1

/

of

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 8243.7-2017 English PDF (GBT8243.7-2017)

GB/T 8243.7-2017 English PDF (GBT8243.7-2017)

Regular price

$90.00 USD

Regular price

Sale price

$90.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 8243.7-2017

Historical versions: GB/T 8243.7-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 8243.7-2017: Methods of test for full-flow lubricating oil filters for internal combustion engines -- Part 7: Vibration fatigue test

GB/T 8243.7-2017

Partitions. Methods of test for full-flow lubricating oil filters for internal combustion engines. Part 7. Vibration fatigue test

ICS 27.020

J95

National Standards of People's Republic of China

Replacing GB/T 8243.7-2006

Full-flow internal combustion engine oil filter test method

Part 7. Vibration Fatigue Test

Part 7. Vibrationfatiguetest

(ISO 4548-7.2012, IDT)

Published on.2017-05-12

2017-12-01 implementation

General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China

China National Standardization Administration released

Foreword

GB/T 8243 "Test method for full-flow internal combustion engine oil filters" currently includes the following parts.

--- Part 1. Differential pressure - flow characteristics;

--- Part 2. Filter by-pass valve characteristics;

--- Part 3. Resistance to high pressure and high temperature characteristics;

--- Part 4. Raw Filtration Efficiency, Lifetime, and Accumulation Efficiency (Gravimetric Method);

--- Part 5. Cold start simulation and hydraulic pulse endurance test;

--- Part 6. Static pressure burst test;

---Part 7. Vibration fatigue test;

--- Part 9. Inlet and outlet check valve tests;

---Part 11. Self-cleaning filters;

--- Part 12. Determination of filtration efficiency and dust holding capacity by particle counting;

--- Part 13. Static pressure burst test for composite filters;

--- Part 15. Vibration fatigue testing of composite filters.

This part is part 7 of GB/T 8243.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 8243.7-2006 "Full-flow Internal Combustion Engine Oil Filter Test Method Part 7. Vibration Fatigue Test".

Compared with GB/T 8243.7-2006, the main content changes as follows.

--- Modify the range requirements of oil pressure gauges and accelerometers (see Chapter 5,.2006 Edition, Chapter 5);

--- Modify the provisions of the test pressure value and input acceleration peak (see Chapter 7,.2006 Edition, Chapter 7);

--- Modify the provisions of the same test filter when testing the direction of the secondary test (see 7.9,.2006 version 7.11).

This section uses the translation method equivalent to the use of ISO 4548-7.2012 "Full internal combustion engine oil filter test method Part 7. Vibration

Dynamic Fatigue Test (English version).

The Chinese documents that are consistent with the normatively quoted international documents in this section are as follows.

---GB/T 8243.1-2003 Internal-combustion engine full-flow oil filter test method Part 1. Differential pressure-flow characteristics

(ISO 4548-1.1997, IDT).

This part is proposed by China Machinery Industry Federation.

This part is under the jurisdiction of the National Standardization Technical Committee for Internal Combustion Engines (SAC/TC177).

This section was drafted by. Shanghai Institute of Internal Combustion Engines, Zhejiang Weitai Auto Parts Co., Ltd., Linhai Jiangnan Internal Combustion Engine Accessories Factory, and Guangxi Huayuan

Filtration System Co., Ltd., Hangzhou Special Paper Co., Ltd., Hangzhou Fuyang North Wood Pulp Co., Ltd., Shanghai Automotive Group Co., Ltd.

Company Commercial Vehicle Technology Center, Hangzhou Xinxing Paper Co., Ltd., Linhai Jiangnan Filter Co., Ltd.

Drafters of this section. Qiao Liangliang, Shen Hongjie, Zhang Yu, Jin Wenhua, Zhao Yubao, Wu Anbo, Chen Qianqian, Meng Hongxia, Li Jianming, Feng Yihai.

The previous editions of the standards replaced by this section are.

--- GB/T 8243.7-2006.

Full-flow internal combustion engine oil filter test method

Part 7. Vibration Fatigue Test

1 Scope

This part of GB/T 8243 specifies a test method for determining the structural integrity of a full-flow oil filter against engine vibration. This test

The test method is applicable to spin-on filters with a maximum flow rate of less than 100 L/min and removable filters with a disposable filter cartridge.

This section applies to test pieces that are manufactured during the service period and the mechanical properties of the manufactured product materials do not change with temperature. For other types

The filter can also be used when the manufacturer of the filter manufacturer agrees with the buyer that it is applicable.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

ISO 4548-1 internal combustion engine full-flow oil filter test methods - Part 1. Differential pressure - flow characteristics (Methodsoftestfor

Ful-flow lubricationoilfiltersforintercomcombustionengines-Part 1.Differentialpressure/flow

Characteristics)

3 Terms, definitions and graphic symbols

3.1 Terms and Definitions

The terms and definitions defined by ISO 4548-1 apply to this document.

