1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 7122-1996 English PDF (GB/T7122-1996)

GB/T 7122-1996 English PDF (GB/T7122-1996)

Regular price

$110.00

Regular price

Sale price

$110.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 7122-1996: Adhesives. Determination of peel resistance of high-strength adhesive bonds. Floating roller method

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 7122-1996 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 7122-1996

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 7122-1996

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

Replacing GB/T 7122-86

Adhesives - Determination of peel resistance of high-

strength adhesive bonds - Floating roller method

(eqv ISO4578:1990)

APPROVED ON: OCTOBER 28, 1996

IMPLEMENTED ON: JUNE 01, 1997

Approved by: State Bureau of Technical Supervision

Table of Contents

Foreword ... 3

ISO Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Definitions ... 5

4 Devices ... 5

5 Specimen ... 7

6 Conditioning and test environment ... 8

7 Test procedure ... 9

8 Processing of test results ... 9

9 Test report ... 10

Foreword

This standard equivalently uses ISO 4578:1990 " Adhesives - Determination of

peel resistance of high-strength adhesive bonds - Floating roller method ".

Differences between this standard and ISO 4578:

1. ISO 4578 specifies the thickness of the rigid adherend is 1.6 mm ± 0.1 mm;

whilst this standard specifies the thickness of the rigid adherend is 2.0 mm ±

0.1 mm, considering that the corresponding material thickness in China is 2 mm.

2. The requirements of test results. ISO 4578 specifies reporting the "the

average value, maximum value, minimum value of the peel strength of each

specimen". Considering the actual conditions in China, this standard specifies

that in the test report, in addition to reporting the "the average value, maximum

value, minimum value of the peel strength of each specimen", it shall also report

the "average value of the peel strength of each group of specimens".

This standard was first published in the 1986. This standard was first revised in

1995.

As compared with the standard before revision, this standard has no change

on the main technical parameters. It only deleted the requirements from the

standard before revision that "unless otherwise specified, the material of the

metal test piece is LY-12CZ aluminum alloy".

This standard replaced GB/T 7122-86 from the date of implementation.

This standard was proposed by the Ministry of Chemical Industry of PRC.

This standard shall be under the jurisdiction of Shanghai Rubber Products

Research Institute.

For this standard, Shanghai Rubber Products Research Institute is responsible

for drafting.

The main drafter of this standard: Zhang Wengang.

For this standard, the National Adhesive Technical Committee is entrusted for

the interpretation.

Adhesives - Determination of peel resistance of high-

strength adhesive bonds - Floating roller method

1 Scope

This standard specifies the method for measuring the peel strength of high-

strength adhesive bonds by the floating roller method. The peel strength refers

to the peel resistance between a rigid metal adherend and a flexible metal

adherend under predetermined test conditions.

Note: The floating roller method can obtain more stable data than other peeling

methods. The surface of the flexible metal adherend is not required to coincide

with the surface of the roller during the test.

2 Normative references

The provisions contained in the following standards constitute the provisions of

this standard through quotation in this standard. At the time of publication, the

editions indicated were valid. All standards will be revised, and all parties using

this standard shall study the possibility of using the latest version of the

following standard.

GB 2918-82 (88) Standard atmospheres for conditioning and testing of

plastic specimens

3 Definitions

This standard uses the following definitions.

Peel strength: Under the specified test conditions, measure the average force

required for the unit width of two specimens of metal adherends that are glued

to each other gradually separated along the glue line, expressed in kN/m.

