1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 6478-2001 English PDF (GB/T6478-2001)

GB/T 6478-2001 English PDF (GB/T6478-2001)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 6478-2001: Steels for cold heading and cold extruding

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.

Newer version: (Replacing this standard) GB/T 6478-2015

Get Quotation: Click GB/T 6478-2001 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 6478-2015

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 6478-2001

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.10

H44

neq ISO 4954.1993

Steels for Cold Heading and Cold Extruding

ISSUED ON. SEPTEMBER 15, 2001

IMPLEMENTED ON. FEBRUARY 1, 2002

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

1 Scope ... 5

2 Normative References ... 5

3 Ordering Instructions ... 8

4 Classification and Code Number ... 9

5 Dimension, Shape, Weight and Allowable Deviation ... 9

6 Technical Requirements ... 9

7 Test Methods ... 14

8 Inspection Rules ... 14

9 Packaging, Marking and Quality Certificate ... 15

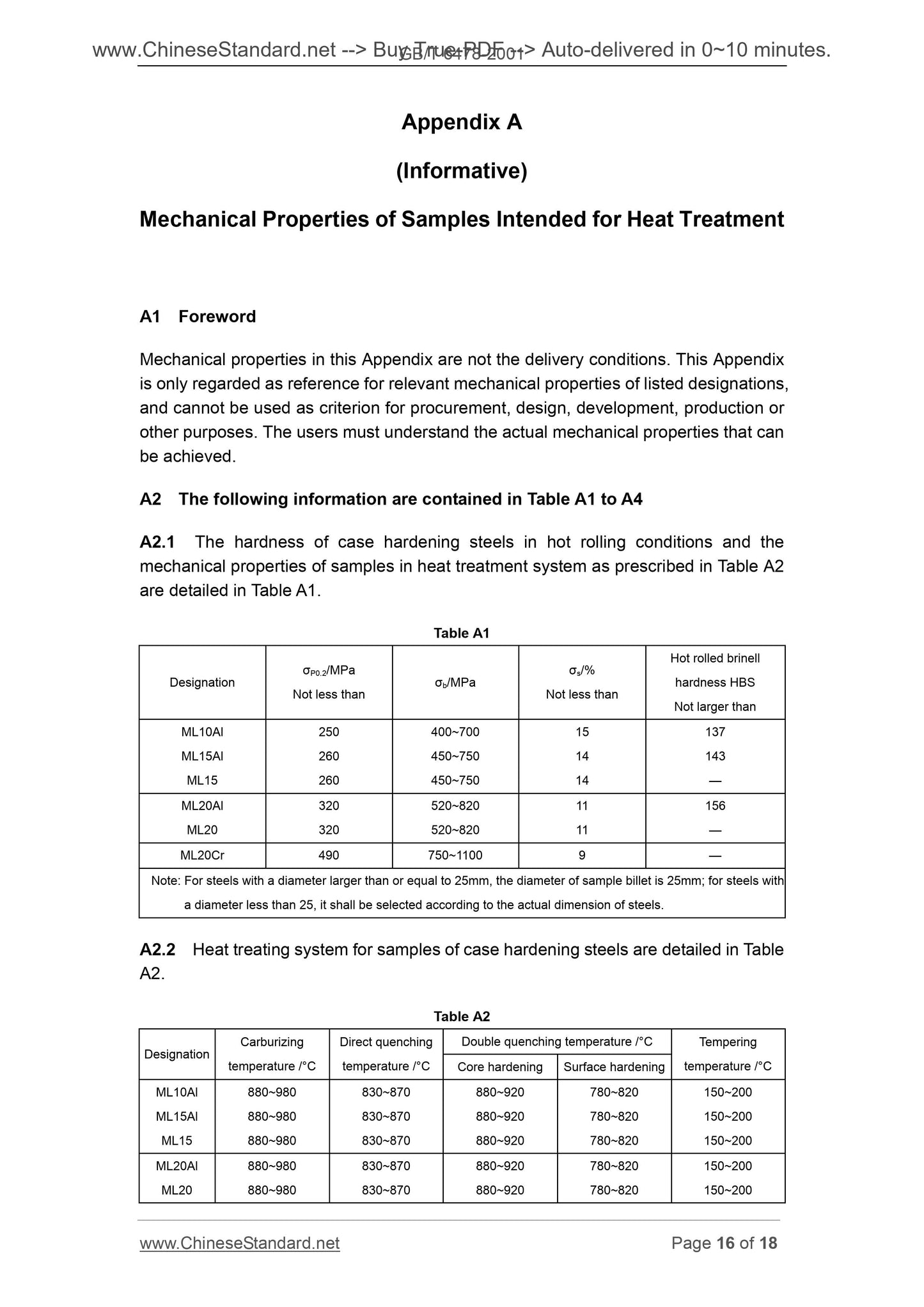

Appendix A (Informative) Mechanical Properties of Samples Intended for

Heat Treatment ... 16

Foreword

This Standard non-equivalently adopts international standard ISO4954.1993 "Steels

for Cold Heading and Cold Extruding". For steels not intended for heat treatment, the

mass fractions of S and P are reduced to 0.035%; for boron treated steels for

quenching and tempering, the mass fraction range of boron is narrowed; acid leaching

macrostructure inspection is added; and the specification for cold upsetting test is

expanded to 5.0mm~40mm and judged by classification.

The changes of main content in this revision are as follows.

- This Standard is named as “Steels for Cold Heading and Cold Extruding";

- Steels for cold heading and cold extruding are classified into three types - steels

not intended for heat treatment, case hardening steels, and steels for quenching

and tempering (including boron treated steel) according to the service

conditions of steel;

- Fourteen designations such as CC4A, CC15K, CC21K, 37Cr4E, CE20BG1,

CE288, CE358, CE20BG2, 35MnB5E, 37CrB1E in ISO 4954.1993 (the

