1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 42391-2023 English PDF (GB/T42391-2023)

GB/T 42391-2023 English PDF (GB/T42391-2023)

Regular price

$260.00

Regular price

Sale price

$260.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 42391-2023: Electrolyte for lead acid storage battery

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 42391-2023 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 42391-2023

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 42391-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 29.220.20

CCS K 84

Electrolyte for Lead Acid Storage Battery

(IEC 62877-1:2016, Electrolyte and Water for Vented Lead Acid Accumulators - Part

1: Requirements for Electrolyte, MOD)

ISSUED ON: MARCH 17, 2023

IMPLEMENTED ON: OCTOBER 1, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative References ... 6

3 Terms and Definitions ... 7

4 Requirements ... 7

5 Determination Method ... 8

6 Inspection Rules ... 21

7 Marking, Packaging, Transportation and Storage ... 22

8 Safety Requirements ... 22

Appendix A (informative) Comparison of Concentration and Density of Sulfuric Acid

... 23

Electrolyte for Lead Acid Storage Battery

1 Scope

This document specifies the requirements, determination methods, inspection rules, marking,

packaging, transportation, storage and safety requirements of the electrolyte (including

colloidal electrolyte) for lead acid storage battery.

This document is applicable to the electrolyte (including colloidal electrolyte) for lead acid

storage battery.

This document does not apply to the electrolyte in lead acid storage battery after disassembly.

2 Normative References

The contents of the following documents constitute indispensable clauses of this document

through the normative references in the text. In terms of references with a specified date, only

versions with a specified date are applicable to this document. In terms of references without a

specified date, the latest version (including all the modifications) is applicable to this document.

GB 190 Packing Symbol of Dangerous Goods

GB/T 622 Chemical Reagent - Hydrochloric Acid (GB/T 622-2006, ISO 6353-2:1983, NEQ)

GB/T 625 Chemical Reagent - Sulfuric Acid (GB/T 625-2007, ISO 6353-2:1983, NEQ)

GB/T 626 Chemical Reagent - Nitric Acid (GB/T 626-2006, ISO 6353-2:1983, NEQ)

GB/T 629 Chemical Reagent - Sodium Hydroxide

GB/T 643 Chemical Reagent - Potassium Permanganate (GB/T 643-2008, ISO 6353-2:1983,

NEQ)

GB/T 661 Chemical Reagent - Ammonium Iron (II) Sulfate Hexahydrate (GB/T 661-2011, ISO

6353-3:1987, NEQ)

GB/T 670 Chemical Reagent - Silver Nitrate (GB/T 670-2007, ISO 6353-2:1983, NEQ)

GB 1253 Working Chemical - Sodium Chloride

GB 1254 Working Chemical - Sodium Oxalate

GB 1257 Working Chemical - Potassium Hydrogen Phthalate

GB 12595 Working Chemical - Silver Nitrate

In a brightly lit room, conduct a visual inspection on whether the surface of the sample is

colorless and transparent.

5.2.2 Density

5.2.2.1 Instrument

Density meter: with a division value of 0.001 g/cm3.

5.2.2.2 Determination steps

Take 250 mL of the specimen in 5.1.2.1, stir it well, then, transfer it into a 250 mL measuring

cylinder; put it in a water bath at 25 C, let it stand for 20 min. Gently put the density meter

into the specimen, wait until it stops sinking, visually observe the tangent line of the concave

surface of the liquid, and read the value on the density meter.

The test result shall retain three decimal places.

5.2.3 Determination of sulfuric acid content

5.2.3.1 Principle

Weigh-take or absorb a certain amount of specimen, and use methyl red-methylene blue as a

mixed indicator. The end point of titration is pH = 5.4, and the solution turns from purple red

to gray green, and the color variation is sensitive and easy to judge.