4 Devices

4.1 Tensile test device

The tensile test device has a suitable load range. The chuck can separate and

apply tensile force at a constant rate. The device shall be equipped with an

5 Specimen

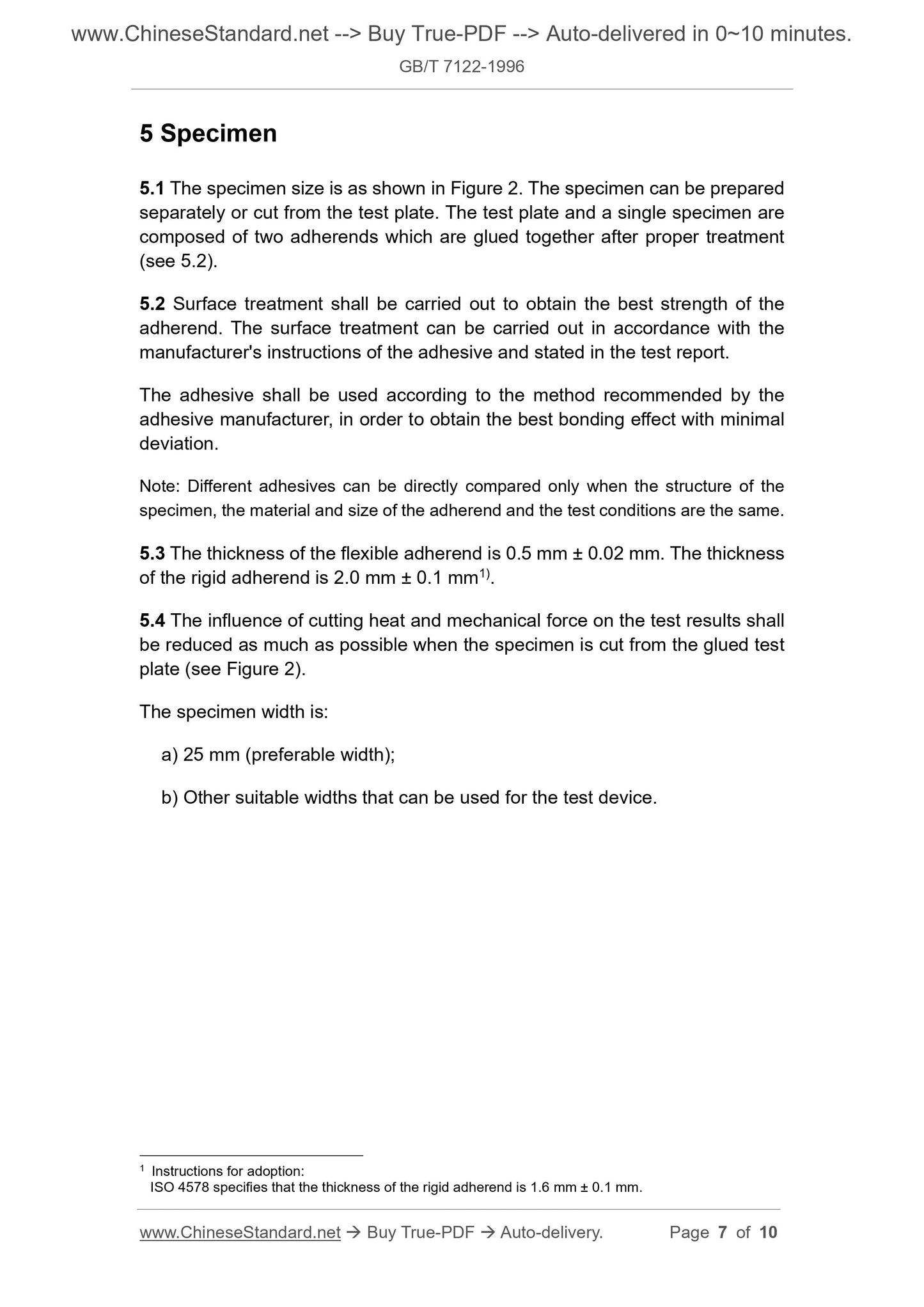

5.1 The specimen size is as shown in Figure 2. The specimen can be prepared

separately or cut from the test plate. The test plate and a single specimen are

composed of two adherends which are glued together after proper treatment

(see 5.2).

5.2 Surface treatment shall be carried out to obtain the best strength of the

adherend. The surface treatment can be carried out in accordance with the

manufacturer's instructions of the adhesive and stated in the test report.

The adhesive shall be used according to the method recommended by the

adhesive manufacturer, in order to obtain the best bonding effect with minimal

deviation.

