1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 40262-2021 English PDF (GB/T40262-2021)

GB/T 40262-2021 English PDF (GB/T40262-2021)

Regular price

$185.00

Regular price

Sale price

$185.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 40262-2021: Metal coating fabric - Determination of metal layer adhesive force - Tape method

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 40262-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 40262-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 40262-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

CCS W 04

Metal Coating Fabric – Determination of Metal Layer

Adhesive Force – Tape Method

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Principle ... 5

5 Apparatus and Materials ... 5

6 Test Environment ... 6

7 Preparation of Specimen ... 6

8 Test Procedures ... 7

9 Evaluation of Test Results ... 8

10 Test Report ... 9

Appendix A (Informative) Evaluation Example Diagram ... 10

Bibliography ... 11

Metal Coating Fabric – Determination of Metal Layer

Adhesive Force – Tape Method

1 Scope

This Document specifies the test method for measuring the metal layer adhesive force

of the metal coating fabric by the tape method, including the method of colour fastness

to rubbing tester and the manual press roller method.

This Document is applicable to all kinds of metal coating fabrics.

2 Normative References

The following documents are essential to the application of this Document. For the

dated documents, only the versions with the dates indicated are applicable to this

Document; for the undated documents, only the latest version (including all the

amendments) is applicable to this Document.

GB/T 2792 Measurement of Peel Adhesion Properties for Adhesive Tapes

GB/T 3920 Textiles - Tests for Colour Fastness - Colour Fastness to Rubbing

GB/T 20631.2 Pressure Sensitive Adhesive Tapes for Electrical Purposes - Part

2: Methods of Test

GB/T 33729 Textiles - Tests for Colour Fastness - Cotton Rubbing Cloth

3 Terms and Definitions

For the purposes of this Document, the following terms and definitions apply.

3.1 Metal coating fabric

Use physical or chemical methods to perform metal coating on the surface to make it

a fabric with specific functions.