5.2.3.2 Reagents and solutions

The reagents and solutions required for the test are as follows:

---Methyl red-methylene blue mixed indicator: one portion of 0.2% methyl red ethanol

solution is mixed with one portion of 0.1% methylene blue ethanol;

---Potassium hydrogen phthalate (GB 1257): benchmark reagent;

---Phenolphthalein: analytically pure, 0.1% ethanol solution;

---Sodium hydroxide (GB/T 629): analytically pure, standard solution of C (NaOH) = 0.5

mol/L.

a) Preparation: prepare a saturated solution of sodium hydroxide and store it in a plastic

bottle, seal it and place it, until the solution becomes clear. Take 26 mL of the

supernatant and place it in 1,000 mL of carbon dioxide-free water, and mix it well;

b) Calibration: weigh-take 3 g (accurate to 0.0001 g) of benchmark potassium hydrogen

phthalate dried at 105 C ~ 110 C for 2 h, put it in a 250 mL conical flask, add 80

mL of water and heat it to boiling. Dropwise add 2 drops ~ 3 drops of 0.1%

phenolphthalein indicator, and use sodium hydroxide solution of C (NaOH) = 0.5

mol/L to titrate it, until the solution turns pink, which is the end point.

5.2.4 Determination of reduced potassium permanganate (calculated by O) content

5.2.4.1 Principle

Inject excess potassium permanganate solution into the specimen to thoroughly oxidize the

reducing substance; use ferrous ammonium sulfate solution to perform back titration, so as to

obtain the content of reduced potassium permanganate.

5.2.4.2 Reagents and solutions

The reagents and solutions required for the test are as follows:

---Sulfuric acid (GB/T 625): analytically pure, 1 + 1 solution and solution with a density

of 1.200 g/cm3;

NOTE: see Appendix A for the comparison of the concentration and density of sulfuric acid.

---Sodium oxalate (GB 1254): benchmark reagent;

---Ferrous ammonium sulfate solution (GB/T 661): analytically pure, C [(NH4)2Fe(SO4)2]

= 0.01 mol/L. Weigh-take 4 g of (NH4)2Fe(SO4)2 6 H2O and dissolve in 100 mL of 1

+ 1 sulfuric acid solution, and use water to dilute to 1,000 mL;

---Potassium permanganate standard solution (GB/T 643): analytically pure, C (1/5

KMnO4) = 0.1 mol/L. This standard solution is used to prepare a standard solution of

C (1/5 KMnO4) = 0.01 mol/L.

a) Preparation: weigh-take 3.30 g of potassium permanganate, dissolve it in 1,050 mL

of water, slowly boil it for 20 min ~ 30 min and place it in the dark for a week. Use

glass wool to filter it, and store the filtrate in a brown bottle with a ground stopper.

b) Calibration: weigh-take 0.2 g of benchmark sodium oxalate dried at 105 C ~ 110 C

for 2 h, accurate to 0.0001 g, and dissolve it in 50 mL of pure water. Add 8 mL of

concentrated sulfuric acid, use potassium permanganate standard solution of C (1/5

KMnO4) = 0.1 mol/L to titrate it, and when it approaches the end point, heat to 70 C

~ 80 C, continue titration, until the solution turns pink and maintains for 30 s,

meanwhile, carry out a blank test.

