1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 9722-2006 English PDF (GBT9722-2006)

GB/T 9722-2006 English PDF (GBT9722-2006)

Regular price

$225.00 USD

Regular price

Sale price

$225.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) GB/T 9722-2023

Get QUOTATION in 1-minute: Click GB/T 9722-2006

Historical versions: GB/T 9722-2006

Preview True-PDF (Reload/Scroll if blank)

GB/T 9722-2006: Chemical reagent -- General rules for the gas chromatography

GB/T 9722-2006

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 71.040.030

G 60

Replacing GB/T 9722-1988

Chemical reagent - General rules for the gas

chromatography

ISSUED ON: JANUARY 23, 2006

IMPLEMENTED ON: NOVEMBER 01, 2006

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Method principle ... 5

5 Reagents and materials ... 5

6 Instruments ... 5

7 Selection of test conditions ... 7

8 Methods of operation ... 8

9 Quantitative method ... 14

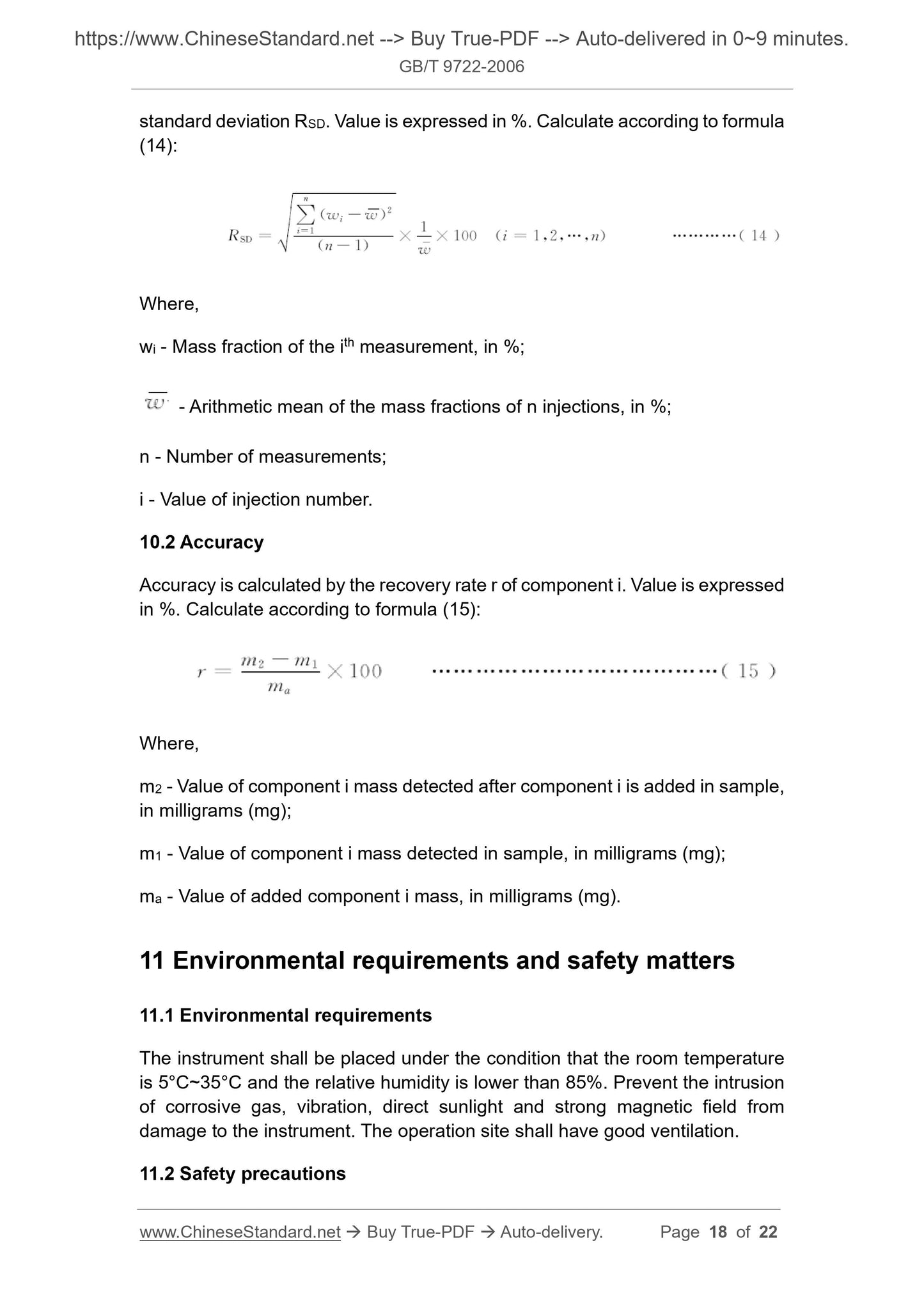

10 Method error ... 17

11 Environmental requirements and safety matters ... 18

Annex A (normative) Illustration diagrams and calculation formulas for related

terms ... 20

Chemical reagent - General rules for the gas

chromatography

1 Scope

This Standard specifies requirements for instruments by chemical reagent gas

chromatography and analysis methods. The detectors used include thermal

conductivity detectors and flame ionization detectors. The chromatographic

columns are packed column and capillary column.

This Standard is applicable to determination of main ingredients and impurities

of organic chemical reagents that contain volatile ingredients.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For dated references, the subsequent

amendments (excluding corrigendum) or revisions do not apply to this Standard,

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 4946, Terms of gas chromatography

JJG 700-1999, Verification Regulation of Gas Chromatograph

No. 250 Gas Cylinder Safety Supervision Regulations issued by Quality and

Technology Supervision Bureau [2000]

3 Terms and definitions

For the purposes of this document, the terms and definitions defined by GB/T

4946 as well as the followings apply.

3.1 asymmetric factor (f)

a parameter that describes the degree of asymmetry of chromatographic peaks;

see Annex A for diagram

3.2 height of an effective plate (Heff)

