1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 40316-2021 English PDF (GBT40316-2021)

GB/T 40316-2021 English PDF (GBT40316-2021)

Regular price

$260.00 USD

Regular price

Sale price

$260.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 40316-2021

Historical versions: GB/T 40316-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40316-2021: Welded high strength shaped and round steel tubes for automobile structure

GB/T 40316-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

CCS H 48

Welded High Strength Shaped and Round Steel Tubes

for Automobile Structure

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 6

4 Classification and Code ... 6

5 Ordering Content ... 7

6 Size, Shape, Weight and Allowable Deviation ... 7

7 Technical Requirements ... 12

8 Test Methods ... 16

9 Inspection Rules ... 17

10 Packaging, Marking and Quality Certificate ... 18

Appendix A (Informative) Sectional Diagram of the Shaped Steel Tube ... 19

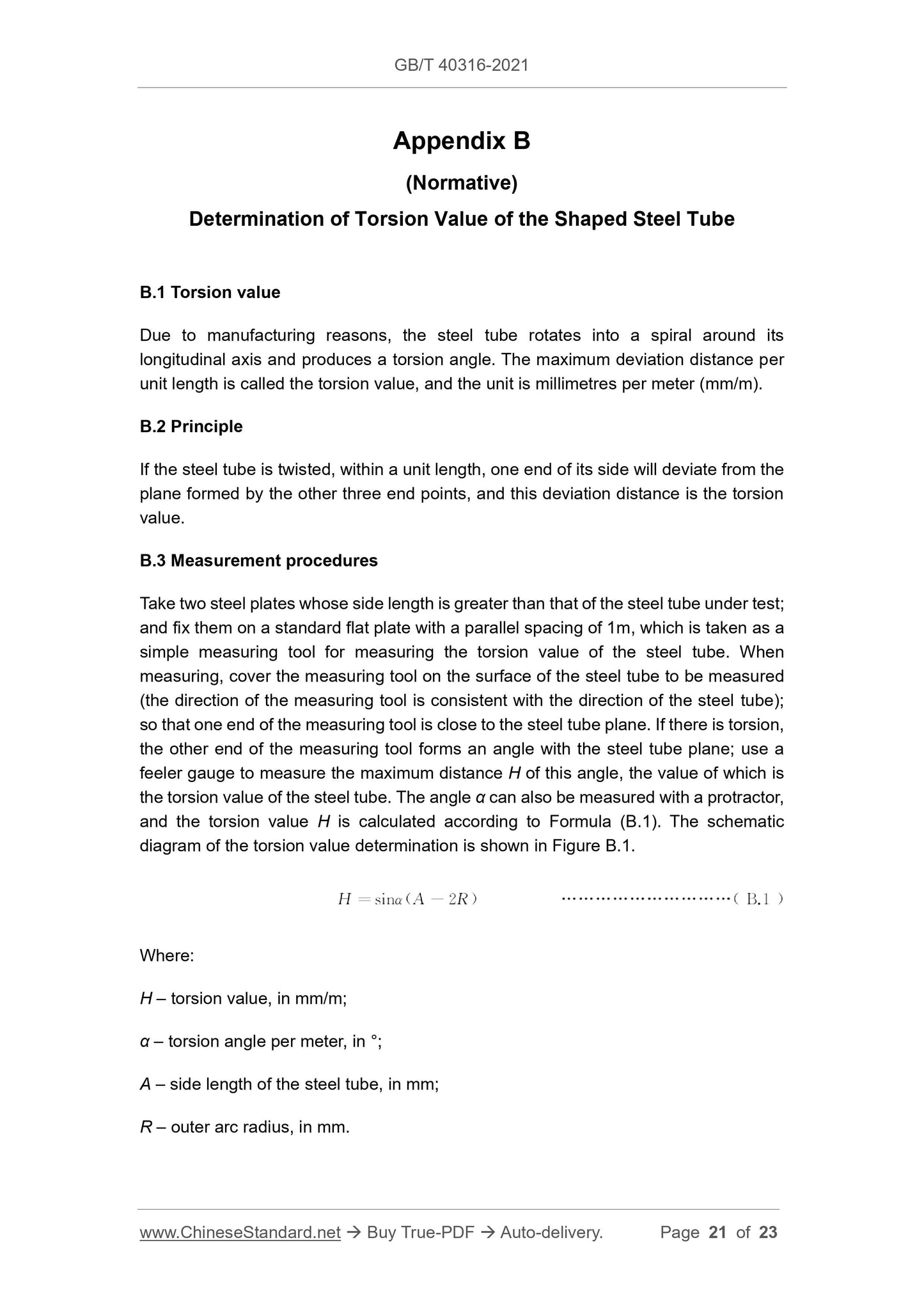

Appendix B (Normative) Determination of Torsion Value of the Shaped Steel

Tube ... 21

Appendix C (Normative) Flattening Test Method of the Shaped Steel Tube .. 23

Welded High Strength Shaped and Round Steel Tubes

for Automobile Structure

1 Scope

This Document specifies the classification and code, ordering content, size, shape,

weight and allowable deviations, technical requirements, test methods, inspection

rules, packaging, markings and quality certificates of the welded high-strength shaped

and round steel tubes for automobile structures.

This Document is applicable to the welded high-strength shaped and round welded

steel tubes for automobile structures (hereinafter referred to as steel tubes).

2 Normative References

The provisions in following documents become the provisions of this Document

through reference in this Document. For the dated documents, only the versions with

the dates indicated are applicable to this Document; for the undated documents, only

the latest version (including all the amendments) is applicable to this Document.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel Products

GB/T 223.9 Iron Steel and Alloy - Determination of Aluminium Content – Chrome

Azurol S Photometric Method

GB/T 223.17 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Photometric Method for the Determination of Titanium

Content

GB/T 223.26 Iron, Steel and Alloy - Determination of Molybdenum Content - The

