1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 9846-2015 English PDF (GB/T9846-2015)

GB/T 9846-2015 English PDF (GB/T9846-2015)

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 9846-2015: Plywood for general use

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 9846-2015 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 9846-2015

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 9846-2015

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 79.060.10

B 70

Replacing GB/T 9846.1 ~ 9846.8-2004

Plywood for general use

ISSUED ON. JULY 03, 2015

IMPLEMENTED ON. NOVEMBER 02, 2015

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification ... 6

5 Requirements ... 6

5.1 Specifications dimensions and their deviations ... 6

5.2 Appearance quality ... 7

5.3 Physical and chemical properties ... 16

5.4 Other technical requirements ... 18

6 Measurement and test methods ... 18

6.1 Specification dimension measurement ... 18

6.2 Sampling and dimension requirements ... 19

6.3 Test methods ... 21

7 Inspection rules ... 23

7.1 Classification of inspections ... 23

7.2 Sampling plan ... 23

7.3 Judgement rules ... 24

7.4 Comprehensive judgment ... 26

7.5 Metering of products ... 26

8 Marking, packaging, transportation and storage ... 26

8.1 Marking ... 26

8.2 Packaging ... 26

8.3 Transportation and storage ... 27

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Foreword

This standard was drafted in accordance with the rules given in GB/T

1.1-2009.

This standard is the integration and revision of GB/T 9846.1 ~ 9846.8-2004

“Plywood”.

As compared with GB/T 9846.1 ~ 9846.8-2004, in addition to editorial changes,

the main technical changes are as follows.

- MODIFY the standard name from the “Plywood” to the “Plywood for

general use”;

- MODIFY the scope of application of the standard;

- INTEGRATE 8 series standards into one standard;

- ADD terms and definitions;

- DELETE the classification by overall appearance, end-user requirements,

composition, mechanical properties, and application;

- MODIFY the length and width deviation;

- MODIFY the thickness deviation;

- ADD the determination of flatness; CANCEL the determination of warpage;

- MODIFY the pretreatment conditions of class III plywood;

- MODIFY the slot depth of the adhesive strength sample;

- MODIFY the lower limit of water content;

- ADD the timber species. eucalyptus, the adhesive strength index value ≥

0.70 MPa;

- ADD the gum canal defect in the appearance defects in the broad-leaved

wood (including tropical broad-leaved wood);

- ADD the sample production schematic diagram;

- Formaldehyde emission index value follows the provisions of GB 18580;

- ADD the test methods and index value of the static bending strength and

elastic modulus;

- ADD the impregnation peeling test method and index value;

Plywood for general use

1 Scope

This standard specifies the terms and definitions, classification, requirements,

measurement and test methods, inspection rules and marking, packaging,

transportation and storage, of plywood for general uses.

This standard applies to the plywood for general use, AND it is not applicable

to the core board, veneer laminated timber, or other plywood having different

structures and special performance requirements.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this Standard.

GB/T 1933 Method for determination of the density of wood

GB/T 2828.1-2012 Sampling procedures for inspection by attributes – Part

1. Sampling schemes indexed by acceptance quality limit (AQL) for

lot-by-lot inspection

GB/T 17657-2013 Test methods of evaluating the properties of wood-based

panels and surface decorated wood-based panels

GB/T 18259-2009 Terms of wood-based panels and its surface decoration

GB 18580 Indoor decorating and refurbishing materials – Limit of

formaldehyde emission of wood-based panels and finishing products

GB/T 19367-2009 Wood-based panels - Determination of dimensions of

panels

3 Terms and definitions

The following definitions and definitions as defined in GB/T 18259-2009 apply

to this document. For ease of use, some of the terms and definitions as defined

in GB/T 18259-2009 are listed below again.

3.1

Class I plywood

It refers to the weather fastness plywood for outdoor use which can pass

the boiling test.

[GB/T 18259-2009, definition 2.2.1.18]

3.2

Class II plywood

It refers to the water-resistant plywood for wet conditions which can pass

the 63 °C ± 3 °C hot water immersion test.

[GB/T 18259-2009, definition 2.2.1.19]

3.3

Class III plywood

It refers to the non-moisture resistant plywood for dry conditions which can

pass the 20 °C ± 3 °C cold water immersion test.

3.4

Plywood tree species

Plywood panel tree species is this plywood tree species.

4 Classification

4.1 In accordance with the environment of use, it is divided into the following.

a) Used under dry conditions;

b) Used under wet conditions;

c) Used under outdoor conditions.