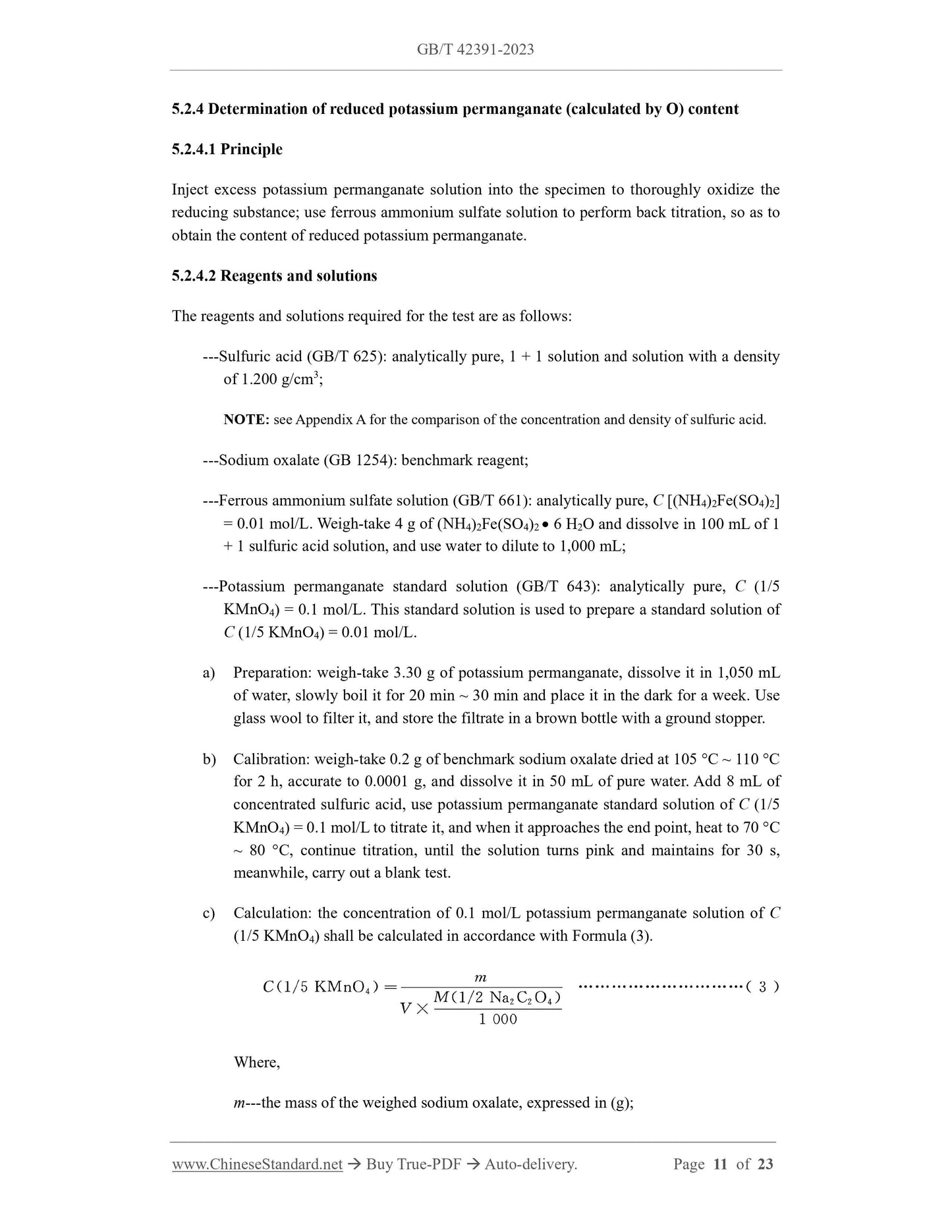

c) Calculation: the concentration of 0.1 mol/L potassium permanganate solution of C

(1/5 KMnO4) shall be calculated in accordance with Formula (3).

Where,

m---the mass of the weighed sodium oxalate, expressed in (g);

V---the volume of potassium permanganate solution used, expressed in (mL);

M (1/2 Na2C2O4)---the mass of 0.5 mol of sodium oxalate, expressed in (g/mol).

d) Preparation of 0.01 mol/L potassium permanganate standard solution: use pure water

to accurately dilute the prepared potassium permanganate standard solution of C (1/5

KMnO4) = 0.1 mol/L to C (1/5 KMnO4) = 0.01 mol/L.

5.2.4.3 Instruments

Commonly used laboratory instruments: 250 mL conical flask and burette, etc.

5.2.4.4 Determination steps

5.2.4.4.1 Correction of ratio

The ratio of the volume (mL) of potassium permanganate standard solution of C (1/5 KMnO4)

= 0.01 mol/L to the volume (mL) of ferrous ammonium sulfate solution of C [(NH4)2Fe(SO4)2]

= 0.01 mol/L, expressed in K, shall be corrected by the following method and calculated in

accordance with Formula (4).

Weigh-take 40 g (accurate to 0.001 g) of diluted sulfuric acid with a density of 1.200 g/cm3 (the

average value of the electrolyte density, so that the reaction is carried out at the same acidity),

place it in a 250 mL conical flask. Use a burette to accurately add 10 mL of potassium

permanganate standard solution of C (1/5 KMnO4) = 0.01 mol/L, and use 0.01 mol/L ferrous

ammonium sulfate solution to perform the titration.

Where,

V---the volume of potassium permanganate standard solution used, expressed in (mL);

V1---the volume of ferrous ammonium sulfate solution used, expressed in (mL).

