1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 5231-2012 English PDF (GBT5231-2012)

GB/T 5231-2012 English PDF (GBT5231-2012)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) GB/T 5231-2022

Get QUOTATION in 1-minute: Click GB/T 5231-2012

Historical versions: GB/T 5231-2012

Preview True-PDF (Reload/Scroll if blank)

GB/T 5231-2012: Designation and chemical composition of wrought copper and copper alloys

GB/T 5231-2012

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.30

H62

Replacing GB/T 5231-2001

Designation and Chemical Composition of Wrought

Copper and Copper Alloys

ISSUED ON. DECEMBER 31, 2012

IMPLEMENTED ON. OCTOBER 1, 2013

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine (AQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Chemical Composition ... 5

Appendix A (Informative) Identical Designation of American Standard ... 22

Foreword

This Standard was drafted in compliance with the rules specified in GB/T 1.1-2009.

This Standard replaces GB/T 5231-2001 "Wrought Copper and Copper Alloys

Chemical Composition Limits and Forms of Wrought Products". Some designations in

this Standard equivalently adopt the designations and chemical composition of

American copper and copper alloys; new requirements are made for some

designations and chemical composition in previous national standards; 111

designations in GB/T 5231-2001 are reserved, and 102 designations are added; 213

designations are included in this Standard in total. Compared with GB/T 5231-2001,

the main changes are as follows.

- Oxygen content of oxygen-free copper in this Standard was adjusted, TU0 in

previous standard was changed as TU00; it is identical to American designation

C10100; TU0 designation was added, and the oxygen content is 0.001%; TU1

and TU2 in previous standard were unchanged, the oxygen contents were 0.002%

and 0.003% respectively; oxygen-free copper TU3 was added and is identical to

American designation C10200;

- Designations QTe0.5, QZr0.2 and QZr0.4 in previous national standard were

integrated into pure copper series; the expression methods of the designations

were modified as TTe0.5, TZr0.2 and TZr0.4 respectively;

- Designations QCd1, QBe0.3-1.5, QBe0.6-2.5, QBe0.4-1.8, QBel.7, QBel.9,

QBel.9-0.1, QBe2, QCr0.5, QCr0.5-0.2-0.1, QCr0.6-0.4-0.05, QCr1, QMg0.8 and

QFe2.5 in previous national standards were integrated into high copper series;

the expression methods of the designations were modified as TCd1, TBe0.3-1.5,

TBe0.6-2.5, TBe0.4-1.8, TBel.7, TBel.9, TBel.9-0.1, TBe2, TCr0.5, TCr0.5-0.2-

0.1, TCro0.6-0.4-0.05, TCr1, TMg0.8 and TFe2.5 respectively;

- Designation H96 in previous national standard is identical to ASTM alloy

designation C21000; copper content was adjusted from 95.0%~97.0% to

94.0%~96.0% and designation was changed as H95;

- 19 designations for pure copper were added. TU0, TU3, TU00Ag0.06, TUAg0.03,

TUAg0.05, TUAg0.1, TUAg0.2, TUAg0.3, TUZr0.15, TAg0.1-0.01, TAg0.15, TP3,

TP4, TTe0.3, TTe0.5-0.008, TTe0.5-0.02, TS0.4, TZr0.15, and TUAl0.12;

- 15 designations for high copper alloy were added. TBel.9-0.4, TNi2.4-0.6-0.5,

TCr0.3-0.3, TCr0.5-0.1, TCr0.7, TCr0.8, TCrl-0.15, TCrl-0.18, TMg0.2, TMg0.4,

TMg0.5, TPb1, TFel.0, TFe0.1, and TTi3.0-0.2;

- 35 designations for brass were added. H66, HB90-0.1, HPb62-2-0.1, HPb61-2-

1, HPb61-2-0.1, HPb60-3, HPb59-2, HPb58-2, HPb58-3, HPb57-4, HSn72-1,

HSn70-1-0.01, HSnT0-1-0.01-0.04, HSn65-0.03, HBi60-2, HBi60-1.3, HBi60-

1.0-0.05, HBi60-0.5-0.01, HBi60-0.8-0.01, HBi60-1.1-0.01, HBi59-1, HBi62-1,

HMn64-5-1.5, HMn62-3-3-1, HMn62-13, HMn59-2-1.5-0.5, HMn57-2-2-0.5,

HSb61-0.8-0.5, HSb60-0.9, HSi75-3, HSi62-0.6, HSi61-0.6, HAl64-5-4-2, HAl61-

4-3-1.5 and HMg60-1;

- 14 designations for bronze were added. QSn0.4, QSn0.6, QSn0.9, QSn0.5-

0.025, QSnl-0.5-0.5, QSnl.8, QSn5-0.2, QSn5-0.3, QSn6-0.05, QSnlS-1-1,

QCr4.5-2.5-0.6, QAl6, QAll0-4-4-1 and QSi0.6-2;

- 19 designations for white copper were added. B23, BFe7-0.4-0.4, BFel0-1.5-1,

BFel0-1.6-1, BFel6-1-0.5, BFe30-0.7, BFe30-2-2, BZnl8-10, BZnl8-17, BZn9-29,

BZnl2-24, BZnl2-26, BZnl2-29, BZnl8-20, BZn22-16, BZn25-18, BZn40-20,

BZnl0-41-2 and BZnl2-37-1.5;

Designations for copper and copper alloy were added; the expression method is -

take T as the initial letter and followed by 5 digits. The alloys identical to American

alloy designation were still adopted with serial number of American designation.

This Standard shall be under the jurisdiction of National Technical Committee on

Nonferrous Metals of Standardization Administration of China (SAC/TC 243).

Drafting organizations of this Standard. Chinalco Shenyang Non-ferrous Metal

Processing Co., Ltd., Chinalco Luoyang Copper Co., Ltd., Zhejiang Hailiang Co., Ltd.,

Ningbo Powerway Group Co., Ltd. AND China Institute of Weights and Measures

Quality of Nonferrous Metal Industry.

Participating drafting organizations of this Standard. Chinalco Shanghai Copper Co.,

Ltd., Jiangsu Baoluo Copper Products Group Co., Ltd., Ningbo Jintian Copper (Group)

Co., Ltd. AND Shaoxing Libo Electric Co., Ltd..

Chief drafting staffs of this Standard. Wang Yanjie, Chen Jiangqiao, Zhao Baohong,

Wang Zhenyou, Zhang Bo, Zhang Caihong, Meng Huijuan, Zhao Wanhua, Cao

Jianguo, Wei Lianyun, Cai Jihua, Wang Yunsong, Yang Lijuan, Shao Shengzhong,

Zhang Yi, Zhang Shu, Wang Yongru, Hong Xieping, Xu Gaolei, Jiang Bochang, Fan

Zhigang, Liu Dongxia, Yu Jiangwen and Bao Jingguo.

The previous editions replaced by this Standard are as follows.

- GB/T 5231-1985, GB/T 5231-2001;

- GB/T 5232-1985, GB/T 5233-1985, GB/T 5234-1985.

Designation and Chemical Composition of Wrought

Copper and Copper Alloys

1 Scope

This Standard specifies designation and chemical composition of wrought copper and

copper alloy.

This Standard is applicable to the wrought product of copper and copper alloy

produced by pressure method, and the ingot casting and blank adopted for copper and

copper alloy.