Note: Different adhesives can be directly compared only when the structure of the

specimen, the material and size of the adherend and the test conditions are the same.

5.3 The thickness of the flexible adherend is 0.5 mm ± 0.02 mm. The thickness

of the rigid adherend is 2.0 mm ± 0.1 mm1).

5.4 The influence of cutting heat and mechanical force on the test results shall

be reduced as much as possible when the specimen is cut from the glued test

plate (see Figure 2).

The specimen width is:

a) 25 mm (preferable width);

b) Other suitable widths that can be used for the test device.

1 Instructions for adoption:

ISO 4578 specifies that the thickness of the rigid adherend is 1.6 mm ± 0.1 mm.

7 Test procedure

7.1 Insert the specimen into the peeling fixture (see 4.2), as shown in Figure 1.

Clamp the unbonded end of the flexible adherend into the lower chuck (see 4.1)

of the testing machine. Unless otherwise specified, the separation rate of the

chuck is 100 mm/min ± 5 mm/min. If the rigid adherend is bent or deformed

during the test, it is recommended to redesign the specimen, so that the rigid

adherend has sufficient rigidity to ensure the smooth progress of the peel test.

7.2 In the peel test, automatically record the relationship curve between the

force and the moving distance of the chuck of the testing machine (the

relationship curve between the force and the peel length). Excluding the initial

peel length of 25 mm, it shall peel at least a length of 115 mm.

7.3 If the damage occurs outside the peeling area as shown in Figure 1, the

result is not counted.

8 Processing of test results

From the automatic recording curve, within the range of the effective peel length

at least 115 mm (excluding the 25 mm peeled first and the end 20 mm),

calculate the average peel force per unit width of the specimen, expressed in

kN/m.

One of the following methods can be used to determine the average peel force

from the curve:

a) Planimeter.

b) Weighing method:

Cut out the part surrounded by the peel curve and the baseline (abscissa)

from the recording paper and weigh the mass. Divide this value by the

previously measured mass of the recording paper per unit area, to get the

area of the cut part. The average height of the curve can be obtained

through dividing the area of the cut part by the baseline length of the cut

part, thereby calculating the average peel force.

c) Use a ruler to draw an estimated isobaric line through the peel curve.

In addition, record the maximum and minimum peel force of each

specimen.

GB/T 7122-1996

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

Replacing GB/T 7122-86

Adhesives - Determination of peel resistance of high-

strength adhesive bonds - Floating roller method

(eqv ISO4578:1990)

APPROVED ON: OCTOBER 28, 1996

IMPLEMENTED ON: JUNE 01, 1997

Approved by: State Bureau of Technical Supervision

Table of Contents

Foreword ... 3

ISO Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Definitions ... 5

4 Devices ... 5

5 Specimen ... 7

6 Conditioning and test environment ... 8

7 Test procedure ... 9

8 Processing of test results ... 9

9 Test report ... 10

Foreword

This standard equivalently uses ISO 4578:1990 " Adhesives - Determination of

peel resistance of high-strength adhesive bonds - Floating roller method ".

Differences between this standard and ISO 4578:

1. ISO 4578 specifies the thickness of the rigid adherend is 1.6 mm ± 0.1 mm;

whilst this standard specifies the thickness of the rigid adherend is 2.0 mm ±

0.1 mm, considering that the corresponding material thickness in China is 2 mm.

2. The requirements of test results. ISO 4578 specifies reporting the "the

average value, maximum value, minimum value of the peel strength of each

specimen". Considering the actual conditions in China, this standard specifies

that in the test report, in addition to reporting the "the average value, maximum

value, minimum value of the peel strength of each specimen", it shall also report

the "average value of the peel strength of each group of specimens".

This standard was first published in the 1986. This standard was first revised in

1995.

As compared with the standard before revision, this standard has no change

on the main technical parameters. It only deleted the requirements from the

standard before revision that "unless otherwise specified, the material of the

metal test piece is LY-12CZ aluminum alloy".