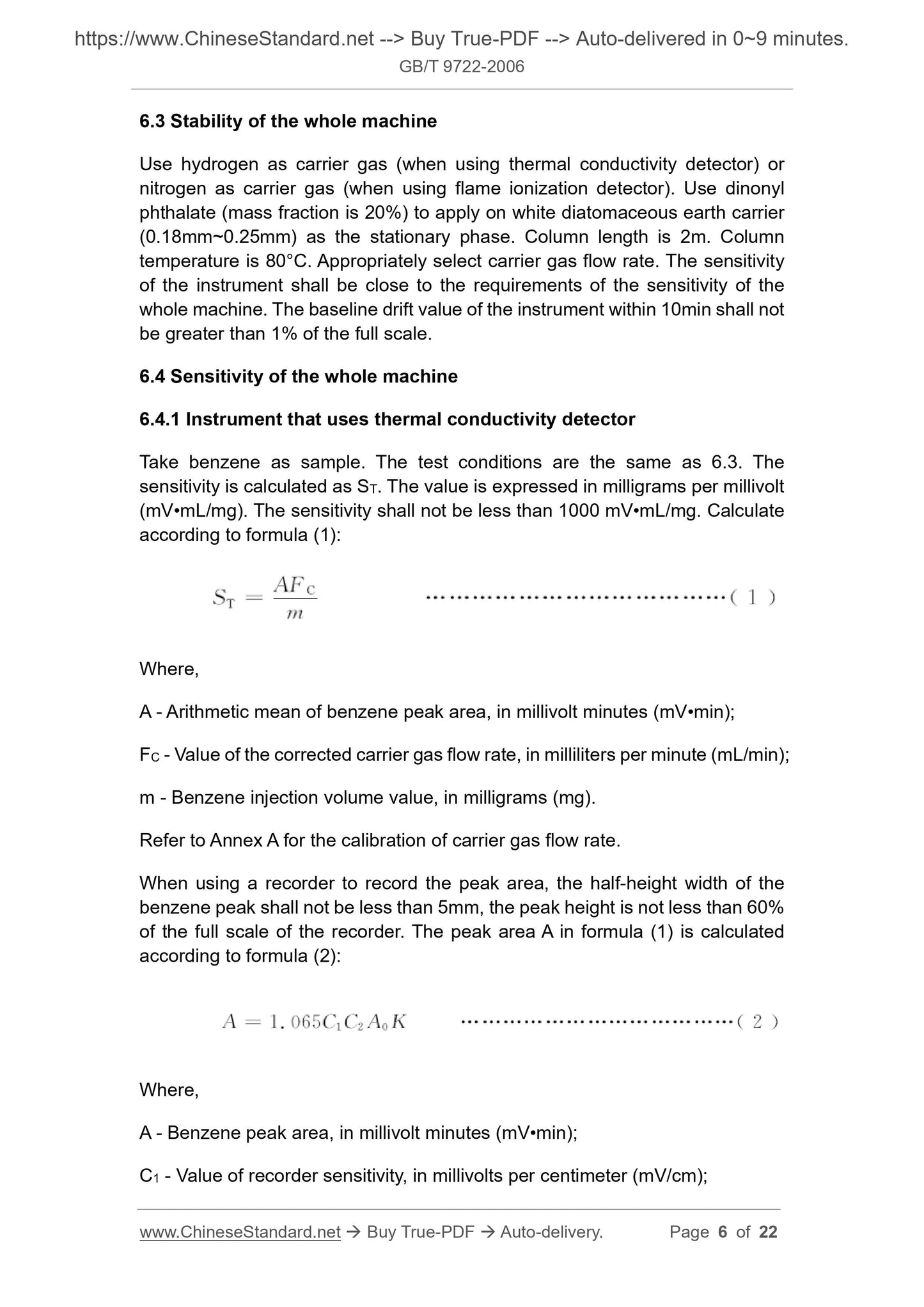

6.3 Stability of the whole machine

Use hydrogen as carrier gas (when using thermal conductivity detector) or

nitrogen as carrier gas (when using flame ionization detector). Use dinonyl

phthalate (mass fraction is 20%) to apply on white diatomaceous earth carrier

(0.18mm~0.25mm) as the stationary phase. Column length is 2m. Column

temperature is 80°C. Appropriately select carrier gas flow rate. The sensitivity

of the instrument shall be close to the requirements of the sensitivity of the

whole machine. The baseline drift value of the instrument within 10min shall not

be greater than 1% of the full scale.

6.4 Sensitivity of the whole machine

6.4.1 Instrument that uses thermal conductivity detector

Take benzene as sample. The test conditions are the same as 6.3. The

sensitivity is calculated as ST. The value is expressed in milligrams per millivolt

(mV•mL/mg). The sensitivity shall not be less than 1000 mV•mL/mg. Calculate

according to formula (1):

Where,

A - Arithmetic mean of benzene peak area, in millivolt minutes (mV•min);

FC - Value of the corrected carrier gas flow rate, in milliliters per minute (mL/min);

m - Benzene injection volume value, in milligrams (mg).

Refer to Annex A for the calibration of carrier gas flow rate.

When using a recorder to record the peak area, the half-height width of the

benzene peak shall not be less than 5mm, the peak height is not less than 60%

of the full scale of the recorder. The peak area A in formula (1) is calculated

according to formula (2):

Where,

A - Benzene peak area, in millivolt minutes (mV•min);

C1 - Value of recorder sensitivity, in millivolts per centimeter (mV/cm);

