1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 36987-2018 English PDF (GB/T36987-2018)

GB/T 36987-2018 English PDF (GB/T36987-2018)

Regular price

$205.00

Regular price

Sale price

$205.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 36987-2018: Testing Methods of Anti-lock Braking System (ABS) Performance for Automobiles

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 36987-2018 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 36987-2018

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 36987-2018

GB

NATIONAL STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.180

R 86

Testing Methods of Anti-lock Braking

System (ABS) Performance for Automobiles

ISSUED ON. DECEMBER 28, 2018

IMPLEMENTED ON. JULY 01, 2019

Issued by. State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Technical Conditions for Performance Test of Anti-lock Braking System

(ABS) ... 6

5 Method for Test the Performance of Vehicle Anti-lock Braking System (ABS)

... 7

Appendix A (Informative) Record List for Using GPS Technology Road Test to

Detect the Vehicle Anti-Lock Braking System (ABS) ... 13

Appendix B (Informative) Record List for Using Roller Bench to Detect the

Vehicle Anti-Lock Braking System (ABS) ... 15

Bibliography ... 17

Testing Methods of Anti-lock Braking

System (ABS) Performance for Automobiles

1 Scope

This Standard specifies the technical conditions and methods for testing the anti-lock

braking system (ABS) performance for automobiles.

This Standard is applicable to the inspection and verification for the anti-lock braking

system (ABS) performance for automobiles.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 18314 Specifications for Global Positioning System (GPS) Surveys

GB 21861-2014 Items and Methods of Motor Vehicles Safety Technology

Inspection

3 Terms and Definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Active safety technology

The technical configuration, means and measures that are adopted and set up by the

vehicle itself to actively avoid and defend against the accident.

3.2 Anti-lock braking systems (ABS)

A system that can automatically control the degree of slip between the vehicle’s wheels

and road during braking period.

3.3 Brake parking slip rate (basing on the distance)

The percentage OF the braking distance (the distance traveled by the vehicle from the

4 Technical Conditions for Performance Test of Anti-

lock Braking System (ABS)

4.1 The technical conditions of the tested vehicle include.

a) The tested vehicle shall be no-load, clean, no obvious oil-leakage, water-leakage,

gas-leakage; and the engine idle speed is normal;

b) The tires are inflated to the specified pressure value; the error shall not exceed

±10kPa;

c) The tires are intact; the pattern of the coaxial tires is the same; no foreign matters

in the patter; the depth of the pattern shall meet the relevant requirements of

6.4.2.2 in GB 21861-2014;

d) Braking air pressure for air braking. the indicated air pressure of the air pressure

gauge shall be no greater than 750kPa;

e) Braking pedal force for hydraulic braking. the passenger cars with seat number

up to 9 shall be no greater than 400N; while other vehicles shall be no greater

than 450N;

f) When carrying out the test, a driver shall sit on the tested vehicle.

4.2 The technical conditions of the roller bench test include.

a) The technical performance of the roller bench shall meet the needs of the anti-

lock braking system (ABS) of the tested vehicle;

b) The drum surface of the roller bench shall be clean, dry, without foreign matters

or oil stains;

c) Measures shall be taken to prevent the tested vehicle from moving on the drum

of the roller bench.

4.3 The technical conditions of road test include.

a) The test pavement shall be hard, clean, dry, flat cement or asphalt pavement; the

pavement adhesion coefficient shall be no less than 0.7; the longitudinal slope

of the pavement shall be no greater than 1%; the pavement part shall not have

obvious damage, protrusion or depression;

b) The length of the tested pavement shall be no less than 100m; its width shall be

no less than 6m;

GPS receiving subsystem for the base station; then screen, cull, and take

arithmetic averaging processing against the collected data; finally, obtain the

coordinate values of such point;

2) Perform eccentric observation on a known point of the national plane with an

absolute standard in the known geodetic control network; then obtain the

coordinate values of such point through projection deformation and coordinate

transformation.

h) The vehicle equipped with mobile station is braked during the driving period; the

GPS receiving subsystem for mobile station collects a series of GPS ephemeris

signals and differential signals from the base station; then transfer them to the

host to analyze, process and calculate; so that obtain the time-related driving

speed, initial speed of braking, acceleration/deceleration, mean fully developed

deceleration (MFDD), braking distance, slip rate and the like ABS braking

performance parameters of the test vehicle equipped with anti-lock braking

system (ABS).

i) The test parameters shall be calculated and processed as follows.

