1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 5686.5-2023 English PDF (GB/T5686.5-2023)

GB/T 5686.5-2023 English PDF (GB/T5686.5-2023)

Regular price

$380.00

Regular price

Sale price

$380.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 5686.5-2023: Ferromanganese, ferromanganese-silicon, nitrogen-bearing ferromanganese and manganese metal - Determination of carbon content - The Infrared absorption method, the gasometric method, the gravimetric method and the coulometric method

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 5686.5-2023 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 5686.5-2023

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 5686.5-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.100

CCS H 11

Replacing GB/T 5686.5-2008

Ferromanganese, ferromanganese-silicon, nitrogen-bearing

ferromanganese and manganese metal - Determination of

carbon content - The Infrared absorption method, the

gasometric method, the gravimetric method and the coulometric

method

ISSUED ON: NOVEMBER 27, 2023

IMPLEMENTED ON: JUNE 01, 2024

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 6

1 Scope ... 8

2 Normative references ... 8

3 Terms and definitions ... 9

4 Method 1: Infrared absorption method ... 9

5 Method 2: Gasometric method ... 14

6 Method 3: Gravimetric method ... 19

7 Method 4: Coulometric method ... 24

8 Test report ... 28

Appendix A (Normative) Sample analysis result acceptance procedure flowchart ... 30

Appendix B (Informative) Raw data of infrared absorption method precision test ... 31

Bibliography ... 32

Ferromanganese, ferromanganese-silicon, nitrogen-bearing

ferromanganese and manganese metal - Determination of

carbon content - The Infrared absorption method, the

gasometric method, the gravimetric method and the

coulometric method

WARNING – Personnel using this document shall have hands-on work experience

in formal laboratory. This document does not indicate all possible safety issues.

Users are responsible for taking appropriate safety and health measures and

ensuring that the conditions specified in relevant national laws and regulations are

met.

1 Scope

This document describes the determination of carbon content in ferromanganese,

ferromanganese-silicon, nitrogen-bearing ferromanganese and manganese metal by the

infrared absorption method, the gasometric method, the gravimetric method and the

coulometric method.

This document is applicable to the determination of carbon content in ferromanganese,

ferromanganese-silicon, nitrogen-bearing ferromanganese and manganese metal.

Determination range (mass fraction): 0.010% ~ 10.00% for method 1; 0.40% ~ 5.00%

for method 2, not applicable to the determination of carbon content in nitrogen-bearing

ferromanganese and manganese metal; 4.00% ~ 8.00% for method 3, applicable to the

determination of carbon content in high carbon ferromanganese; 0.010% ~ 0.40% for

method 4, only applicable to the determination of carbon content in manganese metal.

2 Normative references

The following documents are referred to in the text in such a way that some or all of

their content constitutes requirements of this document. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 4010, Ferroalloys sampling and preparation of samples for chemical analysis

GB/T 6379.1, Accuracy (trueness and precision) of measurement methods and

results - Part 1: General principles and definitions

GB/T 6379.2, Accuracy (trueness and precision) of measurement methods and

results - Part 2: Basic method for the determination of repeatability and

reproducibility of a standard measurement method

GB/T 8170, Rules of rounding off for numerical values and expression and judgment

of limiting values

3 Terms and definitions

No terms and definitions need to be defined in this document.

4 Method 1: Infrared absorption method

4.1 Principle

Burn the sample in a high-frequency induction furnace with an oxygen flow. The carbon

is converted into carbon dioxide and carried to the infrared absorption cell along with

the oxygen flow. The infrared detector measures its absorption of infrared rays of a

specific wavelength. The absorption value is proportional to the carbon dioxide flowing

through it. The carbon content can be measured based on the change in energy received

by the detector.

4.2 Reagents and materials

4.2.1 Acetone: the carbon content (mass fraction) of the residue after evaporation shall

be less than 0.000 5%.

4.2.2 Anhydrous magnesium perchlorate, granular.

4.2.3 Caustic soda asbestos, granular.

4.2.4 Glass wool.

4.2.5 Tungsten particles, carbon content (mass fraction) less than 0.000 5%, particle

size 0.8 mm ~ 1.4 mm.

4.2.6 Tin particles, carbon content (mass fraction) less than 0.000 5%, particle size 0.4

mm ~ 0.8 mm. If necessary, use acetone (4.2.1) to clean the surface.

4.2.7 Pure iron, carbon content (mass fraction) less than 0.000 5%, particle size 0.8 mm

~ 1.68 mm.

4.2.8 Oxygen, purity greater than 99.95%. Other grades of oxygen may be used if a low

and consistent blank can be obtained.

4.2.9 Power gas, nitrogen, argon or compressed air, impurity (water and oil) content

(mass fraction) less than 0.5%.

13 – carbon dioxide detector.

