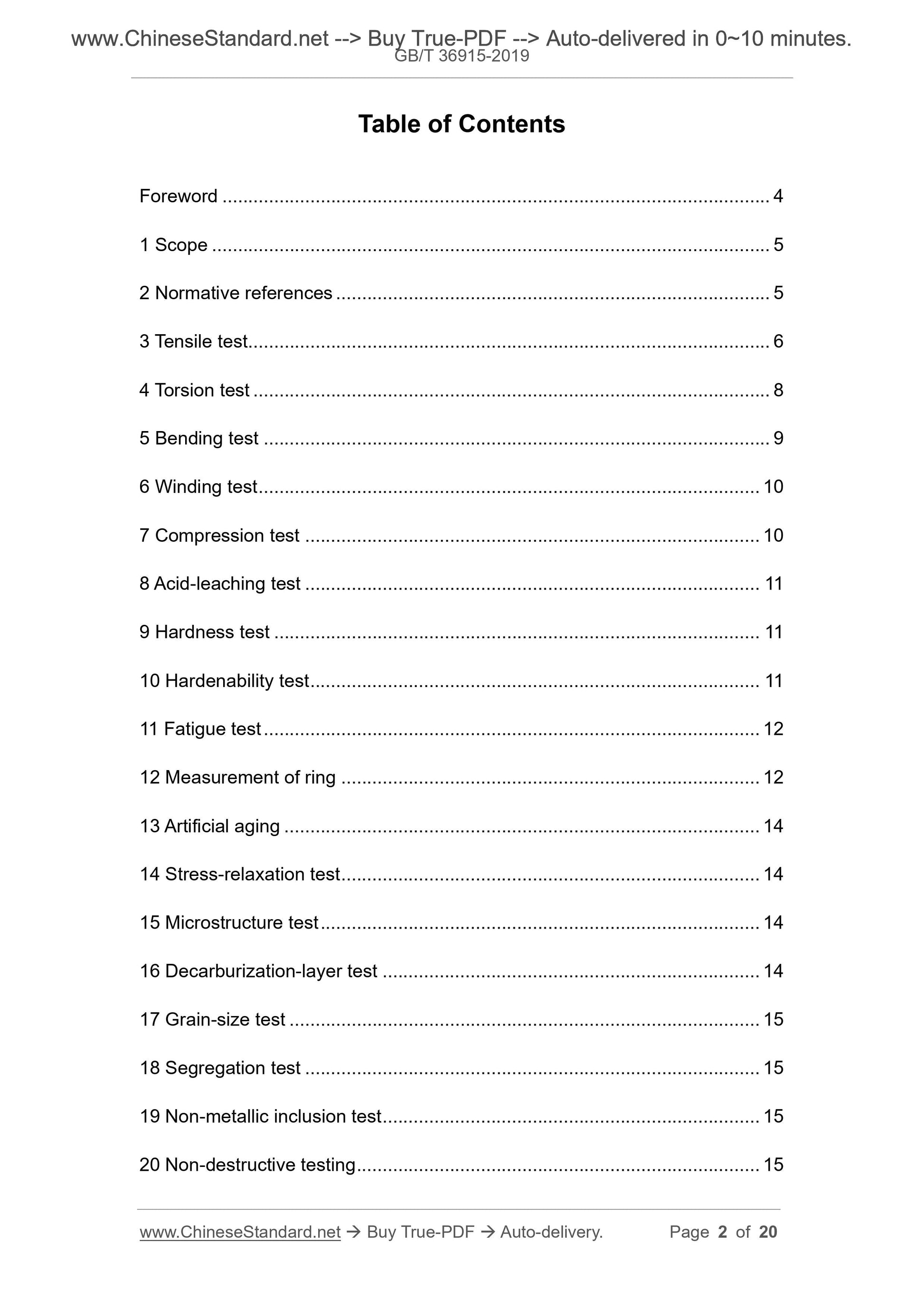

Table of Contents

Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Tensile test ... 6

4 Torsion test ... 8

5 Bending test ... 9

6 Winding test ... 10

7 Compression test ... 10

8 Acid-leaching test ... 11

9 Hardness test ... 11

10 Hardenability test ... 11

11 Fatigue test ... 12

12 Measurement of ring ... 12

13 Artificial aging ... 14

14 Stress-relaxation test ... 14

15 Microstructure test ... 14

16 Decarburization-layer test ... 14

17 Grain-size test ... 15

18 Segregation test ... 15

19 Non-metallic inclusion test ... 15

20 Non-destructive testing ... 15

21 Chemical analysis ... 15

22 Zinc-layer quality ... 15

23 Retest ... 16

Appendix A (Informative) Comparison of clause numbers between this standard

and ISO 22034-1:2007 ... 17

Appendix B (Informative) Technical differences between this standard and ISO

22034-1:2007 and their causes ... 19

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard uses the redrafting method to modify and use ISO 22034-1:2007

“Steel wire and wire products - Part 1: General test methods”.

As compared with ISO 22034-1:2007, this standard has structural adjustments.

Appendix A lists the comparison of clause numbers between this standard and

ISO 22034-1:2007.

There are technical differences between this standard and ISO 22034-1:2007.

The terms involved in these differences have been marked by a vertical single

line (|) in the blank position of the outer margin. Appendix B gives the

corresponding technical differences and their causes.

This standard also made the following editorial changes:

- CHANGE the standard name to “Steel wire and wire products - General

test methods”.

This standard was proposed by the China Iron and Steel Association.

This standard shall be under the jurisdiction of the National Steel

Standardization Technical Committee (SAC/TC 183).

Drafting organizations of this standard: National Wire Rope Product Quality

Supervision and Inspection Center, Guangdong Jianlang Hardware Products

Co., Ltd., Jiangsu Shenyuan Group Co., Ltd., Shandong Daye Co., Ltd.,

Nantong Songcheng Industrial Co., Ltd., Metallurgical Industry Information

Standards Institute.

The main drafters of this standard: Chen Jianhao, Wu Peng, Ren Cuiying, Wang

Lingjun, Han Kun, Zhang Guofu, Chen Ziwang, Li Wenjun, Lu Yafei, Tu Yuguo,

Mao Liuquan, Leng Mingjian.

Steel wire and wire products - General test methods

1 Scope

This standard specifies the tensile test, torsion test, bending test, winding test,

compression test, acid-leaching test, hardness test, hardenability test, fatigue

test, ring-shape measurement, artificial aging, stress-relaxation test,

microstructure test, decarburization layer test, grain size test, segregation test,

non-metallic inclusion test, non-destructive testing, chemical analysis, zinc-

layer quality, retest, other general test methods of steel wire and wire products.