3.2 Graphical symbols

The graphic symbols used in this section refer to the provisions of ISO 1219 [1].

4 Principle

Complete installation Oil filter assemblies that are subject to alternating forces due to vibration of the engine or mounting device, including filter seats, adapters, and safety

Mounting brackets and so on. This test method is used to verify the ability of the filter assembly to withstand vibrations for a predetermined number of cycles when under pressure.

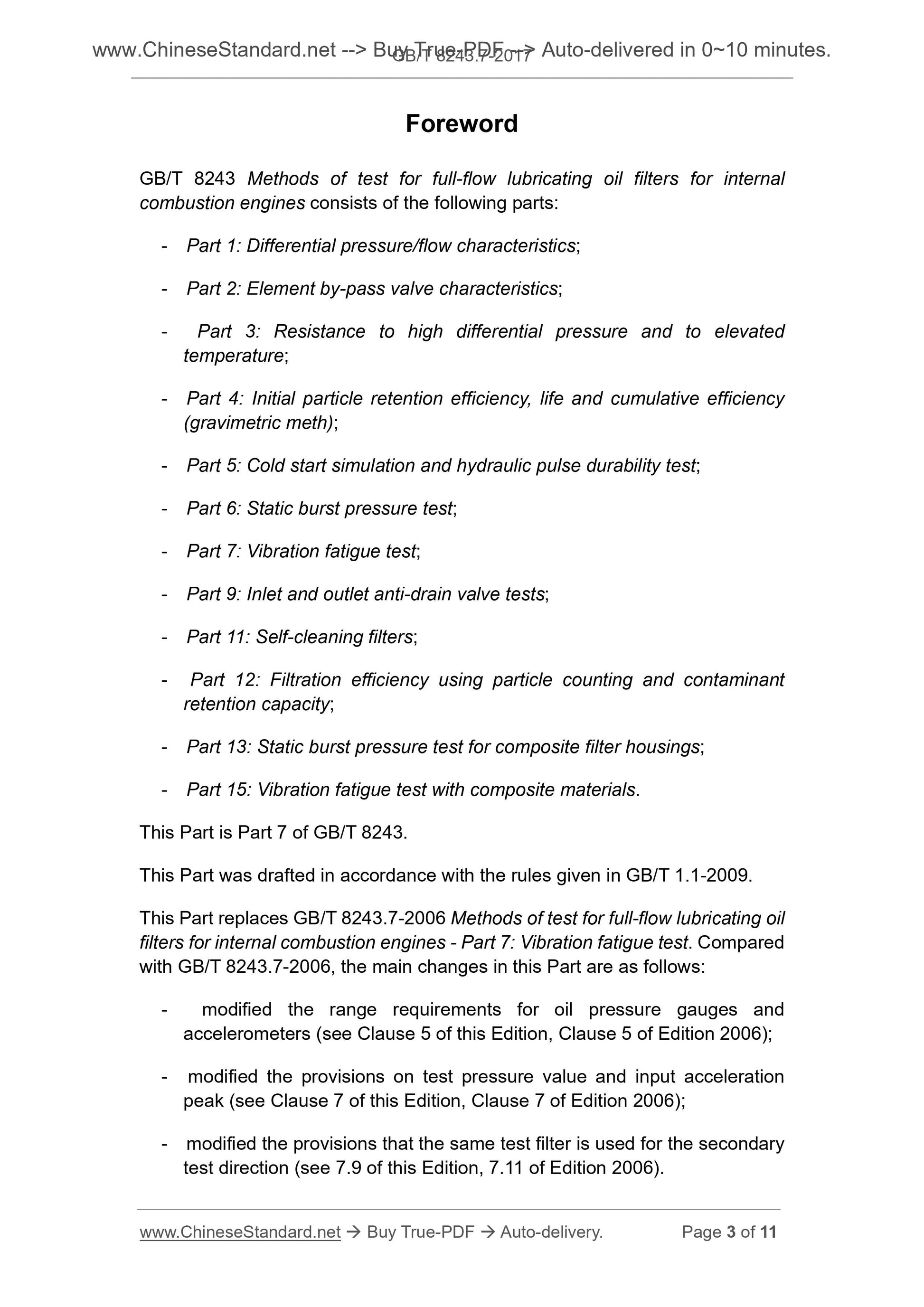

5 Test bench

The test rig should include the following components, as well as the necessary piping, fittings, and brackets (see Figure 1).

a) Electromechanical shakers, including the necessary hardware and electronic equipment for controlling and monitoring displacement, velocity and acceleration;

b) Oil pressure source, manual or mechanical control;

c) Oil pressure gauge, measuring range sufficient to cover the rated pressure of the test filter;

d) Two accelerometers, calibration linearity characteristics and range suitable for the test piece.

