1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 40168-2021 English PDF (GB/T40168-2021)

GB/T 40168-2021 English PDF (GB/T40168-2021)

Regular price

$170.00

Regular price

Sale price

$170.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 40168-2021: Corrugating medium - Determination of the edge crush resistance after laboratory fluting

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 40168-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 40168-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 40168-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 85.010

Y 30

Corrugating medium - Determination of the edge

crush resistance after laboratory fluting

(ISO 16945:2014, MOD)

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Principle ... 5

5 Instruments ... 5

6 Specimen collection ... 7

7 Specimen treatment ... 7

8 Specimen preparation ... 7

9 Test steps ... 8

10 Result calculation ... 8

11 Test report ... 10

Annex A (informative) Precision ... 11

Bibliography ... 13

Corrugating medium - Determination of the edge

crush resistance after laboratory fluting

1 Scope

This Standard specifies the method to determine the edge crush resistance of

corrugating medium after laboratory fluting.

This Standard applies to all kinds of corrugating mediums used to manufacture

corrugated fibreboard after fluting.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 450, Paper and Board - Sampling for Testing and Identification of

Machine and Cross Direction, Wire Side and Felt Side (GB/T 450-2008, ISO

186:2002, MOD)

GB/T 451.2, Paper and board - Determination of grammage (GB/T 451.2-

2002, eqv ISO 536:1995)

GB/T 10739, Paper, board and pulps - STANDARD atmosphere for

conditioning and testing (GB/T 10739-2002, eqv ISO 187:1990)

ISO 13820, Paper, board and corrugated fibreboard -Description and

calibration of compression-testing equipment

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 edge crush resistance; CCT

under the specified conditions, after corrugated core paper is corrugated in the

laboratory, and the edge of the specimen is compressed, the maximum

pressure per unit length that the specimen can withstand before crushing

NOTE: The unit is kilonewtons per meter (kN/m).

3.2 edge crush resistance index

the edge crush resistance is divided by the quantitative value

NOTE: The unit is newton meters per gram (N·m/g).

4 Principle

Pass the specimen between a pair of heated rollers and place it vertically in the

holder to corrugate. Apply pressure to the specimen in a direction perpendicular

to the edge of the specimen. When the specimen is crushed, the maximum

force value per unit length indicates the edge crush resistance of the specimen.

5 Instruments

5.1 Sample cutting equipment

The cut specimen shall meet the requirements of Chapter 8.

5.2 Flute meter

The flute meter consists of a pair of matched steel fluted rollers. One corrugated

roller is the driving roller, and the other corrugated roller is the driven roller. Use

appropriate methods to keep the temperature of the fluted roll within the range

of (175±8)°C. Check the temperature while the fluted roller is in motion.

Under the test conditions, a grooved roller is driven by a motor. The rotating

speed is controlled at (4.5±1.0)r/min. By evenly applying a force of (100±10) N

on the grooved roller, the grooved roller is kept in engagement. In some

instruments, the force between the fluted rollers is applied by a spring in a

stretched state. The friction within the equipment can cause the force acting on

the specimen to be much smaller than the force originally required to be set on

the fluted roller. In order to verify whether the instrument meets the

requirements of this article, it is necessary to test the force required to prevent

the driven roller from moving to the driving roller at a distance of 200μm from

the driving roller.

Each roller shall meet the following necessary characteristics (see Figure 1):

- Addendum circle diameter: (228.5±0.5)mm;

- Tooth thickness: (16±1)mm;

- Number of teeth: 84 (see NOTE 3);

parallelism of the long side of the specimen shall be within 0.01mm. It shall be

clean and free of defects.

9 Test steps

9.1 General rules

The edge crush resistance test can be tested immediately after fluting (see 9.2).

It can also be tested after 30min of temperature and humidity treatment after

fluting (see 9.3).

9.2 Test immediately after fluting

If the compression test is performed immediately after the specimen is fluted,

the time from fluting to pressure application shall be within 20s~25s.

NOTE: In the inter-laboratory comparison experiment conducted in 2012, the shortest time

required from installing the specimen to applying pressure was 20s~25s.

9.3 Test after 30min of temperature and humidity treatment after fluting

If the specimen is subjected to temperature and humidity treatment after fluting,

the specimen shall be treated again for 30min~35min in the environment where

the temperature is (23±1)°C and the relative humidity is (50±2)%. If the

specimen is tested after 30min of temperature and humidity treatment after

fluting, all the specimens can be fluted before the test.