This standard applies to cold-worked steel wire with constant cross-section

(circular or profiled), annealed steel wire, quenched and tempered steel wire,

coated steel wire, etc.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 224 Determination of depth of decarburization of steels (GB/T 224-

2008, ISO 3887:2003, MOD)

GB/T 228.1 Metallic materials - Tensile testing - Part 1: Method of test at

room temperature (GB/T 228.1-2010, ISO 6892-1:2009, MOD)

GB/T 230.1 Metallic materials - Rockwell hardness test - Part 1: Test method

(GB/T 230.1-2018, ISO 6508-1:2016, MOD)

GB/T 231.1 Metallic materials-Brinell hardness test - Part 1: Test method

(GB/T 231.1-2018, ISO 6506-1:2014, MOD)

GB/T 232 Metallic materials - Bend test (GB/T 232-2010, ISO 7438:2005,

MOD)

GB/T 238 Metallic materials - Wire - Reverse bend test (GB/T 238-2013, ISO

7801: 1984, MOD)

GB/T 239.1 Metallic materials - Wire - Part 1: Simple torsion test (GB/T

239.1-2012, ISO 7800:2003, MOD)

GB/T 239.2 Metallic materials - Wire - Part 2: Reverse torsion test (GB/T

239.2-2012, ISO 9649:1990, MOD)

GB/T 1839 Test method for gravimetric determination of the mass per unit

area of galvanized coatings on steel products (GB/T 1839-2008, ISO

1460:1992, MOD)

GB/T 2103 General requirements for acceptance, packing, marking and

quality certification of steel wire

GB/T 2972 Test method for uniformity of zinc coating on zinc-coated steel

wire by the copper sulphate dip (GB/T 2972-2016, ISO 7989-2:2007, NEQ)

GB/T 2975 Steel and steel products - Location and preparation of samples

and test pieces for mechanical testing (GB/T 2975-2018, ISO 377:2017,

MOD)

GB/T 2976 Metallic materials - Wire - Wrapping test (GB/T 2976-2004, ISO

7802:1983, IDT)

GB/T 4337 Metallic materials - Fatigue testing - Rotating bar bending method

(GB/T 4337-2015, ISO 1143:2010, MOD)

GB/T 4340.1 Metallic materials - Vickers hardness test - Part 1: Test method

(GB/T 4340.1-2009, ISO 6507-1: 2005, MOD)

GB/T 6394 Metal - Methods for estimating the average grain size

GB/T 10561 Steel - Determination of Content of Nonmetallic Inclusions -

Micrographic Method Using Standards Diagrams (GB/T 10561-2005, ISO

4967:1998, IDT)

GB/T 13298 Inspection methods of microstructure for metals

GB/T 21839 Steel for prestressed concrete - Test methods (GB/T 21839-

2008, ISO 15630-3:2002, MOD)

YB/T 4413 Metallographic evaluation method for center segregation of high-

carbon steel wire rod

3 Tensile test

3.1 General requirements

The tensile test shall be carried out in accordance with GB/T 228.1. Determine

the mechanical properties such as tensile strength, yield strength, elongation,

percentage reduction of area, modulus of elasticity of the steel wire.

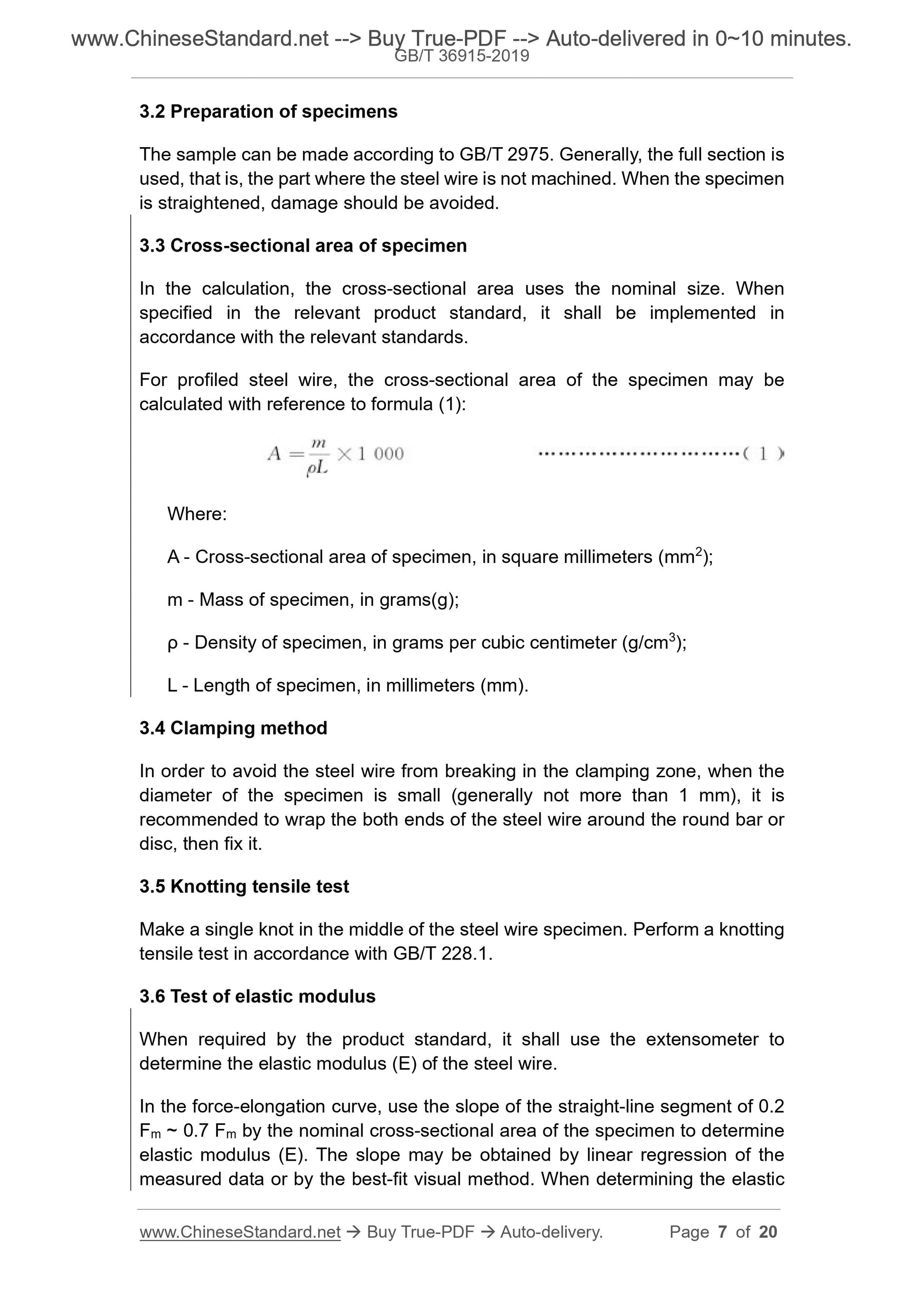

3.2 Preparation of specimens

The sample can be made according to GB/T 2975. Generally, the full section is

used, that is, the part where the steel wire is not machined. When the specimen

is straightened, damage should be avoided.