Figure 1 – Schematic diagram of the device connection for determining carbon

using the infrared absorption method using a high-frequency induction furnace

for combustion

4.3.1.2 Gas washing bottle, containing caustic soda asbestos (4.2.3).

4.3.1.3 Drying tube, filled with anhydrous magnesium perchlorate (4.2.2).

4.3.2 Air source system

4.3.2.1 The carrier gas system includes an oxygen cylinder, a two-stage pressure

regulator and a timing control section to ensure the provision of appropriate pressure

and rated flow.

4.3.2.2 The power gas source system includes power gas (4.2.9), a two-stage pressure

regulator and a timing control section to ensure the provision of appropriate pressure

and rated flow.

4.3.3 High frequency induction furnace

The melting temperature requirements of the sample shall be met.

4.3.4 Control system

4.3.4.1 The microprocessor system includes central processing unit, memory, keyboard

input device, information center display screen, analysis result display screen and

analysis result printer, etc.

4.3.4.2 The control functions include automatic loading and unloading of crucibles and

lifting of the furnace, automatic cleaning, selection and setting of analysis conditions,

monitoring and alarm interruption of the analysis process, collection, calculation,

correction and processing of analysis data, etc.

4.3.5 Measuring system

It is mainly composed of an electronic balance (sensitivity not greater than 0.001 g)

controlled by a microprocessor, an infrared analyzer and electronic measuring elements.

4.4 Sample taking

Collect and prepare samples in accordance with the provisions of GB/T 4010. The

ferromanganese-silicon samples shall pass through a 0.125 mm sieve hole; the nitrogen-

bearing ferromanganese samples shall pass through a 0.149 mm sieve hole; the

manganese metal samples shall pass through a 0.177 mm sieve hole.

4.5 Procedure

4.5.5.1 According to the carbon content of the sample to be tested, select the

corresponding range and channel, and select 3 standard samples of the same type (the

carbon content of the sample to be tested shall fall within the range of the carbon content

of the selected 3 standard samples) and calibrate them in sequence to confirm the

linearity of the system. The fluctuation of the results of the standard samples measured

after calibration shall be within the allowable error range.

4.5.5.2 For different ranges or channels, their blank values shall be measured and

calibrated separately.

4.5.5.3 When the analytical conditions change, for example, if the instrument has not

been preheated for 1 hour, or the blank value of the oxygen source, crucible or flux has

changed, it is required to re-measure the blank and calibrate it.

4.5.6 Determination

4.5.6.1 According to the type and carbon content range of the sample to be tested,

respectively select the best analytical conditions of the instrument, such as the

combustion integration time of the instrument, the setting of the comparison level (or

set number), etc.

4.5.6.2 Ferromanganese-silicon: Weigh 0.200 g of the sample (see Table 1) and place it

in a ceramic crucible (4.2.10) pre-filled with 0.30 g of tin particles (4.2.6); cover it with

0.40 g of pure iron (4.2.7) and 1.80 g of tungsten particles (4.2.5) in sequence. Use

clamps to place the crucible on the crucible base of the instrument. Operate according

to the instrument manual; start analysis and read the results.

4.5.6.3 Ferromanganese, nitrogen-bearing ferromanganese and manganese metal:

Weigh an appropriate amount of sample (see Table 1) and place it in a ceramic crucible

(4.2.10) pre-filled with 0.30 g of tin particles (4.2.6); cover with 1.80 g of tungsten

particles (4.2.5); use clamps to take the crucible and place it on the crucible base of the

instrument; operate according to the instrument manual; start analysis and read the

results.

4.5.6.4 Repeat the measurements in 4.5.6.2 and 4.5.6.3 and carry out continuous parallel

determinations. The analysis results shall be expressed in accordance with 4.6.

4.6 Expression of analysis results

If the absolute value of the difference between two independent analysis results of the

same sample is not greater than the repeatability limit (r), take the arithmetic mean as

the analysis result. If the absolute value of the difference between two independent

analysis results is greater than the repeatability limit (r), increase the number of

measurements in accordance with the provisions of Appendix A and determine the

analysis result.

Round the analysis result to 3 decimal places according to GB/T 8170.