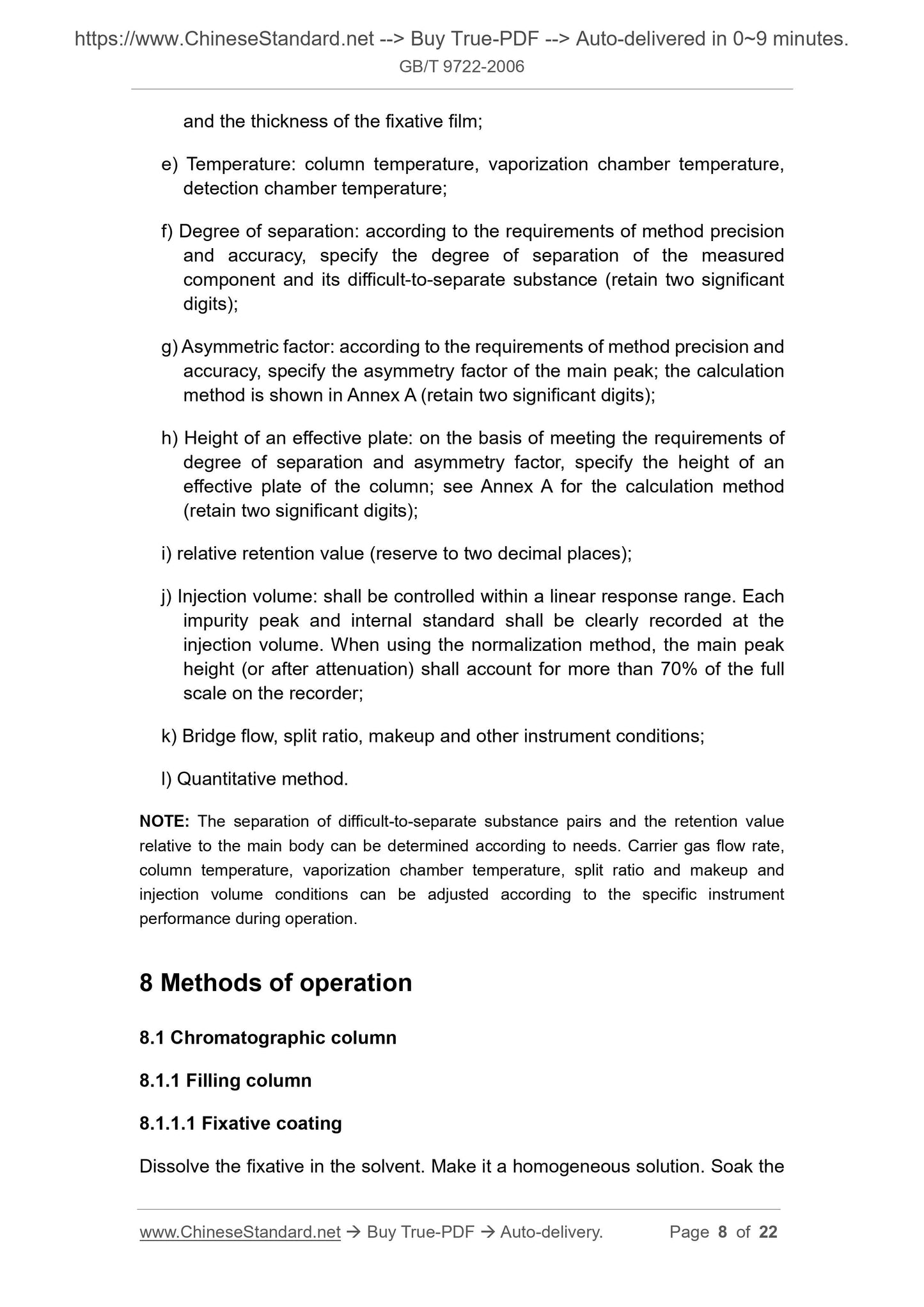

and the thickness of the fixative film;

e) Temperature: column temperature, vaporization chamber temperature,

detection chamber temperature;

f) Degree of separation: according to the requirements of method precision

and accuracy, specify the degree of separation of the measured

component and its difficult-to-separate substance (retain two significant

digits);

g) Asymmetric factor: according to the requirements of method precision and

accuracy, specify the asymmetry factor of the main peak; the calculation

method is shown in Annex A (retain two significant digits);

h) Height of an effective plate: on the basis of meeting the requirements of

degree of separation and asymmetry factor, specify the height of an

effective plate of the column; see Annex A for the calculation method

(retain two significant digits);

i) relative retention value (reserve to two decimal places);

j) Injection volume: shall be controlled within a linear response range. Each

impurity peak and internal standard shall be clearly recorded at the

injection volume. When using the normalization method, the main peak

height (or after attenuation) shall account for more than 70% of the full

scale on the recorder;

k) Bridge flow, split ratio, makeup and other instrument conditions;

l) Quantitative method.

NOTE: The separation of difficult-to-separate substance pairs and the retention value

relative to the main body can be determined according to needs. Carrier gas flow rate,

column temperature, vaporization chamber temperature, split ratio and makeup and

injection volume conditions can be adjusted according to the specific instrument

performance during operation.

8 Methods of operation

8.1 Chromatographic column

8.1.1 Filling column

8.1.1.1 Fixative coating

Dissolve the fixative in the solvent. Make it a homogeneous solution. Soak the

carrier in the solution (heat to reflux if necessary). Stir gently or shake well. Do

not crush the carrier. Place in a fume hood. Volatilize and dry the solvent under

infrared light.