corresponding designations in GB/T 6478 are ML04A1, ML15, ML20, ML37Cr,

ML208, the M1.288, M1.358, ML20MnB, ML35MnB, ML37CrB); and SWRCH1

8A, SWRCH22A in JIS G 3507-1991 "Carbon Steel Wire Rod for Cold Heading"

(the corresponding designations in GB/T 6478 are ML18Mn and ML22Mn); as

well as ML15Mn, ML20MnVB which are produced in large quantity in recent

years;

- Three designations - ML40Mn, ML45Mn and ML15Cr, which have not been used

for ordering are deleted.

- For the same designations of steels that are not intended for heat treatment in

this Standard and GB/T 6478-1986, the mass fraction range of carbon is

narrowed; the mass fraction range of silicon is broaden; and the mass fraction

range of manganese is changed from 0.20%~0.50% to 0.30%~0.60%. For the

designations of steels for case hardening, quenching and tempering (including

boron treated steel), the mass fraction range of carbon is narrowed; and the

mass fraction range of manganese is changed from 0.50%~0.80% to

0.60%~0.90%;

- Requirements for the mechanical properties of steels that are not intended for

heat treatment delivered in hot rolling condition are added in this Standard.

- Requirements for mechanical properties of steels for case hardening, quenching

and tempering (including boron treated steel) delivered in annealing condition

are added.

- The mechanical properties of samples intended for heat treatment are not

necessary in this Standard. If it is required by the purchaser, relevant values

may be determined based on the agreement of both supplier and purchaser,

and indicated in the contract.

Appendix A of this Standard is informative.

This Standard shall replace GB/T 6478-1986 "Cold Heading Steel - Technical

Requirements" since the implementation date.

This Standard was proposed by the State Metallurgical Industry Bureau.

This Standard shall be under the jurisdiction of National Technical Committee on Iron

and Steel of Standardization Administration of China.

Drafting organization of this Standard. Taiyuan Iron and Steel (Group) Co., Ltd.

Chief drafting staffs of this Standard. Liu Peng, Niu Chenmei, Gao Ping, Zhao

Jianping, Han Yi and Liang Zhenshan.

This Standard was issued in June 1986 for the first time.