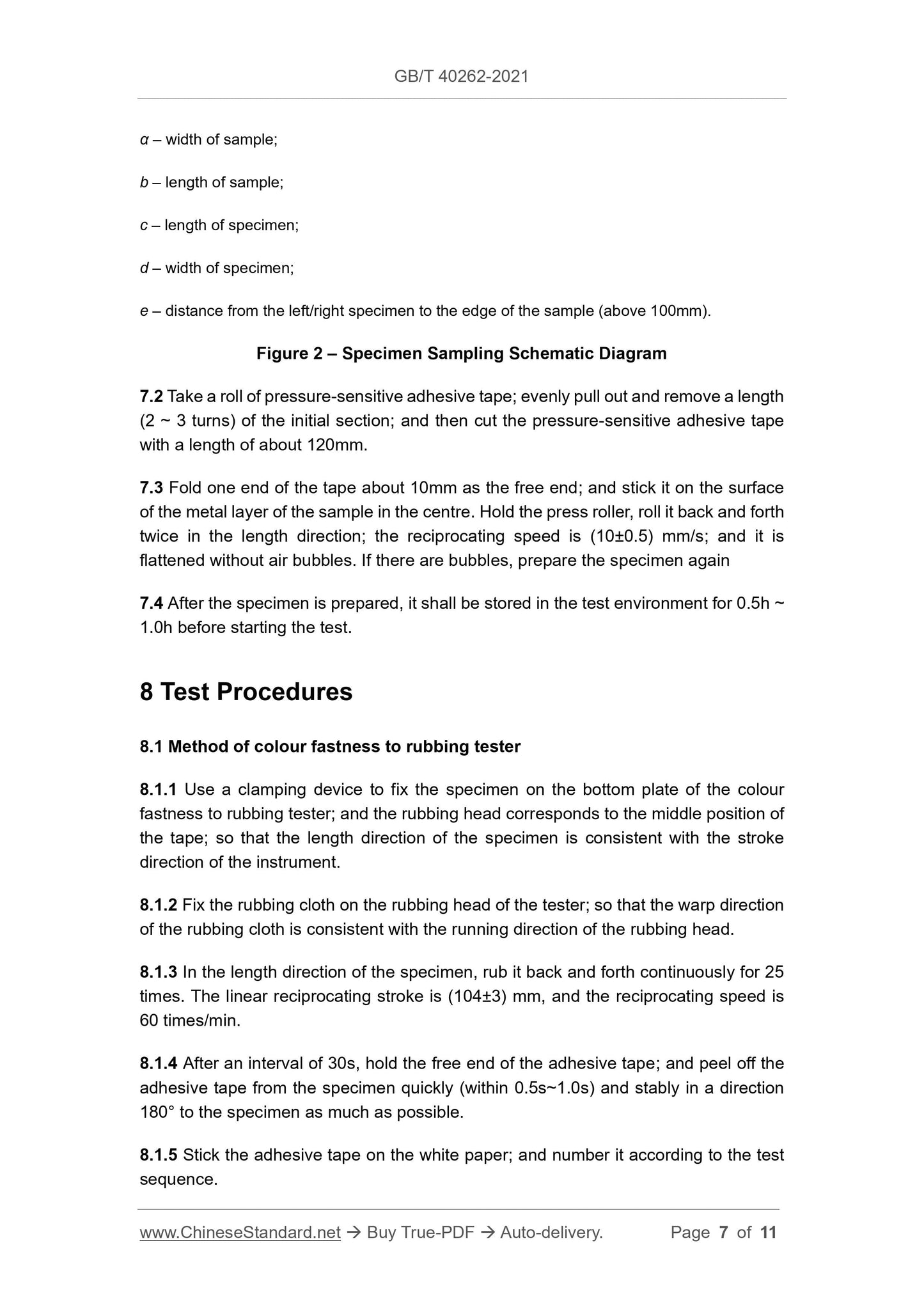

α – width of sample;

b – length of sample;

c – length of specimen;

d – width of specimen;

e – distance from the left/right specimen to the edge of the sample (above 100mm).

Figure 2 – Specimen Sampling Schematic Diagram

7.2 Take a roll of pressure-sensitive adhesive tape; evenly pull out and remove a length

(2 ~ 3 turns) of the initial section; and then cut the pressure-sensitive adhesive tape

with a length of about 120mm.

7.3 Fold one end of the tape about 10mm as the free end; and stick it on the surface

of the metal layer of the sample in the centre. Hold the press roller, roll it back and forth

twice in the length direction; the reciprocating speed is (10±0.5) mm/s; and it is

flattened without air bubbles. If there are bubbles, prepare the specimen again

7.4 After the specimen is prepared, it shall be stored in the test environment for 0.5h ~

1.0h before starting the test.

8 Test Procedures

8.1 Method of colour fastness to rubbing tester

8.1.1 Use a clamping device to fix the specimen on the bottom plate of the colour

fastness to rubbing tester; and the rubbing head corresponds to the middle position of

the tape; so that the length direction of the specimen is consistent with the stroke

direction of the instrument.

8.1.2 Fix the rubbing cloth on the rubbing head of the tester; so that the warp direction

of the rubbing cloth is consistent with the running direction of the rubbing head.

8.1.3 In the length direction of the specimen, rub it back and forth continuously for 25

times. The linear reciprocating stroke is (104±3) mm, and the reciprocating speed is

60 times/min.

8.1.4 After an interval of 30s, hold the free end of the adhesive tape; and peel off the

adhesive tape from the specimen quickly (within 0.5s~1.0s) and stably in a direction

180° to the specimen as much as possible.

8.1.5 Stick the adhesive tape on the white paper; and number it according to the test

sequence.

8.1.6 Repeat procedures 8.1.1 ~ 8.1.5 to test other specimens; and paste them on the

same piece of white paper.

8.2 Manual press roller method

8.2.1 Place the specimen with pressure-sensitive adhesive tape on the tempered flat

glass; so that the length direction of the specimen is consistent with the direction of

movement of the manual press roller; and the linear reciprocating stroke is no less than

110mm.

8.2.2 In the length direction of the specimen, use a press roller to reciprocate 10 times

on the specimen at a speed of (10±0.5) mm/s under its own weight.

8.2.3 After an interval of 30s, hold the free end of the adhesive tape; peel off the

adhesive tape quickly (within 0.5s~1.0s) and stably in a direction 180° to the specimen

as much as possible, namely, it is in the same plane with the specimen, and parallel to

the length direction of the specimen.

8.2.4 Stick the adhesive tape on the white paper; and number it according to the test

sequence.