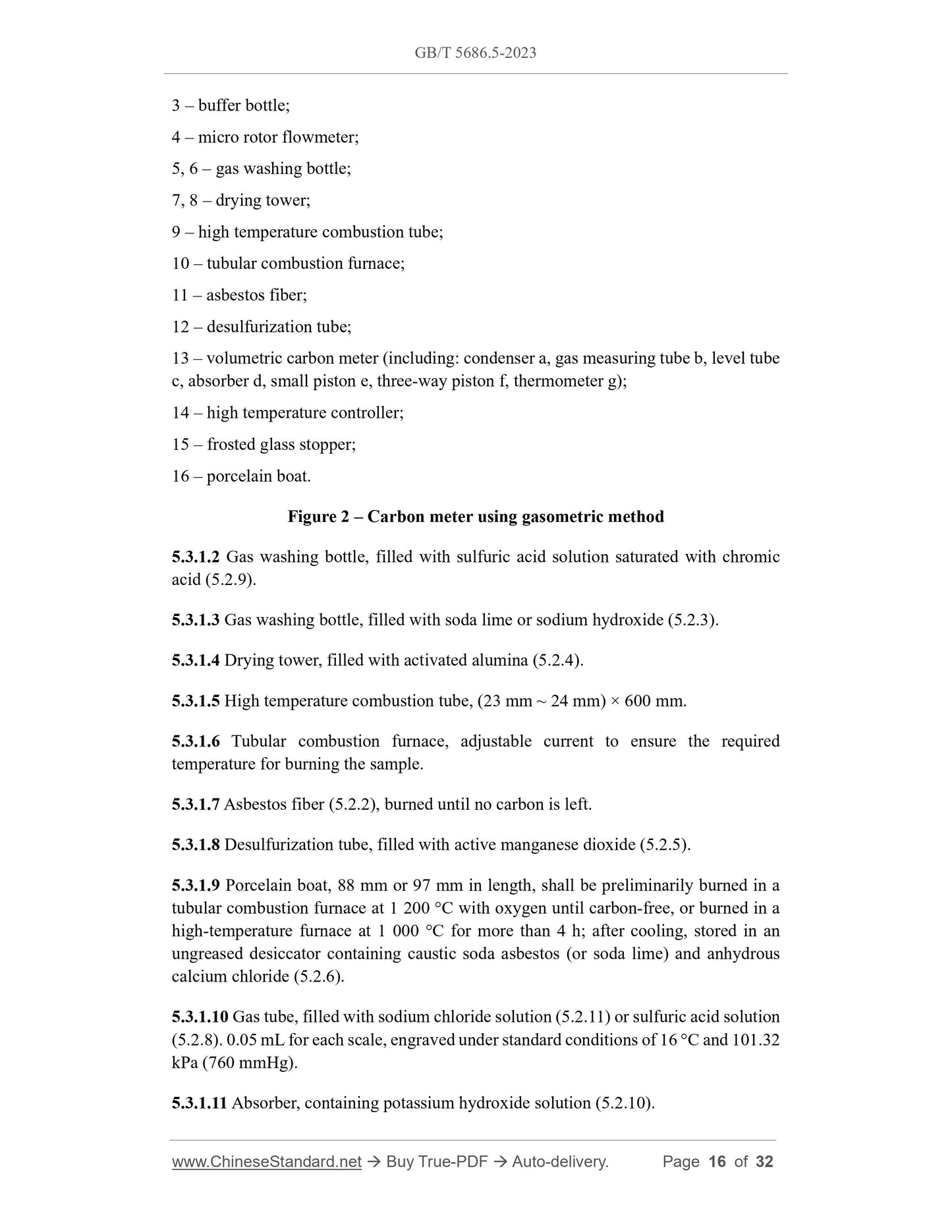

3 – buffer bottle;

4 – micro rotor flowmeter;

5, 6 – gas washing bottle;

7, 8 – drying tower;

9 – high temperature combustion tube;

10 – tubular combustion furnace;

11 – asbestos fiber;

12 – desulfurization tube;

13 – volumetric carbon meter (including: condenser a, gas measuring tube b, level tube

c, absorber d, small piston e, three-way piston f, thermometer g);

14 – high temperature controller;

15 – frosted glass stopper;

16 – porcelain boat.

Figure 2 – Carbon meter using gasometric method

5.3.1.2 Gas washing bottle, filled with sulfuric acid solution saturated with chromic

acid (5.2.9).

5.3.1.3 Gas washing bottle, filled with soda lime or sodium hydroxide (5.2.3).

5.3.1.4 Drying tower, filled with activated alumina (5.2.4).

5.3.1.5 High temperature combustion tube, (23 mm ~ 24 mm) × 600 mm.

5.3.1.6 Tubular combustion furnace, adjustable current to ensure the required

temperature for burning the sample.

5.3.1.7 Asbestos fiber (5.2.2), burned until no carbon is left.

5.3.1.8 Desulfurization tube, filled with active manganese dioxide (5.2.5).

5.3.1.9 Porcelain boat, 88 mm or 97 mm in length, shall be preliminarily burned in a

tubular combustion furnace at 1 200 °C with oxygen until carbon-free, or burned in a

high-temperature furnace at 1 000 °C for more than 4 h; after cooling, stored in an

ungreased desiccator containing caustic soda asbestos (or soda lime) and anhydrous

calcium chloride (5.2.6).

5.3.1.10 Gas tube, filled with sodium chloride solution (5.2.11) or sulfuric acid solution

(5.2.8). 0.05 mL for each scale, engraved under standard conditions of 16 °C and 101.32

kPa (760 mmHg).