This standard replaced GB/T 7122-86 from the date of implementation.

This standard was proposed by the Ministry of Chemical Industry of PRC.

This standard shall be under the jurisdiction of Shanghai Rubber Products

Research Institute.

For this standard, Shanghai Rubber Products Research Institute is responsible

for drafting.

The main drafter of this standard: Zhang Wengang.

For this standard, the National Adhesive Technical Committee is entrusted for

the interpretation.

Adhesives - Determination of peel resistance of high-

strength adhesive bonds - Floating roller method

1 Scope

This standard specifies the method for measuring the peel strength of high-

strength adhesive bonds by the floating roller method. The peel strength refers

to the peel resistance between a rigid metal adherend and a flexible metal

adherend under predetermined test conditions.

Note: The floating roller method can obtain more stable data than other peeling

methods. The surface of the flexible metal adherend is not required to coincide

with the surface of the roller during the test.

2 Normative references

The provisions contained in the following standards constitute the provisions of

this standard through quotation in this standard. At the time of publication, the

editions indicated were valid. All standards will be revised, and all parties using

this standard shall study the possibility of using the latest version of the

following standard.

GB 2918-82 (88) Standard atmospheres for conditioning and testing of

plastic specimens

3 Definitions

This standard uses the following definitions.

Peel strength: Under the specified test conditions, measure the average force

required for the unit width of two specimens of metal adherends that are glued

to each other gradually separated along the glue line, expressed in kN/m.

4 Devices

4.1 Tensile test device

The tensile test device has a suitable load range. The chuck can separate and

apply tensile force at a constant rate. The device shall be equipped with an

5 Specimen

5.1 The specimen size is as shown in Figure 2. The specimen can be prepared

separately or cut from the test plate. The test plate and a single specimen are

composed of two adherends which are glued together after proper treatment

(see 5.2).

5.2 Surface treatment shall be carried out to obtain the best strength of the

adherend. The surface treatment can be carried out in accordance with the

manufacturer's instructions of the adhesive and stated in the test report.

The adhesive shall be used according to the method recommended by the

adhesive manufacturer, in order to obtain the best bonding effect with minimal

deviation.

Note: Different adhesives can be directly compared only when the structure of the

specimen, the material and size of the adherend and the test conditions are the same.

5.3 The thickness of the flexible adherend is 0.5 mm ± 0.02 mm. The thickness

of the rigid adherend is 2.0 mm ± 0.1 mm1).

5.4 The influence of cutting heat and mechanical force on the test results shall

be reduced as much as possible when the specimen is cut from the glued test

plate (see Figure 2).

The specimen width is:

a) 25 mm (preferable width);

b) Other suitable widths that can be used for the test device.

1 Instructions for adoption:

ISO 4578 specifies that the thickness of the rigid adherend is 1.6 mm ± 0.1 mm.

7 Test procedure

7.1 Insert the specimen into the peeling fixture (see 4.2), as shown in Figure 1.

Clamp the unbonded end of the flexible adherend into the lower chuck (see 4.1)

of the testing machine. Unless otherwise specified, the separation rate of the

chuck is 100 mm/min ± 5 mm/min. If the rigid adherend is bent or deformed

during the test, it is recommended to redesign the specimen, so that the rigid

adherend has sufficient rigidity to ensure the smooth progress of the peel test.

7.2 In the peel test, automatically record the relationship curve between the

force and the moving distance of the chuck of the testing machine (the

relationship curve between the force and the peel length). Excluding the initial

peel length of 25 mm, it shall peel at least a length of 115 mm.

7.3 If the damage occurs outside the peeling area as shown in Figure 1, the

result is not counted.

8 Processing of test results

From the automatic recording curve, within the range of the effective peel length

at least 115 mm (excluding the 25 mm peeled first and the end 20 mm),

calculate the average peel force per unit width of the specimen, expressed in

kN/m.