8.2.5 Repeat procedures 8.2.1 ~ 8.2.4 to test other specimens; and paste them on the

same piece of white paper.

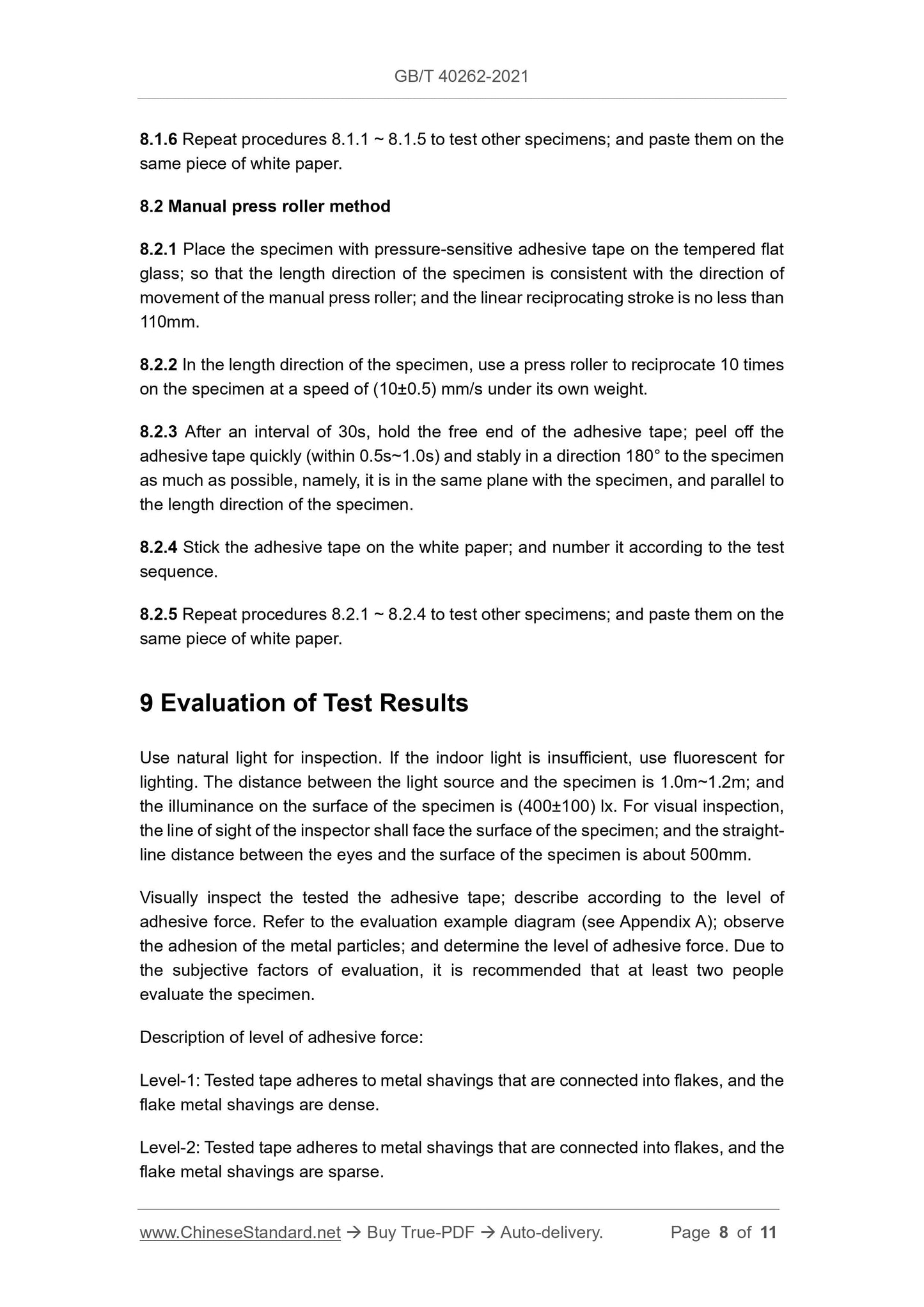

9 Evaluation of Test Results

Use natural light for inspection. If the indoor light is insufficient, use fluorescent for

lighting. The distance between the light source and the specimen is 1.0m~1.2m; and

the illuminance on the surface of the specimen is (400±100) lx. For visual inspection,

the line of sight of the inspector shall face the surface of the specimen; and the straight-

line distance between the eyes and the surface of the specimen is about 500mm.