4.2 In accordance with the surface processing conditions, it is divided into the

following.

a) Non-sanding board;

b) Sanding board.

5 Requirements

5.1 Specifications dimensions and their deviations

5.1.1 Specifications dimensions

5.1.1.1 Plywood dimensions shall comply with the requirements of Table 1.

into three grades. excellent grade product, first grade product, and qualified

grade product. The panels of these three grades shall be sanded/scraped

smooth, AND those panels having special requirements may not be sanded

(scraped) smooth OR sanded (scraped) smooth at both sides.

5.2.1.2 In accordance with user needs, it may produce the plywood which is

composed of the panels and back plates of different grades.

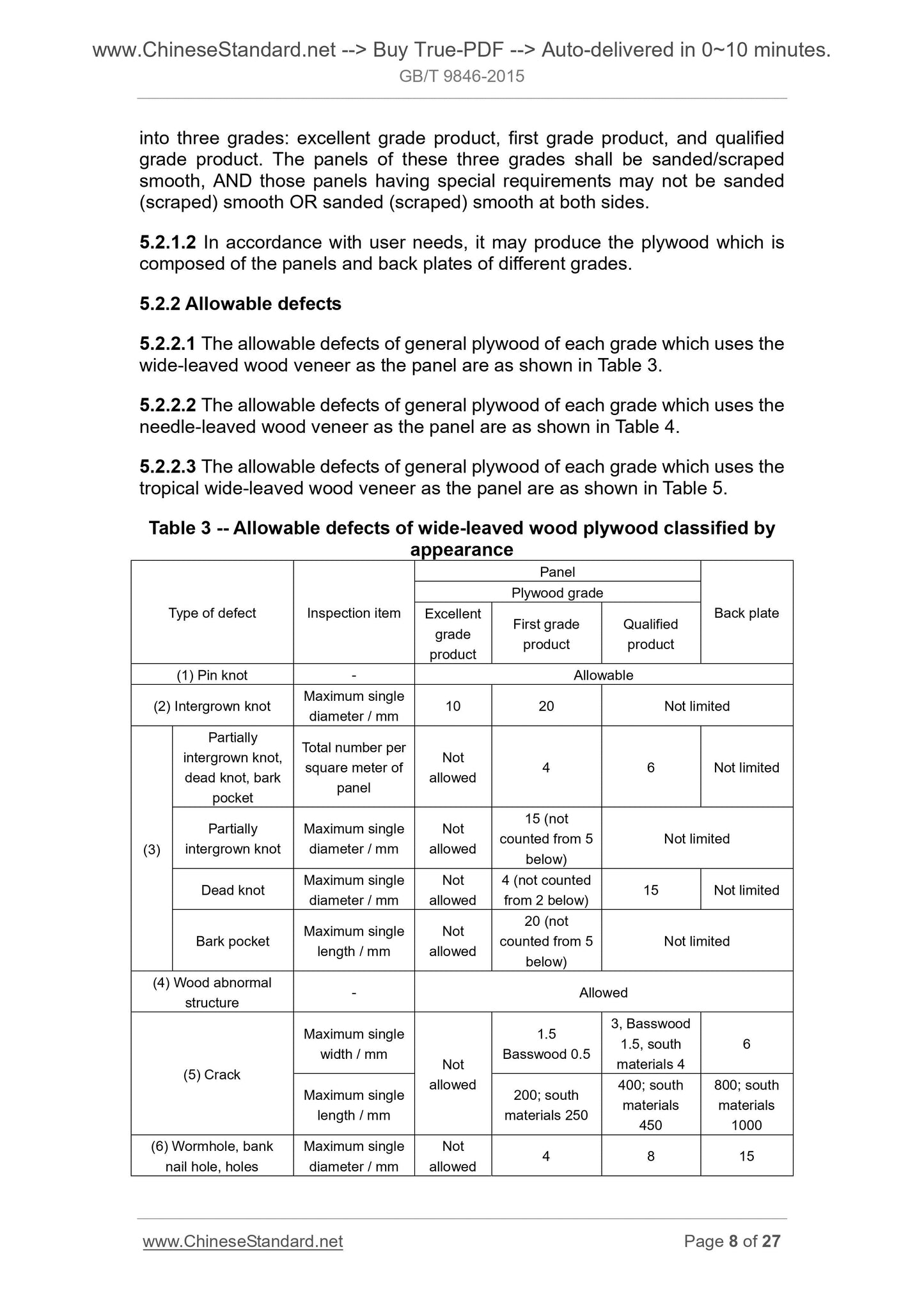

5.2.2 Allowable defects

5.2.2.1 The allowable defects of general plywood of each grade which uses the

wide-leaved wood veneer as the panel are as shown in Table 3.