Thiocyanate Spectrophotometric Method

GB/T 223.40 Iron, Steel and Alloy - Determination of Niobium Content by the

Sulphochlorophenol S Spectrophotometric Method

GB/T 223.59 Iron, Steel and Alloy - Determination of Phosphorus Content -

Bismuth Phosphomolybdate Blue Spectrophotometric Method and Antimony

Phosphomolybdate Blue Spectrophotometric Method

GB/T 223.60 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Perchloric Acid Dehydration Gravimetric Method for the Determination of Silicon

GB/T 10561-2005 Steel - Determination of Content of Nonmetallic Inclusions -

Micrographic Method Using Standards Diagrams

GB/T 12606-2016 Automated Full Peripheral Flux Leakage Testing of Seamless

and Welded (Except Submerged Arc-Welded) Ferromagnetic Steel Tubes for the

Detection of Longitudinal and/or Transverse Imperfections

GB/T 20066 Steel and Iron-Sampling and Preparation of Samples for the

Determination of Chemical Composition

GB/T 20123 Steel and Iron—Determination of Total Carbon and Sulfur Content

Infrared Absorption Method after Combustion in an Induction Furnace (Routine

Method)

GB/T 20125 Low-Alloy Steel - Determination of Multi-Element Contents -

Inductively Coupled Plasma Atomic Emission Spectrometric Method

GB/T 21835 Dimensions and Masses per Unit Length of Welded Steel Pipes

GB/T 30062 Terminology of Steel Pipes and Tubes

3 Terms and Definitions

For the purposes of this Document, the terms and definitions given in GB/T 30062

apply.

4 Classification and Code

4.1 Naming method of steel grade

Steel grades are named according to the specified minimum upper yield strength

values, which are divided into 355, 380, 420, 460, 500, 550, 600, 650, 700.

4.2 Classification and code of steel tube precision level

4.2.1 The steel tubes are classified and coded according to the precision level of the

outer diameter (side length) as follows:

a) Ordinary level: PD (P A/B).a;

b) Higher-level: PD (P A/B).b;

c) Advanced level: PD(P A/B).c.

4.2.2 The steel tubes are classified and coded according to the wall thickness precision

level as follows:

a) Ordinary level: PT.a;

b) Advanced level: PT.c.

4.2.3 The steel tubes are classified and coded according to the precision level of

bending degree are as follows:

a) Ordinary level: PS.a;

b) Higher-level: PS.b;

c) Advanced level: PS.c.

4.2.4 The steel tubes are classified and coded according to the prevision level of side

roughness:

a) Ordinary level: PF.a;

b) Advanced level: PF.c.