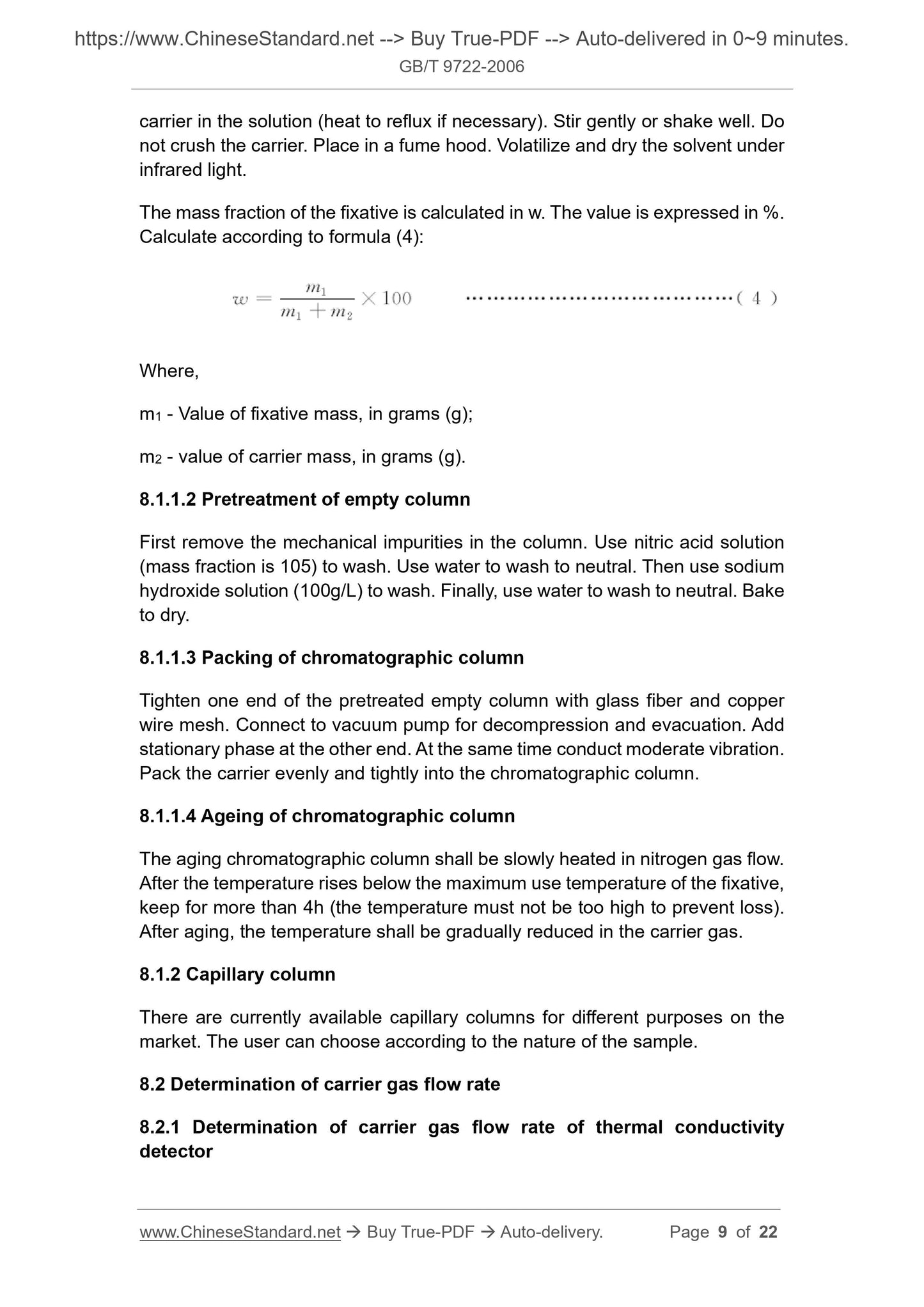

The mass fraction of the fixative is calculated in w. The value is expressed in %.

Calculate according to formula (4):

Where,

m1 - Value of fixative mass, in grams (g);

m2 - value of carrier mass, in grams (g).

8.1.1.2 Pretreatment of empty column

First remove the mechanical impurities in the column. Use nitric acid solution

(mass fraction is 105) to wash. Use water to wash to neutral. Then use sodium

hydroxide solution (100g/L) to wash. Finally, use water to wash to neutral. Bake

to dry.

8.1.1.3 Packing of chromatographic column

Tighten one end of the pretreated empty column with glass fiber and copper

wire mesh. Connect to vacuum pump for decompression and evacuation. Add

stationary phase at the other end. At the same time conduct moderate vibration.

Pack the carrier evenly and tightly into the chromatographic column.

8.1.1.4 Ageing of chromatographic column

The aging chromatographic column shall be slowly heated in nitrogen gas flow.

After the temperature rises below the maximum use temperature of the fixative,

keep for more than 4h (the temperature must not be too high to prevent loss).

After aging, the temperature shall be gradually reduced in the carrier gas.

8.1.2 Capillary column

There are currently available capillary columns for different purposes on the

market. The user can choose accordin...