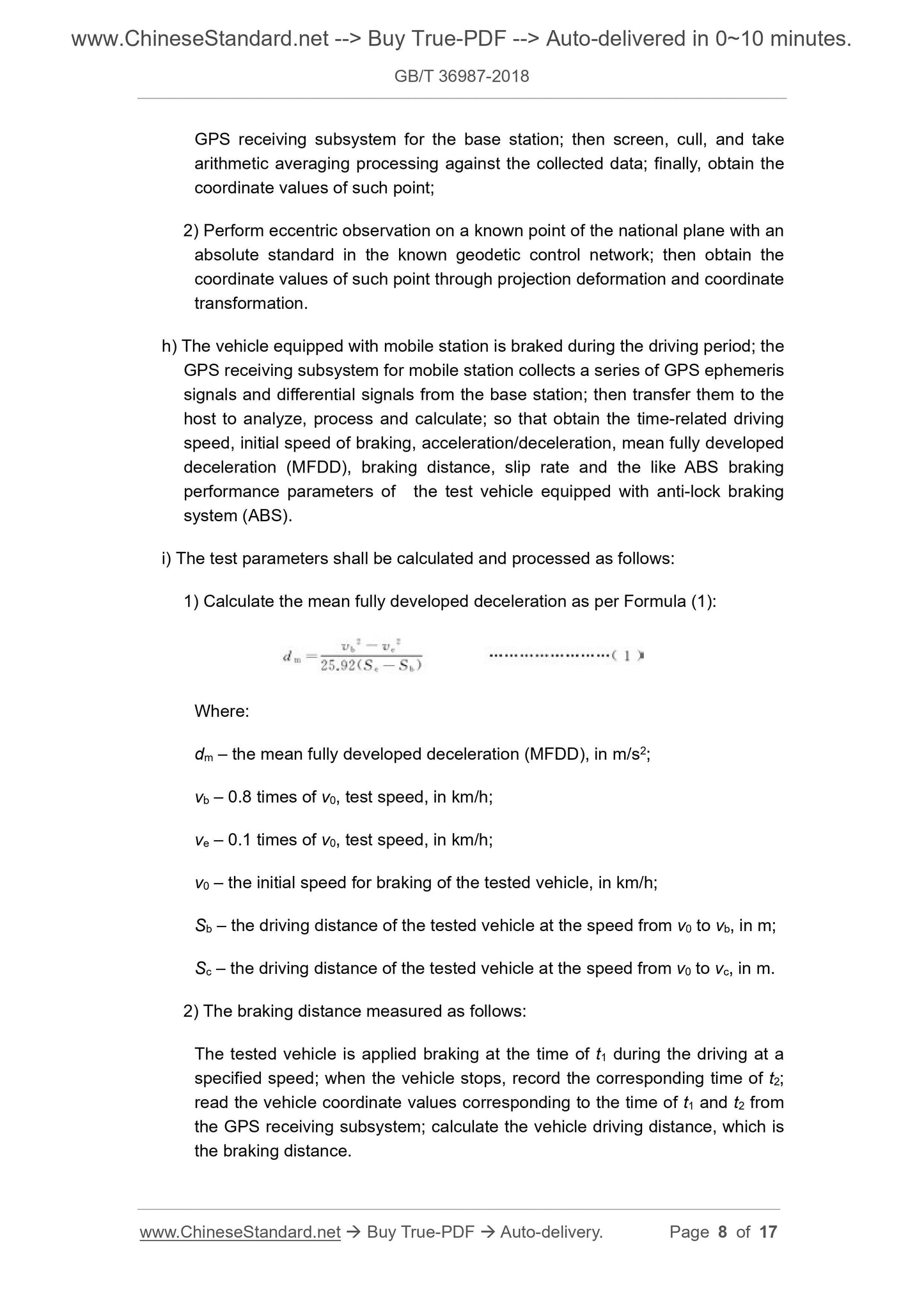

1) Calculate the mean fully developed deceleration as per Formula (1).

Where.

dm – the mean fully developed deceleration (MFDD), in m/s2;

vb – 0.8 times of v0, test speed, in km/h;

ve – 0.1 times of v0, test speed, in km/h;

v0 – the initial speed for braking of the tested vehicle, in km/h;

Sb – the driving distance of the tested vehicle at the speed from v0 to vb, in m;

Sc – the driving distance of the tested vehicle at the speed from v0 to vc, in m.

2) The braking distance measured as follows.

The tested vehicle is applied braking at the time of t1 during the driving at a

specified speed; when the vehicle stops, record the corresponding time of t2;

read the vehicle coordinate values corresponding to the time of t1 and t2 from

the GPS receiving subsystem; calculate the vehicle driving distance, which is

the braking distance.

When taking the testing methods by roller bench, the test parameters include. brake

parking slip rate, instantaneous slip rate, average slip rate, coaxial slip rate difference,

braking distance, brake coordination time, vehicle speed, and wheel block force.

5.2.2 Test methods

The methods taking roller bench to carry out the performance test of the vehicle anti-

lock braking system (ABS) include.

a) The tested vehicle is driven slowly onto the roller bench; place the vehicle

appropriately, so that the front and rear wheels are parked in the middle of the

two main drums on the front and rear of the roller bench; install the wheel speed

testing device.

b) Start the roller bench; the drums of the roller bench drag the wheels of the tested

vehicle to rotate; the linear speed for the drums of the roller bench is increased

form 0km/h to 50km/h; then stop dragging; the speed declines; quickly brake

when the speed is reduced to 40km/h±1.5km/h; read and record the time, t1,

when the feet contact with the brake pedals, speed (the linear speed of the

wheels and drums of roller bench) corresponding to the time, t1; then measure

and take the linear speed of the wheels and drums of the roller bench

corresponding to certain time, t2, when the wheel speed declines to about 30km/h;

measure and take the rolling distance of the wheels and drums from the time, t1,

to when both wheels and drums stop rotating.