5 Ordering Content

The contract or order for ordering steel tubes according to this Document shall include

the following:

a) The number of this Document;

b) Product name;

c) Steel designation (the designation determined through the negotiation between

the supplier and the purchaser on the steel grade);

d) Size specifications (for shaped steel tubes: side length × side length × wall

thickness; round steel tubes: nominal outer diameter × nominal wall thickness,

in millimetres);

e) The ordered quantity (total weight or total length);

f) Special requirements.

6 Size, Shape, Weight and Allowable Deviation

6.1 Dimensions and allowable deviation

6.7.1 Delivery weight

Steel tubes are delivered according to actual weight. If it is stated in the contract, the

steel tubes can also be delivered according to the theoretical weight.

6.7.2 Calculation of theoretical weight

With the density of steel of 7.85kg/dm3, the calculation of the theoretical weight per

unit length of round steel tubes shall comply with the provisions of GB/T 21835; and

the theoretical weight per unit length of the shaped steel tubes shall comply with the

provisions of GB/T 6726.

6.7.3 Allowable deviation of weight

The allowable deviation between the actual weight and the theoretical weight of the

delivered steel tube is ±5%. According to the request of the purchaser, after negotiation

between the supplier and the purchaser and indicated in the contract, other allowable

deviations of weight can be specified.

7 Technical Requirements

7.1 Designation and chemical composition of steel

7.1.1 The steel grade and chemical composition (melting analysis) of the steel shall

comply with the provisions of Table 8. The supplier and the purchaser shall determine

the steel designation through negotiation on the steel grade when ordering. According

to the requirements of the buyer, after negotiation between the supplier and the

purchaser and indicated in the contract, steel tubes of other strength grades and/or

chemical compositions can be supplied.

7.1.2 The allowable deviation of the chemical composition of the finished steel tube

shall comply with the provisions of GB/T 222.