Explanation.

1 --- output accelerometer; 5 --- input accelerometer;

2 --- filter seat or joint; 6 --- test oil filter;

3 --- excitation axis; 7 --- shaking table platform.

4 --- pressure source;

Figure 1 Test bench layout. first direction

6 test solution

The test solution should be a motor oil with a kinematic viscosity of less than 10 mm2/s ± 5 mm2/s at ambient temperature (viscosity class ISO at 63°C)

SAE5W at VG22 or 68°C) [2][3].

7 Vibration durability test

7.1 Mount the filter under test on the filter seat or fitting according to the recommended tightening torque or angle of rotation.

7.2 Mount the filter and the filter holder assembly on a rigid support or a non-deformable flat connector. Use suitable gaskets or seals.

Ensure that the mating surface does not leak.

7.3 Rigidly mount the bracket or plate adapter with the filter assembly on the shaker platform, ensuring that the filter's polar axis is perpendicular to the excitation axis (see Figure 1).

7.4 Connect the filter to the pressure gauge and a normal room temperature oil pressure source. Use a flexible tube to ensure that it does not interfere with the vibration filter device.

7.5 The input accelerometer is mounted on the filter seat/connector, the output accelerometer is mounted on the filter, and the output position of the accelerometer is output to

The approximate distance of the upper surface of the seal ring is 100 mm, and if the length of the filter is less than 120 mm, it is 0.85 times the length of the filter. Two plus

The polar axis of the speedometer should be parallel to the excitation axis (see Figure 1). Elect...

Get QUOTATION in 1-minute: Click GB/T 8243.7-2017

Historical versions: GB/T 8243.7-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 8243.7-2017: Methods of test for full-flow lubricating oil filters for internal combustion engines -- Part 7: Vibration fatigue test

GB/T 8243.7-2017

Partitions. Methods of test for full-flow lubricating oil filters for internal combustion engines. Part 7. Vibration fatigue test

ICS 27.020

J95

National Standards of People's Republic of China

Replacing GB/T 8243.7-2006

Full-flow internal combustion engine oil filter test method

Part 7. Vibration Fatigue Test

Part 7. Vibrationfatiguetest

(ISO 4548-7.2012, IDT)

Published on.2017-05-12

2017-12-01 implementation

General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China

China National Standardization Administration released

Foreword

GB/T 8243 "Test method for full-flow internal combustion engine oil filters" currently includes the following parts.

--- Part 1. Differential pressure - flow characteristics;

--- Part 2. Filter by-pass valve characteristics;

--- Part 3. Resistance to high pressure and high temperature characteristics;

--- Part 4. Raw Filtration Efficiency, Lifetime, and Accumulation Efficiency (Gravimetric Method);

--- Part 5. Cold start simulation and hydraulic pulse endurance test;

--- Part 6. Static pressure burst test;

---Part 7. Vibration fatigue test;

--- Part 9. Inlet and outlet check valve tests;

---Part 11. Self-cleaning filters;

--- Part 12. Determination of filtration efficiency and dust holding capacity by particle counting;

--- Part 13. Static pressure burst test for composite filters;

--- Part 15. Vibration fatigue testing of composite filters.

This part is part 7 of GB/T 8243.

This section was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 8243.7-2006 "Full-flow Internal Combustion Engine Oil Filter Test Method Part 7. Vibration Fatigue Test".

Compared with GB/T 8243.7-2006, the main content changes as follows.

--- Modify the range requirements of oil pressure gauges and accelerometers (see Chapter 5,.2006 Edition, Chapter 5);

--- Modify the provisions of the test pressure value and input acceleration peak (see Chapter 7,.2006 Edition, Chapter 7);

--- Modify the provisions of the same test filter when testing the direction of the secondary test (see 7.9,.2006 version 7.11).

This section uses the translation method equivalent to the use of ISO 4548-7.2012 "Full internal combustion engine oil filter test method Part 7. Vibration

Dynamic Fatigue Test (English version).

The Chinese documents that are consistent with the normatively quoted international documents in this section are as follows.