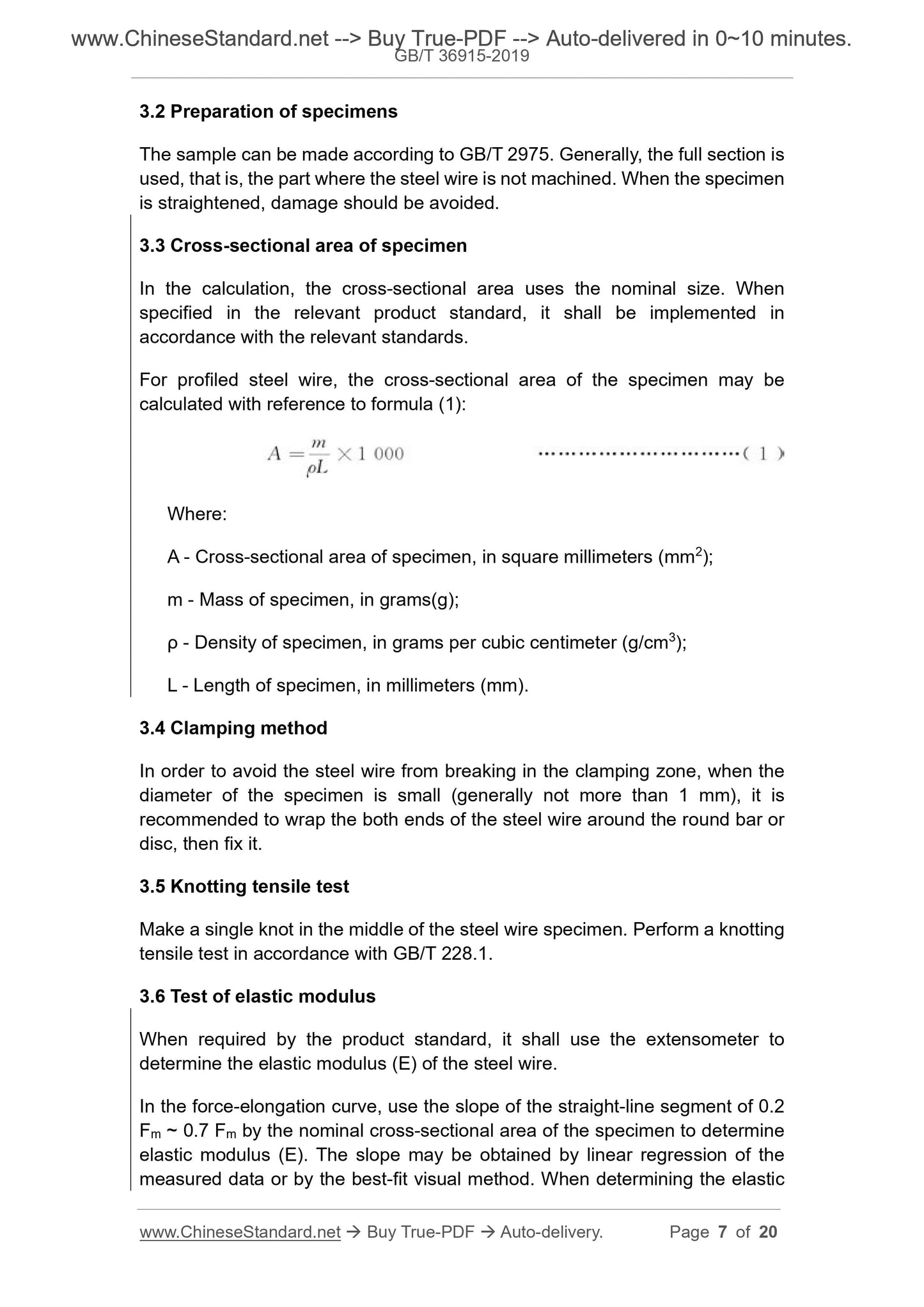

3.3 Cross-sectional area of specimen

In the calculation, the cross-sectional area uses the nominal size. When

specified in the relevant product standard, it shall be implemented in

accordance with the relevant standards.

For profiled steel wire, the cross-sectional area of the specimen may be

calculated with reference to formula (1):

Where:

A - Cross-sectional area of specimen, in square millimeters (mm2);

m - Mass of specimen, in grams(g);

ρ - Density of specimen, in grams per cubic centimeter (g/cm3);

L - Length of specimen, in millimeters (mm).

3.4 Clamping method

In order to avoid the steel wire from breaking in the clamping zone, when the

diameter of the specimen is small (generally not more than 1 mm), it is

recommended to wrap the both ends of the steel wire around the round bar or

disc, then fix it.

3.5 Knotting tensile test

Make a single knot in the middle of the steel wire specimen. Perform a knotting

tensile test in accordance with GB/T 228.1.

3.6 Test of elastic modulus

When required by the product standard, it shall use the extensometer to

determine the elastic modulus (E) of the steel wire.