5.2.4.4.2 Determination of specimen

Weigh-take 40 g (accurate to 0.001 g) of the specimen in 5.1.2.1, place it in a 250 mL conical

flask; use a burette to accurately add 10 mL of potassium permanganate standard solution of C

(1/5 KMnO4) = 0.01 mol/L and heat to 70 C ~ 80 C. Stop heating, and cool to room

temperature, (when the specimen appears discolored, re-sampling shall be considered, and the

quantity of specimens to be weighed shall be reduced) accurately add 10 mL of ferrous

ammonium sulfate solution of C [(NH4)2Fe(SO4)2] = 0.01 mol/L. Immediately use potassium

permanganate standard solution of C (1/5 KMnO4) = 0.01 mol/L to titrate it, until it turns light

purple red, which is the end point.

5.2.4.5 Result calculation

solution contains 0.5 mg of chlorine; Solution B: 1 mL of standard solution contains

0.05 mg of chlorine.

Solution A: accurately weigh-take 0.8245 g of benchmark sodium chloride burned at

500 C ~ 600 C for 1 h, dissolve it in 50 mL of water, then, transfer it into a 1,000 mL

volumetric flask; use water to wash it and dilute to the scale, then, shake it well.

Solution B: accurately draw 10 mL of Solution A and put it in a 100 mL volumetric

flask; use water to dilute to the scale, and shake it well.

5.2.5.3 Instruments

Commonly used laboratory instruments: 50 mL colorimetric tube, 100 mL volumetric flask and

1,000 mL volumetric flask, etc.

5.2.5.4 Determination steps

5.2.5.4.1 Preparation of standard color gradation

Successively add 0.0 mL, 0.4 mL, 0.8 mL, 1.2 mL, 1.6 mL and 2.0 mL of chlorine standard

solution B to six 50 mL colorimetric tubes, then, use a pipette to add 30 mL of chlorine-free

diluted sulfuric acid with the same density as the specimen. Then, respectively add 2 mL of 1

+ 4 nitric acid and 2 mL of 2% silver nitrate, and shake it well. Place it in the dark for 20 min.

5.2.5.4.2 Determination of specimen

Weigh-take 30 g of specimen in a 50 mL colorimetric tube, accurate to 0.001 g (m); add 2 mL

of 1 + 4 nitric acid and 2 mL of 2% silver nitrate. Compare it with the standard color gradation,

and adopt the method of visual turbidimetry to determine the chlorine content.

5.2.5.5 Result calculation

The chlorine content, which is expressed in mass fraction X3 and mg/L, shall be calculated in

accordance with Formula (6):

Where,

m1---the chlorine content of the chlorine standard solution with the same turbidity as the

specimen, expressed in (mg);

m---the mass of the specimen, expressed in (g);

ρ---the density of the specimen, expressed in (g/cm3).

The calculation result shall retain three decimal places.

5.2.6 Determination of iron, copper, manganese, nickel, antimony, bismuth, cadmium,

cobalt, zinc and chromium content

5.2.6.1 Instrument

Atomic absorption spectrophotometer.

5.2.6.2 Preparation of standard solution

The preparation of standard solution is shown in Table 3.

5.2.6.3 Specimen preparation

Use an elongated pipette to take 20 mL of the sample in 5.1.2.1 in a 250 mL volumetric flask,

dilute it to the scale, and take the blank solution as a reference. On the atomic absorption

spectrophotometer, use the acetylene-air flame, and in accordance with the wavelengths in

Table 3, successively determine the concentration of the blank C0 and the specimen C1.

5.2.6.4 Result calculation

The iron, copper, manganese, nickel, antimony, bismuth, cadmium, cobalt, zinc and chromium

content shall be calculated in accordance with Formula (7):

Where,

C x---the concentration of a certain element specimen, expressed in (mg/L);

C1---the read concentration in the determination of a certain element, expressed in (g/mL);

C0---the blank concentration in the determination of a certain element, expressed in (g/mL);

n---the dilution ratio of the specimen (take 12.5).

5.2.7 Determination of titanium, mercury, tin and selenium content

5.2.7.1 Instrument

Inductively coupled plasma emission spectrometer (ICP).