---GB/T 8243.1-2003 Internal-combustion engine full-flow oil filter test method Part 1. Differential pressure-flow characteristics

(ISO 4548-1.1997, IDT).

This part is proposed by China Machinery Industry Federation.

This part is under the jurisdiction of the National Standardization Technical Committee for Internal Combustion Engines (SAC/TC177).

This section was drafted by. Shanghai Institute of Internal Combustion Engines, Zhejiang Weitai Auto Parts Co., Ltd., Linhai Jiangnan Internal Combustion Engine Accessories Factory, and Guangxi Huayuan

Filtration System Co., Ltd., Hangzhou Special Paper Co., Ltd., Hangzhou Fuyang North Wood Pulp Co., Ltd., Shanghai Automotive Group Co., Ltd.

Company Commercial Vehicle Technology Center, Hangzhou Xinxing Paper Co., Ltd., Linhai Jiangnan Filter Co., Ltd.

Drafters of this section. Qiao Liangliang, Shen Hongjie, Zhang Yu, Jin Wenhua, Zhao Yubao, Wu Anbo, Chen Qianqian, Meng Hongxia, Li Jianming, Feng Yihai.

The previous editions of the standards replaced by this section are.

--- GB/T 8243.7-2006.

Full-flow internal combustion engine oil filter test method

Part 7. Vibration Fatigue Test

1 Scope

This part of GB/T 8243 specifies a test method for determining the structural integrity of a full-flow oil filter against engine vibration. This test

The test method is applicable to spin-on filters with a maximum flow rate of less than 100 L/min and removable filters with a disposable filter cartridge.

This section applies to test pieces that are manufactured during the service period and the mechanical properties of the manufactured product materials do not change with temperature. For other types

The filter can also be used when the manufacturer of the filter manufacturer agrees with the buyer that it is applicable.

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article

Pieces. For undated references, the latest version (including all amendments) applies to this document.

ISO 4548-1 internal combustion engine full-flow oil filter test methods - Part 1. Differential pressure - flow characteristics (Methodsoftestfor

Ful-flow lubricationoilfiltersforintercomcombustionengines-Part 1.Differentialpressure/flow

Characteristics)

3 Terms, definitions and graphic symbols

3.1 Terms and Definitions

The terms and definitions defined by ISO 4548-1 apply to this document.

3.2 Graphical symbols

The graphic symbols used in this section refer to the provisions of ISO 1219 [1].

4 Principle

Complete installation Oil filter assemblies that are subject to alternating forces due to vibration of the engine or mounting device, including filter seats, adapters, and safety

Mounting brackets and so on. This test method is used to verify the ability of the filter assembly to withstand vibrations for a predetermined number of cycles when under pressure.

5 Test bench

The test rig should include the following components, as well as the necessary piping, fittings, and brackets (see Figure 1).

a) Electromechanical shakers, including the necessary hardware and electronic equipment for controlling and monitoring displacement, velocity and acceleration;

b) Oil pressure source, manual or mechanical control;

c) Oil pressure gauge, measuring range sufficient to cover the rated pressure of the test filter;

d) Two accelerometers, calibration linearity characteristics and range suitable for the test piece.

Explanation.

1 --- output accelerometer; 5 --- input accelerometer;

2 --- filter seat or joint; 6 --- test oil filter;

3 --- excitation axis; 7 --- shaking table platform.

4 --- pressure source;

Figure 1 Test bench layout. first direction

6 test solution

The test solution should be a motor oil with a kinematic viscosity of less than 10 mm2/s ± 5 mm2/s at ambient temperature (viscosity class ISO at 63°C)

SAE5W at VG22 or 68°C) [2][3].

7 Vibration durability test

7.1 Mount the filter under test on the filter seat or fitting according to the recommended tightening torque or angle of rotation.

7.2 Mount the filter and the filter holder assembly on a rigid support or a non-deformable flat connector. Use suitable gaskets or seals.

Ensure that the mating surface does not leak.

7.3 Rigidly mount the bracket or plate adapter with the filter assembly on the shaker platform, ensuring that the filter's polar axis is perpendicular to the excitation axis (see Figure 1).

7.4 Connect the filter to the pressure gauge and a normal room temperature oil pressure source. Use a flexible tube to ensure that it does not interfere with the vibration filter device.

7.5 The input accelerometer is mounted on the filter seat/connector, the output accelerometer is mounted on the filter, and the output position of the accelerometer is output to

The approximate distance of the upper surface of the seal ring is 100 mm, and if the length of the filter is less than 120 mm, it is 0.85 times the length of the filter. Two plus

The polar axis of the speedometer should be parallel to the excitation axis (see Figure 1). Elect...

Share