9.4 Fluting and testing

Turn on the motor and heat the fluted roller to (175±8)°C.

Insert the specimen vertically into the gap between the two fluted rollers along

the long side of the specimen.

Put the fluted specimen into the holder (5.3). Then put the holder in the middle

of the lower plate of the compression tester. Start the test and take a reading.

Take the maximum test value, accurate to 1N.

Whether it is tested immediately or after 30min of temperature and humidity

treatment, repeat the above steps to test the remaining specimens. At least 10

valid test results have been obtained.

10 Result calculation

10.1 Edge crush resistance

Annex A

(informative)

Precision

A.1 In May 2012, 11 laboratories from 6 countries participated in an

international inter-laboratory comparison.

A.2 This comparison experiment uses 3 different quantitative fluting samples.

CCT0 and CCT30 tests were carried out on each sample.

A.3 The data is shown in Table A.1~Table A.4.

A.4 The calculation basis is ISO/TR 24498 and TAPPI T 1200.

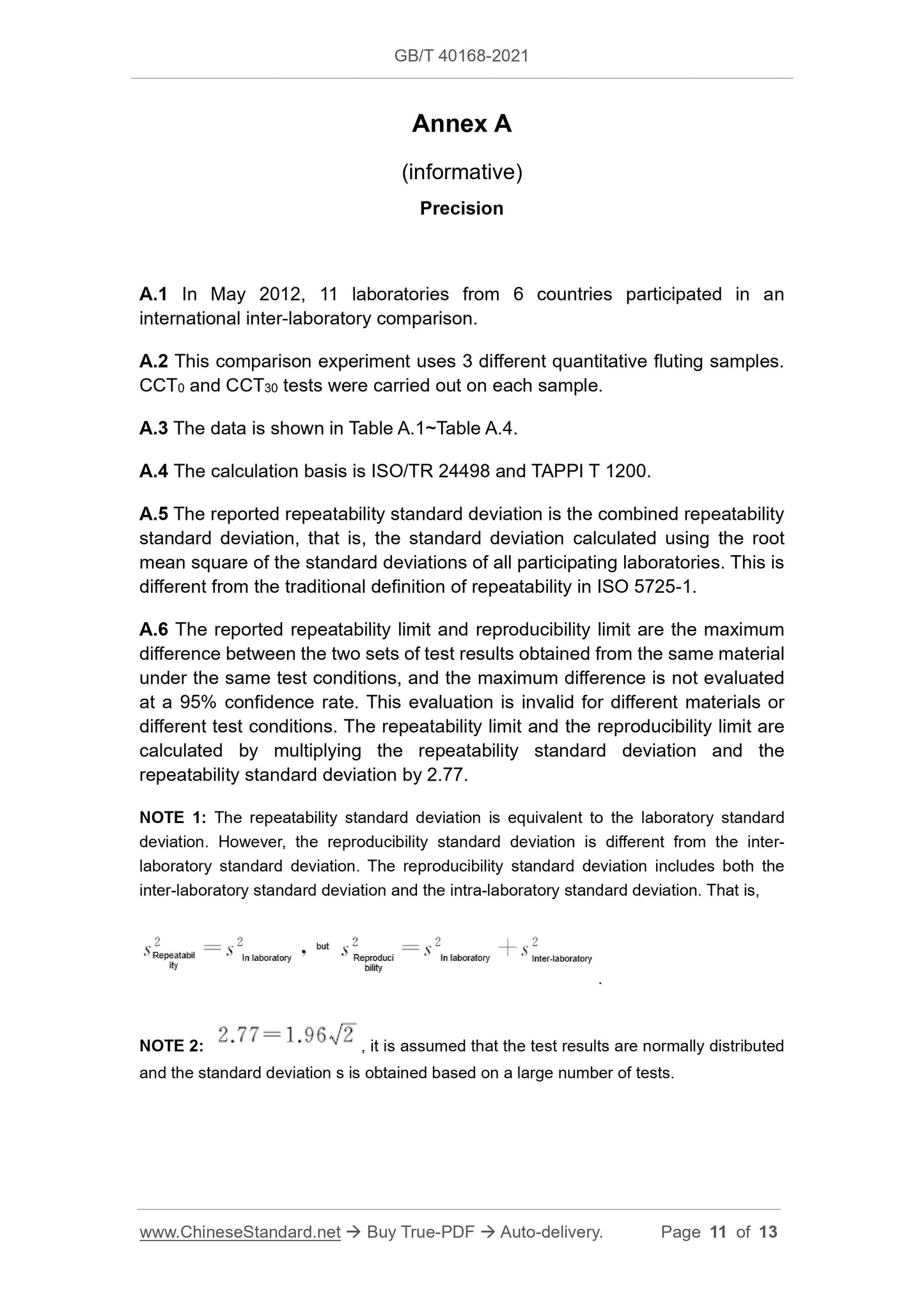

A.5 The reported repeatability standard deviation is the combined repeatability

standard deviation, that is, the standard deviation calculated using the root

mean square of the standard deviations of all participating laboratories. This is