5.3.1.11 Absorber, containing potassium hydroxide solution (5.2.10).

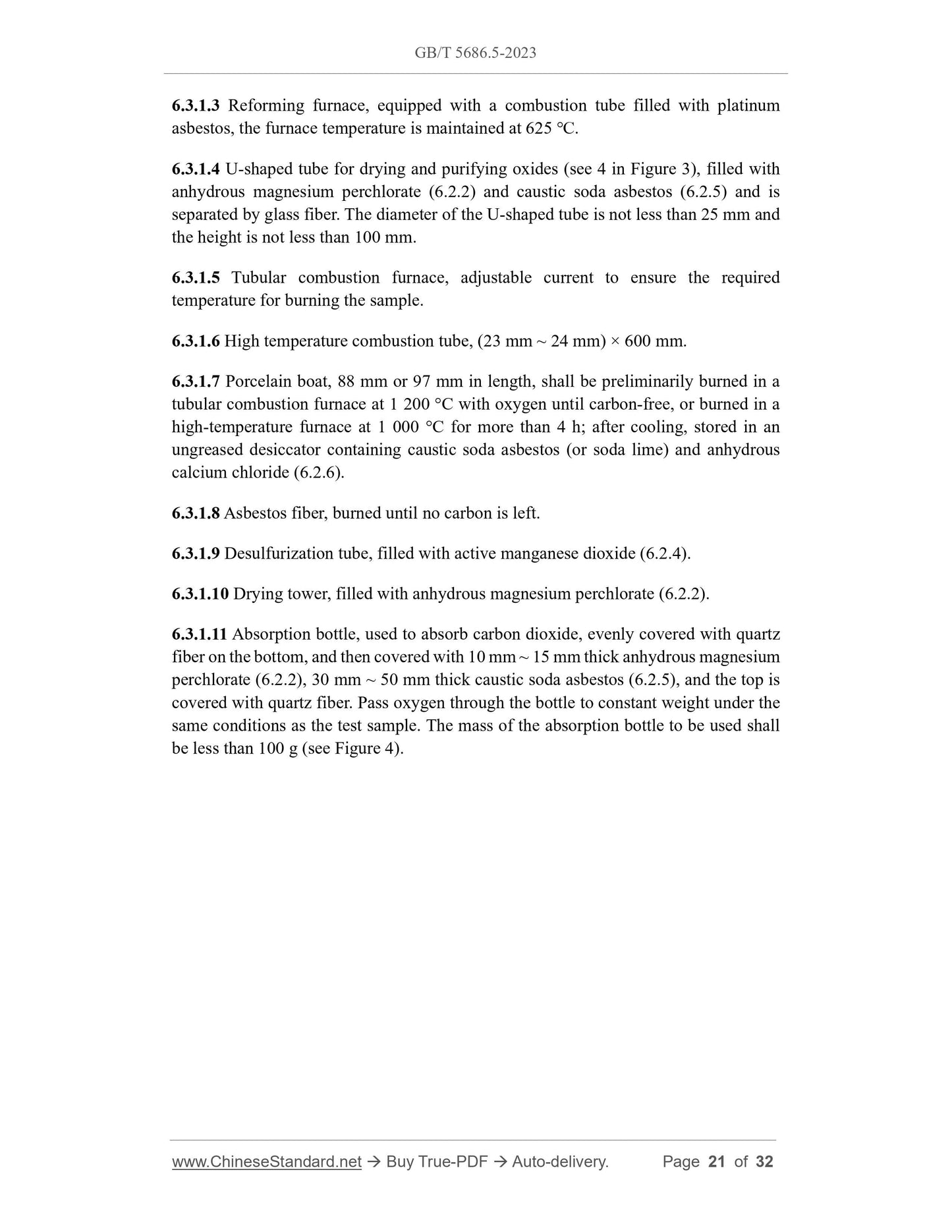

6.3.1.3 Reforming furnace, equipped with a combustion tube filled with platinum

asbestos, the furnace temperature is maintained at 625 ℃.

6.3.1.4 U-shaped tube for drying and purifying oxides (see 4 in Figure 3), filled with

anhydrous magnesium perchlorate (6.2.2) and caustic soda asbestos (6.2.5) and is

separated by glass fiber. The diameter of the U-shaped tube is not less than 25 mm and

the height is not less than 100 mm.

6.3.1.5 Tubular combustion furnace, adjustable current to ensure the required

temperature for burning the sample.

6.3.1.6 High temperature combustion tube, (23 mm ~ 24 mm) × 600 mm.

6.3.1.7 Porcelain boat, 88 mm or 97 mm in length, shall be preliminarily burned in a

tubular combustion furnace at 1 200 °C with oxygen until carbon-free, or burned in a

high-temperature furnace at 1 000 °C for more than 4 h; after cooling, stored in an

ungreased desiccator containing caustic soda asbestos (or soda lime) and anhydrous

calcium chloride (6.2.6).