Steels for Cold Heading and Cold Extruding

1 Scope

This Standard specifies the classification, code number, size, appearance, weight,

allowable deviation, technical requirements, test methods, inspection rules, packaging,

marking and quality certificate of steels for cold heading and cold extruding.

This Standard is applicable to unalloyed and alloyed steel hot rolled wire rod with a

diameter of 5mm~40mm and intended for cold heading and cold extruding, as well as

the unalloyed and alloyed steel hot-rolled round steel with a diameter of

12mm~100mm and intended for cold heading and cold extruding.

2 Normative References

The following normative documents contain provisions which, through reference into

this Standard, constitute the provisions of this Standard. At the time of publication, the

editions indicated were valid. All standards will be revised and all parties who reach an

agreement according to this Standard are encouraged to study whether the latest

editions of the following standards are applicable.

GB/T 222-1984 Method of Sampling Steel for Determination of Chemical

Composition and Permissible Variations for Product Analysis

GB/T 223.3-1988 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Phosphomolybdate Gravimetric Method for the Determination

of Phosphorus Content

GB/T 223.5-1997 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Reduced Molybdosilicate Spectrophotometric Method for the Determination of

Acid-soluble Silicon Content

GB/T 223.8-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Fluoride Separation - EDTA Titration Method for the Determination of

Aluminium Content

GB/T 223.9-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Chrom Azurol S Photometric Method for the Determination of Aluminium Content

GB/T 223.10-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Cupferron Separation-chrome Azurol S Photometric Method for the Determination

of Aluminium Content

GB/T 223.11-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Ammonium Persulfate Oxidation Volumetric Method for the Determination of

Chromium Content

GB/T 223.12-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Carbonate Separation-diphenyl Carbazide Photometric Method for the

Determination of Chromium Content

GB/T 223.13-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Ammonium Ferrous Sulfate Titration Method for the Determination of Vanadium

Content

GB/T 223.14-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

N-benzoy-N-phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.16-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Chromotropic Acid Photometric Method for the Determination of Titanium Content

GB/T 223.17-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Photometric Method for the Determination of Titanium Content

GB/T 223.18-1994 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of Copper

Content

GB/T 223.19-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Neocuproine-chloroform Extraction Photometric Method for the Determination of

Copper Content

GB/T 223.23-1994 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Dimethylglyoxime Spectrophotometric Method for the Determination of Nickel

Content

GB/T 223.24-1994 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Extraction Separation - The Dimethylglyoxime Spectrophotometric Method for the

Determination of Nickel Content

GB/T 223.26-1989 Methods for Chemical Analysis of Iron Steel and Alloy - The

Thiocyanate Direct Photometric Method for the Determination of Molybdenum

Content

GB/T 223.53-1987 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Flame Atomic Absorption Spectrophotometric Method for the Determination of

Copper Content

GB/T 223.58-1987 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Arsenite-sodium Nitrite Titrimetric Method for the Determination of

Manganese Content

GB/T 223.59-1987 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Reduced Molybdoantimonyl Phosphoric Acid Photometric Method for the

Determination of Phosphorus Content

GB/T 223.60-1997 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Perchloric Acid Dehydration Gravimetric Method for the Determination of Silicon

Content

GB/T 223.61-1988 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Ammonium Phosphomolybdate Volumetric Method for the Determination of

Phosphorus Content

GB/T 223.62-1988 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Butyl Acetate Extraction Photometric Method for the Determination of Phosphorus

Content

GB/T 223.63-1988 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium (Potas...