different from the traditional definition of repeatability in ISO 5725-1.

A.6 The reported repeatability limit and reproducibility limit are the maximum

difference between the two sets of test results obtained from the same material

under the same test conditions, and the maximum difference is not evaluated

at a 95% confidence rate. This evaluation is invalid for different materials or

different test conditions. The repeatability limit and the reproducibility limit are

calculated by multiplying the repeatability standard deviation and the

repeatability standard deviation by 2.77.

NOTE 1: The repeatability standard deviation is equivalent to the laboratory standard

deviation. However, the reproducibility standard deviation is different from the inter-

laboratory standard deviation. The reproducibility standard deviation includes both the

inter-laboratory standard deviation and the intra-laboratory standard deviation. That is,

NOTE 2: , it is assumed that the test results are normally distributed

and the standard deviation s is obtained based on a large number of tests.

GB/T 40168-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 85.010

Y 30

Corrugating medium - Determination of the edge

crush resistance after laboratory fluting

(ISO 16945:2014, MOD)

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Principle ... 5

5 Instruments ... 5

6 Specimen collection ... 7

7 Specimen treatment ... 7

8 Specimen preparation ... 7

9 Test steps ... 8

10 Result calculation ... 8

11 Test report ... 10

Annex A (informative) Precision ... 11

Bibliography ... 13

Corrugating medium - Determination of the edge

crush resistance after laboratory fluting

1 Scope

This Standard specifies the method to determine the edge crush resistance of

corrugating medium after laboratory fluting.

This Standard applies to all kinds of corrugating mediums used to manufacture

corrugated fibreboard after fluting.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 450, Paper and Board - Sampling for Testing and Identification of

Machine and Cross Direction, Wire Side and Felt Side (GB/T 450-2008, ISO

186:2002, MOD)

GB/T 451.2, Paper and board - Determination of grammage (GB/T 451.2-

2002, eqv ISO 536:1995)

GB/T 10739, Paper, board and pulps - STANDARD atmosphere for

conditioning and testing (GB/T 10739-2002, eqv ISO 187:1990)

ISO 13820, Paper, board and corrugated fibreboard -Description and

calibration of compression-testing equipment

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 edge crush resistance; CCT

under the specified conditions, after corrugated core paper is corrugated in the

laboratory, and the edge of the specimen is compressed, the maximum

pressure per unit length that the specimen can withstand before crushing

NOTE: The unit is kilonewtons per meter (kN/m).

3.2 edge crush resistance index

the edge crush resistance is divided by the quantitative value

NOTE: The unit is newton meters per gram (N·m/g).

4 Principle

Pass the specimen between a pair of heated rollers and place it vertically in the

holder to corrugate. Apply pressure to the specimen in a direction perpendicular

to the edge of the specimen. When the specimen is crushed, the maximum

force value per unit length indicates the edge crush resistance of the specimen.

5 Instruments

5.1 Sample cutting equipment

The cut specimen shall meet the requirements of Chapter 8.

5.2 Flute meter

The flute meter consists of a pair of matched steel fluted rollers. One corrugated

roller is the driving roller, and the other corrugated roller is the driven roller. Use

appropriate methods to keep the temperature of the fluted roll within the range

of (175±8)°C. Check the temperature while the fluted roller is in motion.

Under the test conditions, a grooved roller is driven by a motor. The rotating

speed is controlled at (4.5±1.0)r/min. By evenly applying a force of (100±10) N

on the grooved roller, the grooved roller is kept in engagement. In some

instruments, the force between the fluted rollers is applied by a spring in a

stretched state. The friction within the equipment can cause the force acting on

the specimen to be much smaller than the force originally required to be set on

the fluted roller. In order to verify whether the instrument meets the

requirements of this article, it is necessary to test the force required to prevent

the driven roller from moving to the driving roller at a distance of 200μm from

the driving roller.