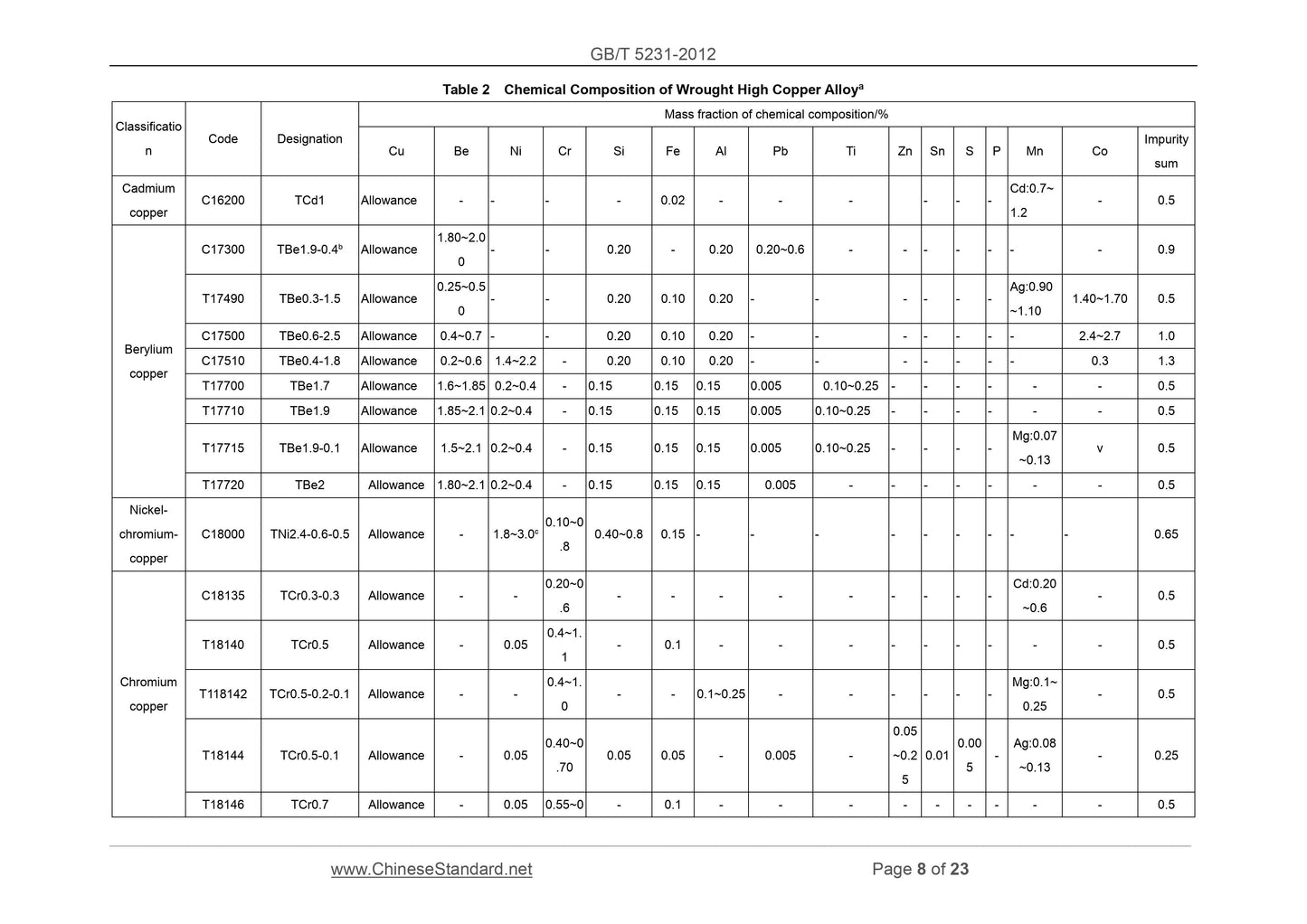

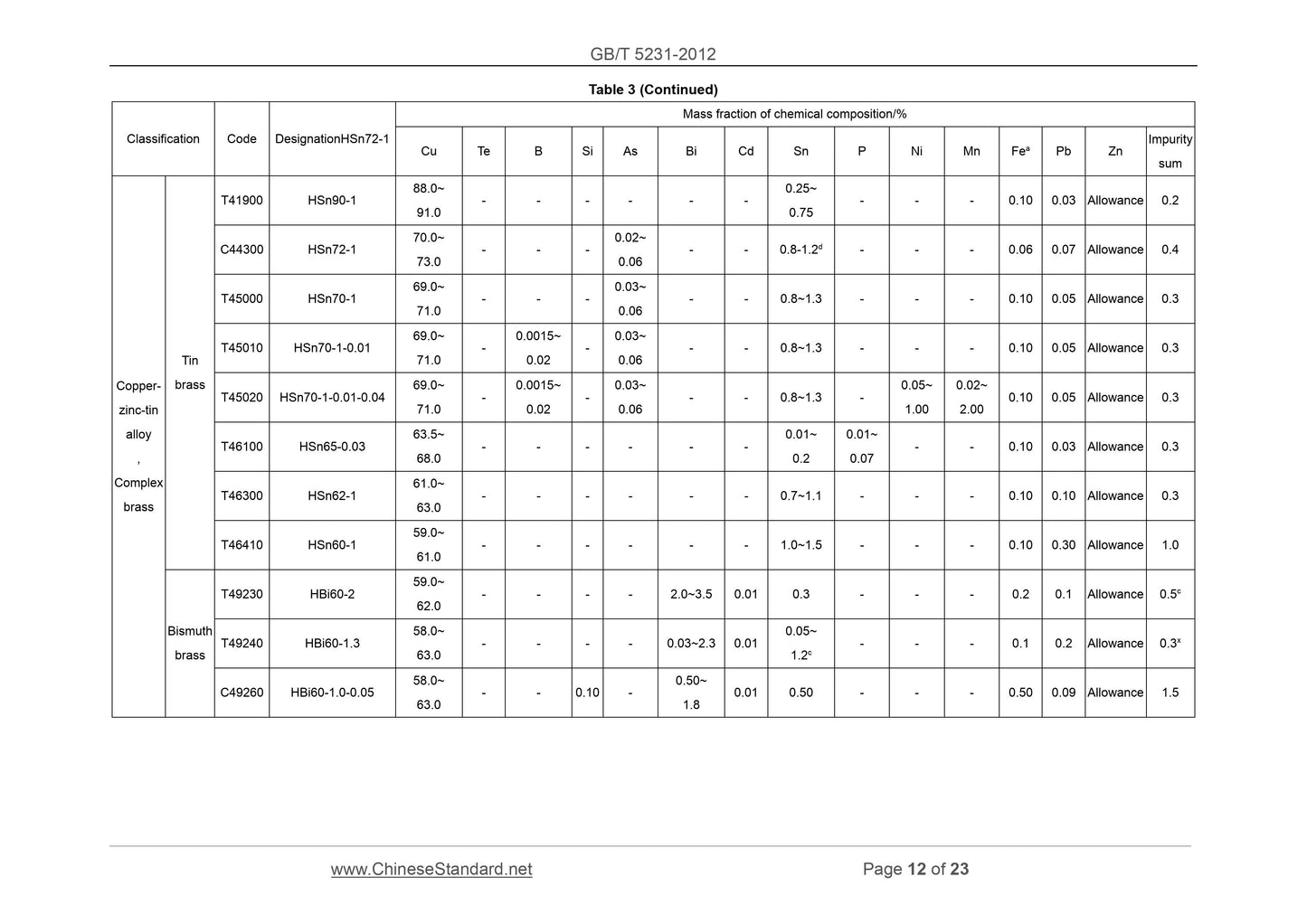

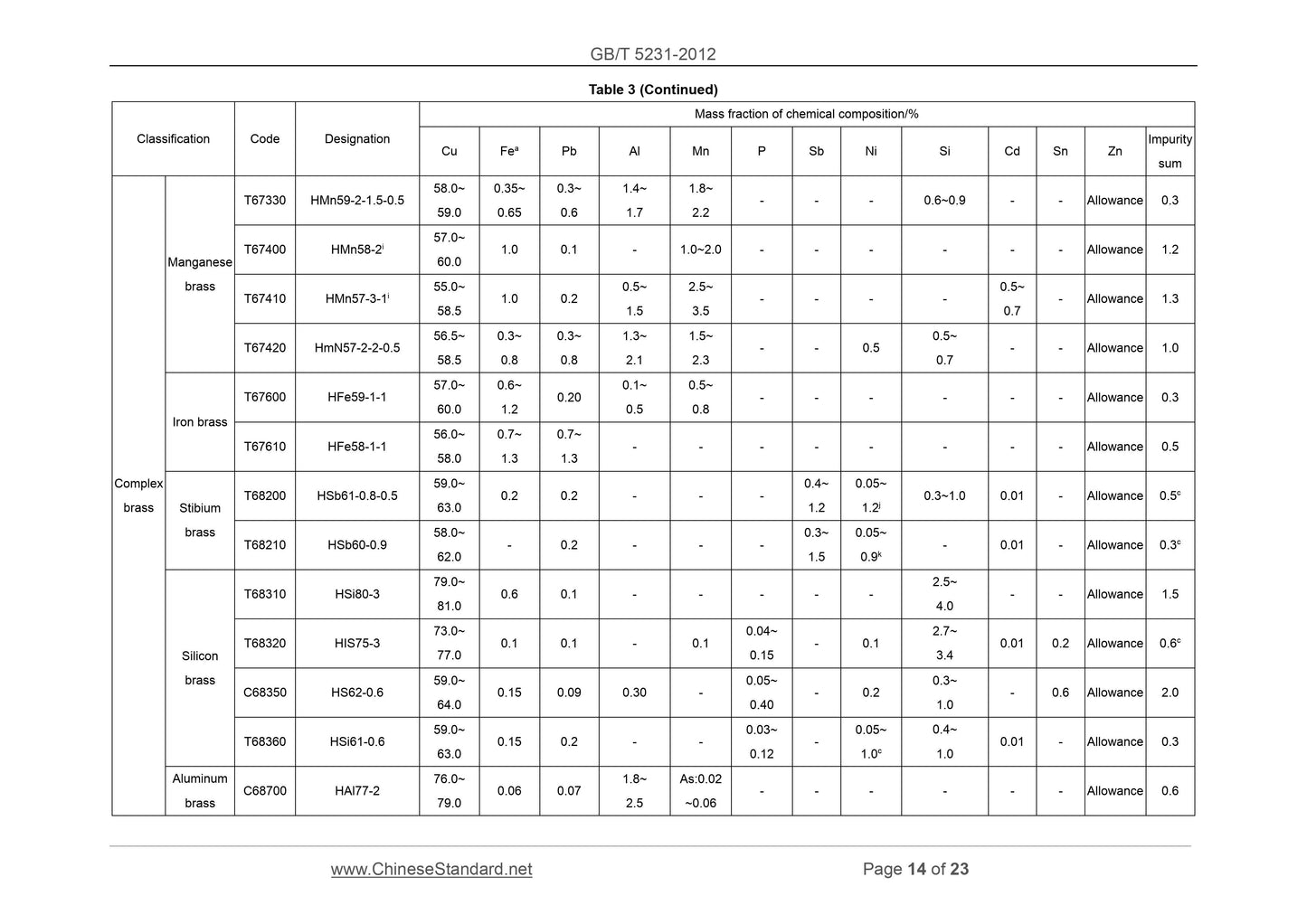

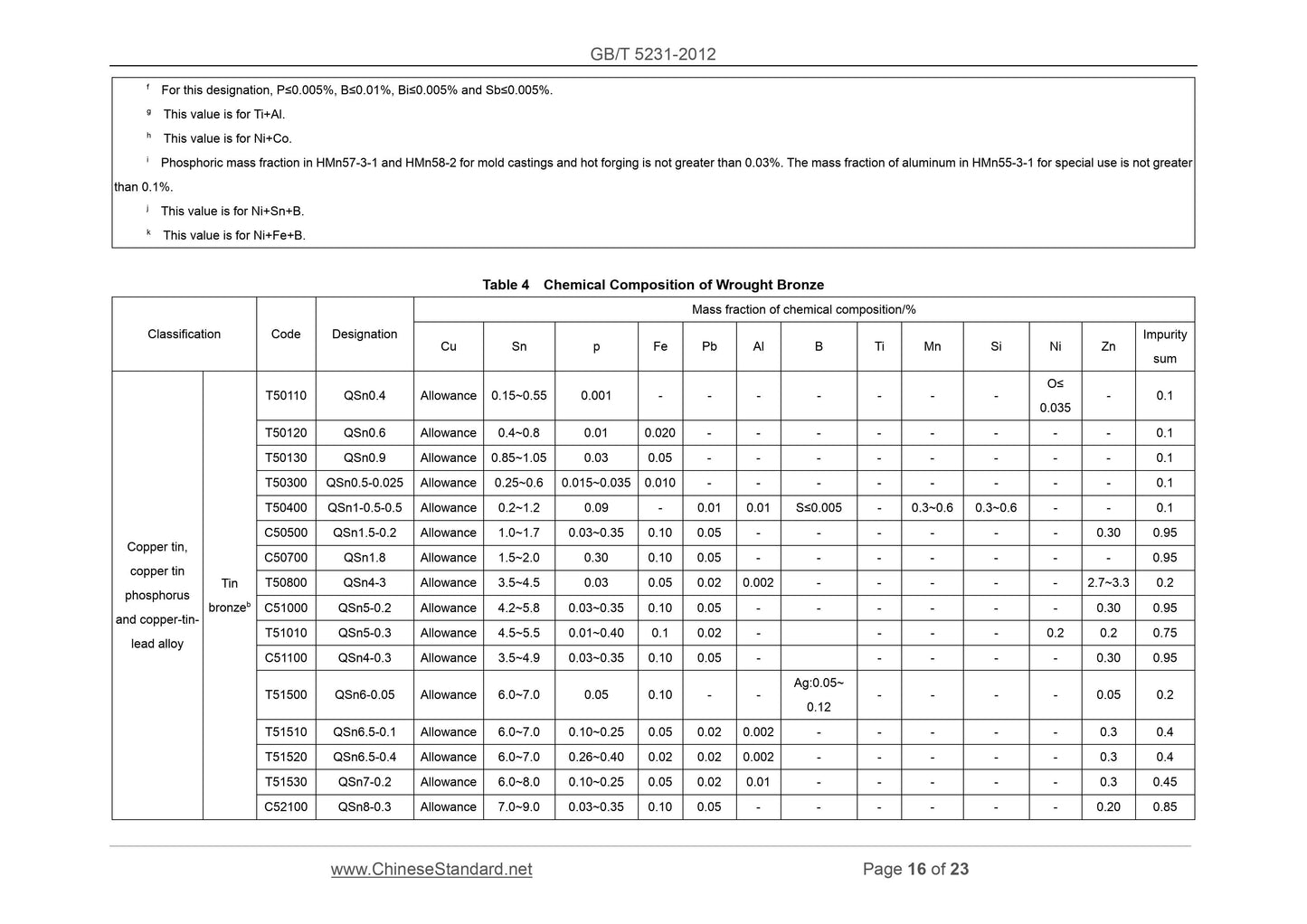