One of the following methods can be used to determine the average peel force

from the curve:

a) Planimeter.

b) Weighing method:

Cut out the part surrounded by the peel curve and the baseline (abscissa)

from the recording paper and weigh the mass. Divide this value by the

previously measured mass of ...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 7122-1996 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 7122-1996

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 7122-1996

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

Replacing GB/T 7122-86

Adhesives - Determination of peel resistance of high-

strength adhesive bonds - Floating roller method

(eqv ISO4578:1990)

APPROVED ON: OCTOBER 28, 1996

IMPLEMENTED ON: JUNE 01, 1997

Approved by: State Bureau of Technical Supervision

Table of Contents

Foreword ... 3

ISO Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Definitions ... 5

4 Devices ... 5

5 Specimen ... 7

6 Conditioning and test environment ... 8

7 Test procedure ... 9

8 Processing of test results ... 9

9 Test report ... 10

Foreword

This standard equivalently uses ISO 4578:1990 " Adhesives - Determination of

peel resistance of high-strength adhesive bonds - Floating roller method ".

Differences between this standard and ISO 4578:

1. ISO 4578 specifies the thickness of the rigid adherend is 1.6 mm ± 0.1 mm;

whilst this standard specifies the thickness of the rigid adherend is 2.0 mm ±

0.1 mm, considering that the corresponding material thickness in China is 2 mm.

2. The requirements of test results. ISO 4578 specifies reporting the "the

average value, maximum value, minimum value of the peel strength of each

specimen". Considering the actual conditions in China, this standard specifies

that in the test report, in addition to reporting the "the average value, maximum

value, minimum value of the peel strength of each specimen", it shall also report

the "average value of the peel strength of each group of specimens".

This standard was first published in the 1986. This standard was first revised in

1995.

As compared with the standard before revision, this standard has no change

on the main technical parameters. It only deleted the requirements from the

standard before revision that "unless otherwise specified, the material of the

metal test piece is LY-12CZ aluminum alloy".

This standard replaced GB/T 7122-86 from the date of implementation.

This standard was proposed by the Ministry of Chemical Industry of PRC.

This standard shall be under the jurisdiction of Shanghai Rubber Products

Research Institute.

For this standard, Shanghai Rubber Products Research Institute is responsible

for drafting.

The main drafter of this standard: Zhang Wengang.

For this standard, the National Adhesive Technical Committee is entrusted for

the interpretation.

Adhesives - Determination of peel resistance of high-

strength adhesive bonds - Floating roller method

1 Scope

This standard specifies the method for measuring the peel strength of high-

strength adhesive bonds by the floating roller method. The peel strength refers

to the peel resistance between a rigid metal adherend and a flexible metal

adherend under predetermined test conditions.

Note: The floating roller method can obtain more stable data than other peeling

methods. The surface of the flexible metal adherend is not required to coincide

with the surface of the roller during the test.

2 Normative references

The provisions contained in the following standards constitute the provisions of

this standard through quotation in this standard. At the time of publication, the

editions indicated were valid. All standards will be revised, and all parties using

this standard shall study the possibility of using the latest version of the

following standard.

GB 2918-82 (88) Standard atmospheres for conditioning and testing of

plastic specimens

3 Definitions

This standard uses the following definitions.

Peel strength: Under the specified test conditions, measure the average force

required for the unit width of two specimens of metal adherends that are glued

to each other gradually separated along the glue line, expressed in kN/m.

4 Devices

4.1 Tensile test device

The tensile test device has a suitable load range. The chuck can separate and

apply tensile force at a constant rate. The device shall be equipped with an

5 Specimen

5.1 The specimen size is as shown in Figure 2. The specimen can be prepared

separately or cut from the test plate. The test plate and a single specimen are

composed of two adherends which are glued together after proper treatment

(see 5.2).

5.2 Surface treatment shall be carried out to obtain the best strength of the

adherend. The surface treatment can be carried out in accordance with the

manufacturer's instructions of the adhesive and stated in the test report.

The adhesive shall be used according to the method recommended by the

adhesive manufacturer, in order to obtain the best bonding effect with minimal

deviation.

Note: Different adhesives can be directly compared only when the structure of the

specimen, the material and size of the adherend and the test conditions are the same.