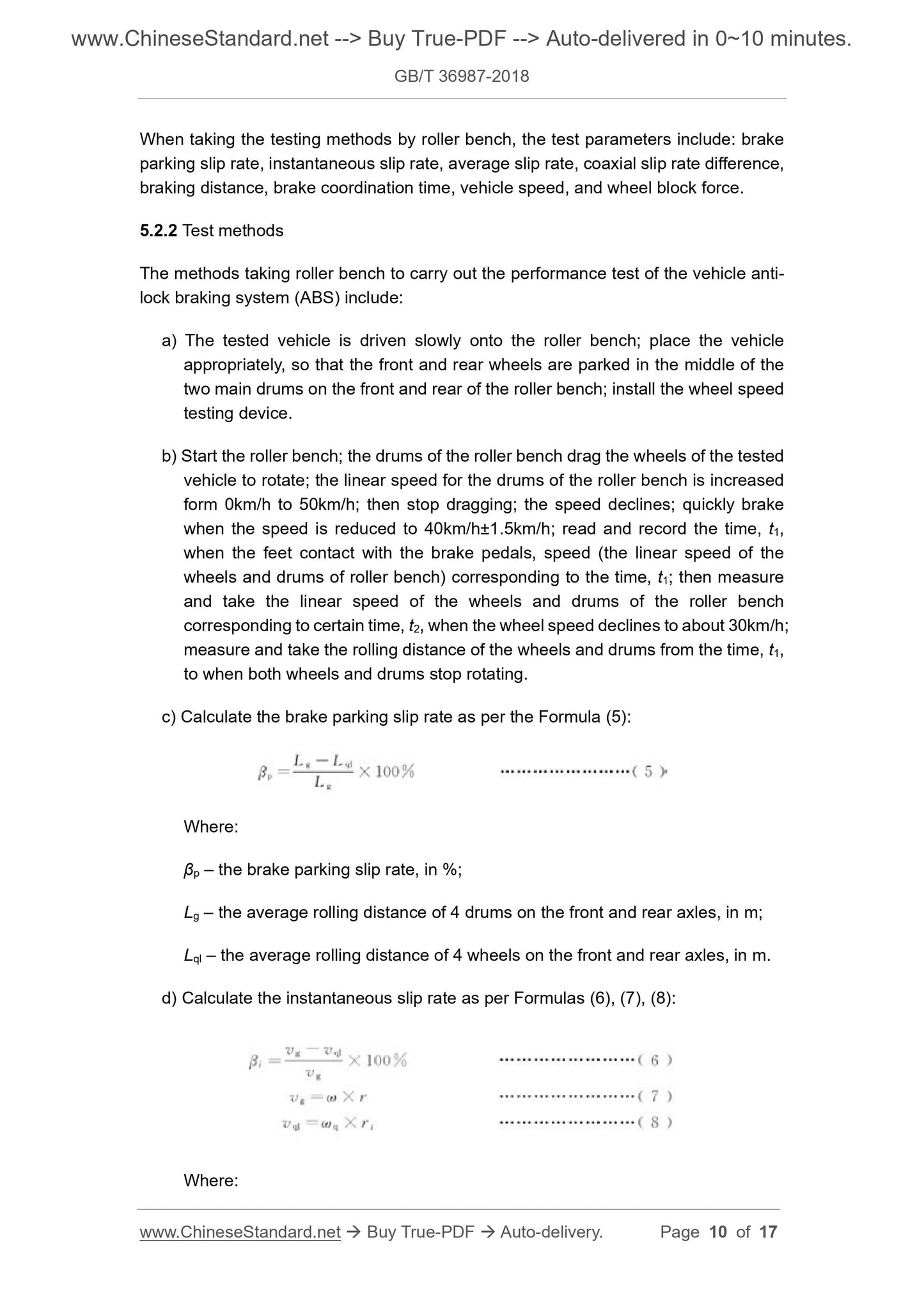

c) Calculate the brake parking slip rate as per the Formula (5).

Where.

βp – the brake parking slip rate, in %;

Lg – the average rolling distance of 4 drums on the front and rear axles, in m;

Lql – the average rolling distance of 4 wheels on the front and rear axles, in m.

d) Calculate the instantaneous slip rate as per Formulas (6), (7), (8).

Where.

GB/T 36987-2018

GB

NATIONAL STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.180

R 86

Testing Methods of Anti-lock Braking

System (ABS) Performance for Automobiles

ISSUED ON. DECEMBER 28, 2018

IMPLEMENTED ON. JULY 01, 2019

Issued by. State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Technical Conditions for Performance Test of Anti-lock Braking System

(ABS) ... 6

5 Method for Test the Performance of Vehicle Anti-lock Braking System (ABS)

... 7

Appendix A (Informative) Record List for Using GPS Technology Road Test to

Detect the Vehicle Anti-Lock Braking System (ABS) ... 13

Appendix B (Informative) Record List for Using Roller Bench to Detect the

Vehicle Anti-Lock Braking System (ABS) ... 15

Bibliography ... 17

Testing Methods of Anti-lock Braking

System (ABS) Performance for Automobiles

1 Scope

This Standard specifies the technical conditions and methods for testing the anti-lock

braking system (ABS) performance for automobiles.