Each roller shall meet the following necessary characteristics (see Figure 1):

- Addendum circle diameter: (228.5±0.5)mm;

- Tooth thickness: (16±1)mm;

- Number of teeth: 84 (see NOTE 3);

parallelism of the long side of the specimen shall be within 0.01mm. It shall be

clean and free of defects.

9 Test steps

9.1 General rules

The edge crush resistance test can be tested immediately after fluting (see 9.2).

It can also be tested after 30min of temperature and humidity treatment after

fluting (see 9.3).

9.2 Test immediately after fluting

If the compression test is performed immediately after the specimen is fluted,

the time from fluting to pressure application shall be within 20s~25s.

NOTE: In the inter-laboratory comparison experiment conducted in 2012, the shortest time

required from installing the specimen to applying pressure was 20s~25s.

9.3 Test after 30min of temperature and humidity treatment after fluting

If the specimen is subjected to temperature and humidity treatment after fluting,

the specimen shall be treated again for 30min~35min in the environment where

the temperature is (23±1)°C and the relative humidity is (50±2)%. If the

specimen is tested after 30min of temperature and humidity treatment after

fluting, all the specimens can be fluted before the test.

9.4 Fluting and testing

Turn on the motor and heat the fluted roller to (175±8)°C.

Insert the specimen vertically into the gap between the two fluted rollers along

the long side of the specimen.

Put the fluted specimen into the holder (5.3). Then put the holder in the middle

of the lower plate of the compression tester. Start the test and take a reading.

Take the maximum test value, accurate to 1N.

Whether it is tested immediately or after 30min of temperature and humidity

treatment, repeat the above steps to test the remaining specimens. At least 10

valid test results have been obtained.

10 Result calculation

10.1 Edge crush resistance

Annex A

(informative)

Precision

A.1 In May 2012, 11 laboratories from 6 countries participated in an

international inter-laboratory comparison.

A.2 This comparison experiment uses 3 different quantitative fluting samples.

CCT0 and CCT30 tests were carried out on each sample.

A.3 The data is shown in Table A.1~Table A.4...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 40168-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 40168-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 40168-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 85.010

Y 30

Corrugating medium - Determination of the edge

crush resistance after laboratory fluting

(ISO 16945:2014, MOD)

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Principle ... 5

5 Instruments ... 5

6 Specimen collection ... 7

7 Specimen treatment ... 7

8 Specimen preparation ... 7

9 Test steps ... 8

10 Result calculation ... 8

11 Test report ... 10

Annex A (informative) Precision ... 11

Bibliography ... 13

Corrugating medium - Determination of the edge

crush resistance after laboratory fluting

1 Scope

This Standard specifies the method to determine the edge crush resistance of

corrugating medium after laboratory fluting.

This Standard applies to all kinds of corrugating mediums used to manufacture

corrugated fibreboard after fluting.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 450, Paper and Board - Sampling for Testing and Identification of

Machine and Cross Direction, Wire Side and Felt Side (GB/T 450-2008, ISO

186:2002, MOD)

GB/T 451.2, Paper and board - Determination of grammage (GB/T 451.2-

2002, eqv ISO 536:1995)

GB/T 10739, Paper, board and pulps - STANDARD atmosphere for

conditioning and testing (GB/T 10739-2002, eqv ISO 187:1990)

ISO 13820, Paper, board and corrugated fibreboard -Description and

calibration of compression-testing equipment

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 edge crush resistance; CCT

under the specified conditions, after corrugated core paper is corrugated in the

laboratory, and the edge of the specimen is compressed, the maximum

pressure per unit length that the specimen can withstand before crushing

NOTE: The unit is kilonewtons per meter (kN/m).

3.2 edge crush resistance index

the edge crush resistance is divided by the quantitative value

NOTE: The unit is newton meters per gram (N·m/g).

4 Principle

Pass the specimen between a pair of heated rollers and place it vertically in the

holder to corrugate. Apply pressure to the specimen in a direction perpendicular

to the edge of the specimen. When the specimen is crushed, the maximum

force value per unit length indicates the edge crush resistance of the specimen.

5 Instruments

5.1 Sample cutting equipment

The cut specimen shall meet the requirements of Chapter 8.

5.2 Flute meter

The flute meter consists of a pair of matched steel fluted rollers. One corrugated

roller is the driving roller, and the other corrugated roller is the driven roller. Use

appropriate methods to keep the temperature of the fluted roll within the range

of (175±8)°C. Check the temperature while the fluted roller is in motion.