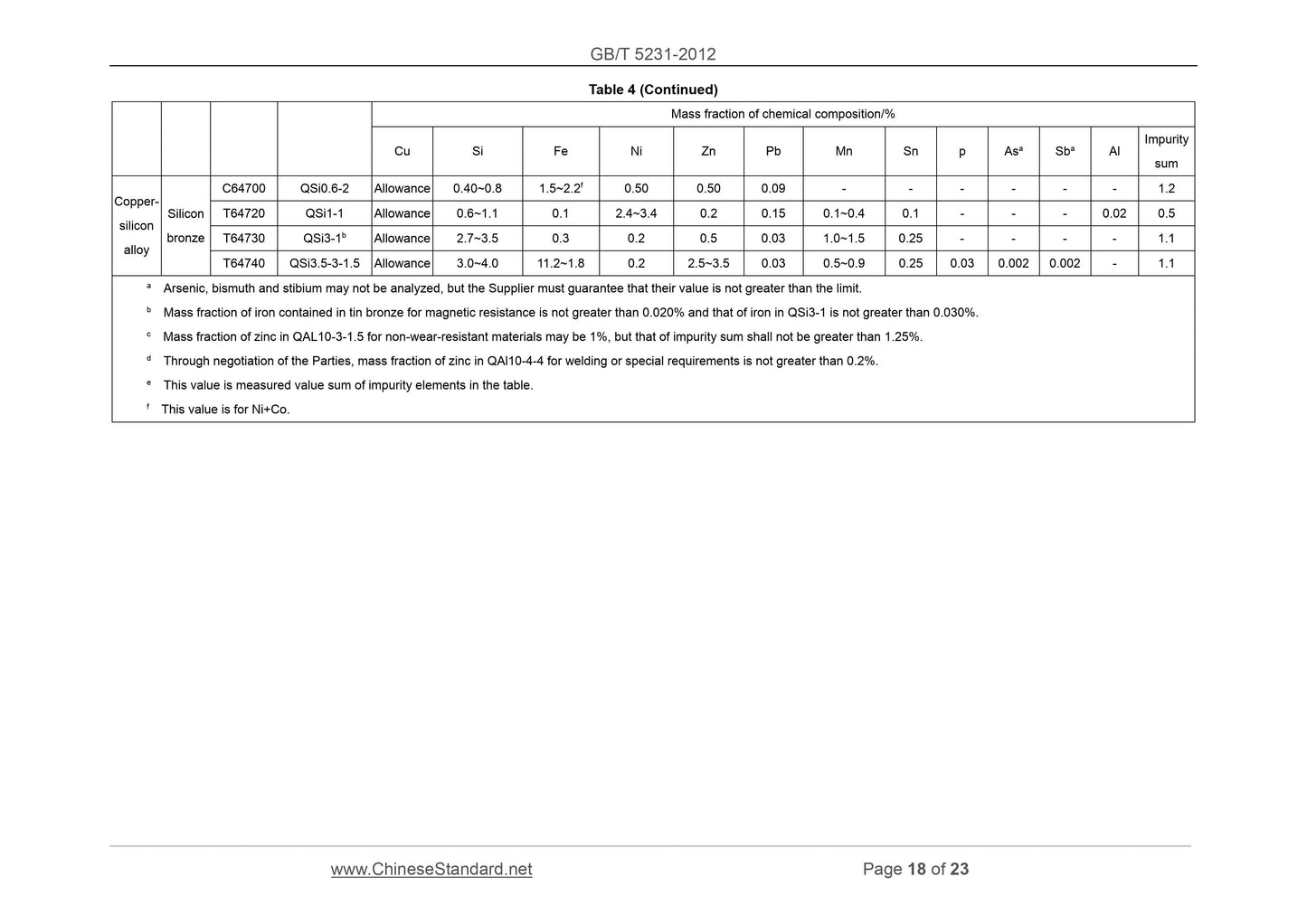

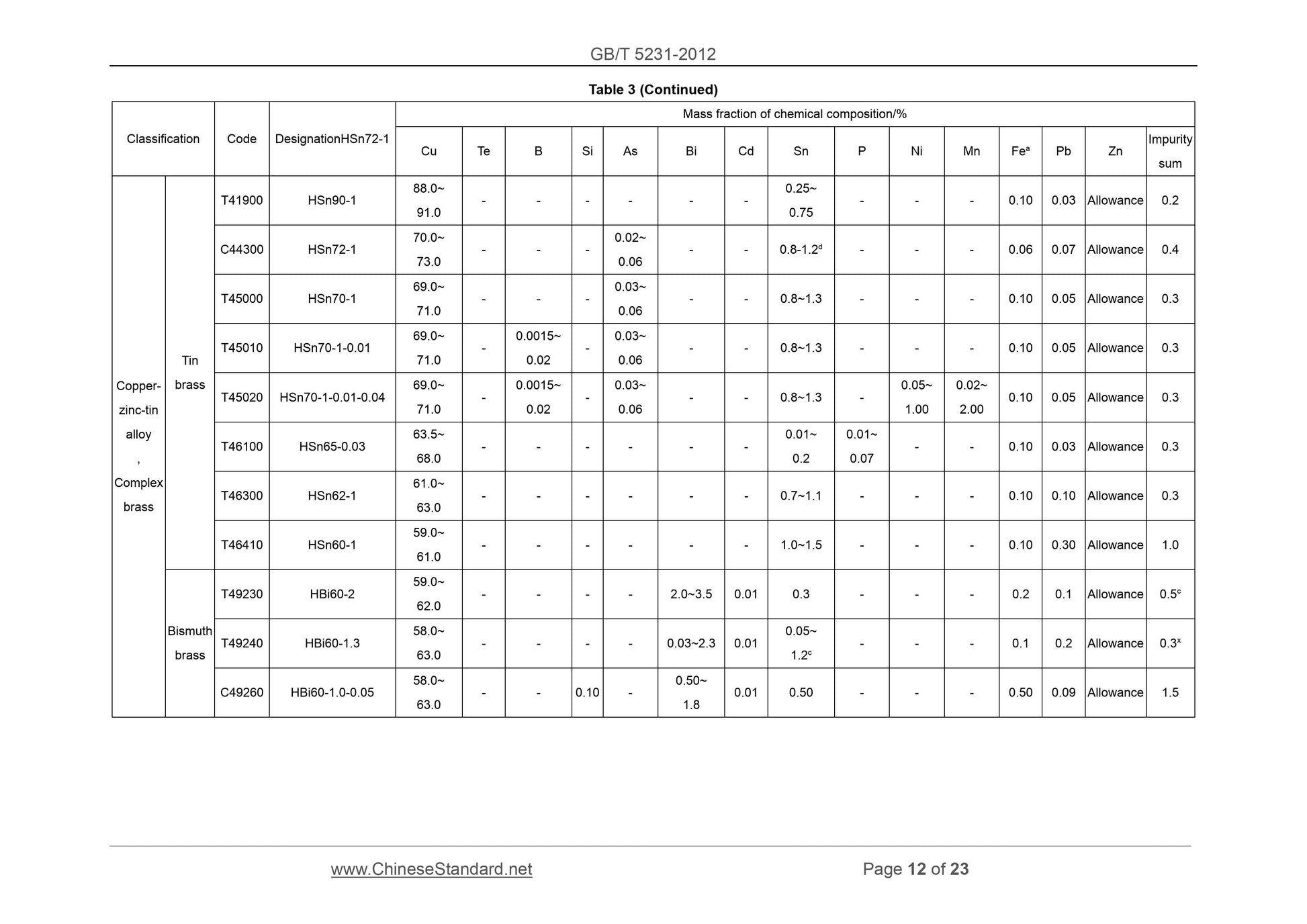

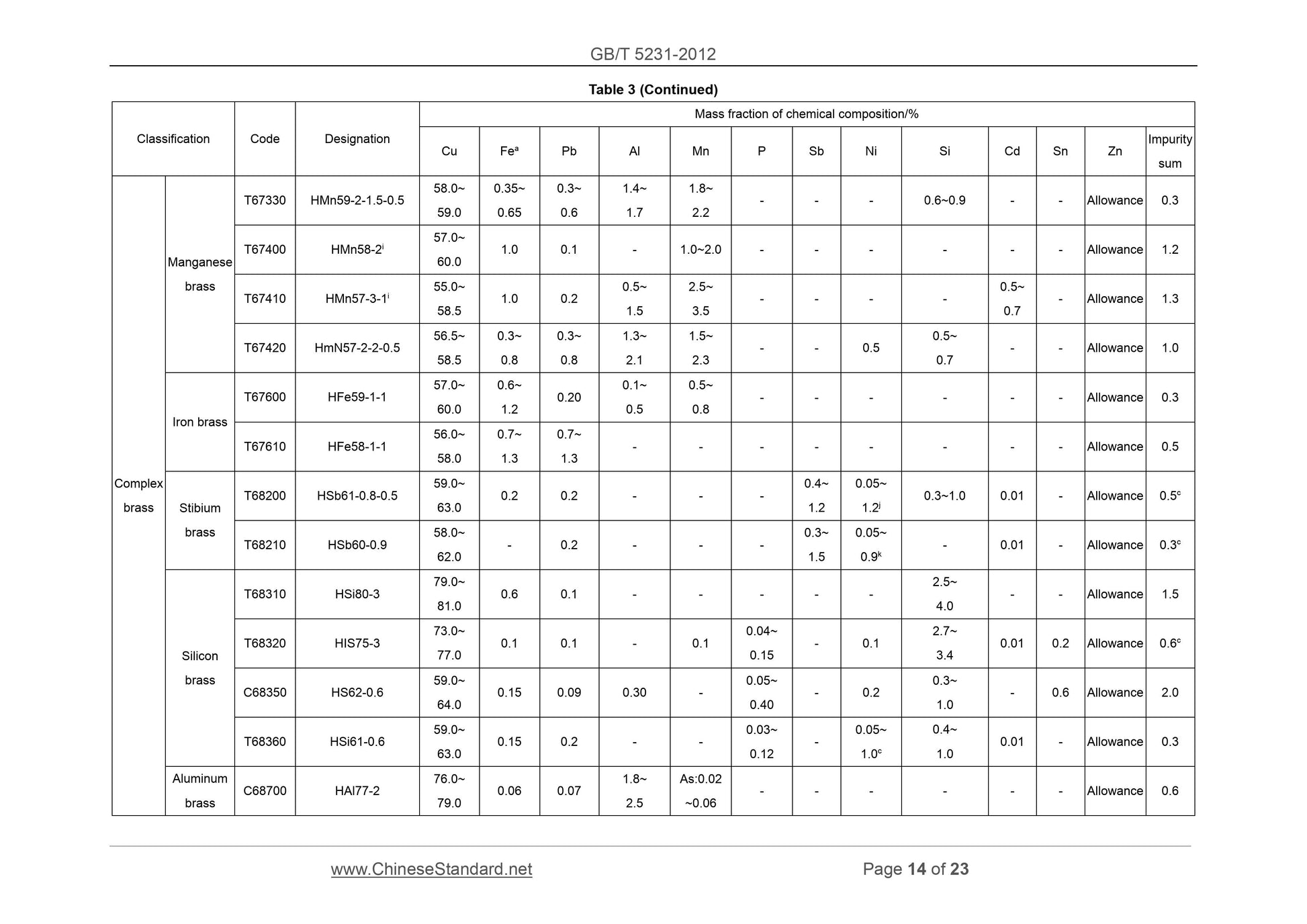

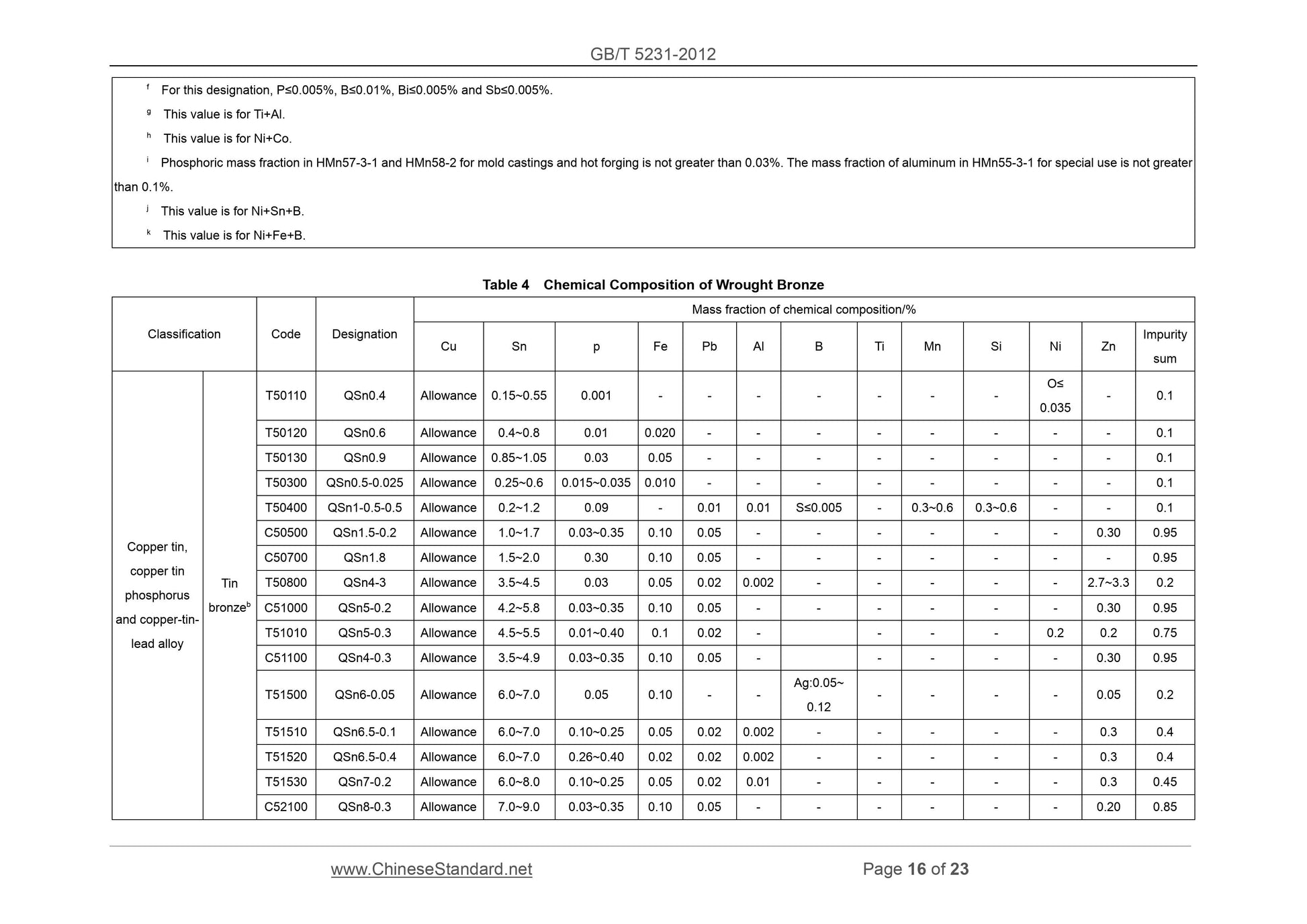

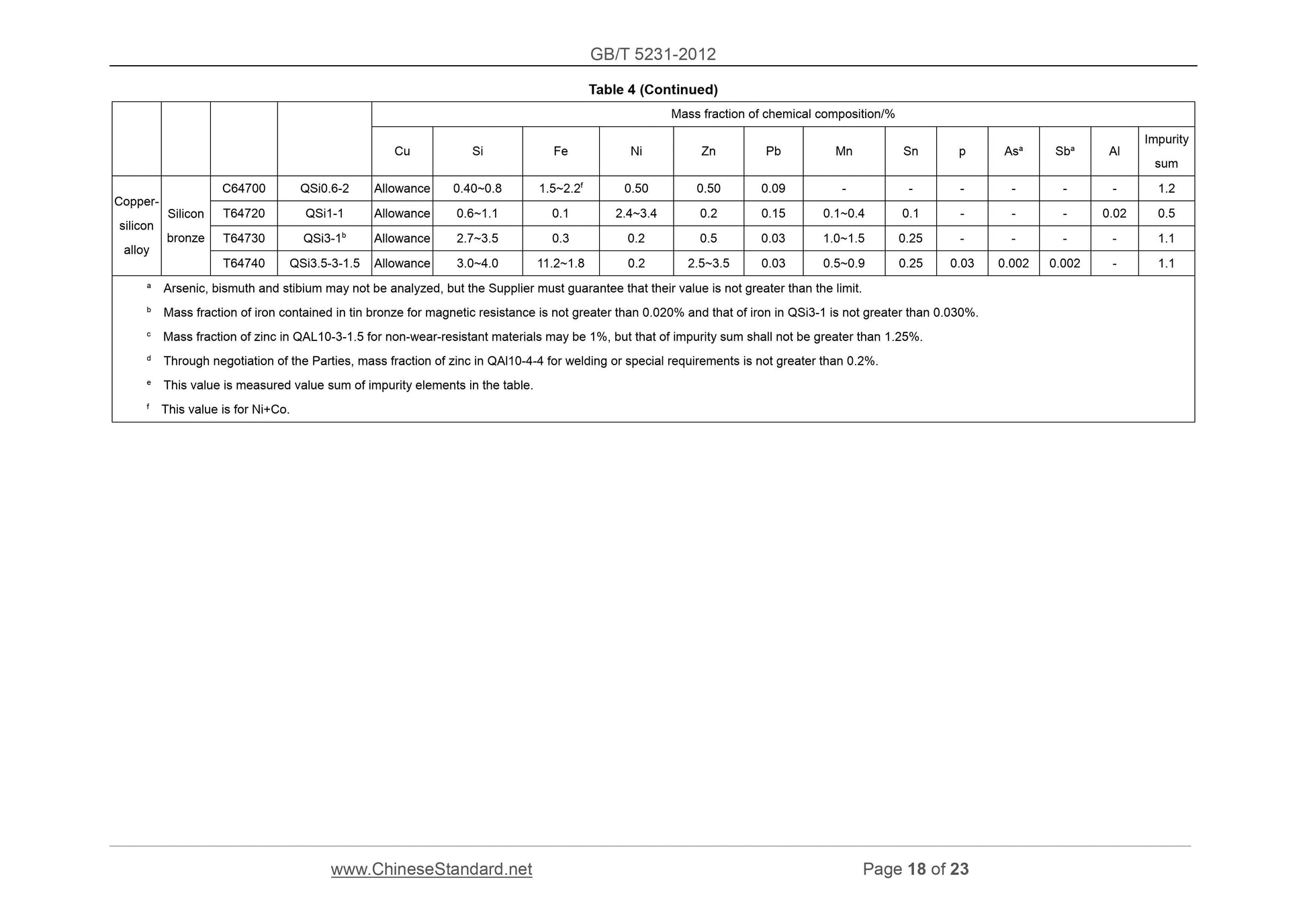

2 Chemical Composition

2.1 Designation and chemical composition of wrought copper and copper alloy shall

meet those specified in Tables 1~5.

2.2 Content of alloy elements in Table 1 ~ Table 5 has upper and lower limits; if the

content is in single-value, the minimum limit is for copper; and the maximum limit is for

impurity element.