5.3 The thickness of the flexible adherend is 0.5 mm ± 0.02 mm. The thickness

of the rigid adherend is 2.0 mm ± 0.1 mm1).

5.4 The influence of cutting heat and mechanical force on the test results shall

be reduced as much as possible when the specimen is cut from the glued test

plate (see Figure 2).

The specimen width is:

a) 25 mm (preferable width);

b) Other suitable widths that can be used for the test device.

1 Instructions for adoption:

ISO 4578 specifies that the thickness of the rigid adherend is 1.6 mm ± 0.1 mm.

7 Test procedure

7.1 Insert the specimen into the peeling fixture (see 4.2), as shown in Figure 1.

Clamp the unbonded end of the flexible adherend into the lower chuck (see 4.1)

of the testing machine. Unless otherwise specified, the separation rate of the

chuck is 100 mm/min ± 5 mm/min. If the rigid adherend is bent or deformed

during the test, it is recommended to redesign the specimen, so that the rigid

adherend has sufficient rigidity to ensure the smooth progress of the peel test.

7.2 In the peel test, automatically record the relationship curve between the

force and the moving distance of the chuck of the testing machine (the

relationship curve between the force and the peel length). Excluding the initial

peel length of 25 mm, it shall peel at least a length of 115 mm.

7.3 If the damage occurs outside the peeling area as shown in Figure 1, the

result is not counted.

8 Processing of test results

From the automatic recording curve, within the range of the effective peel length

at least 115 mm (excluding the 25 mm peeled first and the end 20 mm),

calculate the average peel force per unit width of the specimen, expressed in

kN/m.

One of the following methods can be used to determine the average peel force

from the curve:

a) Planimeter.

b) Weighing method:

Cut out the part surrounded by the peel curve and the baseline (abscissa)

from the recording paper and weigh the mass. Divide this value by the

previously measured mass of the recording paper per unit area, to get the

area of the cut part. The average height of the curve can be obtained

through dividing the area of the cut part by the baseline length of the cut

part, thereby calculating the average peel force.

c) Use a ruler to draw an estimated isobaric line through the peel curve.

In addition, record the maximum and minimum peel force of each

specimen.

GB/T 7122-1996

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

Replacing GB/T 7122-86

Adhesives - Determination of peel resistance of high-

strength adhesive bonds - Floating roller method

(eqv ISO4578:1990)

APPROVED ON: OCTOBER 28, 1996

IMPLEMENTED ON: JUNE 01, 1997

Approved by: State Bureau of Technical Supervision

Table of Contents

Foreword ... 3

ISO Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Definitions ... 5

4 Devices ... 5

5 Specimen ... 7

6 Conditioning and test environment ... 8

7 Test procedure ... 9

8 Processing of test results ... 9

9 Test report ... 10

Foreword

This standard equivalently uses ISO 4578:1990 " Adhesives - Determination of

peel resistance of high-strength adhesive bonds - Floating roller method ".

Differences between this standard and ISO 4578:

1. ISO 4578 specifies the thickness of the rigid adherend is 1.6 mm ± 0.1 mm;

whilst this standard specifies the thickness of the rigid adherend is 2.0 mm ±

0.1 mm, considering that the corresponding material thickness in China is 2 mm.

2. The requirements of test results. ISO 4578 specifies reporting the "the

average value, maximum value, minimum value of the peel strength of each

specimen". Considering the actual conditions in China, this standard specifies

that in the test report, in addition to reporting the "the average value, maximum

value, minimum value of the peel strength of each specimen", it shall also report

the "average value of the peel strength of each group of specimens".

This standard was first published in the 1986. This standard was first revised in

1995.

As compared with the standard before revision, this standard has no change

on the main technical parameters. It only deleted the requirements from the

standard before revision that "unless otherwise specified, the material of the

metal test piece is LY-12CZ aluminum alloy".

This standard replaced GB/T 7122-86 from the date of implementation.

This standard was proposed by the Ministry of Chemical Industry of PRC.