Under the test conditions, a grooved roller is driven by a motor. The rotating

speed is controlled at (4.5±1.0)r/min. By evenly applying a force of (100±10) N

on the grooved roller, the grooved roller is kept in engagement. In some

instruments, the force between the fluted rollers is applied by a spring in a

stretched state. The friction within the equipment can cause the force acting on

the specimen to be much smaller than the force originally required to be set on

the fluted roller. In order to verify whether the instrument meets the

requirements of this article, it is necessary to test the force required to prevent

the driven roller from moving to the driving roller at a distance of 200μm from

the driving roller.

Each roller shall meet the following necessary characteristics (see Figure 1):

- Addendum circle diameter: (228.5±0.5)mm;

- Tooth thickness: (16±1)mm;

- Number of teeth: 84 (see NOTE 3);

parallelism of the long side of the specimen shall be within 0.01mm. It shall be

clean and free of defects.

9 Test steps

9.1 General rules

The edge crush resistance test can be tested immediately after fluting (see 9.2).

It can also be tested after 30min of temperature and humidity treatment after

fluting (see 9.3).

9.2 Test immediately after fluting

If the compression test is performed immediately after the specimen is fluted,

the time from fluting to pressure application shall be within 20s~25s.

NOTE: In the inter-laboratory comparison experiment conducted in 2012, the shortest time

required from installing the specimen to applying pressure was 20s~25s.

9.3 Test after 30min of temperature and humidity treatment after fluting

If the specimen is subjected to temperature and humidity treatment after fluting,

the specimen shall be treated again for 30min~35min in the environment where

the temperature is (23±1)°C and the relative humidity is (50±2)%. If the

specimen is tested after 30min of temperature and humidity treatment after

fluting, all the specimens can be fluted before the test.

9.4 Fluting and testing

Turn on the motor and heat the fluted roller to (175±8)°C.

Insert the specimen vertically into the gap between the two fluted rollers along

the long side of the specimen.

Put the fluted specimen into the holder (5.3). Then put the holder in the middle

of the lower plate of the compression tester. Start the test and take a reading.

Take the maximum test value, accurate to 1N.

Whether it is tested immediately or after 30min of temperature and humidity

treatment, repeat the above steps to test the remaining specimens. At least 10

valid test results have been obtained.

10 Result calculation

10.1 Edge crush resistance

Annex A

(informative)

Precision

A.1 In May 2012, 11 laboratories from 6 countries participated in an

international inter-laboratory comparison.

A.2 This comparison experiment uses 3 different quantitative fluting samples.

CCT0 and CCT30 tests were carried out on each sample.

A.3 The data is shown in Table A.1~Table A.4.

A.4 The calculation basis is ISO/TR 24498 and TAPPI T 1200.

A.5 The reported repeatability standard deviation is the combined repeatability

standard deviation, that is, the standard deviation calculated using the root

mean square of the standard deviations of all participating laboratories. This is

different from the traditional definition of repeatability in ISO 5725-1.

A.6 The reported repeatability limit and reproducibility limit are the maximum

difference between the two sets of test results obtained from the same material

under the same test conditions, and the maximum difference is not evaluated

at a 95% confidence rate. This evaluation is invalid for different materials or

different test conditions. The repeatability limit and the reproducibility limit are

calculated by multiplying the repeatability standard deviation and the

repeatability standard deviation by 2.77.

NOTE 1: The repeatability standard deviation is equivalent to the laboratory standard

deviation. However, the reproducibility standard deviation is different from the inter-

laboratory standard deviation. The reproducibility standard deviation includes both the

inter-laboratory standard deviation and the intra-laboratory standard deviation. That is,

NOTE 2: , it is assumed that the test results are normally distributed

and the standard deviation s is obtained based on a large number of tests.

GB/T 40168-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 85.010

Y 30

Corrugating medium - Determination of the edge

crush resistance after laboratory fluting

(ISO 16945:2014, MOD)

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Principle ... 5

5 Instruments ... 5

6 Specimen collection ... 7

7 Specimen treatment ... 7

8 Specimen preparation ... 7

9 Test steps ... 8

10 Result calculation ... 8

11 Test report ... 10

Annex A (informative) Precision ... 11

Bibliography ... 13

Corrugating medium - Determination of the edge

crush resistance after laboratory fluting

1 Scope

This Standard specifies the method to determine the edge crush resistance of

corrugating medium after laboratory fluting.