5.2.7.2 Preparation of standard solution

See the preparation of standard solution in Table 3.

5.2.7.3 Specimen preparation

Use an elongated pipette to take 20 mL of the sample in 5.1.2.1 in a 250 mL volumetric flask,

dilute it to the scale, and take the blank solution as a reference. On the inductively coupled

plasma emission spectrometer, successively determine the concentration of the blank C0 and

5.3 Determination Method for Colloids

5.3.1 Appearance

In a brightly lit room, conduct a visual inspection on whether the color of the appearance of the

specimen is uniform.

5.3.2 pH

Take a piece of pH test paper universal, dip it into the specimen, after 1 s, take it out, compare

it with the standard color plate and read the pH.

The test result shall retain an integer.

5.3.3 Density

5.3.3.1 Instrument

Density meter: 1.000 g/cm3 ~ 2.000 g/cm3, with a division value of 0.005 g/cm3.

5.3.3.2 Determination steps

Take 250 mL of the specimen in 5.1.2.2, thoroughly stir it, then, transfer it into a 250 mL

graduated cylinder. Place the graduated cylinder in a water bath at 25 C 1 C and maintain

the temperature constant; let it stand for 20 min, so that the air bubbles can overflow. Gently

put the density meter into the test solution, wait for it to stop sinking, then, visually observe the

tangent line of the concave surface of the specimen solution, and read the value on the density

meter.

The test result shall retain three decimal places.

5.3.4 Determination of silicon dioxide content

5.3.4.1 Instrument

High-temperature chamber electric resistance furnace, with the temperature controlled at 950

C ~ 1,000 C.

5.3.4.2 Reagent and solution

Hydrochloric acid (GB/T 622): analytically pure, with a density of 1.190 g/cm3.

5.3.4.3 Determination steps

Weigh-take 10 g of specimen (accurate to 0.0001 g) in a 120 mL porcelain, slowly add 10 mL

of concentrated hydrochloric acid with a density of 1.190 g/cm3. Place the soluti...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 42391-2023 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 42391-2023

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 42391-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 29.220.20

CCS K 84

Electrolyte for Lead Acid Storage Battery

(IEC 62877-1:2016, Electrolyte and Water for Vented Lead Acid Accumulators - Part

1: Requirements for Electrolyte, MOD)

ISSUED ON: MARCH 17, 2023

IMPLEMENTED ON: OCTOBER 1, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative References ... 6

3 Terms and Definitions ... 7

4 Requirements ... 7

5 Determination Method ... 8

6 Inspection Rules ... 21

7 Marking, Packaging, Transportation and Storage ... 22

8 Safety Requirements ... 22

Appendix A (informative) Comparison of Concentration and Density of Sulfuric Acid

... 23

Electrolyte for Lead Acid Storage Battery

1 Scope

This document specifies the requirements, determination methods, inspection rules, marking,

packaging, transportation, storage and safety requirements of the electrolyte (including

colloidal electrolyte) for lead acid storage battery.

This document is applicable to the electrolyte (including colloidal electrolyte) for lead acid

storage battery.

This document does not apply to the electrolyte in lead acid storage battery after disassembly.

2 Normative References

The contents of the following documents constitute indispensable clauses of this document

through the normative references in the text. In terms of references with a specified date, only

versions with a specified date are applicable to this document. In terms of references without a

specified date, the latest version (including all the modifications) is applicable to this document.

GB 190 Packing Symbol of Dangerous Goods

GB/T 622 Chemical Reagent - Hydrochloric Acid (GB/T 622-2006, ISO 6353-2:1983, NEQ)

GB/T 625 Chemical Reagent - Sulfuric Acid (GB/T 625-2007, ISO 6353-2:1983, NEQ)

GB/T 626 Chemical Reagent - Nitric Acid (GB/T 626-2006, ISO 6353-2:1983, NEQ)

GB/T 629 Chemical Reagent - Sodium Hydroxide

GB/T 643 Chemical Reagent - Potassium Permanganate (GB/T 643-2008, ISO 6353-2:1983,

NEQ)

GB/T 661 Chemical Reagent - Ammonium Iron (II) Sulfate Hexahydrate (GB/T 661-2011, ISO

6353-3:1987, NEQ)

GB/T 670 Chemical Reagent - Silver Nitrate (GB/T 670-2007, ISO 6353-2:1983, NEQ)

GB 1253 Working Chemical - Sodium Chloride

GB 1254 Working Chemical - Sodium Oxalate

GB 1257 Working Chemical - Potassium Hydrogen Phthalate

GB 12595 Working Chemical - Silver Nitrate

In a brightly lit room, conduct a visual inspection on whether the surface of the sample is

colorless and transparent.