5.2.2.2 The allowable defects of general plywood of each grade which uses the

needle-leaved wood veneer as the panel are as shown in Table 4.

5.2.2.3 The allowable defects of general plywood of each grade which uses the

tropical wide-leaved wood veneer as the panel are as shown in Table 5.

Table 3 -- Allowable defects of wide-leaved wood plywood classified by

appearance

Type of defect Inspection item

Panel

Back plate

Plywood grade

Excellent

grade

product

First grade

product

Qualified

product

(1) Pin knot - Allowable

(2) Intergrown knot Maximum single diameter / mm 10 20 Not limited

(3)

Partially

intergrown knot,

dead knot, bark

pocket

Total number per

square meter of

panel

Not

allowed 4 6 Not limited

Partially

intergrown knot

Maximum single

diameter / mm

Not

allowed

15 (not

counted from 5

below)

Not limited

Dead knot Maximum single diameter / mm

Not

allowed

4 (not counted

from 2 below) 15 Not limited

Bark pocket Maximum single length / mm

Not

allowed

20 (not

counted from 5

below)

Not limited

(4) Wood abnormal

structure - Allowed

(5) Crack

Maximum single

width / mm Not

allowed

1.5

Basswood 0.5

3, Basswood

1.5, south

materials 4

Maximum single

length / mm

200; south

materials 250

400; south

materials

800; south

materials

(6) Wormhole, bank

nail hole, holes

Maximum single

diameter / mm

...

GB/T 9846-2015

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 79.060.10

B 70

Replacing GB/T 9846.1 ~ 9846.8-2004

Plywood for general use

ISSUED ON. JULY 03, 2015

IMPLEMENTED ON. NOVEMBER 02, 2015

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification ... 6

5 Requirements ... 6

5.1 Specifications dimensions and their deviations ... 6

5.2 Appearance quality ... 7

5.3 Physical and chemical properties ... 16

5.4 Other technical requirements ... 18

6 Measurement and test methods ... 18

6.1 Specification dimension measurement ... 18

6.2 Sampling and dimension requirements ... 19

6.3 Test methods ... 21

7 Inspection rules ... 23

7.1 Classification of inspections ... 23

7.2 Sampling plan ... 23

7.3 Judgement rules ... 24

7.4 Comprehensive judgment ... 26

7.5 Metering of products ... 26

8 Marking, packaging, transportation and storage ... 26

8.1 Marking ... 26

8.2 Packaging ... 26

8.3 Transportation and storage ... 27

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Foreword

This standard was drafted in accordance with the rules given in GB/T

1.1-2009.

This standard is the integration and revision of GB/T 9846.1 ~ 9846.8-2004

“Plywood”.

As compared with GB/T 9846.1 ~ 9846.8-2004, in addition to editorial changes,

the main technical changes are as follows.

- MODIFY the standard name from the “Plywood” to the “Plywood for

general use”;

- MODIFY the scope of application of the standard;

- INTEGRATE 8 series standards into one standard;

- ADD terms and definitions;

- DELETE the classification by overall appearance, end-user requirements,

composition, mechanical properties, and application;

- MODIFY the length and width deviation;

- MODIFY the thickness deviation;

- ADD the determination of flatness; CANCEL the determination of warpage;

- MODIFY the pretreatment conditions of class III plywood;

- MODIFY the slot depth of the adhesive strength sample;

- MODIFY the lower limit of water content;

- ADD the timber species. eucalyptus, the adhesive strength index value ≥

0.70 MPa;

- ADD the gum canal defect in the appearance defects in the broad-leaved

wood (including tropical broad-leaved wood);

- ADD the sample production schematic diagram;

- Formaldehyde emission index value follows the provisions of GB 18580;

- ADD the test methods and index value of the static bending strength and

elastic modulus;

- ADD the impregnation peeling test method and index value;

Plywood for general use

1 Scope

This standard specifies the terms and definitions, classification, requirements,

measurement and test methods, inspection rules and marking, packaging,

transportation and storage, of plywood for general uses.

This standard applies to the plywood for general use, AND it is not applicable

to the core board, veneer laminated timber, or other plywood having different

structures and special performance requirements.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this Standard.