GB/T 6478-2001

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.10

H44

neq ISO 4954.1993

Steels for Cold Heading and Cold Extruding

ISSUED ON. SEPTEMBER 15, 2001

IMPLEMENTED ON. FEBRUARY 1, 2002

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

1 Scope ... 5

2 Normative References ... 5

3 Ordering Instructions ... 8

4 Classification and Code Number ... 9

5 Dimension, Shape, Weight and Allowable Deviation ... 9

6 Technical Requirements ... 9

7 Test Methods ... 14

8 Inspection Rules ... 14

9 Packaging, Marking and Quality Certificate ... 15

Appendix A (Informative) Mechanical Properties of Samples Intended for

Heat Treatment ... 16

Foreword

This Standard non-equivalently adopts international standard ISO4954.1993 "Steels

for Cold Heading and Cold Extruding". For steels not intended for heat treatment, the

mass fractions of S and P are reduced to 0.035%; for boron treated steels for

quenching and tempering, the mass fraction range of boron is narrowed; acid leaching

macrostructure inspection is added; and the specification for cold upsetting test is

expanded to 5.0mm~40mm and judged by classification.

The changes of main content in this revision are as follows.

- This Standard is named as “Steels for Cold Heading and Cold Extruding";

- Steels for cold heading and cold extruding are classified into three types - steels

not intended for heat treatment, case hardening steels, and steels for quenching

and tempering (including boron treated steel) according to the service

conditions of steel;

- Fourteen designations such as CC4A, CC15K, CC21K, 37Cr4E, CE20BG1,

CE288, CE358, CE20BG2, 35MnB5E, 37CrB1E in ISO 4954.1993 (the

corresponding designations in GB/T 6478 are ML04A1, ML15, ML20, ML37Cr,

ML208, the M1.288, M1.358, ML20MnB, ML35MnB, ML37CrB); and SWRCH1

8A, SWRCH22A in JIS G 3507-1991 "Carbon Steel Wire Rod for Cold Heading"

(the corresponding designations in GB/T 6478 are ML18Mn and ML22Mn); as

well as ML15Mn, ML20MnVB which are produced in large quantity in recent

years;

- Three designations - ML40Mn, ML45Mn and ML15Cr, which have not been used

for ordering are deleted.

- For the same designations of steels that are not intended for heat treatment in

this Standard and GB/T 6478-1986, the mass fraction range of carbon is

narrowed; the mass fraction range of silicon is broaden; and the mass fraction

range of manganese is changed from 0.20%~0.50% to 0.30%~0.60%. For the

designations of steels for case hardening, quenching and tempering (including

boron treated steel), the mass fraction range of carbon is narrowed; and the

mass fraction range of manganese is changed from 0.50%~0.80% to

0.60%~0.90%;

- Requirements for the mechanical properties of steels that are not intended for

heat treatment delivered in hot rolling condition are added in this Standard.

- Requirements for mechanical properties of steels for case hardening, quenching

and tempering (including boron treated steel) delivered in annealing condition

are added.

- The mechanical properties of samples intended for heat treatment are not

necessary in this Standard. If it is required by the purchaser, relevant values

may be determined based on the agreement of both supplier and purchaser,

and indicated in the contract.

Appendix A of this Standard is informative.

This Standard shall replace GB/T 6478-1986 "Cold Heading Steel - Technical

Requirements" since the implementation date.

This Standard was proposed by the State Metallurgical Industry Bureau.

This Standard shall be under the jurisdiction of National Technical Committee on Iron

and Steel of Standardization Administration of China.

Drafting organization of this Standard. Taiyuan Iron and Steel (Group) Co., Ltd.

Chief drafting staffs of this Standard. Liu Peng, Niu Chenmei, Gao Ping, Zhao

Jianping, Han Yi and Liang Zhenshan.

This Standard was issued in June 1986 for the first time.

Steels for Cold Heading and Cold Extruding

1 Scope

This Standard specifies the classification, code number, size, appearance, weight,

allowable deviation, technical requirements, test methods, inspection rules, packaging,

marking and quality certificate of steels for cold heading and cold extruding.

This Standard is applicable to unalloyed and alloyed steel hot rolled wire rod with a

diameter of 5mm~40mm and intended for cold heading and cold extruding, as well as

the unalloyed and alloyed steel hot-rolled round steel with a diameter of

12mm~100mm and intended for cold heading and cold extruding.

2 Normative References

The following normative documents contain provisions which, through reference into

this Standard, constitute the provisions of this Standard. At the time of publication, the

editions indicated were valid. All standards will be revised and all p...