6.3.1.8 Asbestos fiber, burned until no carbon is left.

6.3.1.9 Desulfurization tube, filled with active manganese dioxide (6.2.4).

6.3.1.10 Drying tower, filled with anhydrous magnesium perchlorate (6.2.2).

6.3.1.11 Absorption bottle, used to absorb carbon dioxide, evenly covered with quartz

fiber on the bottom, and then covered with 10 mm ~ 15 mm thick anhydrous magnesium

perchlorate (6.2.2), 30 mm ~ 50 mm thick caustic soda asbestos (6.2.5), and the top is

covered with quartz fiber. Pass oxygen through the bottle to constant weight under the

same conditions as the test sample. The mass of the absorption bottle to be used shall

be less than 100 g (see Figure 4).

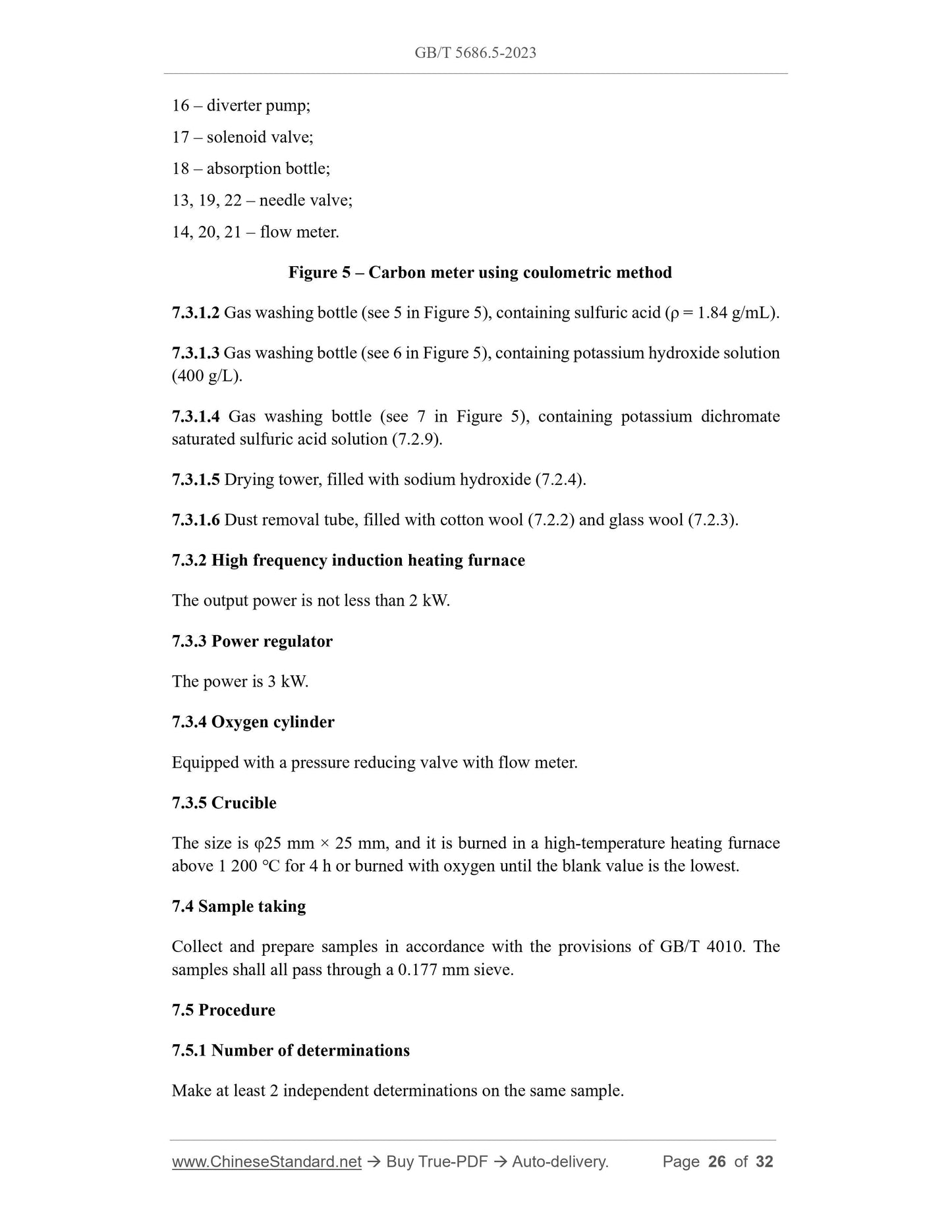

16 – diverter pump;

17 – solenoid valve;

18 – absorption bottle;

13, 19, 22 – needle valve;

14, 20, 21 – flow meter.

Figure 5 – Carbon meter using coulometric method

7.3.1.2 Gas washing bottle (see 5 in Figure 5), containing sulfuric acid (ρ = 1.84 g/mL).

7.3.1.3 Gas washing bottle (see 6 in Figure 5), containing potassium hydroxide solution

(400 g/L).