Get QUOTATION in 1-minute: Click GB/T 9722-2006

Historical versions: GB/T 9722-2006

Preview True-PDF (Reload/Scroll if blank)

GB/T 9722-2006: Chemical reagent -- General rules for the gas chromatography

GB/T 9722-2006

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 71.040.030

G 60

Replacing GB/T 9722-1988

Chemical reagent - General rules for the gas

chromatography

ISSUED ON: JANUARY 23, 2006

IMPLEMENTED ON: NOVEMBER 01, 2006

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Method principle ... 5

5 Reagents and materials ... 5

6 Instruments ... 5

7 Selection of test conditions ... 7

8 Methods of operation ... 8

9 Quantitative method ... 14

10 Method error ... 17

11 Environmental requirements and safety matters ... 18

Annex A (normative) Illustration diagrams and calculation formulas for related

terms ... 20

Chemical reagent - General rules for the gas

chromatography

1 Scope

This Standard specifies requirements for instruments by chemical reagent gas

chromatography and analysis methods. The detectors used include thermal

conductivity detectors and flame ionization detectors. The chromatographic

columns are packed column and capillary column.

This Standard is applicable to determination of main ingredients and impurities

of organic chemical reagents that contain volatile ingredients.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For dated references, the subsequent

amendments (excluding corrigendum) or revisions do not apply to this Standard,

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 4946, Terms of gas chromatography

JJG 700-1999, Verification Regulation of Gas Chromatograph

No. 250 Gas Cylinder Safety Supervision Regulations issued by Quality and

Technology Supervision Bureau [2000]

3 Terms and definitions

For the purposes of this document, the terms and definitions defined by GB/T

4946 as well as the followings apply.

3.1 asymmetric factor (f)

a parameter that describes the degree of asymmetry of chromatographic peaks;

see Annex A for diagram

3.2 height of an effective plate (Heff)

6.3 Stability of the whole machine

Use hydrogen as carrier gas (when using thermal conductivity detector) or

nitrogen as carrier gas (when using flame ionization detector). Use dinonyl

phthalate (mass fraction is 20%) to apply on white diatomaceous earth carrier

(0.18mm~0.25mm) as the stationary phase. Column length is 2m. Column

temperature is 80°C. Appropriately select carrier gas flow rate. The sensitivity

of the instrument shall be close to the requirements of the sensitivity of the

whole machine. The baseline drift value of the instrument within 10min shall not

be greater than 1% of the full scale.

6.4 Sensitivity of the whole machine

6.4.1 Instrument that uses thermal conductivity detector

Take benzene as sample. The test conditions are the same as 6.3. The

sensitivity is calculated as ST. The value is expressed in milligrams per millivolt

(mV•mL/mg). The sensitivity shall not be less than 1000 mV•mL/mg. Calculate

according to formula (1):

Where,

A - Arithmetic mean of benzene peak area, in millivolt minutes (mV•min);

FC - Value of the corrected carrier gas flow rate, in milliliters per minute (mL/min);

m - Benzene injection volume value, in milligrams (mg).

Refer to Annex A for the calibration of carrier gas flow rate.

When using a recorder to record the peak area, the half-height width of the

benzene peak shall not be less than 5mm, the peak height is not less than 60%

of the full scale of the recorder. The peak area A in formula (1) is calculated

according to formula (2):

Where,

A - Benzene peak area, in millivolt minutes (mV•min);

C1 - Value of recorder sensitivity, in millivolts per centimeter (mV/cm);

and the thickness of the fixative film;

e) Temperature: column temperature, vaporization chamber temperature,

detection chamber temperature;

f) Degree of separation: according to the requirements of method precision

and accuracy, specify the degree of separation of the measured

component and its difficult-to-separate substance (retain two significant

digits);

g) Asymmetric factor: according to the requirements of method precision and

accuracy, specify the asymmetry factor of the main peak; the calculation

method is shown in Annex A (retain two significant digits);

h) Height of an effective plate: on the basis of meeting the requirements of

degree of separation and asymmetry factor, specify the height of an

effective plate of the column; see Annex A for the calculation method

(retain two significant digits);

i) relative retention value (reserve to two decimal places);

j) Injection volume: shall be controlled within a linear response range. Each

impurity peak and internal standard shall be clearly recorded at the

injection volume. When using the normalization method, the main peak

height (or after attenuation) shall account for more than 70% of the full

scale on the recorder;

k) Bridge flow, split ratio, makeup and other instrument conditions;

l) Quantitative method.

NOTE: The separation of difficult-to-separate substance pairs and the retention value

relative to the main body can be determined according to needs. Carrier gas flow rate,

column temperature, vaporization chamber temperature, split ratio and makeup and

injection volume conditions can be adjusted according to the specific instrument

performance during operation.

8 Methods of operation

8.1 Chromatographic column

8.1.1 Filling column

8.1.1.1 Fixative coating

Dissolve the fixative in the solvent. Make it a homogeneous solution. Soak the

carrier in the solution (heat to reflux if necessary). Stir gently or shake well. Do

not crush the carrier. Place in a fume hood. Volatilize and dry the solvent under

infrared light.