In the force-elongation curve, use the slope of the straight-line segment of 0.2

Fm ~ 0.7 Fm by the nominal cross-sectional area of the specimen to determine

elastic modulus (E). The slope may be obtained by linear regression of the

measured data or by the best-fit visual method. When determining the elastic

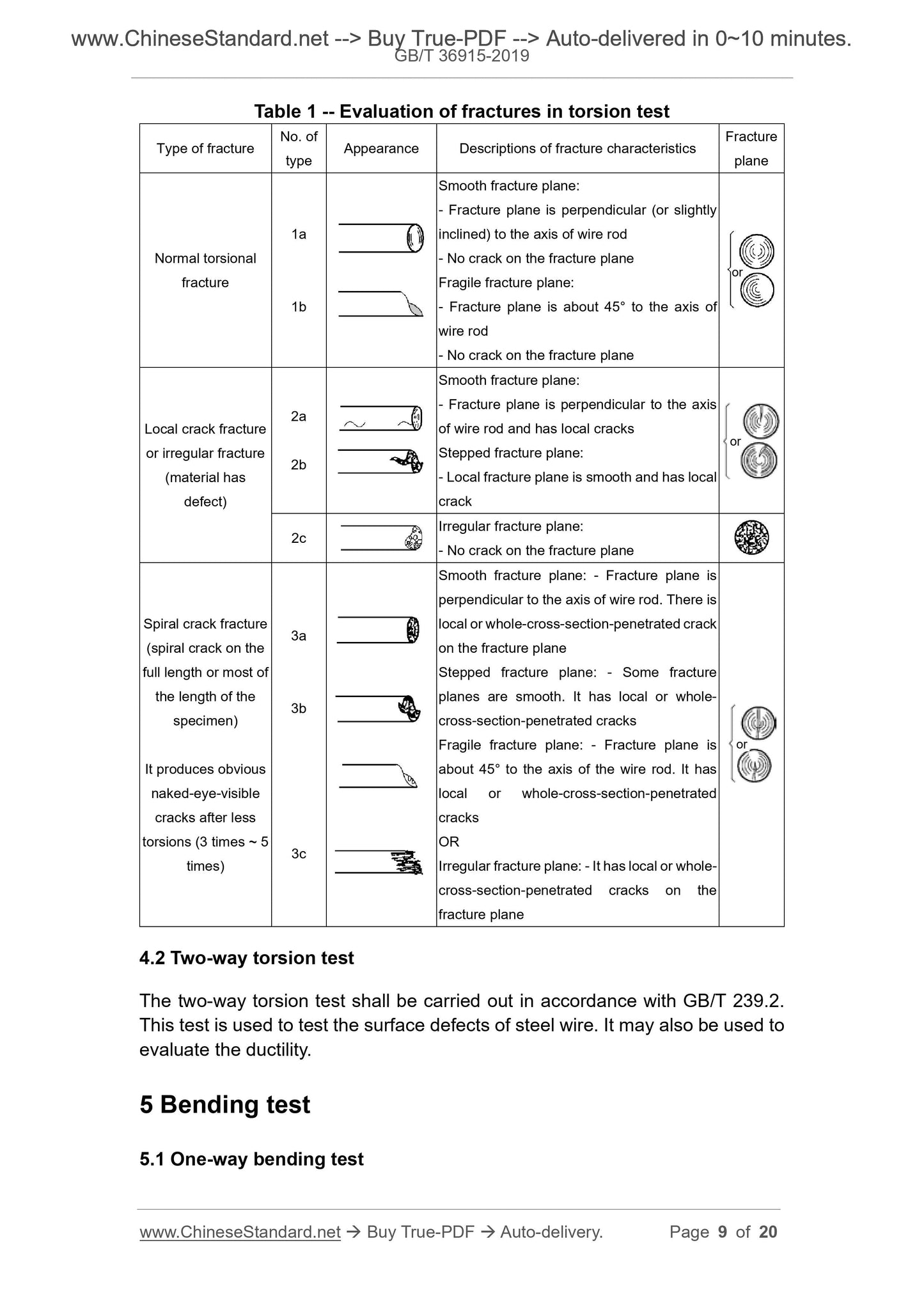

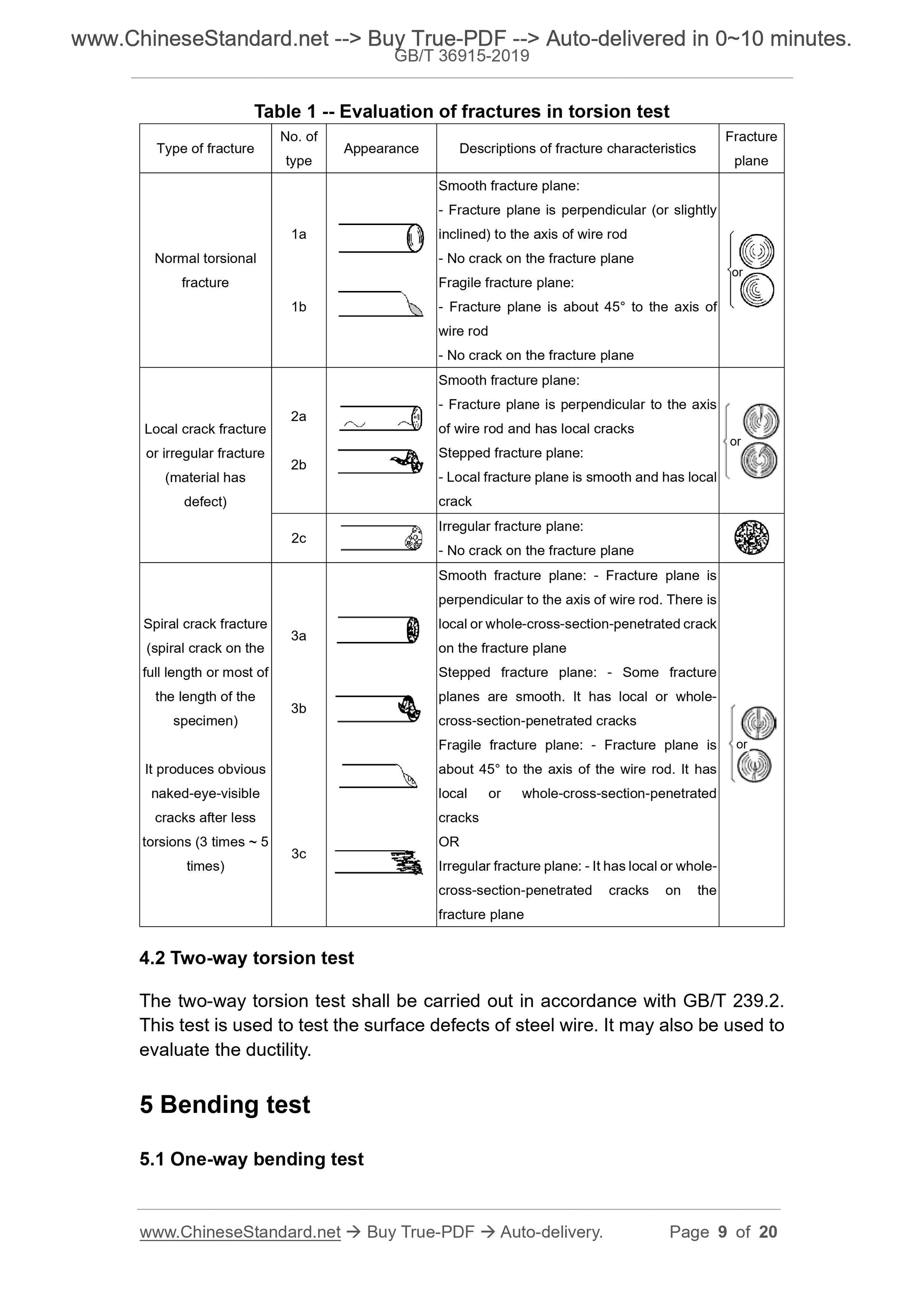

Table 1 -- Evaluation of fractures in torsion test

Type of fracture No. of type Appearance Descriptions of fracture characteristics

Fracture

plane

Normal torsional

fracture

1a

1b

Smooth fracture plane:

- Fracture plane is perpendicular (or slightly

inclined) to the axis of wire rod

- No crack on the fracture plane

Fragile fracture plane:

- Fracture plane is about 45° to the axis of

wire rod

- No crack on the fracture plane

Local crack fracture

or irregular fracture

(material has

defect)

2a

2b

Smooth fracture plane:

- Fracture plane is perpendicular to the axis

of wire rod and has local cracks

Stepped fracture plane:

- Local fracture plane is smooth and has local

crack

2c

Irregular fracture plane:

- No crack on the fracture plane

Spiral crack fracture

(spiral crack on the

full length or most of

the length of the

specimen)

It produces obvious

naked-eye-visible

cracks after less

torsions (3 times ~ 5

times)

3a

3b

3c

Smooth fracture plane: - Fracture plane is

perpendicular to the axis of wire rod. There is

local or whole-cross-section-penetrated crack

on the fracture plane

Stepped fracture plane: - Some fracture

planes are smooth. It has local or whole-

cross-section-penetrated cracks

Fragile fracture plane: - Fracture plane is

about 45° to the axis of the wire rod. It has

local or whole-cross-section-penetrated

cracks

OR

Irregular fracture plane: - It has local or whole-

cross-section-penetrated cracks on the

fracture plane

4.2 Two-way torsion test

The two-way torsion test shall be carried out in accordance with GB/T 239.2.

This test is used to test the surface defects of steel wire. It may also be used to

evaluate the ductility.