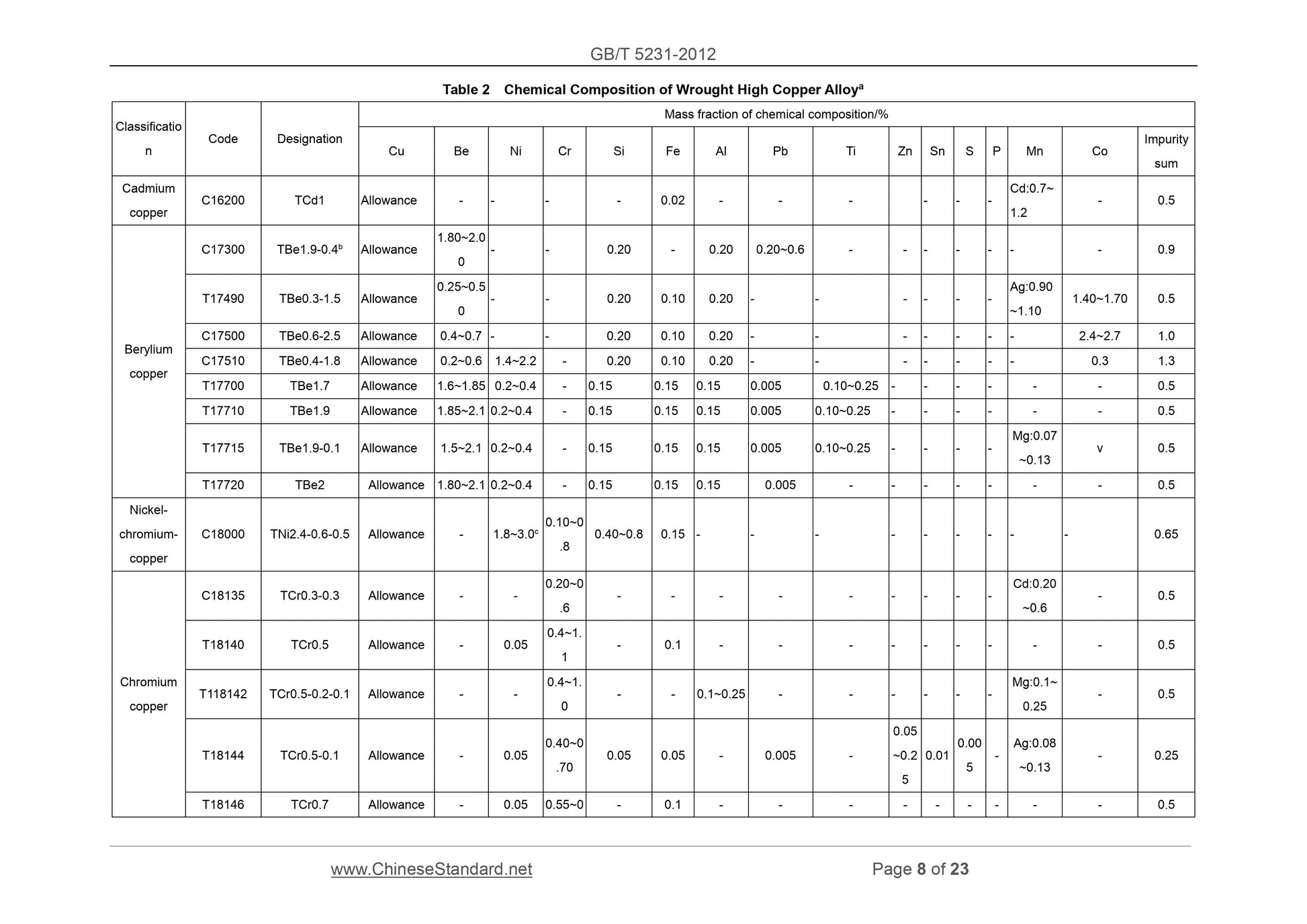

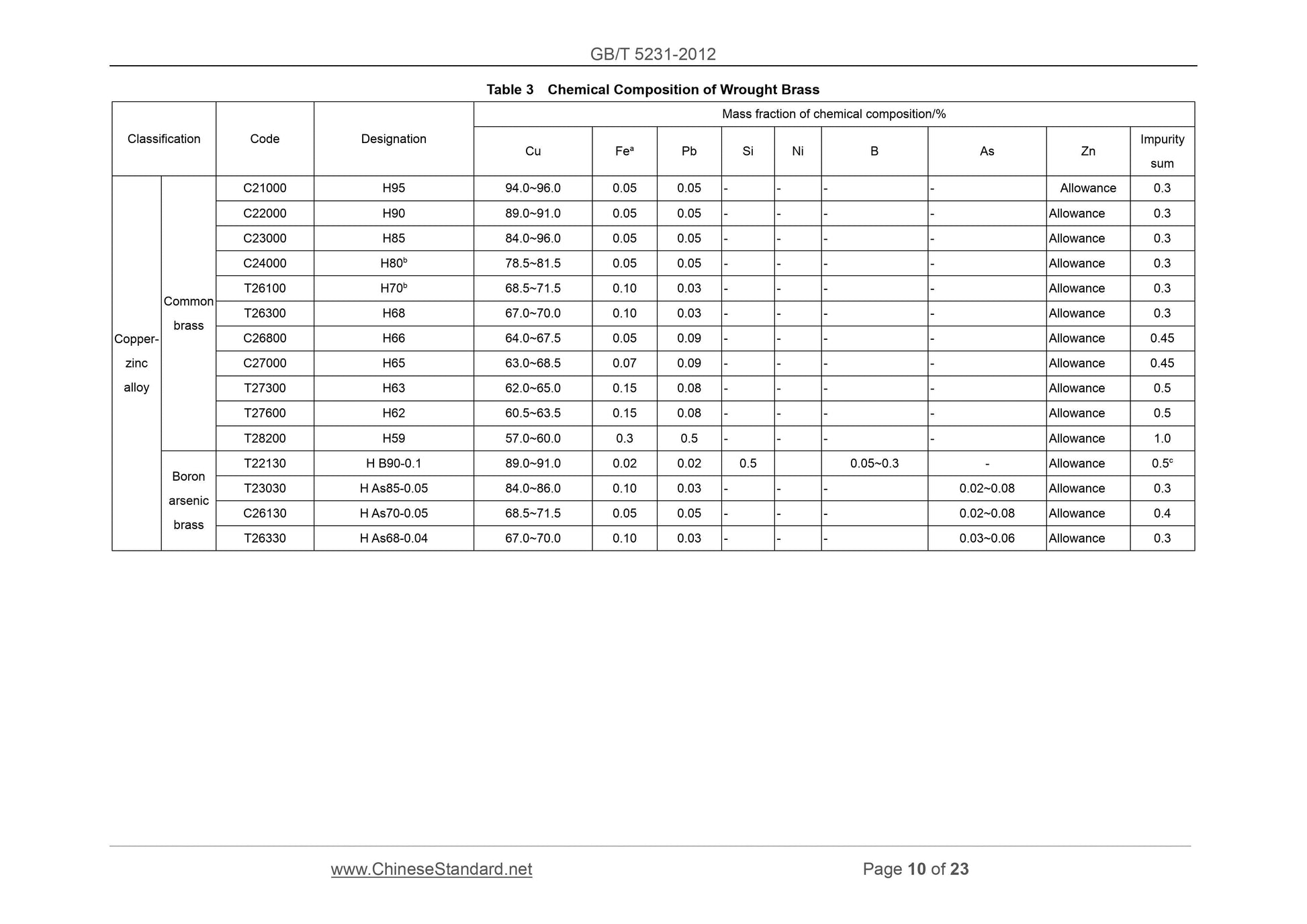

2.3 Impurity sum in Table 2 ~ Table 5 is the sum of all impurity elements, except the

principal composition; it mainly includes Ag, As, Bi, Cd, Co, Cr, Fe, Mn, Ni, O, P, Pb, S,

Sb, Se, Si, Sn, Te and Zn.

2.4 The limit value of elements not specified in Table 1 ~ Table 5 may be determined

through the negotiation of the Supplier and Purchaser. Where copper or zinc is the

element of allowance, the difference BETWEEN all analyzed elements AND 100% may

be taken.

2.5 This Standard equivalently adopts ASTM standard’s copper and copper alloy; its

codes are identical to ASTM’s designations. The summary of identical designations of

American standards is detailed in Appendix A.