The mass fraction of the fixative is calculated in w. The value is expressed in %.

Calculate according to formula (4):

Where,

m1 - Value of fixative mass, in grams (g);

m2 - value of carrier mass, in grams (g).

8.1.1.2 Pretreatment of empty column

First remove the mechanical impurities in the column. Use nitric acid solution

(mass fraction is 105) to wash. Use water to wash to neutral. Then use sodium

hydroxide solution (100g/L) to wash. Finally, use water to wash to neutral. Bake

to dry.

8.1.1.3 Packing of chromatographic column

Tighten one end of the pretreated empty column with glass fiber and copper

wire mesh. Connect to vacuum pump for decompression and evacuation. Add

stationary phase at the other end. At the same time conduct moderate vibration.

Pack the carrier evenly and tightly into the chromatographic column.

8.1.1.4 Ageing of chromatographic column

The aging chromatographic column shall be slowly heated in nitrogen gas flow.

After the temperature rises below the maximum use temperature of the fixative,

keep for more than 4h (the temperature must not be too high to prevent loss).

After aging, the temperature shall be gradually reduced in the carrier gas.

8.1.2 Capillary column

There are currently available capillary columns for different purposes on the

market. The user can choose accordin...

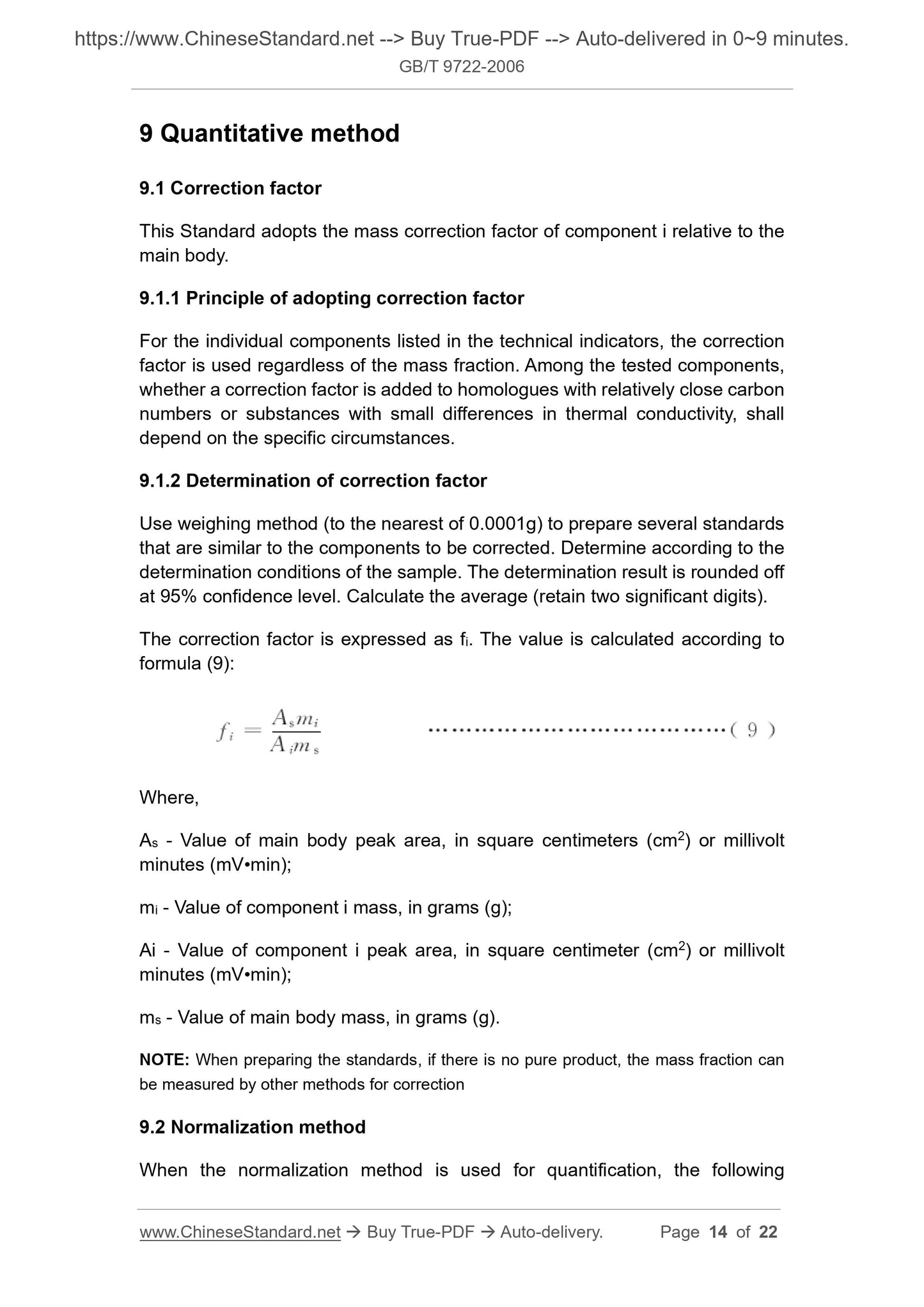

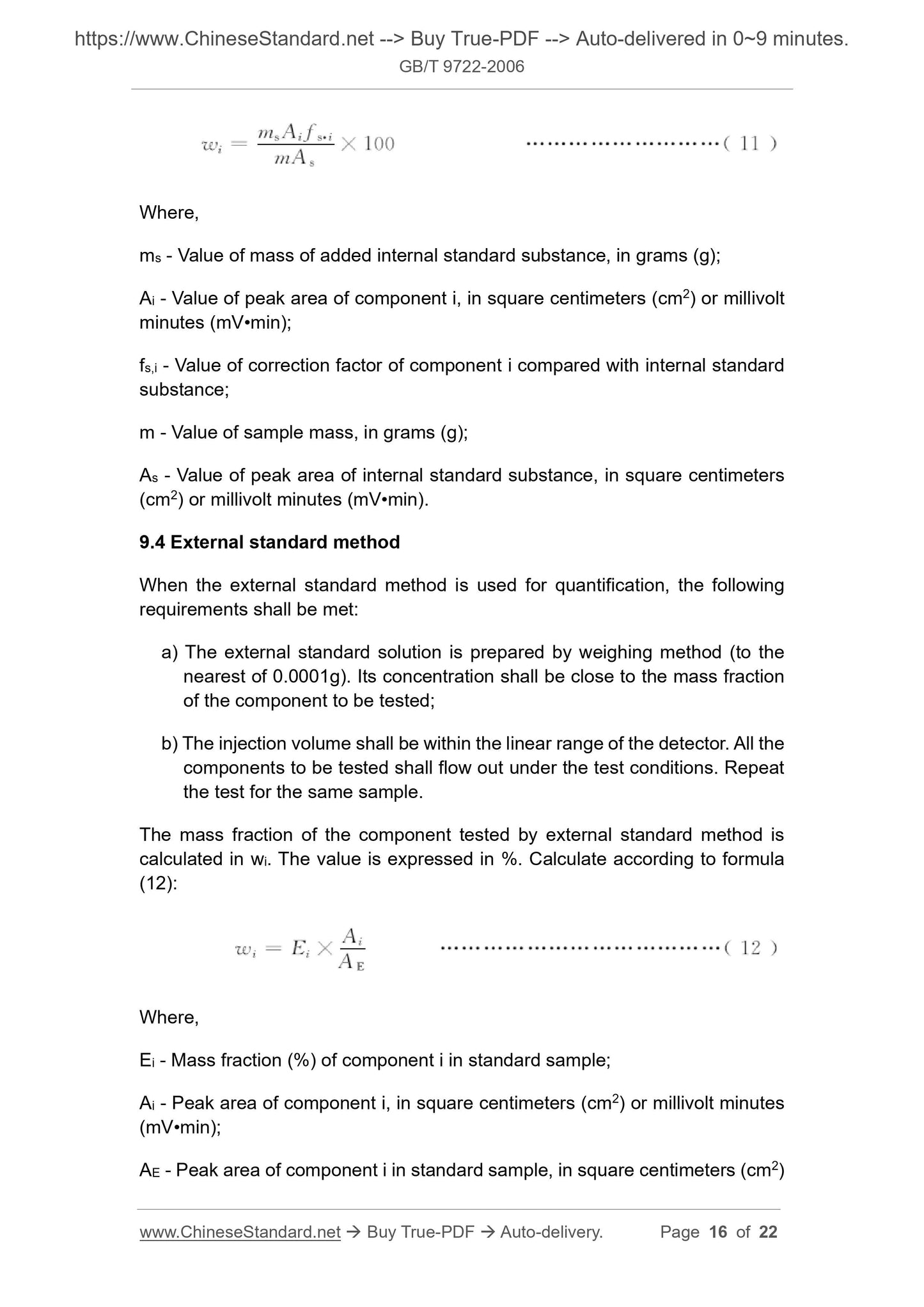

Share