This Standard is applicable to the inspection and verification for the anti-lock braking

system (ABS) performance for automobiles.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 18314 Specifications for Global Positioning System (GPS) Surveys

GB 21861-2014 Items and Methods of Motor Vehicles Safety Technology

Inspection

3 Terms and Definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Active safety technology

The technical configuration, means and measures that are adopted and set up by the

vehicle itself to actively avoid and defend against the accident.

3.2 Anti-lock braking systems (ABS)

A system that can automatically control the degree of slip between the vehicle’s wheels

and road during braking period.

3.3 Brake parking slip rate (basing on the distance)

The percentage OF the braking distance (the distance traveled by the vehicle from the

4 Technical Conditions for Performance Test of Anti-

lock Braking System (ABS)

4.1 The technical conditions of the tested vehicle include.

a) The tested vehicle shall be no-load, clean, no obvious oil-leakage, water-leakage,

gas-leakage; and the engine idle speed is normal;

b) The tires are inflated to the specified pressure value; the error shall not exceed

±10kPa;

c) The tires are intact; the pattern of the coaxial tires is the same; no foreign matters

in the patter; the depth of the pattern shall meet the relevant requirements of

6.4.2.2 in GB 21861-2014;

d) Braking air pressure for air braking. the indicated air pressure of the air pressure

gauge shall be no greater than 750kPa;

e) Braking pedal force for hydraulic braking. the passenger cars with seat number

up to 9 shall be no greater than 400N; while other vehicles shall be no greater

than 450N;

f) When carrying out the test, a driver shall sit on the tested vehicle.

4.2 The technical conditions of the roller bench test include.

a) The technical performance of the roller bench shall meet the needs of the anti-

lock braking system (ABS) of the tested vehicle;

b) The drum surface of the roller bench shall be clean, dry, without foreign matters

or oil stains;

c) Measures shall be taken to prevent the tested vehicle from moving on the drum

of the roller bench.

4.3 The technical conditions of road test include.

a) The test pavement shall be hard, clean, dry, flat cement or asphalt pavement; the

pavement adhesion coefficient shall be no less than 0.7; the longitudinal slope

of the pavement shall be no greater than 1%; the pavement part shall not have

obvious damage, protrusion or depression;

b) The length of the tested pavement shall be no less than 100m; its width shall be

no less than 6m;

GPS receiving subsystem for the base station; then screen, cull, and take

arithmetic averaging processing against the collected data; finally, obtain the

coordinate values of such point;

2) Perform eccentric observation on a known point of the national plane with an

absolute standard in the known geodetic control network; then obtain the

coordinate values of such point through projection deformation and coordinate

transformation.

h) The vehicle equipped with mobile station is braked during the driving period; the

GPS receiving subsystem for mobile station collects a series of GPS ephemeris

signals and differential signals from the base station; then transfer them to the

host to analyze, process and calculate; so that obtain the time-related driving

speed, initial speed of braking, acceleration/deceleration, mean fully developed

deceleration (MFDD), braking distance, slip rate and the like ABS braking

performance parameters of the test vehicle equipped with anti-lock braking

system (ABS).

i) The test parameters shall be calculated and processed as follows.

1) Calculate the mean fully developed deceleration as per Formula (1).

Where.

dm – the mean fully developed deceleration (MFDD), in m/s2;

vb – 0.8 times of v0, test speed, in km/h;

ve – 0.1 times of v0, test speed, in km/h;

v0 – the initial speed for braking of the tested vehicle, in km/h;

Sb – the driving distance of the tested vehicle at the speed from v0 to vb, in m;

Sc – the driving distance of the tested vehicle at the speed from v0 to vc, in m.

2) The braking distance measured as follows.

The tested vehicle is applied braking at the time of t1 during the driving at a

specified speed; when the vehicle stops, record the corresponding time of t2;

read the vehicle coordinate values corresponding to the time of t1 and t2 from

the GPS receiving subsystem; calculate the vehicle driving distance, which is

the braking distance.