Visually inspect the tested the adhesive tape; describe according to the level of

adhesive force. Refer to the evaluation example diagram (see Appendix A); observe

the adhesion of the metal particles; and determine the level of adhesive force. Due to

the subjective factors of evaluation, it is recommended that at least two people

evaluate the specimen.

Description of level of adhesive force:

Level-1: Tested tape adheres to metal shavings that are connected into flakes, and the

flake metal shavings are dense.

Level-2: Tested tape adheres to metal shavings that are connected into flakes, and the

flake metal shavings are sparse.

GB/T 40262-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

CCS W 04

Metal Coating Fabric – Determination of Metal Layer

Adhesive Force – Tape Method

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Principle ... 5

5 Apparatus and Materials ... 5

6 Test Environment ... 6

7 Preparation of Specimen ... 6

8 Test Procedures ... 7

9 Evaluation of Test Results ... 8

10 Test Report ... 9

Appendix A (Informative) Evaluation Example Diagram ... 10

Bibliography ... 11

Metal Coating Fabric – Determination of Metal Layer

Adhesive Force – Tape Method

1 Scope

This Document specifies the test method for measuring the metal layer adhesive force

of the metal coating fabric by the tape method, including the method of colour fastness

to rubbing tester and the manual press roller method.

This Document is applicable to all kinds of metal coating fabrics.

2 Normative References

The following documents are essential to the application of this Document. For the

dated documents, only the versions with the dates indicated are applicable to this

Document; for the undated documents, only the latest version (including all the

amendments) is applicable to this Document.

GB/T 2792 Measurement of Peel Adhesion Properties for Adhesive Tapes

GB/T 3920 Textiles - Tests for Colour Fastness - Colour Fastness to Rubbing

GB/T 20631.2 Pressure Sensitive Adhesive Tapes for Electrical Purposes - Part

2: Methods of Test

GB/T 33729 Textiles - Tests for Colour Fastness - Cotton Rubbing Cloth

3 Terms and Definitions

For the purposes of this Document, the following terms and definitions apply.

3.1 Metal coating fabric

Use physical or chemical methods to perform metal coating on the surface to make it

a fabric with specific functions.

α – width of sample;

b – length of sample;

c – length of specimen;

d – width of specimen;

e – distance from the left/right specimen to the edge of the sample (above 100mm).

Figure 2 – Specimen Sampling Schematic Diagram

7.2 Take a roll of pressure-sensitive adhesive tape; evenly pull out and remove a length

(2 ~ 3 turns) of the initial section; and then cut the pressure-sensitive adhesive tape

with a length of about 120mm.

7.3 Fold one end of the tape about 10mm as the free end; and stick it on the surface

of the metal layer of the sample in the centre. Hold the press roller, roll it back and forth

twice in the length direction; the reciprocating speed is (10±0.5) mm/s; and it is

flattened without air bubbles. If there are bubbles, prepare the specimen again

7.4 After the specimen is prepared, it shall be stored in the test environment for 0.5h ~

1.0h before starting the test.

8 Test Procedures

8.1 Method of colour fastness to rubbing tester

8.1.1 Use a clamping device to fix the specimen on the bottom plate of the colour

fastness to rubbing tester; and the rubbing head corresponds to the middle position of

the tape; so that the length direction of the specimen is consistent with the stroke

direction of the instrument.

8.1.2 Fix the rubbing cloth on the rubbing head of the tester; so that the warp direction

of the rubbing cloth is consistent with the running direction of the rubbing head.

8.1.3 In the length direction of the specimen, rub it back and forth continuously for 25

times. The linear reciprocating stroke is (104±3) mm, and the reciprocating speed is

60 times/min.

8.1.4 After an interval of 30s, hold the free end of the adhesive tape; and peel off the

adhesive tape from the specimen quickly (within 0.5s~1.0s) and stably in a direction

180° to the specimen as much as possible.

8.1.5 Stick the adhesive tape on the white paper; and number it according to the test

sequence.

8.1.6 Repeat procedures 8.1.1 ~ 8.1.5 to test other specimens; and paste them on the

same piece of white paper.