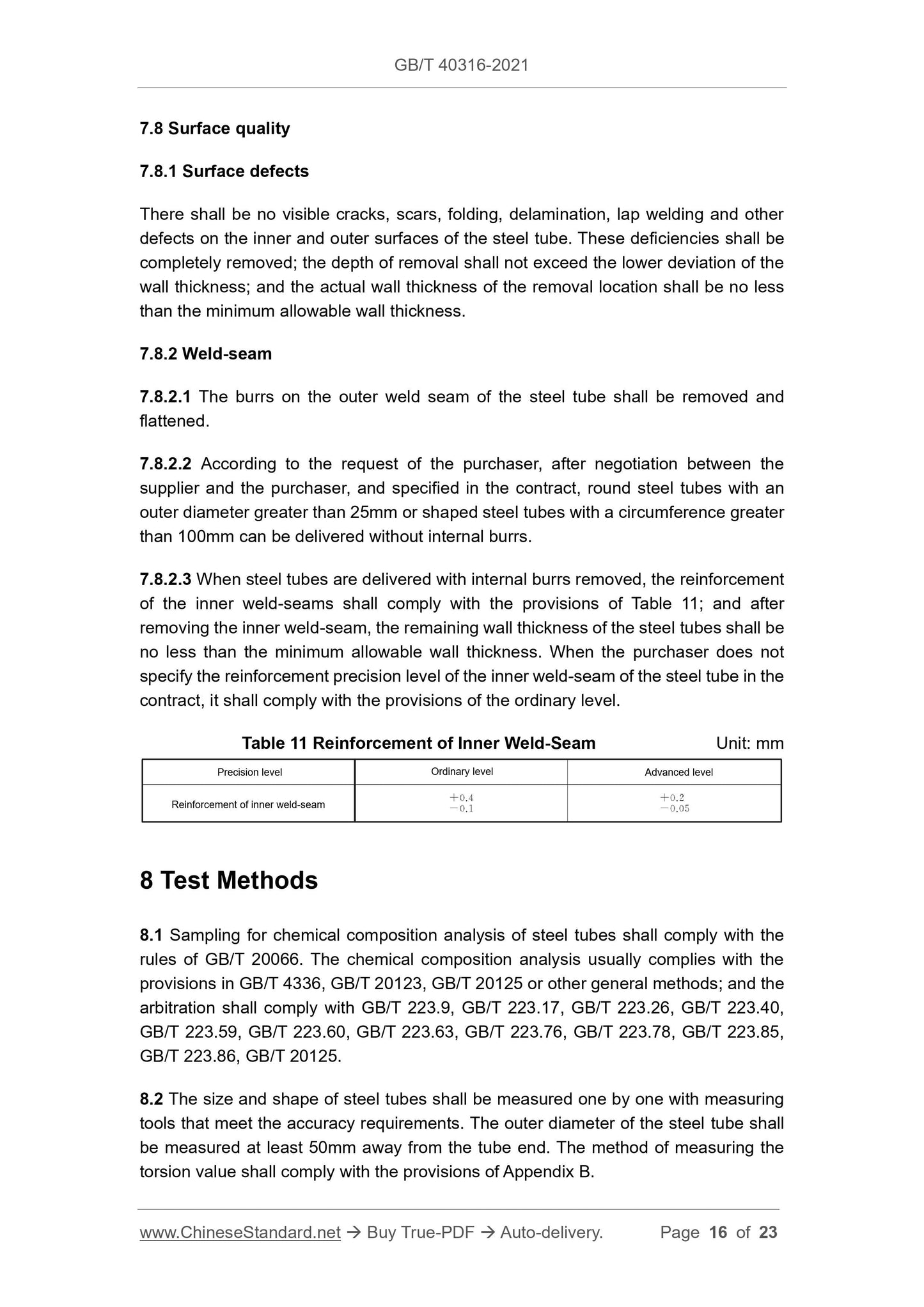

7.6.1 Flattening

7.6.1.1 The round steel tube shall be subjected to a flattening test. The length of the

flattened sample shall be no less than 63.5mm. The weld-seams of the two samples

shall be located at 90° and 0° from the direction of force. The sample shall be pressed

until the distance between the two plates is 2/3 of the outer diameter of the steel tube.

After the test, the sample should not show cracks or clefts.

7.6.1.2 Shaped steel tubes shall be subjecte...

Get QUOTATION in 1-minute: Click GB/T 40316-2021

Historical versions: GB/T 40316-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40316-2021: Welded high strength shaped and round steel tubes for automobile structure

GB/T 40316-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

CCS H 48

Welded High Strength Shaped and Round Steel Tubes

for Automobile Structure

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 6

4 Classification and Code ... 6

5 Ordering Content ... 7

6 Size, Shape, Weight and Allowable Deviation ... 7

7 Technical Requirements ... 12

8 Test Methods ... 16

9 Inspection Rules ... 17

10 Packaging, Marking and Quality Certificate ... 18

Appendix A (Informative) Sectional Diagram of the Shaped Steel Tube ... 19

Appendix B (Normative) Determination of Torsion Value of the Shaped Steel

Tube ... 21

Appendix C (Normative) Flattening Test Method of the Shaped Steel Tube .. 23

Welded High Strength Shaped and Round Steel Tubes

for Automobile Structure

1 Scope

This Document specifies the classification and code, ordering content, size, shape,

weight and allowable deviations, technical requirements, test methods, inspection

rules, packaging, markings and quality certificates of the welded high-strength shaped

and round steel tubes for automobile structures.

This Document is applicable to the welded high-strength shaped and round welded

steel tubes for automobile structures (hereinafter referred to as steel tubes).

2 Normative References

The provisions in following documents become the provisions of this Document

through reference in this Document. For the dated documents, only the versions with

the dates indicated are applicable to this Document; for the undated documents, only

the latest version (including all the amendments) is applicable to this Document.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel Products

GB/T 223.9 Iron Steel and Alloy - Determination of Aluminium Content – Chrome

Azurol S Photometric Method

GB/T 223.17 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Photometric Method for the Determination of Titanium

Content

GB/T 223.26 Iron, Steel and Alloy - Determination of Molybdenum Content - The

Thiocyanate Spectrophotometric Method

GB/T 223.40 Iron, Steel and Alloy - Determination of Niobium Content by the

Sulphochlorophenol S Spectrophotometric Method

GB/T 223.59 Iron, Steel and Alloy - Determination of Phosphorus Content -

Bismuth Phosphomolybdate Blue Spectrophotometric Method and Antimony

Phosphomolybdate Blue Spectrophotometric Method

GB/T 223.60 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Perchloric Acid Dehydration Gravimetric Method for the Determination of Silicon