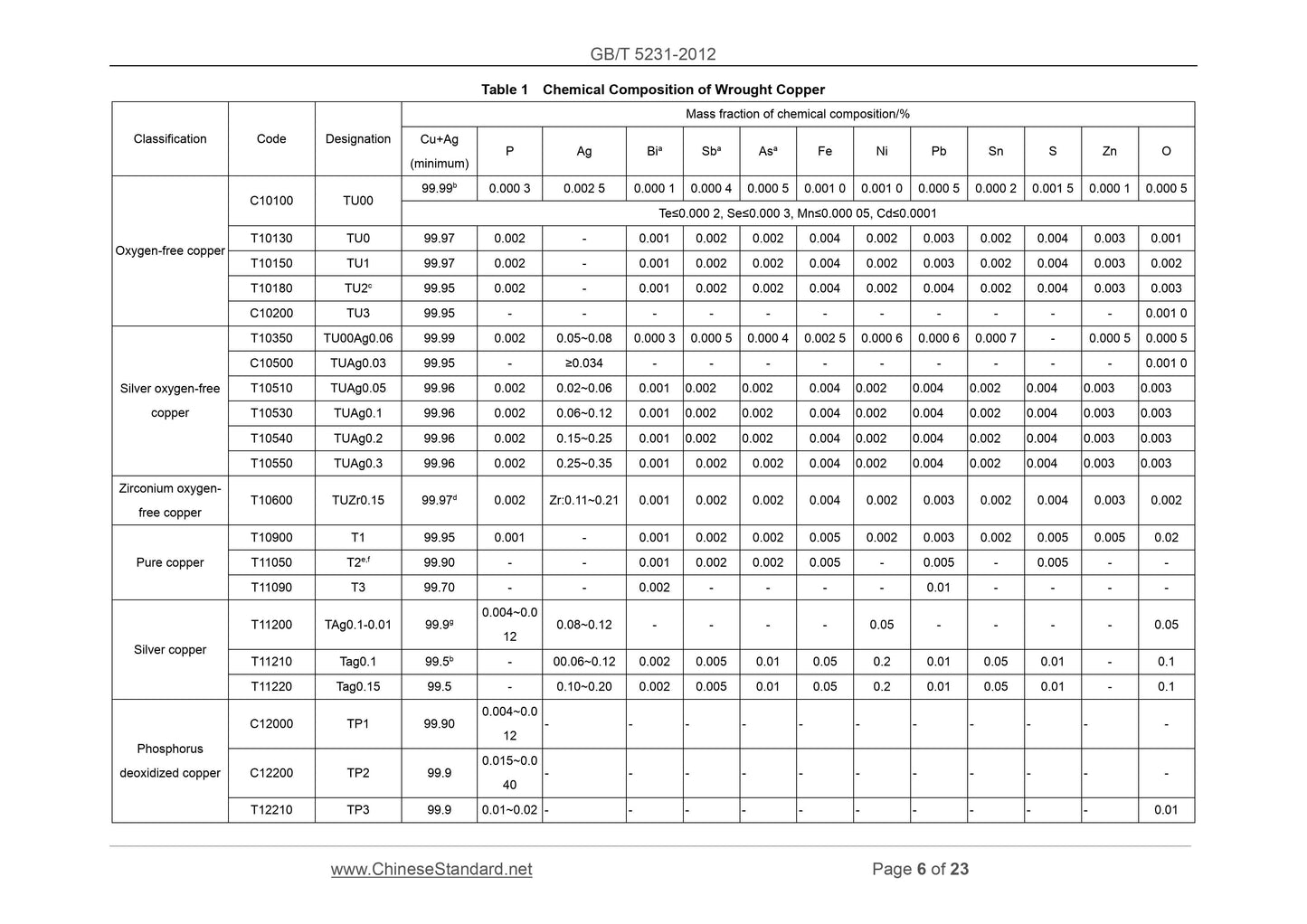

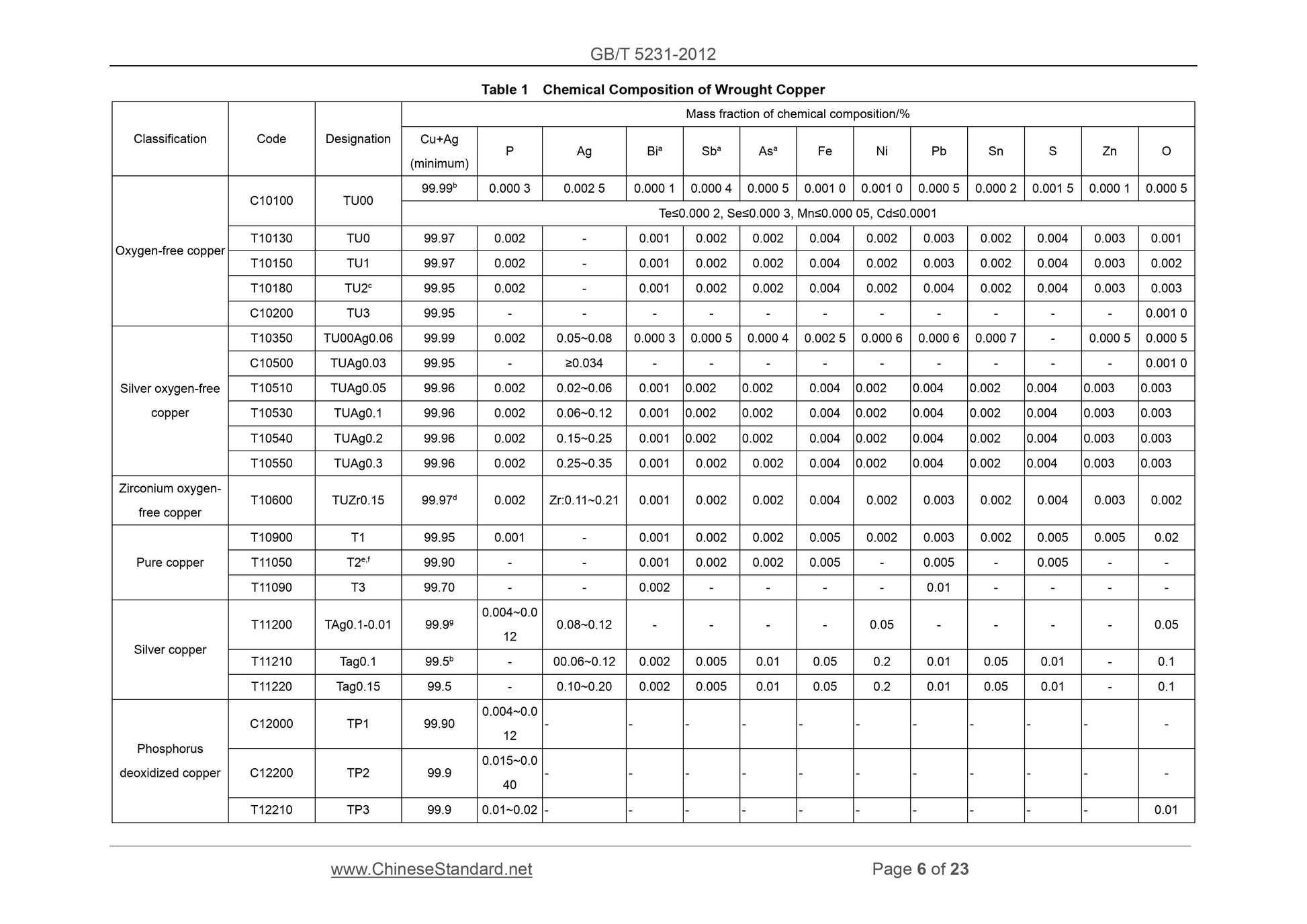

Table 1 Chemical Composition of Wrought Copper

Classification Code Designation

Mass fraction of chemical composition/%

Cu+Ag

(minimum) P Ag Bi

a Sba Asa Fe Ni Pb Sn S Zn O

Oxygen-free copper

C10100 TU00

99.99b 0.000 3 0.002 5 0.000 1 0.000 4 0.000 5 0.001 0 0.001 0 0.000 5 0.000 2 0.001 5 0.000 1 0.000 5

Te≤0.000 2, Se≤0.000 3, Mn≤0.000 05, Cd≤0.0001

T10130 TU0 99.97 0.002 - 0.001 0.002 0.002 0.004 0.002 0.003 0.002 0.004 0.003 0.001

T10150 TU1 99.97 0.002 - 0.001 0.002 0.002 0.004 0.002 0.003 0.002 0.004 0.003 0.002

T10180 TU2c 99.95 0.002 - 0.001 0.002 0.002 0.004 0.002 0.004 0.002 0.004 0.003 0.003

C10200 TU3 99.95 - - - - - - - - - - - 0.001 0

Silver oxygen-free

copper

T10350 TU00Ag0.06 99.99 0.002 0.05~0.08 0.000 3 0.000 5 0.000 4 0.002 5 0.000 6 0...

Get QUOTATION in 1-minute: Click GB/T 5231-2012

Historical versions: GB/T 5231-2012

Preview True-PDF (Reload/Scroll if blank)

GB/T 5231-2012: Designation and chemical composition of wrought copper and copper alloys

GB/T 5231-2012

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.30

H62

Replacing GB/T 5231-2001

Designation and Chemical Composition of Wrought

Copper and Copper Alloys

ISSUED ON. DECEMBER 31, 2012

IMPLEMENTED ON. OCTOBER 1, 2013

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine (AQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Chemical Composition ... 5

Appendix A (Informative) Identical Designation of American Standard ... 22

Foreword

This Standard was drafted in compliance with the rules specified in GB/T 1.1-2009.

This Standard replaces GB/T 5231-2001 "Wrought Copper and Copper Alloys

Chemical Composition Limits and Forms of Wrought Products". Some designations in

this Standard equivalently adopt the designations and chemical composition of

American copper and copper alloys; new requirements are made for some

designations and chemical composition in previous national standards; 111

designations in GB/T 5231-2001 are reserved, and 102 designations are added; 213

designations are included in this Standard in total. Compared with GB/T 5231-2001,

the main changes are as follows.

- Oxygen content of oxygen-free copper in this Standard was adjusted, TU0 in

previous standard was changed as TU00; it is identical to American designation

C10100; TU0 designation was added, and the oxygen content is 0.001%; TU1

and TU2 in previous standard were unchanged, the oxygen contents were 0.002%

and 0.003% respectively; oxygen-free copper TU3 was added and is identical to

American designation C10200;

- Designations QTe0.5, QZr0.2 and QZr0.4 in previous national standard were

integrated into pure copper series; the expression methods of the designations

were modified as TTe0.5, TZr0.2 and TZr0.4 respectively;

- Designations QCd1, QBe0.3-1.5, QBe0.6-2.5, QBe0.4-1.8, QBel.7, QBel.9,

QBel.9-0.1, QBe2, QCr0.5, QCr0.5-0.2-0.1, QCr0.6-0.4-0.05, QCr1, QMg0.8 and

QFe2.5 in previous national standards were integrated into high copper series;

the expression methods of the designations were modified as TCd1, TBe0.3-1.5,

TBe0.6-2.5, TBe0.4-1.8, TBel.7, TBel.9, TBel.9-0.1, TBe2, TCr0.5, TCr0.5-0.2-

0.1, TCro0.6-0.4-0.05, TCr1, TMg0.8 and TFe2.5 respectively;

- Designation H96 in previous national standard is identical to ASTM alloy

designation C21000; copper content was adjusted from 95.0%~97.0% to

94.0%~96.0% and designation was changed as H95;

- 19 designations for pure copper were added. TU0, TU3, TU00Ag0.06, TUAg0.03,

TUAg0.05, TUAg0.1, TUAg0.2, TUAg0.3, TUZr0.15, TAg0.1-0.01, TAg0.15, TP3,

TP4, TTe0.3, TTe0.5-0.008, TTe0.5-0.02, TS0.4, TZr0.15, and TUAl0.12;

- 15 designations for high copper alloy were added. TBel.9-0.4, TNi2.4-0.6-0.5,

TCr0.3-0.3, TCr0.5-0.1, TCr0.7, TCr0.8, TCrl-0.15, TCrl-0.18, TMg0.2, TMg0.4,

TMg0.5, TPb1, TFel.0, TFe0.1, and TTi3.0-0.2;