GB/T 1933 Method for determination of the density of wood

GB/T 2828.1-2012 Sampling procedures for inspection by attributes – Part

1. Sampling schemes indexed by acceptance quality limit (AQL) for

lot-by-lot inspection

GB/T 17657-2013 Test methods of evaluating the properties of wood-based

panels and surface decorated wood-based panels

GB/T 18259-2009 Terms of wood-based panels and its surface decoration

GB 18580 Indoor decorating and refurbishing materials – Limit of

formaldehyde emission of wood-based panels and finishing products

GB/T 19367-2009 Wood-based panels - Determination of dimensions of

panels

3 Terms and definitions

The following definitions and definitions as defined in GB/T 18259-2009 apply

to this document. For ease of use, some of the terms and definitions as defined

in GB/T 18259-2009 are listed below again.

3.1

Class I plywood

It refers to the weather fastness plywood for outdoor use which can pass

the boiling test.

[GB/T 18259-2009, definition 2.2.1.18]

3.2

Class II plywood

It refers to the water-resistant plywood for wet conditions which can pass

the 63 °C ± 3 °C hot water immersion test.

[GB/T 18259-2009, definition 2.2.1.19]

3.3

Class III plywood

It refers to the non-moisture resistant plywood for dry conditions which can

pass the 20 °C ± 3 °C cold water immersion test.

3.4

Plywood tree species

Plywood panel tree species is this plywood tree species.

4 Classification

4.1 In accordance with the environment of use, it is divided into the following.

a) Used under dry conditions;

b) Used under wet conditions;

c) Used under outdoor conditions.

4.2 In accordance with the surface processing conditions, it is divided into the

following.

a) Non-sanding board;

b) Sanding board.

5 Requirements

5.1 Specifications dimensions and their deviations

5.1.1 Specifications dimensions

5.1.1.1 Plywood dimensions shall comply with the requirements of Table 1.

into three grades. excellent grade product, first grade product, and qualified

grade product. The panels of these three grades shall be sanded/scraped

smooth, AND those panels having special requirements may not be sanded

(scraped) smooth OR sanded (scraped) smooth a...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 9846-2015 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 9846-2015

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 9846-2015

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 79.060.10

B 70

Replacing GB/T 9846.1 ~ 9846.8-2004

Plywood for general use

ISSUED ON. JULY 03, 2015

IMPLEMENTED ON. NOVEMBER 02, 2015

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification ... 6

5 Requirements ... 6

5.1 Specifications dimensions and their deviations ... 6

5.2 Appearance quality ... 7

5.3 Physical and chemical properties ... 16

5.4 Other technical requirements ... 18

6 Measurement and test methods ... 18

6.1 Specification dimension measurement ... 18

6.2 Sampling and dimension requirements ... 19

6.3 Test methods ... 21

7 Inspection rules ... 23

7.1 Classification of inspections ... 23

7.2 Sampling plan ... 23

7.3 Judgement rules ... 24

7.4 Comprehensive judgment ... 26

7.5 Metering of products ... 26

8 Marking, packaging, transportation and storage ... 26

8.1 Marking ... 26

8.2 Packaging ... 26

8.3 Transportation and storage ... 27

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Foreword

This standard was drafted in accordance with the rules given in GB/T

1.1-2009.

This standard is the integration and revision of GB/T 9846.1 ~ 9846.8-2004

“Plywood”.

As compared with GB/T 9846.1 ~ 9846.8-2004, in addition to editorial changes,

the main technical changes are as follows.

- MODIFY the standard name from the “Plywood” to the “Plywood for

general use”;

- MODIFY the scope of application of the standard;

- INTEGRATE 8 series standards into one standard;

- ADD terms and definitions;

- DELETE the classification by overall appearance, end-user requirements,

composition, mechanical properties, and application;

- MODIFY the length and width deviation;

- MODIFY the thickness deviation;

- ADD the determination of flatness; CANCEL the determination of warpage;

- MODIFY the pretreatment conditions of class III plywood;

- MODIFY the slot depth of the adhesive strength sample;

- MODIFY the lower limit of water content;

- ADD the timber species. eucalyptus, the adhesive strength index value ≥

0.70 MPa;

- ADD the gum canal defect in the appearance defects in the broad-leaved

wood (including tropical broad-leaved wood);

- ADD the sample production schematic diagram;

- Formaldehyde emission index value follows the provisions of GB 18580;

- ADD the test methods and index value of the static bending strength and

elastic modulus;

- ADD the impregnation peeling test method and index value;

Plywood for general use

1 Scope

This standard specifies the terms and definitions, classification, requirements,

measurement and test methods, inspection rules and marking, packaging,

transportation and storage, of plywood for general uses.