GB/T 10561-2005 Steel - Determination of Content of Nonmetallic Inclusions -

Micrographic Method Using Standards Diagrams

GB/T 12606-2016 Automated Full Peripheral Flux Leakage Testing of Seamless

and Welded (Except Submerged Arc-Welded) Ferromagnetic Steel Tubes for the

Detection of Longitudinal and/or Transverse Imperfections

GB/T 20066 Steel and Iron-Sampling and Preparation of Samples for the

Determination of Chemical Composition

GB/T 20123 Steel and Iron—Determination of Total Carbon and Sulfur Content

Infrared Absorption Method after Combustion in an Induction Furnace (Routine

Method)

GB/T 20125 Low-Alloy Steel - Determination of Multi-Element Contents -

Inductively Coupled Plasma Atomic Emission Spectrometric Method

GB/T 21835 Dimensions and Masses per Unit Length of Welded Steel Pipes

GB/T 30062 Terminology of Steel Pipes and Tubes

3 Terms and Definitions

For the purposes of this Document, the terms and definitions given in GB/T 30062

apply.

4 Classification and Code

4.1 Naming method of steel grade

Steel grades are named according to the specified minimum upper yield strength

values, which are divided into 355, 380, 420, 460, 500, 550, 600, 650, 700.

4.2 Classification and code of steel tube precision level

4.2.1 The steel tubes are classified and coded according to the precision level of the

outer diameter (side length) as follows:

a) Ordinary level: PD (P A/B).a;

b) Higher-level: PD (P A/B).b;

c) Advanced level: PD(P A/B).c.

4.2.2 The steel tubes are classified and coded according to the wall thickness precision

level as follows:

a) Ordinary level: PT.a;

b) Advanced level: PT.c.

4.2.3 The steel tubes are classified and coded according to the precision level of

bending degree are as follows:

a) Ordinary level: PS.a;

b) Higher-level: PS.b;

c) Advanced level: PS.c.

4.2.4 The steel tubes are classified and coded according to the prevision level of side

roughness:

a) Ordinary level: PF.a;

b) Advanced level: PF.c.

5 Ordering Content

The contract or order for ordering steel tubes according to this Document shall include

the following:

a) The number of this Document;

b) Product name;

c) Steel designation (the designation determined through the negotiation between

the supplier and the purchaser on the steel grade);

d) Size specifications (for shaped steel tubes: side length × side length × wall

thickness; round steel tubes: nominal outer diameter × nominal wall thickness,

in millimetres);

e) The ordered quantity (total weight or total length);

f) Special requirements.

6 Size, Shape, Weight and Allowable Deviation

6.1 Dimensions and allowable deviation

6.7.1 Delivery weight

Steel tubes are delivered according to actual weight. If it is stated in the contract, the

steel tubes can also be delivered according to the theoretical weight.

6.7.2 Calculation of theoretical weight

With the density of steel of 7.85kg/dm3, the calculation of the theoretical weight per

unit length of round steel tubes shall comply with the provisions of GB/T 21835; and

the theoretical weight per unit length of the shaped steel tubes shall comply with the

provisions of GB/T 6726.

6.7.3 Allowable deviation of weight

The allowable deviation between the actual weight and the theoretical weight of the

delivered steel tube is ±5%. According to the request of the purchaser, after negotiation

between the supplier and the purchaser and indicated in the contract, other allowable

deviations of weight can be specified.

7 Technical Requirements

7.1 Designation and chemical composition of steel

7.1.1 The steel grade and chemical composition (melting analysis) of the steel shall

comply with the provisions of Table 8. The supplier and the purchaser shall determine

the steel designation through negotiation on the steel grade when ordering. According

to the requirements of the buyer, after negotiation between the supplier and the

purchaser and indicated in the contract, steel tubes of other strength grades and/or

chemical compositions can be supplied.

7.1.2 The allowable deviation of the chemical composition of the finished steel tube

shall comply with the provisions of GB/T 222.

7.6.1 Flattening

7.6.1.1 The round steel tube shall be subjected to a flattening test. The length of the

flattened sample shall be no less than 63.5mm. The weld-seams of the two samples

shall be located at 90° and 0° from the direction of force. The sample shall be pressed

until the distance between the two plates is 2/3 of the outer diameter of the steel tube.

After the test, the sample should not show cracks or clefts.

7.6.1.2 Shaped steel tubes shall be subjecte...

Share