8.2 Manual press roller method

8.2.1 Place the specimen with pressure-sensitive adhesive tape on the tempered flat

glass; so that the length direction of the specimen is consistent with the direction of

movement of the manual press roller; and the linear reciprocating stroke is no less than

110mm.

8.2.2 In the length direction of the specimen, use a press roller to reciprocate 10 times

on the specimen at a speed of (10±0.5) mm/s under its own weight.

8.2.3 After an interval of 30s, hold the free end of the adhesive tape; peel off the

adhesive tape quickly (within 0.5s~1.0s) and stably in a direction 180° to the specimen

as much as possible, namely, it is in the same plane with the specimen, and parallel to

the length direction of the specimen.

8.2.4 Stick the adhesive tape on the white paper; and number it according to the test

sequence.

8.2.5 Repeat procedures 8.2.1 ~ 8.2.4 to test other specimens; and paste them on the

same piece of white paper.

9 Evaluation of Test Results

Use natural light for inspection. If the indoor light is insufficient, use fluorescent for

lighting. The distance between the light source and the specimen is 1.0m~1.2m; and

the illuminance on the surface of the specimen is (400±100) lx. For visual inspection,

the line of sight of the inspector shall face the surface of the specimen; and the straight-

line distance between the eyes and the surface of the specimen is about 500mm.

Visually inspect the tested the adhesive tape; describe according to the level of

adhesive force. Refer to the evaluation example diagram (see Appendix A); observe

the adhesion of the metal particles; and determine the level of adhesive force. Due to

the subjective factors of evaluation, it is recommended that at least two people

evaluate the specimen.

Description of level of adhesive force:

Level-1: Tested tape adheres to metal shavings that are connected into flakes, and the

flake metal shavings are dense.

Level-2: Tested tape adheres to metal shavings that are connected into flakes, and the

flake metal shavings are sparse.

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 40262-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 40262-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 40262-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

CCS W 04

Metal Coating Fabric – Determination of Metal Layer

Adhesive Force – Tape Method

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Principle ... 5

5 Apparatus and Materials ... 5

6 Test Environment ... 6

7 Preparation of Specimen ... 6

8 Test Procedures ... 7

9 Evaluation of Test Results ... 8

10 Test Report ... 9

Appendix A (Informative) Evaluation Example Diagram ... 10

Bibliography ... 11

Metal Coating Fabric – Determination of Metal Layer

Adhesive Force – Tape Method

1 Scope

This Document specifies the test method for measuring the metal layer adhesive force

of the metal coating fabric by the tape method, including the method of colour fastness

to rubbing tester and the manual press roller method.

This Document is applicable to all kinds of metal coating fabrics.

2 Normative References

The following documents are essential to the application of this Document. For the

dated documents, only the versions with the dates indicated are applicable to this

Document; for the undated documents, only the latest version (including all the

amendments) is applicable to this Document.

GB/T 2792 Measurement of Peel Adhesion Properties for Adhesive Tapes

GB/T 3920 Textiles - Tests for Colour Fastness - Colour Fastness to Rubbing

GB/T 20631.2 Pressure Sensitive Adhesive Tapes for Electrical Purposes - Part

2: Methods of Test

GB/T 33729 Textiles - Tests for Colour Fastness - Cotton Rubbing Cloth

3 Terms and Definitions

For the purposes of this Document, the following terms and definitions apply.

3.1 Metal coating fabric

Use physical or chemical methods to perform metal coating on the surface to make it

a fabric with specific functions.

α – width of sample;

b – length of sample;

c – length of specimen;

d – width of specimen;

e – distance from the left/right specimen to the edge of the sample (above 100mm).

Figure 2 – Specimen Sampling Schematic Diagram

7.2 Take a roll of pressure-sensitive adhesive tape; evenly pull out and remove a length

(2 ~ 3 turns) of the initial section; and then cut the pressure-sensitive adhesive tape

with a length of about 120mm.

7.3 Fold one end of the tape about 10mm as the free end; and stick it on the surface

of the metal layer of the sample in the centre. Hold the press roller, roll it back and forth

twice in the length direction; the reciprocating speed is (10±0.5) mm/s; and it is

flattened without air bubbles. If there are bubbles, prepare the specimen again

7.4 After the specimen is prepared, it shall be stored in the test environment for 0.5h ~

1.0h before starting the test.