When taking the testing methods by roller bench, the test parameters include. brake

parking slip rate, instantaneous...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 36987-2018 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 36987-2018

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 36987-2018

GB

NATIONAL STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.180

R 86

Testing Methods of Anti-lock Braking

System (ABS) Performance for Automobiles

ISSUED ON. DECEMBER 28, 2018

IMPLEMENTED ON. JULY 01, 2019

Issued by. State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Technical Conditions for Performance Test of Anti-lock Braking System

(ABS) ... 6

5 Method for Test the Performance of Vehicle Anti-lock Braking System (ABS)

... 7

Appendix A (Informative) Record List for Using GPS Technology Road Test to

Detect the Vehicle Anti-Lock Braking System (ABS) ... 13

Appendix B (Informative) Record List for Using Roller Bench to Detect the

Vehicle Anti-Lock Braking System (ABS) ... 15

Bibliography ... 17

Testing Methods of Anti-lock Braking

System (ABS) Performance for Automobiles

1 Scope

This Standard specifies the technical conditions and methods for testing the anti-lock

braking system (ABS) performance for automobiles.

This Standard is applicable to the inspection and verification for the anti-lock braking

system (ABS) performance for automobiles.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 18314 Specifications for Global Positioning System (GPS) Surveys

GB 21861-2014 Items and Methods of Motor Vehicles Safety Technology

Inspection

3 Terms and Definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Active safety technology

The technical configuration, means and measures that are adopted and set up by the

vehicle itself to actively avoid and defend against the accident.

3.2 Anti-lock braking systems (ABS)

A system that can automatically control the degree of slip between the vehicle’s wheels

and road during braking period.

3.3 Brake parking slip rate (basing on the distance)

The percentage OF the braking distance (the distance traveled by the vehicle from the

4 Technical Conditions for Performance Test of Anti-

lock Braking System (ABS)

4.1 The technical conditions of the tested vehicle include.

a) The tested vehicle shall be no-load, clean, no obvious oil-leakage, water-leakage,

gas-leakage; and the engine idle speed is normal;

b) The tires are inflated to the specified pressure value; the error shall not exceed

±10kPa;

c) The tires are intact; the pattern of the coaxial tires is the same; no foreign matters

in the patter; the depth of the pattern shall meet the relevant requirements of

6.4.2.2 in GB 21861-2014;

d) Braking air pressure for air braking. the indicated air pressure of the air pressure

gauge shall be no greater than 750kPa;

e) Braking pedal force for hydraulic braking. the passenger cars with seat number

up to 9 shall be no greater than 400N; while other vehicles shall be no greater

than 450N;

f) When carrying out the test, a driver shall sit on the tested vehicle.

4.2 The technical conditions of the roller bench test include.

a) The technical performance of the roller bench shall meet the needs of the anti-

lock braking system (ABS) of the tested vehicle;

b) The drum surface of the roller bench shall be clean, dry, without foreign matters

or oil stains;

c) Measures shall be taken to prevent the tested vehicle from moving on the drum

of the roller bench.

4.3 The technical conditions of road test include.

a) The test pavement shall be hard, clean, dry, flat cement or asphalt pavement; the

pavement adhesion coefficient shall be no less than 0.7; the longitudinal slope

of the pavement shall be no greater than 1%; the pavement part shall not have

obvious damage, protrusion or depression;

b) The length of the tested pavement shall be no less than 100m; its width shall be

no less than 6m;

GPS receiving subsystem for the base station; then screen, cull, and take

arithmetic averaging processing against the collected data; finally, obtain the

coordinate values of such point;

2) Perform eccentric observation on a known point of the national plane with an

absolute standard in the known geodetic control network; then obtain the

coordinate values of such point through projection deformation and coordinate

transformation.

h) The vehicle equipped with mobile station is braked during the driving period; the

GPS receiving subsystem for mobile station collects a series of GPS ephemeris

signals and differential signals from the base station; then transfer them to the

host to analyze, process and calculate; so that obtain the time-related driving

speed, initial speed of braking, acceleration/deceleration, mean fully developed

deceleration (MFDD), braking distance, slip rate and the like ABS braking

performance parameters of the test vehicle equipped with anti-lock braking

system (ABS).

i) The test parameters shall be calculated and processed as follows.