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.

Newer version: (Replacing this standard) GB/T 6478-2015

Get Quotation: Click GB/T 6478-2001 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 6478-2015

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 6478-2001

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.10

H44

neq ISO 4954.1993

Steels for Cold Heading and Cold Extruding

ISSUED ON. SEPTEMBER 15, 2001

IMPLEMENTED ON. FEBRUARY 1, 2002

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

1 Scope ... 5

2 Normative References ... 5

3 Ordering Instructions ... 8

4 Classification and Code Number ... 9

5 Dimension, Shape, Weight and Allowable Deviation ... 9

6 Technical Requirements ... 9

7 Test Methods ... 14

8 Inspection Rules ... 14

9 Packaging, Marking and Quality Certificate ... 15

Appendix A (Informative) Mechanical Properties of Samples Intended for

Heat Treatment ... 16

Foreword

This Standard non-equivalently adopts international standard ISO4954.1993 "Steels

for Cold Heading and Cold Extruding". For steels not intended for heat treatment, the

mass fractions of S and P are reduced to 0.035%; for boron treated steels for

quenching and tempering, the mass fraction range of boron is narrowed; acid leaching

macrostructure inspection is added; and the specification for cold upsetting test is

expanded to 5.0mm~40mm and judged by classification.

The changes of main content in this revision are as follows.

- This Standard is named as “Steels for Cold Heading and Cold Extruding";

- Steels for cold heading and cold extruding are classified into three types - steels

not intended for heat treatment, case hardening steels, and steels for quenching

and tempering (including boron treated steel) according to the service

conditions of steel;

- Fourteen designations such as CC4A, CC15K, CC21K, 37Cr4E, CE20BG1,

CE288, CE358, CE20BG2, 35MnB5E, 37CrB1E in ISO 4954.1993 (the

corresponding designations in GB/T 6478 are ML04A1, ML15, ML20, ML37Cr,

ML208, the M1.288, M1.358, ML20MnB, ML35MnB, ML37CrB); and SWRCH1

8A, SWRCH22A in JIS G 3507-1991 "Carbon Steel Wire Rod for Cold Heading"

(the corresponding designations in GB/T 6478 are ML18Mn and ML22Mn); as

well as ML15Mn, ML20MnVB which are produced in large quantity in recent

years;

- Three designations - ML40Mn, ML45Mn and ML15Cr, which have not been used

for ordering are deleted.

- For the same designations of steels that are not intended for heat treatment in

this Standard and GB/T 6478-1986, the mass fraction range of carbon is

narrowed; the mass fraction range of silicon is broaden; and the mass fraction

range of manganese is changed from 0.20%~0.50% to 0.30%~0.60%. For the

designations of steels for case hardening, quenching and tempering (including

boron treated steel), the mass fraction range of carbon is narrowed; and the

mass fraction range of manganese is changed from 0.50%~0.80% to

0.60%~0.90%;

- Requirements for the mechanical properties of steels that are not intended for

heat treatment delivered in hot rolling condition are added in this Standard.

- Requirements for mechanical properties of steels for case hardening, quenching

and tempering (including boron treated steel) delivered in annealing condition

are added.

- The mechanical properties of samples intended for heat treatment are not

necessary in this Standard. If it is required by the purchaser, relevant values

may be determined based on the agreement of both supplier and purchaser,

and indicated in the contract.

Appendix A of this Standard is informative.

This Standard shall replace GB/T 6478-1986 "Cold Heading Steel - Technical

Requirements" since the implementation date.

This Standard was proposed by the State Metallurgical Industry Bureau.

This Standard shall be under the jurisdiction of National Technical Committee on Iron

and Steel of Standardization Administration of China.

Drafting organization of this Standard. Taiyuan Iron and Steel (Group) Co., Ltd.

Chief drafting staffs of this Standard. Liu Peng, Niu Chenmei, Gao Ping, Zhao

Jianping, Han Yi and Liang Zhenshan.

This Standard was issued in June 1986 for the first time.