This Standard applies to all kinds of corrugating mediums used to manufacture

corrugated fibreboard after fluting.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 450, Paper and Board - Sampling for Testing and Identification of

Machine and Cross Direction, Wire Side and Felt Side (GB/T 450-2008, ISO

186:2002, MOD)

GB/T 451.2, Paper and board - Determination of grammage (GB/T 451.2-

2002, eqv ISO 536:1995)

GB/T 10739, Paper, board and pulps - STANDARD atmosphere for

conditioning and testing (GB/T 10739-2002, eqv ISO 187:1990)

ISO 13820, Paper, board and corrugated fibreboard -Description and

calibration of compression-testing equipment

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 edge crush resistance; CCT

under the specified conditions, after corrugated core paper is corrugated in the

laboratory, and the edge of the specimen is compressed, the maximum

pressure per unit length that the specimen can withstand before crushing

NOTE: The unit is kilonewtons per meter (kN/m).

3.2 edge crush resistance index

the edge crush resistance is divided by the quantitative value

NOTE: The unit is newton meters per gram (N·m/g).

4 Principle

Pass the specimen between a pair of heated rollers and place it vertically in the

holder to corrugate. Apply pressure to the specimen in a direction perpendicular

to the edge of the specimen. When the specimen is crushed, the maximum

force value per unit length indicates the edge crush resistance of the specimen.

5 Instruments

5.1 Sample cutting equipment

The cut specimen shall meet the requirements of Chapter 8.

5.2 Flute meter

The flute meter consists of a pair of matched steel fluted rollers. One corrugated

roller is the driving roller, and the other corrugated roller is the driven roller. Use

appropriate methods to keep the temperature of the fluted roll within the range

of (175±8)°C. Check the temperature while the fluted roller is in motion.

Under the test conditions, a grooved roller is driven by a motor. The rotating

speed is controlled at (4.5±1.0)r/min. By evenly applying a force of (100±10) N

on the grooved roller, the grooved roller is kept in engagement. In some

instruments, the force between the fluted rollers is applied by a spring in a

stretched state. The friction within the equipment can cause the force acting on

the specimen to be much smaller than the force originally required to be set on

the fluted roller. In order to verify whether the instrument meets the

requirements of this article, it is necessary to test the force required to prevent

the driven roller from moving to the driving roller at a distance of 200μm from

the driving roller.

Each roller shall meet the following necessary characteristics (see Figure 1):

- Addendum circle diameter: (228.5±0.5)mm;

- Tooth thickness: (16±1)mm;

- Number of teeth: 84 (see NOTE 3);

parallelism of the long side of the specimen shall be within 0.01mm. It shall be

clean and free of defects.

9 Test steps

9.1 General rules

The edge crush resistance test can be tested immediately after fluting (see 9.2).

It can also be tested after 30min of temperature and humidity treatment after

fluting (see 9.3).

9.2 Test immediately after fluting

If the compression test is performed immediately after the specimen is fluted,

the time from fluting to pressure application shall be within 20s~25s.

NOTE: In the inter-laboratory comparison experiment conducted in 2012, the shortest time

required from installing the specimen to applying pressure was 20s~25s.

9.3 Test after 30min of temperature and humidity treatment after fluting

If the specimen is subjected to temperature and humidity treatment after fluting,

the specimen shall be treated again for 30min~35min in the environment where

the temperature is (23±1)°C and the relative humidity is (50±2)%. If the

specimen is tested after 30min of temperature and humidity treatment after

fluting, all the specimens can be fluted before the test.

9.4 Fluting and testing

Turn on the motor and heat the fluted roller to (175±8)°C.

Insert the specimen vertically into the gap between the two fluted rollers along

the long side of the specimen.

Put the fluted specimen into the holder (5.3). Then put the holder in the middle

of the lower plate of the compression tester. Start the test and take a reading.

Take the maximum test value, accurate to 1N.

Whether it is tested immediately or after 30min of temperature and humidity

treatment, repeat the above steps to test the remaining specimens. At least 10

valid test results have been obtained.

10 Result calculation

10.1 Edge crush resistance

Annex A

(informative)

Precision

A.1 In May 2012, 11 laboratories from 6 countries participated in an

international inter-laboratory comparison.

A.2 This comparison experiment uses 3 different quantitative fluting samples.

CCT0 and CCT30 tests were carried out on each sample.

A.3 The data is shown in Table A.1~Table A.4...

Share