1) Calculate the mean fully developed deceleration as per Formula (1).

Where.

dm – the mean fully developed deceleration (MFDD), in m/s2;

vb – 0.8 times of v0, test speed, in km/h;

ve – 0.1 times of v0, test speed, in km/h;

v0 – the initial speed for braking of the tested vehicle, in km/h;

Sb – the driving distance of the tested vehicle at the speed from v0 to vb, in m;

Sc – the driving distance of the tested vehicle at the speed from v0 to vc, in m.

2) The braking distance measured as follows.

The tested vehicle is applied braking at the time of t1 during the driving at a

specified speed; when the vehicle stops, record the corresponding time of t2;

read the vehicle coordinate values corresponding to the time of t1 and t2 from

the GPS receiving subsystem; calculate the vehicle driving distance, which is

the braking distance.

When taking the testing methods by roller bench, the test parameters include. brake

parking slip rate, instantaneous slip rate, average slip rate, coaxial slip rate difference,

braking distance, brake coordination time, vehicle speed, and wheel block force.

5.2.2 Test methods

The methods taking roller bench to carry out the performance test of the vehicle anti-

lock braking system (ABS) include.

a) The tested vehicle is driven slowly onto the roller bench; place the vehicle

appropriately, so that the front and rear wheels are parked in the middle of the

two main drums on the front and rear of the roller bench; install the wheel speed

testing device.

b) Start the roller bench; the drums of the roller bench drag the wheels of the tested

vehicle to rotate; the linear speed for the drums of the roller bench is increased

form 0km/h to 50km/h; then stop dragging; the speed declines; quickly brake

when the speed is reduced to 40km/h±1.5km/h; read and record the time, t1,

when the feet contact with the brake pedals, speed (the linear speed of the

wheels and drums of roller bench) corresponding to the time, t1; then measure

and take the linear speed of the wheels and drums of the roller bench

corresponding to certain time, t2, when the wheel speed declines to about 30km/h;

measure and take the rolling distance of the wheels and drums from the time, t1,

to when both wheels and drums stop rotating.

c) Calculate the brake parking slip rate as per the Formula (5).

Where.

βp – the brake parking slip rate, in %;

Lg – the average rolling distance of 4 drums on the front and rear axles, in m;

Lql – the average rolling distance of 4 wheels on the front and rear axles, in m.

d) Calculate the instantaneous slip rate as per Formulas (6), (7), (8).

Where.

GB/T 36987-2018

GB

NATIONAL STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.180

R 86

Testing Methods of Anti-lock Braking

System (ABS) Performance for Automobiles

ISSUED ON. DECEMBER 28, 2018

IMPLEMENTED ON. JULY 01, 2019

Issued by. State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Technical Conditions for Performance Test of Anti-lock Braking System

(ABS) ... 6

5 Method for Test the Performance of Vehicle Anti-lock Braking System (ABS)

... 7

Appendix A (Informative) Record List for Using GPS Technology Road Test to

Detect the Vehicle Anti-Lock Braking System (ABS) ... 13

Appendix B (Informative) Record List for Using Roller Bench to Detect the

Vehicle Anti-Lock Braking System (ABS) ... 15

Bibliography ... 17

Testing Methods of Anti-lock Braking

System (ABS) Performance for Automobiles

1 Scope

This Standard specifies the technical conditions and methods for testing the anti-lock

braking system (ABS) performance for automobiles.