5 Bending test

5.1 One-way bending test

or

or

or

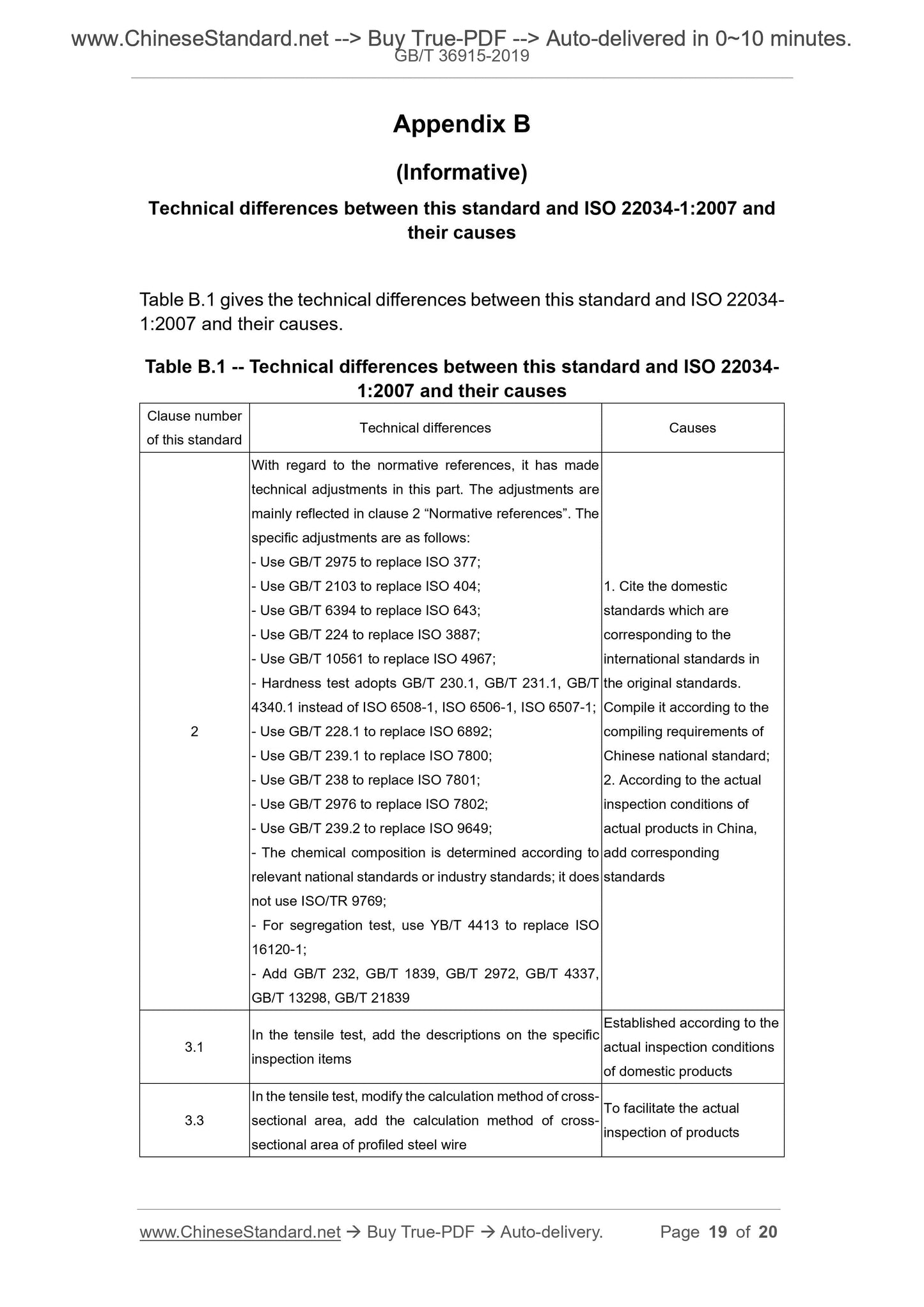

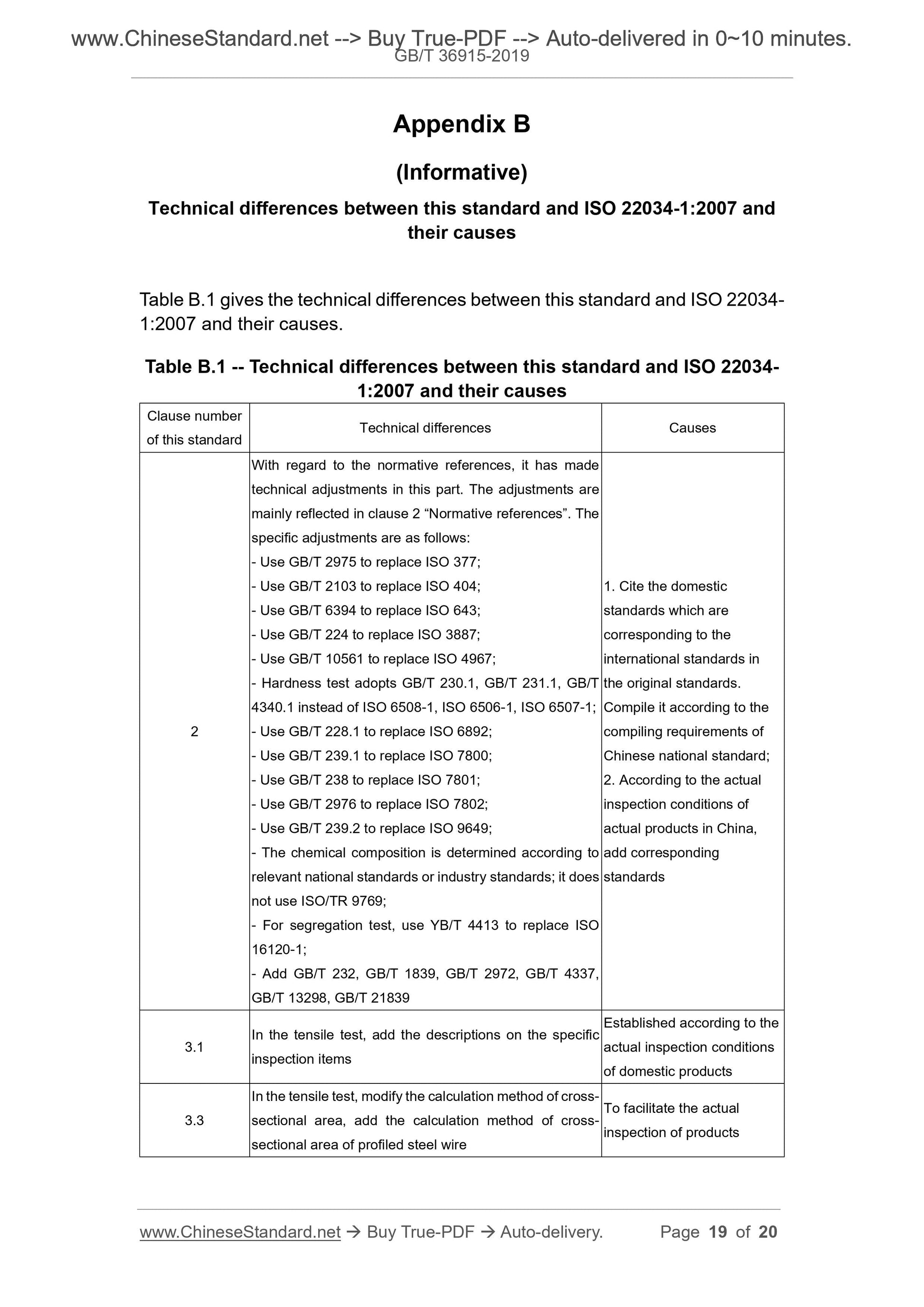

Appendix B

(Informative)

Technical differences between this standard and ISO 22034-1:2007 and

their causes

Table B.1 gives the technical differences between this standard and ISO 22034-

1:2007 and their causes.

Table B.1 -- Technical differences between this standard and ISO 22034-

1:2007 and their causes

Clause number

of this standard Technical differences Causes

With regard to the normative references, it has made

technical adjustments in this part. The adjustments are

mainly reflected in clause 2 “Normative references”. The

specific adjustments are as follows:

- Use GB/T 2975 to replace ISO 377;

- Use GB/T 2103 to replace ISO 404;

- Use GB/T 6394 to replace ISO 643;

- Use GB/T 224 to replace ISO 3887;

- Use GB/T 10561 to replace ISO 4967;

- Hardness test adopts GB/T 230.1, GB/T 231.1, GB/T

4340.1 instead of ISO 6508-1, ISO 6506-1, ISO 6507-1;

- Use GB/T 228.1 to replace ISO 6892;

- Use GB/T 239.1 to replace ISO 7800;

- Use GB/T 238 to replace ISO 7801;

- Use GB/T 2976 to replace ISO 7802;

- Use GB/T 239.2 to replace ISO 9649;

- The chemical composition is determined according to

relevant national standards or industry standards; it does

not use ISO/TR 9769;

- For segregation test, use YB/T 4413 to replace ISO

16120-1;

- Add GB/T 232, GB/T 1839, GB/T 2972, GB/T 4337,

GB/T 13298, GB/T 21839

1. Cite the domestic

standards which are

corresponding to the

international standards in

the original standards.

Compile it according to the

compiling requirements of

Chinese national standard;

2. According to the actual

inspection conditions of

actual products in China,

add corresponding

standards

3.1 In the tensile test, add the descriptions on the specific inspection items

Established according to the

actual inspection conditions

of domestic products

3.3

In the tensile test, modify the calculation method of cross-

sectional area, add the calculation method of cross-

sectional area of profiled steel wire

To facilitate the actual

inspection of products

GB/T 36915-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.65

H 22

Steel wire and wire products - General test methods

(ISO 22034-1:2007, Steel wire and wire products -

Part 1: General test methods, MOD)

ISSUED ON: MARCH 25, 2019

IMPLEMENTED ON: FEBRUARY 01, 2020

Issued by: State Market Regulatory Administration;

Standardization Administration of PRC.

Table of Contents

Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Tensile test ... 6

4 Torsion test ... 8

5 Bending test ... 9

6 Winding test ... 10

7 Compression test ... 10

8 Acid-leaching test ... 11

9 Hardness test ... 11

10 Hardenability test ... 11

11 Fatigue test ... 12

12 Measurement of ring ... 12

13 Artificial aging ... 14

14 Stress-relaxation test ... 14

15 Microstructure test ... 14

16 Decarburization-layer test ... 14

17 Grain-size test ... 15

18 Segregation test ... 15

19 Non-metallic inclusion test ... 15

20 Non-destructive testing ... 15

21 Chemical analysis ... 15

22 Zinc-layer quality ... 15

23 Retest ... 16

Appendix A (Informative) Comparison of clause numbers between this standard

and ISO 22034-1:2007 ... 17

Appendix B (Informative) Technical differences between this standard and ISO

22034-1:2007 and their causes ... 19

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard uses the redrafting method to modify and use ISO 22034-1:2007

“Steel wire and wire products - Part 1: General test methods”.

As compared with ISO 22034-1:2007, this standard has structural adjustments.

Appendix A lists the comparison of clause numbers between this standard and

ISO 22034-1:2007.