7.3.1.4 Gas washing bottle (see 7 in Figure 5), containing potassium dichromate

saturated sulfuric acid solution (7.2.9).

7.3.1.5 Drying tower, filled with sodium hydroxide (7.2.4).

7.3.1.6 Dust removal tube, filled with cotton wool (7.2.2) and glass wool (7.2.3).

7.3.2 High frequency induction heating furnace

The output power is not less than 2 kW.

7.3.3 Power regulator

The power is 3 kW.

7.3.4 Oxygen cylinder

Equipped with a pressure reducing valve with flow meter.

7.3.5 Crucible

The size is φ25 mm × 25 mm, and it is burned in a high-temperature heating furnace

above 1 200 ℃ for 4 h or burned with oxygen until the blank value is the lowest.

7.4 Sample taking

Collect and prepare samples in accordance with the provisions of GB/T 4010. The

samples sh...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 5686.5-2023 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 5686.5-2023

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 5686.5-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.100

CCS H 11

Replacing GB/T 5686.5-2008

Ferromanganese, ferromanganese-silicon, nitrogen-bearing

ferromanganese and manganese metal - Determination of

carbon content - The Infrared absorption method, the

gasometric method, the gravimetric method and the coulometric

method

ISSUED ON: NOVEMBER 27, 2023

IMPLEMENTED ON: JUNE 01, 2024

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 6

1 Scope ... 8

2 Normative references ... 8

3 Terms and definitions ... 9

4 Method 1: Infrared absorption method ... 9

5 Method 2: Gasometric method ... 14

6 Method 3: Gravimetric method ... 19

7 Method 4: Coulometric method ... 24

8 Test report ... 28

Appendix A (Normative) Sample analysis result acceptance procedure flowchart ... 30

Appendix B (Informative) Raw data of infrared absorption method precision test ... 31

Bibliography ... 32

Ferromanganese, ferromanganese-silicon, nitrogen-bearing

ferromanganese and manganese metal - Determination of

carbon content - The Infrared absorption method, the

gasometric method, the gravimetric method and the

coulometric method

WARNING – Personnel using this document shall have hands-on work experience

in formal laboratory. This document does not indicate all possible safety issues.

Users are responsible for taking appropriate safety and health measures and

ensuring that the conditions specified in relevant national laws and regulations are

met.

1 Scope

This document describes the determination of carbon content in ferromanganese,

ferromanganese-silicon, nitrogen-bearing ferromanganese and manganese metal by the

infrared absorption method, the gasometric method, the gravimetric method and the

coulometric method.

This document is applicable to the determination of carbon content in ferromanganese,

ferromanganese-silicon, nitrogen-bearing ferromanganese and manganese metal.

Determination range (mass fraction): 0.010% ~ 10.00% for method 1; 0.40% ~ 5.00%

for method 2, not applicable to the determination of carbon content in nitrogen-bearing

ferromanganese and manganese metal; 4.00% ~ 8.00% for method 3, applicable to the

determination of carbon content in high carbon ferromanganese; 0.010% ~ 0.40% for

method 4, only applicable to the determination of carbon content in manganese metal.

2 Normative references

The following documents are referred to in the text in such a way that some or all of

their content constitutes requirements of this document. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 4010, Ferroalloys sampling and preparation of samples for chemical analysis

GB/T 6379.1, Accuracy (trueness and precision) of measurement methods and

results - Part 1: General principles and definitions

GB/T 6379.2, Accuracy (trueness and precision) of measurement methods and

results - Part 2: Basic method for the determination of repeatability and

reproducibility of a standard measurement method

GB/T 8170, Rules of rounding off for numerical values and expression and judgment

of limiting values

3 Terms and definitions

No terms and definitions need to be defined in this document.

4 Method 1: Infrared absorption method

4.1 Principle

Burn the sample in a high-frequency induction furnace with an oxygen flow. The carbon

is converted into carbon dioxide and carried to the infrared absorption cell along with

the oxygen flow. The infrared detector measures its absorption of infrared rays of a

specific wavelength. The absorption value is proportional to the carbon dioxide flowing

through it. The carbon content can be measured based on the change in energy received

by the detector.

4.2 Reagents and materials

4.2.1 Acetone: the carbon content (mass fraction) of the residue after evaporation shall

be less than 0.000 5%.

4.2.2 Anhydrous magnesium perchlorate, granular.

4.2.3 Caustic soda asbestos, granular.

4.2.4 Glass wool.

4.2.5 Tungsten particles, carbon content (mass fraction) less than 0.000 5%, particle

size 0.8 mm ~ 1.4 mm.

4.2.6 Tin particles, carbon content (mass fraction) less than 0.000 5%, particle size 0.4

mm ~ 0.8 mm. If necessary, use acetone (4.2.1) to clean the surface.