This standard applies to the plywood for general use, AND it is not applicable

to the core board, veneer laminated timber, or other plywood having different

structures and special performance requirements.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this Standard.

GB/T 1933 Method for determination of the density of wood

GB/T 2828.1-2012 Sampling procedures for inspection by attributes – Part

1. Sampling schemes indexed by acceptance quality limit (AQL) for

lot-by-lot inspection

GB/T 17657-2013 Test methods of evaluating the properties of wood-based

panels and surface decorated wood-based panels

GB/T 18259-2009 Terms of wood-based panels and its surface decoration

GB 18580 Indoor decorating and refurbishing materials – Limit of

formaldehyde emission of wood-based panels and finishing products

GB/T 19367-2009 Wood-based panels - Determination of dimensions of

panels

3 Terms and definitions

The following definitions and definitions as defined in GB/T 18259-2009 apply

to this document. For ease of use, some of the terms and definitions as defined

in GB/T 18259-2009 are listed below again.

3.1

Class I plywood

It refers to the weather fastness plywood for outdoor use which can pass

the boiling test.

[GB/T 18259-2009, definition 2.2.1.18]

3.2

Class II plywood

It refers to the water-resistant plywood for wet conditions which can pass

the 63 °C ± 3 °C hot water immersion test.

[GB/T 18259-2009, definition 2.2.1.19]

3.3

Class III plywood

It refers to the non-moisture resistant plywood for dry conditions which can

pass the 20 °C ± 3 °C cold water immersion test.

3.4

Plywood tree species

Plywood panel tree species is this plywood tree species.

4 Classification

4.1 In accordance with the environment of use, it is divided into the following.

a) Used under dry conditions;

b) Used under wet conditions;

c) Used under outdoor conditions.

4.2 In accordance with the surface processing conditions, it is divided into the

following.

a) Non-sanding board;

b) Sanding board.

5 Requirements

5.1 Specifications dimensions and their deviations

5.1.1 Specifications dimensions

5.1.1.1 Plywood dimensions shall comply with the requirements of Table 1.

into three grades. excellent grade product, first grade product, and qualified

grade product. The panels of these three grades shall be sanded/scraped

smooth, AND those panels having special requirements may not be sanded

(scraped) smooth OR sanded (scraped) smooth at both sides.

5.2.1.2 In accordance with user needs, it may produce the plywood which is

composed of the panels and back plates of different grades.

5.2.2 Allowable defects

5.2.2.1 The allowable defects of general plywood of each grade which uses the

wide-leaved wood veneer as the panel are as shown in Table 3.

5.2.2.2 The allowable defects of general plywood of each grade which uses the

needle-leaved wood veneer as the panel are as shown in Table 4.

5.2.2.3 The allowable defects of general plywood of each grade which uses the

tropical wide-leaved wood veneer as the panel are as shown in Table 5.

Table 3 -- Allowable defects of wide-leaved wood plywood classified by

appearance

Type of defect Inspection item

Panel

Back plate

Plywood grade

Excellent

grade

product

First grade

product

Qualified

product

(1) Pin knot - Allowable

(2) Intergrown knot Maximum single diameter / mm 10 20 Not limited

(3)

Partially

intergrown knot,

dead knot, bark

Total number per

square meter of

panel

Not

allowed 4 6 Not limited

Partially

intergrown knot

Maximum single

diameter / mm

Not

allowed

15 (not

counted from 5

below)

Not limited

Dead knot Maximum single diameter / mm

Not

allowed

4 (not counted

from 2 below) 15 Not limited

Bark pocket Maximum single length / mm

Not

allowed

20 (not

counted from 5

below)

Not limited

(4) Wood abnormal

structure - Allowed

(5) Crack

Maximum single

width / mm Not

allowed

1.5

Basswood 0.5

3, Basswood

1.5, south

materials 4

Maximum single

length / mm

200; south

materials 250

400; south

materials

800; south

materials

(6) Wormhole, bank

nail hole, holes

Maximum single

diameter / mm

...