There are technical differences between this standard and ISO 22034-1:2007.

The t...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 36915-2019 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 36915-2019

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 36915-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.65

H 22

Steel wire and wire products - General test methods

(ISO 22034-1:2007, Steel wire and wire products -

Part 1: General test methods, MOD)

ISSUED ON: MARCH 25, 2019

IMPLEMENTED ON: FEBRUARY 01, 2020

Issued by: State Market Regulatory Administration;

Standardization Administration of PRC.

Table of Contents

Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Tensile test ... 6

4 Torsion test ... 8

5 Bending test ... 9

6 Winding test ... 10

7 Compression test ... 10

8 Acid-leaching test ... 11

9 Hardness test ... 11

10 Hardenability test ... 11

11 Fatigue test ... 12

12 Measurement of ring ... 12

13 Artificial aging ... 14

14 Stress-relaxation test ... 14

15 Microstructure test ... 14

16 Decarburization-layer test ... 14

17 Grain-size test ... 15

18 Segregation test ... 15

19 Non-metallic inclusion test ... 15

20 Non-destructive testing ... 15

21 Chemical analysis ... 15

22 Zinc-layer quality ... 15

23 Retest ... 16

Appendix A (Informative) Comparison of clause numbers between this standard

and ISO 22034-1:2007 ... 17

Appendix B (Informative) Technical differences between this standard and ISO

22034-1:2007 and their causes ... 19

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard uses the redrafting method to modify and use ISO 22034-1:2007

“Steel wire and wire products - Part 1: General test methods”.

As compared with ISO 22034-1:2007, this standard has structural adjustments.

Appendix A lists the comparison of clause numbers between this standard and

ISO 22034-1:2007.

There are technical differences between this standard and ISO 22034-1:2007.

The terms involved in these differences have been marked by a vertical single

line (|) in the blank position of the outer margin. Appendix B gives the

corresponding technical differences and their causes.

This standard also made the following editorial changes:

- CHANGE the standard name to “Steel wire and wire products - General

test methods”.

This standard was proposed by the China Iron and Steel Association.

This standard shall be under the jurisdiction of the National Steel

Standardization Technical Committee (SAC/TC 183).

Drafting organizations of this standard: National Wire Rope Product Quality

Supervision and Inspection Center, Guangdong Jianlang Hardware Products

Co., Ltd., Jiangsu Shenyuan Group Co., Ltd., Shandong Daye Co., Ltd.,

Nantong Songcheng Industrial Co., Ltd., Metallurgical Industry Information

Standards Institute.

The main drafters of this standard: Chen Jianhao, Wu Peng, Ren Cuiying, Wang

Lingjun, Han Kun, Zhang Guofu, Chen Ziwang, Li Wenjun, Lu Yafei, Tu Yuguo,

Mao Liuquan, Leng Mingjian.

Steel wire and wire products - General test methods

1 Scope

This standard specifies the tensile test, torsion test, bending test, winding test,

compression test, acid-leaching test, hardness test, hardenability test, fatigue

test, ring-shape measurement, artificial aging, stress-relaxation test,

microstructure test, decarburization layer test, grain size test, segregation test,

non-metallic inclusion test, non-destructive testing, chemical analysis, zinc-

layer quality, retest, other general test methods of steel wire and wire products.

This standard applies to cold-worked steel wire with constant cross-section

(circular or profiled), annealed steel wire, quenched and tempered steel wire,

coated steel wire, etc.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 224 Determination of depth of decarburization of steels (GB/T 224-

2008, ISO 3887:2003, MOD)

GB/T 228.1 Metallic materials - Tensile testing - Part 1: Method of test at

room temperature (GB/T 228.1-2010, ISO 6892-1:2009, MOD)

GB/T 230.1 Metallic materials - Rockwell hardness test - Part 1: Test method

(GB/T 230.1-2018, ISO 6508-1:2016, MOD)

GB/T 231.1 Metallic materials-Brinell hardness test - Part 1: Test method

(GB/T 231.1-2018, ISO 6506-1:2014, MOD)

GB/T 232 Metallic materials - Bend test (GB/T 232-2010, ISO 7438:2005,

MOD)

GB/T 238 Metallic materials - Wire - Reverse bend test (GB/T 238-2013, ISO

7801: 1984, MOD)

GB/T 239.1 Metallic materials - Wire - Part 1: Simple torsion test (GB/T

239.1-2012, ISO 7800:2003, MOD)

GB/T 239.2 Metallic materials - Wire - Part 2: Reverse torsion test (GB/T

239.2-2012, ISO 9649:1990, MOD)

GB/T 1839 Test method for gravimetric determination of the mass per unit

area of galvanized coatings on steel products (GB/T 1839-2008, ISO

1460:1992, MOD)

GB/T 2103 General requirements for acceptance, packing, marking and

quality certification of steel wire

GB/T 2972 Test method for uniformity of zinc coating on zinc-coated steel

wire by the copper sulphate dip (GB/T 2972-2016, ISO 7989-2:2007, NEQ)

GB/T 2975 Steel and steel products - Location and preparation of samples

and test pieces for mechanical testing (GB/T 2975-2018, ISO 377:2017,

MOD)

GB/T 2976 Metallic materials - Wire - Wrapping test (GB/T 2976-2004, ISO

7802:1983, IDT)

GB/T 4337 Metallic materials - Fatigue testing - Rotating bar bending method

(GB/T 4337-2015, ISO 1143:2010, MOD)

GB/T 4340.1 Metallic materials - Vickers hardness test - Part 1: Test method

(GB/T 4340.1-2009, ISO 6507-1: 2005, MOD)

GB/T 6394 Metal - Methods for estimating the average grain size

GB/T 10561 Steel - Determination of Content of Nonmetallic Inclusions -

Micrographic Method Using Standards Diagrams (GB/T 10561-2005, ISO

4967:1998, IDT)

GB/T 13298 Inspection methods of microstructure for metals

GB/T 21839 Steel for prestressed concrete - Test methods (GB/T 21839-

2008, ISO 15630-3:2002, MOD)

YB/T 4413 Metallographic evaluation method for center segregation of high-

carbon steel wire rod

3 Tensile test

3.1 General requirements

The tensile test shall be carried out in accordance with GB/T 228.1. Determine

the mechanical properties such as tensile strength, yield strength, elongation,

percentage reduction of area, modulus of elasticity of the steel wire.

3.2 Preparation of specimens

The sample can be made according to GB/T 2975. Generally, the full section is

used, that is, the part where the steel wire is not machined. When the specimen

is straightened, damage should be avoided.