This Standard is applicable to the inspection and verification for the anti-lock braking

system (ABS) performance for automobiles.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 18314 Specifications for Global Positioning System (GPS) Surveys

GB 21861-2014 Items and Methods of Motor Vehicles Safety Technology

Inspection

3 Terms and Definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Active safety technology

The technical configuration, means and measures that are adopted and set up by the

vehicle itself to actively avoid and defend against the accident.

3.2 Anti-lock braking systems (ABS)

A system that can automatically control the degree of slip between the vehicle’s wheels

and road during braking period.

3.3 Brake parking slip rate (basing on the distance)

The percentage OF the braking distance (the distance traveled by the vehicle from the

4 Technical Conditions for Performance Test of Anti-

lock Braking System (ABS)

4.1 The technical conditions of the tested vehicle include.

a) The tested vehicle shall be no-load, clean, no obvious oil-leakage, water-leakage,

gas-leakage; and the engine idle speed is normal;

b) The tires are inflated to the specified pressure value; the error shall not exceed

±10kPa;

c) The tires are intact; the pattern of the coaxial tires is the same; no foreign matters

in the patter; the depth of the pattern shall meet the relevant requirements of

6.4.2.2 in GB 21861-2014;

d) Braking air pressure for air braking. the indicated air pressure of the air pressure

gauge shall be no greater than 750kPa;

e) Braking pedal force for hydraulic braking. the passenger cars with seat number

up to 9 shall be no greater than 400N; while other vehicles shall be no greater

than 450N;

f) When carrying out the test, a driver shall sit on the tested vehicle.

4.2 The technical conditions of the roller bench test include.

a) The technical performance of the roller bench shall meet the needs of the anti-

lock braking system (ABS) of the tested vehicle;

b) The drum surface of the roller bench shall be clean, dry, without foreign matters

or oil stains;

c) Measures shall be taken to prevent the tested vehicle from moving on the drum

of the roller bench.

4.3 The technical conditions of road test include.

a) The test pavement shall be hard, clean, dry, flat cement or asphalt pavement; the

pavement adhesion coefficient shall be no less than 0.7; the longitudinal slope

of the pavement shall be no greater than 1%; the pavement part shall not have

obvious damage, protrusion or depression;

b) The length of the tested pavement shall be no less than 100m; its width shall be

no less than 6m;

GPS receiving subsystem for the base station; then screen, cull, and take

arithmetic averaging processing against the collected data; finally, obtain the

coordinate values of such point;

2) Perform eccentric observation on a known point of the national plane with an

absolute standard in the known geodetic control network; then obtain the

coordinate values of such point through projection deformation and coordinate

transformation.

h) The vehicle equipped with mobile station is braked during the driving period; the

GPS receiving subsystem for mobile station collects a series of GPS ephemeris

signals and differential signals from the base station; then transfer them to the

host to analyze, process and calculate; so that obtain the time-related driving

speed, initial speed of braking, acceleration/deceleration, mean fully developed

deceleration (MFDD), braking distance, slip rate and the like ABS braking

performance parameters of the test vehicle equipped with anti-lock braking

system (ABS).

i) The test parameters shall be calculated and processed as follows.

1) Calculate the mean fully developed deceleration as per Formula (1).

Where.

dm – the mean fully developed deceleration (MFDD), in m/s2;

vb – 0.8 times of v0, test speed, in km/h;

ve – 0.1 times of v0, test speed, in km/h;

v0 – the initial speed for braking of the tested vehicle, in km/h;

Sb – the driving distance of the tested vehicle at the speed from v0 to vb, in m;

Sc – the driving distance of the tested vehicle at the speed from v0 to vc, in m.

2) The braking distance measured as follows.

The tested vehicle is applied braking at the time of t1 during the driving at a

specified speed; when the vehicle stops, record the corresponding time of t2;

read the vehicle coordinate values corresponding to the time of t1 and t2 from

the GPS receiving subsystem; calculate the vehicle driving distance, which is

the braking distance.

When taking the testing methods by roller bench, the test parameters include. brake

parking slip rate, instantaneous...

Share