5.2.2 Density

5.2.2.1 Instrument

Density meter: with a division value of 0.001 g/cm3.

5.2.2.2 Determination steps

Take 250 mL of the specimen in 5.1.2.1, stir it well, then, transfer it into a 250 mL measuring

cylinder; put it in a water bath at 25 C, let it stand for 20 min. Gently put the density meter

into the specimen, wait until it stops sinking, visually observe the tangent line of the concave

surface of the liquid, and read the value on the density meter.

The test result shall retain three decimal places.

5.2.3 Determination of sulfuric acid content

5.2.3.1 Principle

Weigh-take or absorb a certain amount of specimen, and use methyl red-methylene blue as a

mixed indicator. The end point of titration is pH = 5.4, and the solution turns from purple red

to gray green, and the color variation is sensitive and easy to judge.

5.2.3.2 Reagents and solutions

The reagents and solutions required for the test are as follows:

---Methyl red-methylene blue mixed indicator: one portion of 0.2% methyl red ethanol

solution is mixed with one portion of 0.1% methylene blue ethanol;

---Potassium hydrogen phthalate (GB 1257): benchmark reagent;

---Phenolphthalein: analytically pure, 0.1% ethanol solution;

---Sodium hydroxide (GB/T 629): analytically pure, standard solution of C (NaOH) = 0.5

mol/L.

a) Preparation: prepare a saturated solution of sodium hydroxide and store it in a plastic

bottle, seal it and place it, until the solution becomes clear. Take 26 mL of the

supernatant and place it in 1,000 mL of carbon dioxide-free water, and mix it well;

b) Calibration: weigh-take 3 g (accurate to 0.0001 g) of benchmark potassium hydrogen

phthalate dried at 105 C ~ 110 C for 2 h, put it in a 250 mL conical flask, add 80

mL of water and heat it to boiling. Dropwise add 2 drops ~ 3 drops of 0.1%

phenolphthalein indicator, and use sodium hydroxide solution of C (NaOH) = 0.5

mol/L to titrate it, until the solution turns pink, which is the end point.

5.2.4 Determination of reduced potassium permanganate (calculated by O) content

5.2.4.1 Principle

Inject excess potassium permanganate solution into the specimen to thoroughly oxidize the

reducing substance; use ferrous ammonium sulfate solution to perform back titration, so as to

obtain the content of reduced potassium permanganate.

5.2.4.2 Reagents and solutions

The reagents and solutions required for the test are as follows:

---Sulfuric acid (GB/T 625): analytically pure, 1 + 1 solution and solution with a density

of 1.200 g/cm3;

NOTE: see Appendix A for the comparison of the concentration and density of sulfuric acid.

---Sodium oxalate (GB 1254): benchmark reagent;

---Ferrous ammonium sulfate solution (GB/T 661): analytically pure, C [(NH4)2Fe(SO4)2]

= 0.01 mol/L. Weigh-take 4 g of (NH4)2Fe(SO4)2 6 H2O and dissolve in 100 mL of 1

+ 1 sulfuric acid solution, and use water to dilute to 1,000 mL;

---Potassium permanganate standard solution (GB/T 643): analytically pure, C (1/5

KMnO4) = 0.1 mol/L. This standard solution is used to prepare a standard solution of

C (1/5 KMnO4) = 0.01 mol/L.

a) Preparation: weigh-take 3.30 g of potassium permanganate, dissolve it in 1,050 mL

of water, slowly boil it for 20 min ~ 30 min and place it in the dark for a week. Use

glass wool to filter it, and store the filtrate in a brown bottle with a ground stopper.

b) Calibration: weigh-take 0.2 g of benchmark sodium oxalate dried at 105 C ~ 110 C

for 2 h, accurate to 0.0001 g, and dissolve it in 50 mL of pure water. Add 8 mL of

concentrated sulfuric acid, use potassium permanganate standard solution of C (1/5

KMnO4) = 0.1 mol/L to titrate it, and when it approaches the end point, heat to 70 C

~ 80 C, continue titration, until the solution turns pink and maintains for 30 s,

meanwhile, carry out a blank test.

c) Calculation: the concentration of 0.1 mol/L potassium permanganate solution of C

(1/5 KMnO4) shall be calculated in accordance with Formula (3).