8 Test Procedures

8.1 Method of colour fastness to rubbing tester

8.1.1 Use a clamping device to fix the specimen on the bottom plate of the colour

fastness to rubbing tester; and the rubbing head corresponds to the middle position of

the tape; so that the length direction of the specimen is consistent with the stroke

direction of the instrument.

8.1.2 Fix the rubbing cloth on the rubbing head of the tester; so that the warp direction

of the rubbing cloth is consistent with the running direction of the rubbing head.

8.1.3 In the length direction of the specimen, rub it back and forth continuously for 25

times. The linear reciprocating stroke is (104±3) mm, and the reciprocating speed is

60 times/min.

8.1.4 After an interval of 30s, hold the free end of the adhesive tape; and peel off the

adhesive tape from the specimen quickly (within 0.5s~1.0s) and stably in a direction

180° to the specimen as much as possible.

8.1.5 Stick the adhesive tape on the white paper; and number it according to the test

sequence.

8.1.6 Repeat procedures 8.1.1 ~ 8.1.5 to test other specimens; and paste them on the

same piece of white paper.

8.2 Manual press roller method

8.2.1 Place the specimen with pressure-sensitive adhesive tape on the tempered flat

glass; so that the length direction of the specimen is consistent with the direction of

movement of the manual press roller; and the linear reciprocating stroke is no less than

110mm.

8.2.2 In the length direction of the specimen, use a press roller to reciprocate 10 times

on the specimen at a speed of (10±0.5) mm/s under its own weight.

8.2.3 After an interval of 30s, hold the free end of the adhesive tape; peel off the

adhesive tape quickly (within 0.5s~1.0s) and stably in a direction 180° to the specimen

as much as possible, namely, it is in the same plane with the specimen, and parallel to

the length direction of the specimen.

8.2.4 Stick the adhesive tape on the white paper; and number it according to the test

sequence.

8.2.5 Repeat procedures 8.2.1 ~ 8.2.4 to test other specimens; and paste them on the

same piece of white paper.

9 Evaluation of Test Results

Use natural light for inspection. If the indoor light is insufficient, use fluorescent for

lighting. The distance between the light source and the specimen is 1.0m~1.2m; and

the illuminance on the surface of the specimen is (400±100) lx. For visual inspection,

the line of sight of the inspector shall face the surface of the specimen; and the straight-

line distance between the eyes and the surface of the specimen is about 500mm.

Visually inspect the tested the adhesive tape; describe according to the level of

adhesive force. Refer to the evaluation example diagram (see Appendix A); observe

the adhesion of the metal particles; and determine the level of adhesive force. Due to

the subjective factors of evaluation, it is recommended that at least two people

evaluate the specimen.

Description of level of adhesive force:

Level-1: Tested tape adheres to metal shavings that are connected into flakes, and the

flake metal shavings are dense.

Level-2: Tested tape adheres to metal shavings that are connected into flakes, and the

flake metal shavings are sparse.

GB/T 40262-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

CCS W 04

Metal Coating Fabric – Determination of Metal Layer

Adhesive Force – Tape Method

ISSUED ON: MAY 21, 2021

IMPLEMENTED ON: DECEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Principle ... 5

5 Apparatus and Materials ... 5

6 Test Environment ... 6

7 Preparation of Specimen ... 6

8 Test Procedures ... 7

9 Evaluation of Test Results ... 8

10 Test Report ... 9

Appendix A (Informative) Evaluation Example Diagram ... 10

Bibliography ... 11

Metal Coating Fabric – Determination of Metal Layer

Adhesive Force – Tape Method

1 Scope

This Document specifies the test method for measuring the metal layer adhesive force

of the metal coating fabric by the tape method, including the method of colour fastness

to rubbing tester and the manual press roller method.

This Document is applicable to all kinds of metal coating fabrics.

2 Normative References

The following documents are essential to the application of this Document. For the

dated documents, only the versions with the dates indicated are applicable to this

Document; for the undated documents, only the latest version (including all the

amendments) is applicable to this Document.