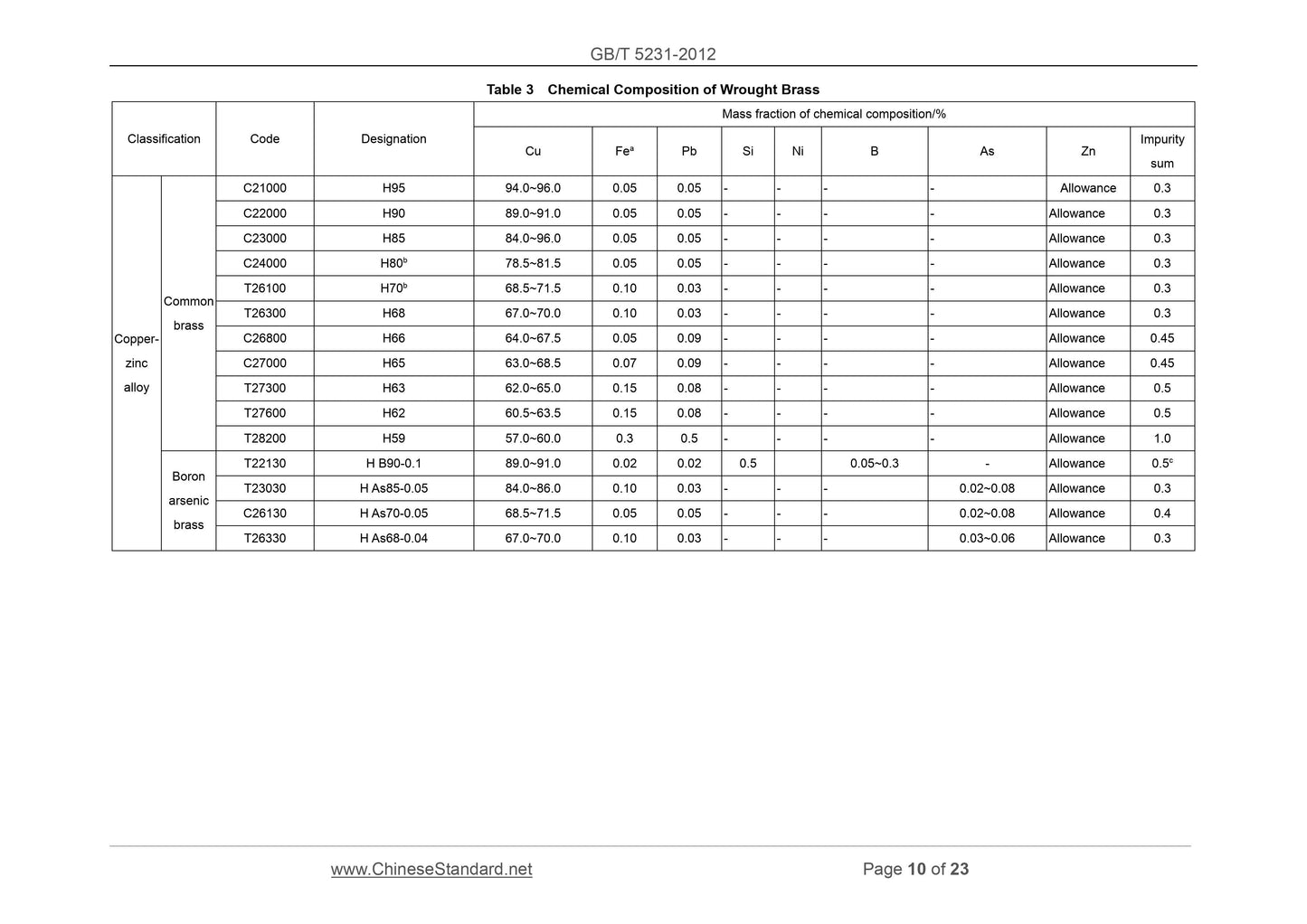

- 35 designations for brass were added. H66, HB90-0.1, HPb62-2-0.1, HPb61-2-

1, HPb61-2-0.1, HPb60-3, HPb59-2, HPb58-2, HPb58-3, HPb57-4, HSn72-1,

HSn70-1-0.01, HSnT0-1-0.01-0.04, HSn65-0.03, HBi60-2, HBi60-1.3, HBi60-

1.0-0.05, HBi60-0.5-0.01, HBi60-0.8-0.01, HBi60-1.1-0.01, HBi59-1, HBi62-1,

HMn64-5-1.5, HMn62-3-3-1, HMn62-13, HMn59-2-1.5-0.5, HMn57-2-2-0.5,

HSb61-0.8-0.5, HSb60-0.9, HSi75-3, HSi62-0.6, HSi61-0.6, HAl64-5-4-2, HAl61-

4-3-1.5 and HMg60-1;

- 14 designations for bronze were added. QSn0.4, QSn0.6, QSn0.9, QSn0.5-

0.025, QSnl-0.5-0.5, QSnl.8, QSn5-0.2, QSn5-0.3, QSn6-0.05, QSnlS-1-1,

QCr4.5-2.5-0.6, QAl6, QAll0-4-4-1 and QSi0.6-2;

- 19 designations for white copper were added. B23, BFe7-0.4-0.4, BFel0-1.5-1,

BFel0-1.6-1, BFel6-1-0.5, BFe30-0.7, BFe30-2-2, BZnl8-10, BZnl8-17, BZn9-29,

BZnl2-24, BZnl2-26, BZnl2-29, BZnl8-20, BZn22-16, BZn25-18, BZn40-20,

BZnl0-41-2 and BZnl2-37-1.5;

Designations for copper and copper alloy were added; the expression method is -

take T as the initial letter and followed by 5 digits. The alloys identical to American

alloy designation were still adopted with serial number of American designation.

This Standard shall be under the jurisdiction of National Technical Committee on

Nonferrous Metals of Standardization Administration of China (SAC/TC 243).

Drafting organizations of this Standard. Chinalco Shenyang Non-ferrous Metal

Processing Co., Ltd., Chinalco Luoyang Copper Co., Ltd., Zhejiang Hailiang Co., Ltd.,

Ningbo Powerway Group Co., Ltd. AND China Institute of Weights and Measures

Quality of Nonferrous Metal Industry.

Participating drafting organizations of this Standard. Chinalco Shanghai Copper Co.,

Ltd., Jiangsu Baoluo Copper Products Group Co., Ltd., Ningbo Jintian Copper (Group)

Co., Ltd. AND Shaoxing Libo Electric Co., Ltd..

Chief drafting staffs of this Standard. Wang Yanjie, Chen Jiangqiao, Zhao Baohong,

Wang Zhenyou, Zhang Bo, Zhang Caihong, Meng Huijuan, Zhao Wanhua, Cao

Jianguo, Wei Lianyun, Cai Jihua, Wang Yunsong, Yang Lijuan, Shao Shengzhong,

Zhang Yi, Zhang Shu, Wang Yongru, Hong Xieping, Xu Gaolei, Jiang Bochang, Fan

Zhigang, Liu Dongxia, Yu Jiangwen and Bao Jingguo.

The previous editions replaced by this Standard are as follows.

- GB/T 5231-1985, GB/T 5231-2001;

- GB/T 5232-1985, GB/T 5233-1985, GB/T 5234-1985.

Designation and Chemical Composition of Wrought

Copper and Copper Alloys

1 Scope

This Standard specifies designation and chemical composition of wrought copper and

copper alloy.

This Standard is applicable to the wrought product of copper and copper alloy

produced by pressure method, and the ingot casting and blank adopted for copper and

copper alloy.

2 Chemical Composition

2.1 Designation and chemical composition of wrought copper and copper alloy shall

meet those specified in Tables 1~5.

2.2 Content of alloy elements in Table 1 ~ Table 5 has upper and lower limits; if the

content is in single-value, the minimum limit is for copper; and the maximum limit is for

impurity element.

2.3 Impurity sum in Table 2 ~ Table 5 is the sum of all impurity elements, except the

principal composition; it mainly includes Ag, As, Bi, Cd, Co, Cr, Fe, Mn, Ni, O, P, Pb, S,

Sb, Se, Si, Sn, Te and Zn.

2.4 The limit value of elements not specified in Table 1 ~ Table 5 may be determined

through the negotiation of the Supplier and Purchaser. Where copper or zinc is the

element of allowance, the difference BETWEEN all analyzed elements AND 100% may

be taken.

2.5 This Standard equivalently adopts ASTM standard’s copper and copper alloy; its

codes are identical to ASTM’s designations. The summary of identical designations of

American standards is detailed in Appendix A.

Table 1 Chemical Composition of Wrought Copper

Classification Code Designation

Mass fraction of chemical composition/%

Cu+Ag

(minimum) P Ag Bi

a Sba Asa Fe Ni Pb Sn S Zn O

Oxygen-free copper

C10100 TU00

99.99b 0.000 3 0.002 5 0.000 1 0.000 4 0.000 5 0.001 0 0.001 0 0.000 5 0.000 2 0.001 5 0.000 1 0.000 5

Te≤0.000 2, Se≤0.000 3, Mn≤0.000 05, Cd≤0.0001

T10130 TU0 99.97 0.002 - 0.001 0.002 0.002 0.004 0.002 0.003 0.002 0.004 0.003 0.001

T10150 TU1 99.97 0.002 - 0.001 0.002 0.002 0.004 0.002 0.003 0.002 0.004 0.003 0.002

T10180 TU2c 99.95 0.002 - 0.001 0.002 0.002 0.004 0.002 0.004 0.002 0.004 0.003 0.003

C10200 TU3 99.95 - - - - - - - - - - - 0.001 0

Silver oxygen-free

copper

T10350 TU00Ag0.06 99.99 0.002 0.05~0.08 0.000 3 0.000 5 0.000 4 0.002 5 0.000 6 0...

Share