Steels for Cold Heading and Cold Extruding

1 Scope

This Standard specifies the classification, code number, size, appearance, weight,

allowable deviation, technical requirements, test methods, inspection rules, packaging,

marking and quality certificate of steels for cold heading and cold extruding.

This Standard is applicable to unalloyed and alloyed steel hot rolled wire rod with a

diameter of 5mm~40mm and intended for cold heading and cold extruding, as well as

the unalloyed and alloyed steel hot-rolled round steel with a diameter of

12mm~100mm and intended for cold heading and cold extruding.

2 Normative References

The following normative documents contain provisions which, through reference into

this Standard, constitute the provisions of this Standard. At the time of publication, the

editions indicated were valid. All standards will be revised and all parties who reach an

agreement according to this Standard are encouraged to study whether the latest

editions of the following standards are applicable.

GB/T 222-1984 Method of Sampling Steel for Determination of Chemical

Composition and Permissible Variations for Product Analysis

GB/T 223.3-1988 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Phosphomolybdate Gravimetric Method for the Determination

of Phosphorus Content

GB/T 223.5-1997 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Reduced Molybdosilicate Spectrophotometric Method for the Determination of

Acid-soluble Silicon Content

GB/T 223.8-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Fluoride Separation - EDTA Titration Method for the Determination of

Aluminium Content

GB/T 223.9-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Chrom Azurol S Photometric Method for the Determination of Aluminium Content

GB/T 223.10-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Cupferron Separation-chrome Azurol S Photometric Method for the Determination

of Aluminium Content

GB/T 223.11-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Ammonium Persulfate Oxidation Volumetric Method for the Determination of

Chromium Content

GB/T 223.12-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Carbonate Separation-diphenyl Carbazide Photometric Method for the

Determination of Chromium Content

GB/T 223.13-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Ammonium Ferrous Sulfate Titration Method for the Determination of Vanadium

Content

GB/T 223.14-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

N-benzoy-N-phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.16-1991 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Chromotropic Acid Photometric Method for the Determination of Titanium Content

GB/T 223.17-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Diantipyrylmethane Photometric Method for the Determination of Titanium Content

GB/T 223.18-1994 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of Copper

Content

GB/T 223.19-1989 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Neocuproine-chloroform Extraction Photometric Method for the Determination of

Copper Content

GB/T 223.23-1994 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Dimethylglyoxime Spectrophotometric Method for the Determination of Nickel

Content

GB/T 223.24-1994 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Extraction Separation - The Dimethylglyoxime Spectrophotometric Method for the

Determination of Nickel Content

GB/T 223.26-1989 Methods for Chemical Analysis of Iron Steel and Alloy - The

Thiocyanate Direct Photometric Method for the Determination of Molybdenum

Content

GB/T 223.53-1987 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Flame Atomic Absorption Spectrophotometric Method for the Determination of

Copper Content

GB/T 223.58-1987 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Arsenite-sodium Nitrite Titrimetric Method for the Determination of

Manganese Content

GB/T 223.59-1987 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Reduced Molybdoantimonyl Phosphoric Acid Photometric Method for the

Determination of Phosphorus Content

GB/T 223.60-1997 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Perchloric Acid Dehydration Gravimetric Method for the Determination of Silicon

Content

GB/T 223.61-1988 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Ammonium Phosphomolybdate Volumetric Method for the Determination of

Phosphorus Content

GB/T 223.62-1988 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Butyl Acetate Extraction Photometric Method for the Determination of Phosphorus

Content

GB/T 223.63-1988 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium (Potas...