4.2.7 Pure iron, carbon content (mass fraction) less than 0.000 5%, particle size 0.8 mm

~ 1.68 mm.

4.2.8 Oxygen, purity greater than 99.95%. Other grades of oxygen may be used if a low

and consistent blank can be obtained.

4.2.9 Power gas, nitrogen, argon or compressed air, impurity (water and oil) content

(mass fraction) less than 0.5%.

13 – carbon dioxide detector.

Figure 1 – Schematic diagram of the device connection for determining carbon

using the infrared absorption method using a high-frequency induction furnace

for combustion

4.3.1.2 Gas washing bottle, containing caustic soda asbestos (4.2.3).

4.3.1.3 Drying tube, filled with anhydrous magnesium perchlorate (4.2.2).

4.3.2 Air source system

4.3.2.1 The carrier gas system includes an oxygen cylinder, a two-stage pressure

regulator and a timing control section to ensure the provision of appropriate pressure

and rated flow.

4.3.2.2 The power gas source system includes power gas (4.2.9), a two-stage pressure

regulator and a timing control section to ensure the provision of appropriate pressure

and rated flow.

4.3.3 High frequency induction furnace

The melting temperature requirements of the sample shall be met.

4.3.4 Control system

4.3.4.1 The microprocessor system includes central processing unit, memory, keyboard

input device, information center display screen, analysis result display screen and

analysis result printer, etc.

4.3.4.2 The control functions include automatic loading and unloading of crucibles and

lifting of the furnace, automatic cleaning, selection and setting of analysis conditions,

monitoring and alarm interruption of the analysis process, collection, calculation,

correction and processing of analysis data, etc.

4.3.5 Measuring system

It is mainly composed of an electronic balance (sensitivity not greater than 0.001 g)

controlled by a microprocessor, an infrared analyzer and electronic measuring elements.

4.4 Sample taking

Collect and prepare samples in accordance with the provisions of GB/T 4010. The

ferromanganese-silicon samples shall pass through a 0.125 mm sieve hole; the nitrogen-

bearing ferromanganese samples shall pass through a 0.149 mm sieve hole; the

manganese metal samples shall pass through a 0.177 mm sieve hole.

4.5 Procedure

4.5.5.1 According to the carbon content of the sample to be tested, select the

corresponding range and channel, and select 3 standard samples of the same type (the

carbon content of the sample to be tested shall fall within the range of the carbon content

of the selected 3 standard samples) and calibrate them in sequence to confirm the

linearity of the system. The fluctuation of the results of the standard samples measured

after calibration shall be within the allowable error range.

4.5.5.2 For different ranges or channels, their blank values shall be measured and

calibrated separately.

4.5.5.3 When the analytical conditions change, for example, if the instrument has not

been preheated for 1 hour, or the blank value of the oxygen source, crucible or flux has

changed, it is required to re-measure the blank and calibrate it.

4.5.6 Determination

4.5.6.1 According to the type and carbon content range of the sample to be tested,

respectively select the best analytical conditions of the instrument, such as the

combustion integration time of the instrument, the setting of the comparison level (or

set number), etc.

4.5.6.2 Ferromanganese-silicon: Weigh 0.200 g of the sample (see Table 1) and place it

in a ceramic crucible (4.2.10) pre-filled with 0.30 g of tin particles (4.2.6); cover it with

0.40 g of pure iron (4.2.7) and 1.80 g of tungsten particles (4.2.5) in sequence. Use

clamps to place the crucible on the crucible base of the instrument. Operate according

to the instrument manual; start analysis and read the results.

4.5.6.3 Ferromanganese, nitrogen-bearing ferromanganese and manganese metal:

Weigh an appropriate amount of sample (see Table 1) and place it in a ceramic crucible

(4.2.10) pre-filled with 0.30 g of tin particles (4.2.6); cover with 1.80 g of tungsten

particles (4.2.5); use clamps to take the crucible and place it on the crucible base of the

instrument; operate according to the instrument manual; start analysis and read the

results.

4.5.6.4 Repeat the measurements in 4.5.6.2 and 4.5.6.3 and carry out continuous parallel

determinations. The analysis results shall be expressed in accordance with 4.6.

4.6 Expression of analysis results

If the absolute value of the difference between two independent analysis results of the

same sample is not greater than the repeatability limit (r), take the arithmetic mean as

the analysis result. If the absolute value of the difference between two independent

analysis results is greater than the repeatability limit (r), increase the number of

measurements in accordance with the provisions of Appendix A and determine the

analysis result.

Round the analysis result to 3 decimal places according to GB/T 8170.

3 – buffer bottle;

4 – micro rotor flowmeter;

5, 6 – gas washing bottle;

7, 8 – drying tower;

9 – high temperature combustion tube;

10 – tubular combustion furnace;

11 – asbestos fiber;

12 – desulfurization tube;

13 – volumetric carbon meter (including: condenser a, gas measuring tube b, level tube

c, absorber d, small piston e, three-way piston f, thermometer g);

14 – high temperature controller;

15 – frosted glass stopper;

16 – porcelain boat.