GB/T 2792 Measurement of Peel Adhesion Properties for Adhesive Tapes

GB/T 3920 Textiles - Tests for Colour Fastness - Colour Fastness to Rubbing

GB/T 20631.2 Pressure Sensitive Adhesive Tapes for Electrical Purposes - Part

2: Methods of Test

GB/T 33729 Textiles - Tests for Colour Fastness - Cotton Rubbing Cloth

3 Terms and Definitions

For the purposes of this Document, the following terms and definitions apply.

3.1 Metal coating fabric

Use physical or chemical methods to perform metal coating on the surface to make it

a fabric with specific functions.

α – width of sample;

b – length of sample;

c – length of specimen;

d – width of specimen;

e – distance from the left/right specimen to the edge of the sample (above 100mm).

Figure 2 – Specimen Sampling Schematic Diagram

7.2 Take a roll of pressure-sensitive adhesive tape; evenly pull out and remove a length

(2 ~ 3 turns) of the initial section; and then cut the pressure-sensitive adhesive tape

with a length of about 120mm.

7.3 Fold one end of the tape about 10mm as the free end; and stick it on the surface

of the metal layer of the sample in the centre. Hold the press roller, roll it back and forth

twice in the length direction; the reciprocating speed is (10±0.5) mm/s; and it is

flattened without air bubbles. If there are bubbles, prepare the specimen again

7.4 After the specimen is prepared, it shall be stored in the test environment for 0.5h ~

1.0h before starting the test.

8 Test Procedures

8.1 Method of colour fastness to rubbing tester

8.1.1 Use a clamping device to fix the specimen on the bottom plate of the colour

fastness to rubbing tester; and the rubbing head corresponds to the middle position of

the tape; so that the length direction of the specimen is consistent with the stroke

direction of the instrument.

8.1.2 Fix the rubbing cloth on the rubbing head of the tester; so that the warp direction

of the rubbing cloth is consistent with the running direction of the rubbing head.

8.1.3 In the length direction of the specimen, rub it back and forth continuously for 25

times. The linear reciprocating stroke is (104±3) mm, and the reciprocating speed is

60 times/min.

8.1.4 After an interval of 30s, hold the free end of the adhesive tape; and peel off the

adhesive tape from the specimen quickly (within 0.5s~1.0s) and stably in a direction

180° to the specimen as much as possible.

8.1.5 Stick the adhesive tape on the white paper; and number it according to the test

sequence.

8.1.6 Repeat procedures 8.1.1 ~ 8.1.5 to test other specimens; and paste them on the

same piece of white paper.

8.2 Manual press roller method

8.2.1 Place the specimen with pressure-sensitive adhesive tape on the tempered flat

glass; so that the length direction of the specimen is consistent with the direction of

movement of the manual press roller; and the linear reciprocating stroke is no less than

110mm.

8.2.2 In the length direction of the specimen, use a press roller to reciprocate 10 times

on the specimen at a speed of (10±0.5) mm/s under its own weight.

8.2.3 After an interval of 30s, hold the free end of the adhesive tape; peel off the

adhesive tape quickly (within 0.5s~1.0s) and stably in a direction 180° to the specimen

as much as possible, namely, it is in the same plane with the specimen, and parallel to

the length direction of the specimen.

8.2.4 Stick the adhesive tape on the white paper; and number it according to the test

sequence.

8.2.5 Repeat procedures 8.2.1 ~ 8.2.4 to test other specimens; and paste them on the

same piece of white paper.

9 Evaluation of Test Results

Use natural light for inspection. If the indoor light is insufficient, use fluorescent for

lighting. The distance between the light source and the specimen is 1.0m~1.2m; and

the illuminance on the surface of the specimen is (400±100) lx. For visual inspection,

the line of sight of the inspector shall face the surface of the specimen; and the straight-

line distance between the eyes and the surface of the specimen is about 500mm.

Visually inspect the tested the adhesive tape; describe according to the level of

adhesive force. Refer to the evaluation example diagram (see Appendix A); observe

the adhesion of the metal particles; and determine the level of adhesive force. Due to

the subjective factors of evaluation, it is recommended that at least two people

evaluate the specimen.

Description of level of adhesive force:

Level-1: Tested tape adheres to metal shavings that are connected into flakes, and the

flake metal shavings are dense.

Level-2: Tested tape adheres to metal shavings that are connected into flakes, and the

flake metal shavings are sparse.

Share