This standard shall be under the jurisdiction of Shanghai Rubber Products

Research Institute.

For this standard, Shanghai Rubber Products Research Institute is responsible

for drafting.

The main drafter of this standard: Zhang Wengang.

For this standard, the National Adhesive Technical Committee is entrusted for

the interpretation.

Adhesives - Determination of peel resistance of high-

strength adhesive bonds - Floating roller method

1 Scope

This standard specifies the method for measuring the peel strength of high-

strength adhesive bonds by the floating roller method. The peel strength refers

to the peel resistance between a rigid metal adherend and a flexible metal

adherend under predetermined test conditions.

Note: The floating roller method can obtain more stable data than other peeling

methods. The surface of the flexible metal adherend is not required to coincide

with the surface of the roller during the test.

2 Normative references

The provisions contained in the following standards constitute the provisions of

this standard through quotation in this standard. At the time of publication, the

editions indicated were valid. All standards will be revised, and all parties using

this standard shall study the possibility of using the latest version of the

following standard.

GB 2918-82 (88) Standard atmospheres for conditioning and testing of

plastic specimens

3 Definitions

This standard uses the following definitions.

Peel strength: Under the specified test conditions, measure the average force

required for the unit width of two specimens of metal adherends that are glued

to each other gradually separated along the glue line, expressed in kN/m.

4 Devices

4.1 Tensile test device

The tensile test device has a suitable load range. The chuck can separate and

apply tensile force at a constant rate. The device shall be equipped with an

5 Specimen

5.1 The specimen size is as shown in Figure 2. The specimen can be prepared

separately or cut from the test plate. The test plate and a single specimen are

composed of two adherends which are glued together after proper treatment

(see 5.2).

5.2 Surface treatment shall be carried out to obtain the best strength of the

adherend. The surface treatment can be carried out in accordance with the

manufacturer's instructions of the adhesive and stated in the test report.

The adhesive shall be used according to the method recommended by the

adhesive manufacturer, in order to obtain the best bonding effect with minimal

deviation.

Note: Different adhesives can be directly compared only when the structure of the

specimen, the material and size of the adherend and the test conditions are the same.

5.3 The thickness of the flexible adherend is 0.5 mm ± 0.02 mm. The thickness

of the rigid adherend is 2.0 mm ± 0.1 mm1).

5.4 The influence of cutting heat and mechanical force on the test results shall

be reduced as much as possible when the specimen is cut from the glued test

plate (see Figure 2).

The specimen width is:

a) 25 mm (preferable width);

b) Other suitable widths that can be used for the test device.

1 Instructions for adoption:

ISO 4578 specifies that the thickness of the rigid adherend is 1.6 mm ± 0.1 mm.

7 Test procedure

7.1 Insert the specimen into the peeling fixture (see 4.2), as shown in Figure 1.

Clamp the unbonded end of the flexible adherend into the lower chuck (see 4.1)

of the testing machine. Unless otherwise specified, the separation rate of the

chuck is 100 mm/min ± 5 mm/min. If the rigid adherend is bent or deformed

during the test, it is recommended to redesign the specimen, so that the rigid

adherend has sufficient rigidity to ensure the smooth progress of the peel test.

7.2 In the peel test, automatically record the relationship curve between the

force and the moving distance of the chuck of the testing machine (the

relationship curve between the force and the peel length). Excluding the initial

peel length of 25 mm, it shall peel at least a length of 115 mm.

7.3 If the damage occurs outside the peeling area as shown in Figure 1, the

result is not counted.

8 Processing of test results

From the automatic recording curve, within the range of the effective peel length

at least 115 mm (excluding the 25 mm peeled first and the end 20 mm),

calculate the average peel force per unit width of the specimen, expressed in

kN/m.

One of the following methods can be used to determine the average peel force

from the curve:

a) Planimeter.

b) Weighing method:

Cut out the part surrounded by the peel curve and the baseline (abscissa)

from the recording paper and weigh the mass. Divide this value by the

previously measured mass of ...

Share