Figure 2 – Carbon meter using gasometric method

5.3.1.2 Gas washing bottle, filled with sulfuric acid solution saturated with chromic

acid (5.2.9).

5.3.1.3 Gas washing bottle, filled with soda lime or sodium hydroxide (5.2.3).

5.3.1.4 Drying tower, filled with activated alumina (5.2.4).

5.3.1.5 High temperature combustion tube, (23 mm ~ 24 mm) × 600 mm.

5.3.1.6 Tubular combustion furnace, adjustable current to ensure the required

temperature for burning the sample.

5.3.1.7 Asbestos fiber (5.2.2), burned until no carbon is left.

5.3.1.8 Desulfurization tube, filled with active manganese dioxide (5.2.5).

5.3.1.9 Porcelain boat, 88 mm or 97 mm in length, shall be preliminarily burned in a

tubular combustion furnace at 1 200 °C with oxygen until carbon-free, or burned in a

high-temperature furnace at 1 000 °C for more than 4 h; after cooling, stored in an

ungreased desiccator containing caustic soda asbestos (or soda lime) and anhydrous

calcium chloride (5.2.6).

5.3.1.10 Gas tube, filled with sodium chloride solution (5.2.11) or sulfuric acid solution

(5.2.8). 0.05 mL for each scale, engraved under standard conditions of 16 °C and 101.32

kPa (760 mmHg).

5.3.1.11 Absorber, containing potassium hydroxide solution (5.2.10).

6.3.1.3 Reforming furnace, equipped with a combustion tube filled with platinum

asbestos, the furnace temperature is maintained at 625 ℃.

6.3.1.4 U-shaped tube for drying and purifying oxides (see 4 in Figure 3), filled with

anhydrous magnesium perchlorate (6.2.2) and caustic soda asbestos (6.2.5) and is

separated by glass fiber. The diameter of the U-shaped tube is not less than 25 mm and

the height is not less than 100 mm.

6.3.1.5 Tubular combustion furnace, adjustable current to ensure the required

temperature for burning the sample.

6.3.1.6 High temperature combustion tube, (23 mm ~ 24 mm) × 600 mm.

6.3.1.7 Porcelain boat, 88 mm or 97 mm in length, shall be preliminarily burned in a

tubular combustion furnace at 1 200 °C with oxygen until carbon-free, or burned in a

high-temperature furnace at 1 000 °C for more than 4 h; after cooling, stored in an

ungreased desiccator containing caustic soda asbestos (or soda lime) and anhydrous

calcium chloride (6.2.6).

6.3.1.8 Asbestos fiber, burned until no carbon is left.

6.3.1.9 Desulfurization tube, filled with active manganese dioxide (6.2.4).

6.3.1.10 Drying tower, filled with anhydrous magnesium perchlorate (6.2.2).

6.3.1.11 Absorption bottle, used to absorb carbon dioxide, evenly covered with quartz

fiber on the bottom, and then covered with 10 mm ~ 15 mm thick anhydrous magnesium

perchlorate (6.2.2), 30 mm ~ 50 mm thick caustic soda asbestos (6.2.5), and the top is

covered with quartz fiber. Pass oxygen through the bottle to constant weight under the

same conditions as the test sample. The mass of the absorption bottle to be used shall

be less than 100 g (see Figure 4).

16 – diverter pump;

17 – solenoid valve;

18 – absorption bottle;

13, 19, 22 – needle valve;

14, 20, 21 – flow meter.

Figure 5 – Carbon meter using coulometric method

7.3.1.2 Gas washing bottle (see 5 in Figure 5), containing sulfuric acid (ρ = 1.84 g/mL).

7.3.1.3 Gas washing bottle (see 6 in Figure 5), containing potassium hydroxide solution

(400 g/L).

7.3.1.4 Gas washing bottle (see 7 in Figure 5), containing potassium dichromate

saturated sulfuric acid solution (7.2.9).

7.3.1.5 Drying tower, filled with sodium hydroxide (7.2.4).

7.3.1.6 Dust removal tube, filled with cotton wool (7.2.2) and glass wool (7.2.3).

7.3.2 High frequency induction heating furnace

The output power is not less than 2 kW.

7.3.3 Power regulator

The power is 3 kW.

7.3.4 Oxygen cylinder

Equipped with a pressure reducing valve with flow meter.

7.3.5 Crucible

The size is φ25 mm × 25 mm, and it is burned in a high-temperature heating furnace

above 1 200 ℃ for 4 h or burned with oxygen until the blank value is the lowest.

7.4 Sample taking

Collect and prepare samples in accordance with the provisions of GB/T 4010. The

samples sh...

Share