Where,

m---the mass of the weighed sodium oxalate, expressed in (g);

V---the volume of potassium permanganate solution used, expressed in (mL);

M (1/2 Na2C2O4)---the mass of 0.5 mol of sodium oxalate, expressed in (g/mol).

d) Preparation of 0.01 mol/L potassium permanganate standard solution: use pure water

to accurately dilute the prepared potassium permanganate standard solution of C (1/5

KMnO4) = 0.1 mol/L to C (1/5 KMnO4) = 0.01 mol/L.

5.2.4.3 Instruments

Commonly used laboratory instruments: 250 mL conical flask and burette, etc.

5.2.4.4 Determination steps

5.2.4.4.1 Correction of ratio

The ratio of the volume (mL) of potassium permanganate standard solution of C (1/5 KMnO4)

= 0.01 mol/L to the volume (mL) of ferrous ammonium sulfate solution of C [(NH4)2Fe(SO4)2]

= 0.01 mol/L, expressed in K, shall be corrected by the following method and calculated in

accordance with Formula (4).

Weigh-take 40 g (accurate to 0.001 g) of diluted sulfuric acid with a density of 1.200 g/cm3 (the

average value of the electrolyte density, so that the reaction is carried out at the same acidity),

place it in a 250 mL conical flask. Use a burette to accurately add 10 mL of potassium

permanganate standard solution of C (1/5 KMnO4) = 0.01 mol/L, and use 0.01 mol/L ferrous

ammonium sulfate solution to perform the titration.

Where,

V---the volume of potassium permanganate standard solution used, expressed in (mL);

V1---the volume of ferrous ammonium sulfate solution used, expressed in (mL).

5.2.4.4.2 Determination of specimen

Weigh-take 40 g (accurate to 0.001 g) of the specimen in 5.1.2.1, place it in a 250 mL conical

flask; use a burette to accurately add 10 mL of potassium permanganate standard solution of C

(1/5 KMnO4) = 0.01 mol/L and heat to 70 C ~ 80 C. Stop heating, and cool to room

temperature, (when the specimen appears discolored, re-sampling shall be considered, and the

quantity of specimens to be weighed shall be reduced) accurately add 10 mL of ferrous

ammonium sulfate solution of C [(NH4)2Fe(SO4)2] = 0.01 mol/L. Immediately use potassium

permanganate standard solution of C (1/5 KMnO4) = 0.01 mol/L to titrate it, until it turns light

purple red, which is the end point.

5.2.4.5 Result calculation

solution contains 0.5 mg of chlorine; Solution B: 1 mL of standard solution contains

0.05 mg of chlorine.

Solution A: accurately weigh-take 0.8245 g of benchmark sodium chloride burned at

500 C ~ 600 C for 1 h, dissolve it in 50 mL of water, then, transfer it into a 1,000 mL

volumetric flask; use water to wash it and dilute to the scale, then, shake it well.

Solution B: accurately draw 10 mL of Solution A and put it in a 100 mL volumetric

flask; use water to dilute to the scale, and shake it well.

5.2.5.3 Instruments

Commonly used laboratory instruments: 50 mL colorimetric tube, 100 mL volumetric flask and

1,000 mL volumetric flask, etc.

5.2.5.4 Determination steps

5.2.5.4.1 Preparation of standard color gradation

Successively add 0.0 mL, 0.4 mL, 0.8 mL, 1.2 mL, 1.6 mL and 2.0 mL of chlorine standard

solution B to six 50 mL colorimetric tubes, then, use a pipette to add 30 mL of chlorine-free

diluted sulfuric acid with the same density as the specimen. Then, respectively add 2 mL of 1

+ 4 nitric acid and 2 mL of 2% silver nitrate, and shake it well. Place it in the dark for 20 min.