3.3 Cross-sectional area of specimen

In the calculation, the cross-sectional area uses the nominal size. When

specified in the relevant product standard, it shall be implemented in

accordance with the relevant standards.

For profiled steel wire, the cross-sectional area of the specimen may be

calculated with reference to formula (1):

Where:

A - Cross-sectional area of specimen, in square millimeters (mm2);

m - Mass of specimen, in grams(g);

ρ - Density of specimen, in grams per cubic centimeter (g/cm3);

L - Length of specimen, in millimeters (mm).

3.4 Clamping method

In order to avoid the steel wire from breaking in the clamping zone, when the

diameter of the specimen is small (generally not more than 1 mm), it is

recommended to wrap the both ends of the steel wire around the round bar or

disc, then fix it.

3.5 Knotting tensile test

Make a single knot in the middle of the steel wire specimen. Perform a knotting

tensile test in accordance with GB/T 228.1.

3.6 Test of elastic modulus

When required by the product standard, it shall use the extensometer to

determine the elastic modulus (E) of the steel wire.

In the force-elongation curve, use the slope of the straight-line segment of 0.2

Fm ~ 0.7 Fm by the nominal cross-sectional area of the specimen to determine

elastic modulus (E). The slope may be obtained by linear regression of the

measured data or by the best-fit visual method. When determining the elastic

Table 1 -- Evaluation of fractures in torsion test

Type of fracture No. of type Appearance Descriptions of fracture characteristics

Fracture

plane

Normal torsional

fracture

1a

1b

Smooth fracture plane:

- Fracture plane is perpendicular (or slightly

inclined) to the axis of wire rod

- No crack on the fracture plane

Fragile fracture plane:

- Fracture plane is about 45° to the axis of

wire rod

- No crack on the fracture plane

Local crack fracture

or irregular fracture

(material has

defect)

2a

2b

Smooth fracture plane:

- Fracture plane is perpendicular to the axis

of wire rod and has local cracks

Stepped fracture plane:

- Local fracture plane is smooth and has local

crack

2c

Irregular fracture plane:

- No crack on the fracture plane

Spiral crack fracture

(spiral crack on the

full length or most of

the length of the

specimen)

It produces obvious

naked-eye-visible

cracks after less

torsions (3 times ~ 5

times)

3a

3b

3c

Smooth fracture plane: - Fracture plane is

perpendicular to the axis of wire rod. There is

local or whole-cross-section-penetrated crack

on the fracture plane

Stepped fracture plane: - Some fracture

planes are smooth. It has local or whole-

cross-section-penetrated cracks

Fragile fracture plane: - Fracture plane is

about 45° to the axis of the wire rod. It has

local or whole-cross-section-penetrated

cracks

OR

Irregular fracture plane: - It has local or whole-

cross-section-penetrated cracks on the

fracture plane

4.2 Two-way torsion test

The two-way torsion test shall be carried out in accordance with GB/T 239.2.

This test is used to test the surface defects of steel wire. It may also be used to

evaluate the ductility.

5 Bending test

5.1 One-way bending test

or

or

or

Appendix B

(Informative)

Technical differences between this standard and ISO 22034-1:2007 and

their causes

Table B.1 gives the technical differences between this standard and ISO 22034-

1:2007 and their causes.

Table B.1 -- Technical differences between this standard and ISO 22034-

1:2007 and their causes

Clause number

of this standard Technical differences Causes

With regard to the normative references, it has made

technical adjustments in this part. The adjustments are

mainly reflected in clause 2 “Normative references”. The

specific adjustments are as follows:

- Use GB/T 2975 to replace ISO 377;

- Use GB/T 2103 to replace ISO 404;

- Use GB/T 6394 to replace ISO 643;

- Use GB/T 224 to replace ISO 3887;

- Use GB/T 10561 to replace ISO 4967;

- Hardness test adopts GB/T 230.1, GB/T 231.1, GB/T

4340.1 instead of ISO 6508-1, ISO 6506-1, ISO 6507-1;

- Use GB/T 228.1 to replace ISO 6892;

- Use GB/T 239.1 to replace ISO 7800;

- Use GB/T 238 to replace ISO 7801;

- Use GB/T 2976 to replace ISO 7802;

- Use GB/T 239.2 to replace ISO 9649;

- The chemical composition is determined according to

relevant national standards or industry standards; it does

not use ISO/TR 9769;

- For segregation test, use YB/T 4413 to replace ISO

16120-1;

- Add GB/T 232, GB/T 1839, GB/T 2972, GB/T 4337,

GB/T 13298, GB/T 21839

1. Cite the domestic

standards which are

corresponding to the

international standards in

the original standards.

Compile it according to the

compiling requirements of

Chinese national standard;

2. According to the actual

inspection conditions of

actual products in China,

add corresponding

standards

3.1 In the tensile test, add the descriptions on the specific inspection items

Established according to the

actual inspection conditions

of domestic products

3.3

In the tensile test, modify the calculation method of cross-

sectional area, add the calculation method of cross-

sectional area of profiled steel wire

To facilitate the actual

inspection of products

GB/T 36915-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.65

H 22

Steel wire and wire products - General test methods

(ISO 22034-1:2007, Steel wire and wire products -

Part 1: General test methods, MOD)

ISSUED ON: MARCH 25, 2019

IMPLEMENTED ON: FEBRUARY 01, 2020

Issued by: State Market Regulatory Administration;

Standardization Administration of PRC.

Table of Contents

Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Tensile test ... 6

4 Torsion test ... 8

5 Bending test ... 9

6 Winding test ... 10

7 Compression test ... 10

8 Acid-leaching test ... 11

9 Hardness test ... 11

10 Hardenability test ... 11

11 Fatigue test ... 12

12 Measurement of ring ... 12

13 Artificial aging ... 14

14 Stress-relaxation test ... 14

15 Microstructure test ... 14

16 Decarburization-layer test ... 14

17 Grain-size test ... 15

18 Segregation test ... 15

19 Non-metallic inclusion test ... 15

20 Non-destructive testing ... 15

21 Chemical analysis ... 15

22 Zinc-layer quality ... 15

23 Retest ... 16

Appendix A (Informative) Comparison of clause numbers between this standard

and ISO 22034-1:2007 ... 17

Appendix B (Informative) Technical differences between this standard and ISO

22034-1:2007 and their causes ... 19

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard uses the redrafting method to modify and use ISO 22034-1:2007

“Steel wire and wire products - Part 1: General test methods”.

As compared with ISO 22034-1:2007, this standard has structural adjustments.

Appendix A lists the comparison of clause numbers between this standard and

ISO 22034-1:2007.

There are technical differences between this standard and ISO 22034-1:2007.

The t...

Share