GB/T 6478-2001

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.10

H44

neq ISO 4954.1993

Steels for Cold Heading and Cold Extruding

ISSUED ON. SEPTEMBER 15, 2001

IMPLEMENTED ON. FEBRUARY 1, 2002

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

1 Scope ... 5

2 Normative References ... 5

3 Ordering Instructions ... 8

4 Classification and Code Number ... 9

5 Dimension, Shape, Weight and Allowable Deviation ... 9

6 Technical Requirements ... 9

7 Test Methods ... 14

8 Inspection Rules ... 14

9 Packaging, Marking and Quality Certificate ... 15

Appendix A (Informative) Mechanical Properties of Samples Intended for

Heat Treatment ... 16

Foreword

This Standard non-equivalently adopts international standard ISO4954.1993 "Steels

for Cold Heading and Cold Extruding". For steels not intended for heat treatment, the

mass fractions of S and P are reduced to 0.035%; for boron treated steels for

quenching and tempering, the mass fraction range of boron is narrowed; acid leaching

macrostructure inspection is added; and the specification for cold upsetting test is

expanded to 5.0mm~40mm and judged by classification.

The changes of main content in this revision are as follows.

- This Standard is named as “Steels for Cold Heading and Cold Extruding";

- Steels for cold heading and cold extruding are classified into three types - steels

not intended for heat treatment, case hardening steels, and steels for quenching

and tempering (including boron treated steel) according to the service

conditions of steel;

- Fourteen designations such as CC4A, CC15K, CC21K, 37Cr4E, CE20BG1,

CE288, CE358, CE20BG2, 35MnB5E, 37CrB1E in ISO 4954.1993 (the

corresponding designations in GB/T 6478 are ML04A1, ML15, ML20, ML37Cr,

ML208, the M1.288, M1.358, ML20MnB, ML35MnB, ML37CrB); and SWRCH1

8A, SWRCH22A in JIS G 3507-1991 "Carbon Steel Wire Rod for Cold Heading"

(the corresponding designations in GB/T 6478 are ML18Mn and ML22Mn); as

well as ML15Mn, ML20MnVB which are produced in large quantity in recent

years;

- Three designations - ML40Mn, ML45Mn and ML15Cr, which have not been used

for ordering are deleted.

- For the same designations of steels that are not intended for heat treatment in

this Standard and GB/T 6478-1986, the mass fraction range of carbon is

narrowed; the mass fraction range of silicon is broaden; and the mass fraction

range of manganese is changed from 0.20%~0.50% to 0.30%~0.60%. For the

designations of steels for case hardening, quenching and tempering (including

boron treated steel), the mass fraction range of carbon is narrowed; and the

mass fraction range of manganese is changed from 0.50%~0.80% to

0.60%~0.90%;

- Requirements for the mechanical properties of steels that are not intended for

heat treatment delivered in hot rolling condition are added in this Standard.

- Requirements for mechanical properties of steels for case hardening, quenching

and tempering (including boron treated steel) delivered in annealing condition

are added.

- The mechanical properties of samples intended for heat treatment are not

necessary in this Standard. If it is required by the purchaser, relevant values

may be determined based on the agreement of both supplier and purchaser,

and indicated in the contract.

Appendix A of this Standard is informative.

This Standard shall replace GB/T 6478-1986 "Cold Heading Steel - Technical

Requirements" since the implementation date.

This Standard was proposed by the State Metallurgical Industry Bureau.

This Standard shall be under the jurisdiction of National Technical Committee on Iron

and Steel of Standardization Administration of China.

Drafting organization of this Standard. Taiyuan Iron and Steel (Group) Co., Ltd.

Chief drafting staffs of this Standard. Liu Peng, Niu Chenmei, Gao Ping, Zhao

Jianping, Han Yi and Liang Zhenshan.

This Standard was issued in June 1986 for the first time.

Steels for Cold Heading and Cold Extruding

1 Scope

This Standard specifies the classification, code number, size, appearance, weight,

allowable deviation, technical requirements, test methods, inspection rules, packaging,

marking and quality certificate of steels for cold heading and cold extruding.

This Standard is applicable to unalloyed and alloyed steel hot rolled wire rod with a

diameter of 5mm~40mm and intended for cold heading and cold extruding, as well as

the unalloyed and alloyed steel hot-rolled round steel with a diameter of

12mm~100mm and intended for cold heading and cold extruding.

2 Normative References

The following normative documents contain provisions which, through reference into

this Standard, constitute the provisions of this Standard. At the time of publication, the

editions indicated were valid. All standards will be revised and all p...

Share