GB/T 9846-2015

GB

NATIONAL STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 79.060.10

B 70

Replacing GB/T 9846.1 ~ 9846.8-2004

Plywood for general use

ISSUED ON. JULY 03, 2015

IMPLEMENTED ON. NOVEMBER 02, 2015

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification ... 6

5 Requirements ... 6

5.1 Specifications dimensions and their deviations ... 6

5.2 Appearance quality ... 7

5.3 Physical and chemical properties ... 16

5.4 Other technical requirements ... 18

6 Measurement and test methods ... 18

6.1 Specification dimension measurement ... 18

6.2 Sampling and dimension requirements ... 19

6.3 Test methods ... 21

7 Inspection rules ... 23

7.1 Classification of inspections ... 23

7.2 Sampling plan ... 23

7.3 Judgement rules ... 24

7.4 Comprehensive judgment ... 26

7.5 Metering of products ... 26

8 Marking, packaging, transportation and storage ... 26

8.1 Marking ... 26

8.2 Packaging ... 26

8.3 Transportation and storage ... 27

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Foreword

This standard was drafted in accordance with the rules given in GB/T

1.1-2009.

This standard is the integration and revision of GB/T 9846.1 ~ 9846.8-2004

“Plywood”.

As compared with GB/T 9846.1 ~ 9846.8-2004, in addition to editorial changes,

the main technical changes are as follows.

- MODIFY the standard name from the “Plywood” to the “Plywood for

general use”;

- MODIFY the scope of application of the standard;

- INTEGRATE 8 series standards into one standard;

- ADD terms and definitions;

- DELETE the classification by overall appearance, end-user requirements,

composition, mechanical properties, and application;

- MODIFY the length and width deviation;

- MODIFY the thickness deviation;

- ADD the determination of flatness; CANCEL the determination of warpage;

- MODIFY the pretreatment conditions of class III plywood;

- MODIFY the slot depth of the adhesive strength sample;

- MODIFY the lower limit of water content;

- ADD the timber species. eucalyptus, the adhesive strength index value ≥

0.70 MPa;

- ADD the gum canal defect in the appearance defects in the broad-leaved

wood (including tropical broad-leaved wood);

- ADD the sample production schematic diagram;

- Formaldehyde emission index value follows the provisions of GB 18580;

- ADD the test methods and index value of the static bending strength and

elastic modulus;

- ADD the impregnation peeling test method and index value;

Plywood for general use

1 Scope

This standard specifies the terms and definitions, classification, requirements,

measurement and test methods, inspection rules and marking, packaging,

transportation and storage, of plywood for general uses.

This standard applies to the plywood for general use, AND it is not applicable

to the core board, veneer laminated timber, or other plywood having different

structures and special performance requirements.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this Standard.

GB/T 1933 Method for determination of the density of wood

GB/T 2828.1-2012 Sampling procedures for inspection by attributes – Part

1. Sampling schemes indexed by acceptance quality limit (AQL) for

lot-by-lot inspection

GB/T 17657-2013 Test methods of evaluating the properties of wood-based

panels and surface decorated wood-based panels

GB/T 18259-2009 Terms of wood-based panels and its surface decoration

GB 18580 Indoor decorating and refurbishing materials – Limit of

formaldehyde emission of wood-based panels and finishing products

GB/T 19367-2009 Wood-based panels - Determination of dimensions of

panels

3 Terms and definitions

The following definitions and definitions as defined in GB/T 18259-2009 apply

to this document. For ease of use, some of the terms and definitions as defined

in GB/T 18259-2009 are listed below again.

3.1

Class I plywood

It refers to the weather fastness plywood for outdoor use which can pass

the boiling test.

[GB/T 18259-2009, definition 2.2.1.18]

3.2

Class II plywood

It refers to the water-resistant plywood for wet conditions which can pass

the 63 °C ± 3 °C hot water immersion test.

[GB/T 18259-2009, definition 2.2.1.19]

3.3

Class III plywood

It refers to the non-moisture resistant plywood for dry conditions which can

pass the 20 °C ± 3 °C cold water immersion test.

3.4

Plywood tree species

Plywood panel tree species is this plywood tree species.

4 Classification

4.1 In accordance with the environment of use, it is divided into the following.

a) Used under dry conditions;

b) Used under wet conditions;

c) Used under outdoor conditions.

4.2 In accordance with the surface processing conditions, it is divided into the

following.

a) Non-sanding board;

b) Sanding board.

5 Requirements

5.1 Specifications dimensions and their deviations

5.1.1 Specifications dimensions

5.1.1.1 Plywood dimensions shall comply with the requirements of Table 1.

into three grades. excellent grade product, first grade product, and qualified

grade product. The panels of these three grades shall be sanded/scraped

smooth, AND those panels having special requirements may not be sanded

(scraped) smooth OR sanded (scraped) smooth a...

Share