5.2.5.4.2 Determination of specimen

Weigh-take 30 g of specimen in a 50 mL colorimetric tube, accurate to 0.001 g (m); add 2 mL

of 1 + 4 nitric acid and 2 mL of 2% silver nitrate. Compare it with the standard color gradation,

and adopt the method of visual turbidimetry to determine the chlorine content.

5.2.5.5 Result calculation

The chlorine content, which is expressed in mass fraction X3 and mg/L, shall be calculated in

accordance with Formula (6):

Where,

m1---the chlorine content of the chlorine standard solution with the same turbidity as the

specimen, expressed in (mg);

m---the mass of the specimen, expressed in (g);

ρ---the density of the specimen, expressed in (g/cm3).

The calculation result shall retain three decimal places.

5.2.6 Determination of iron, copper, manganese, nickel, antimony, bismuth, cadmium,

cobalt, zinc and chromium content

5.2.6.1 Instrument

Atomic absorption spectrophotometer.

5.2.6.2 Preparation of standard solution

The preparation of standard solution is shown in Table 3.

5.2.6.3 Specimen preparation

Use an elongated pipette to take 20 mL of the sample in 5.1.2.1 in a 250 mL volumetric flask,

dilute it to the scale, and take the blank solution as a reference. On the atomic absorption

spectrophotometer, use the acetylene-air flame, and in accordance with the wavelengths in

Table 3, successively determine the concentration of the blank C0 and the specimen C1.

5.2.6.4 Result calculation

The iron, copper, manganese, nickel, antimony, bismuth, cadmium, cobalt, zinc and chromium

content shall be calculated in accordance with Formula (7):

Where,

C x---the concentration of a certain element specimen, expressed in (mg/L);

C1---the read concentration in the determination of a certain element, expressed in (g/mL);

C0---the blank concentration in the determination of a certain element, expressed in (g/mL);

n---the dilution ratio of the specimen (take 12.5).

5.2.7 Determination of titanium, mercury, tin and selenium content

5.2.7.1 Instrument

Inductively coupled plasma emission spectrometer (ICP).

5.2.7.2 Preparation of standard solution

See the preparation of standard solution in Table 3.

5.2.7.3 Specimen preparation

Use an elongated pipette to take 20 mL of the sample in 5.1.2.1 in a 250 mL volumetric flask,

dilute it to the scale, and take the blank solution as a reference. On the inductively coupled

plasma emission spectrometer, successively determine the concentration of the blank C0 and

5.3 Determination Method for Colloids

5.3.1 Appearance

In a brightly lit room, conduct a visual inspection on whether the color of the appearance of the

specimen is uniform.

5.3.2 pH

Take a piece of pH test paper universal, dip it into the specimen, after 1 s, take it out, compare

it with the standard color plate and read the pH.

The test result shall retain an integer.

5.3.3 Density

5.3.3.1 Instrument

Density meter: 1.000 g/cm3 ~ 2.000 g/cm3, with a division value of 0.005 g/cm3.

5.3.3.2 Determination steps

Take 250 mL of the specimen in 5.1.2.2, thoroughly stir it, then, transfer it into a 250 mL

graduated cylinder. Place the graduated cylinder in a water bath at 25 C 1 C and maintain

the temperature constant; let it stand for 20 min, so that the air bubbles can overflow. Gently

put the density meter into the test solution, wait for it to stop sinking, then, visually observe the

tangent line of the concave surface of the specimen solution, and read the value on the density

meter.

The test result shall retain three decimal places.

5.3.4 Determination of silicon dioxide content

5.3.4.1 Instrument

High-temperature chamber electric resistance furnace, with the temperature controlled at 950

C ~ 1,000 C.

5.3.4.2 Reagent and solution

Hydrochloric acid (GB/T 622): analytically pure, with a density of 1.190 g/cm3.

5.3.4.3 Determination steps

Weigh-take 10 g of specimen (accurate to 0.0001 g) in a 120 mL porcelain, slowly add 10 mL

of concentrated hydrochloric acid with a density of 1.190 g/cm3. Place the soluti...

Share