1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

HJ 577-2010 English PDF (HJ577-2010)

HJ 577-2010 English PDF (HJ577-2010)

Regular price

$365.00 USD

Regular price

Sale price

$365.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click HJ 577-2010

Historical versions: HJ 577-2010

Preview True-PDF (Reload/Scroll if blank)

HJ 577-2010: Technical specifications for sequencing batch reactor activated sludge process

HJ 577-2010

ENVIRONMENTAL PROTECTION STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Technical specifications for sequencing

batch reactor activated sludge process

ISSUED ON: OCTOBER 12, 2010

IMPLEMENTED ON: JANUARY 01, 2011

Issued by: Ministry of Environmental Protection

Table of Contents

Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 7

4 General requirements ... 10

5 Design flowrate and design water quality ... 11

6 Process design ... 14

7 Main process equipment ... 27

8 Testing and control ... 29

9 Electrical ... 31

10 Construction and acceptance ... 31

11 Operation and maintenance ... 38

Appendix A (Informative) Other deformation processes of the sequencing

batch reactor activated sludge process ... 42

Technical specifications for sequencing

batch reactor activated sludge process

1 Scope

This standard specifies the technical requirements for the process design, main

process equipment, testing and control, construction and acceptance, operation

and maintenance of the sewage treatment projects which use the sequencing

batch reactor activated sludge method.

This standard is applicable to urban sewage and industrial wastewater

treatment projects which use the sequencing batch reactor activated sludge

process. It can be used as technical basis for environmental impact assessment,

design, construction, environmental protection acceptance, facility operation

management.

2 Normative references

The contents of this standard refer to the terms in the following documents. For

undated references, the valid version applies to this standard.

GB 3096 Environmental quality standard for noise

GB 12348 Emission standard for industrial enterprises noise at boundary

GB 12801 General principles for the requirements of safety and health in

production process

GB 18599 Standard for pollution control on the storage and disposal site for

general industrial solid wastes

GB 18918 Discharge standard of pollutants for municipal wastewater

treatment plant

GB 50014 Code for design of outdoor waste-water engineering

GB 50015 Code for design of building water supply and drainage

GB 50040 Code for design of dynamic machine foundation

GB 50053 Code for design of 10kV and under electric substation

GB 50187 Code for design of general plan of industrial enterprises

GB 50204 Code for acceptance of constructional quality of concrete

structures

GB 50222 Code for fire prevention in design of interior decoration of

buildings

GB 50231 General code for construction and acceptance of mechanical

equipment installation engineering

GB 50254 Code for construction and acceptance of cow-voltage apparatus

electric equipment installation engineering

GB 50268 Code for construction and acceptance of water and sewerage

pipeline works

GB 50334 Quality acceptance code for municipal sewage treatment plant

engineering

GB 50352 Code for design of civil buildings

GBJ 16 Code for fire protection of building design

GBJ 87 Specifications for the design of noise control system in industrial

enterprises

GB 50141 Code for construction and acceptance of water and sewerage

structures

GBZ 1 Hygienic standards for the design of industrial enterprises

GBZ 2 Occupational exposure limit for hazardous agents in the workplace

CJJ 60 Technical specification for operation, maintenance and safety of

municipal wastewater treatment plants

HJ/T 91 Technical specifications requirements for monitoring of surface

water and waste water

HJ/T 247 Specifications for environmental protection product. Vertical shaft

mechanical surface aerator

HJ/T 251 Specifications for environmental protection product. Roots blower

HJ/T 252 Specifications for environmental protection product. Middle and

fine bubble diffusers

HJ/T 260 Specifications for environmental protection product. Blast

submerged aerator

HJ/T 277 Specifications for environmental protection product - Rotary

decanter

HJ/T 278 Specifications for environmental protection product - Single stage

and high speed aeration centrifugal blower

HJ/T 279 Specifications for environmental protection product - Pusher

submersible agitator

HJ/T 353 Technical guidelines of wastewater on-line monitoring equipment

and installation (on trial)

HJ/T 354 Technical specifications for check and acceptance of wastewater

on-line monitoring system (on trial)

HJ/T 355 Technical specifications for the operation and assessment of

Wastewater on-line monitoring system (on trial)

Administrative measures for environmental protection acceptance of

completion of construction projects (State Environmental Protection

Administration, 2001)

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

Sequencing batch reactor activated sludge process

Refers to the activated sludge wastewater treatment method consisting of

five basic processes of fill, aeration, settle, drawn, idle in the same reaction

tank (reactor), abbreviated as SBR method. The main deformation

processes include a cyclic activated sludge system/technology (CASS or

CAST process), a demand aeration tank-intermittent aeration tank (DAT-IAT

process), an alternating internal circulation activated sludge process (AICS

process), etc.

3.2

Operating cycle

Refers to a cycle in which a reaction tank completes the fill, aeration, settle,

drawn, idle work procedures in sequence. The time elapsed during an

operating cycle is called the cycle time.

3.9

Reaction time

Refers to the time it takes for the aeration to stop during the fill and aeration

processes in one operating cycle.

3.10

Biological selector

Refers to the pre-reaction zone that is provided at the front end of the

reaction tank, to bring the return sludge into contact with and mix the

undiluted sewage. The types of biological selectors are aerobic, anoxic and

anaerobic.

3.11

Main reaction zone

Refers to the aerobic reaction zone downstream of the biological selector in

the CASS or CAST reaction tank.

3.12

Pretreatment

Refers to the treatment measures set in front of the SBR reaction tank when

the influent water’s quality can meet the biochemical requirements of the

SBR process, such as grilles, grit chambers, primary sinks, air floatation

tanks, grease traps, fiber and hair traps, etc.

3.13

Preprocessing

Refers to the treatment process set in front of the SBR reaction tank

according to the need to adjust the water quality when the influent water’s

quality cannot meet the biochemical requirements of the SBR process, such

as hydrolysis acidification tank, coagulation sedimentation tank,

neutralization tank, etc.

3.14

Standard state

It refers to a state where the atmospheric pressure is 101325 Pa and the

temperature is 293.15 K.

Qs - Design flowrate of rainwater, L/s.

5.1.1.3 The design flowrate of integrated domestic sewage is the product of the

served population and the corresponding quota of integrated domestic sewage

quota. The quota of integrated domestic sewage shall be determined according

to the local water quota, combined with the level of the water supply and drainage

facilities inside building and the popularity of the drainage system; it can be

designed according to 80% ~ 90% of the local relevant water quota.

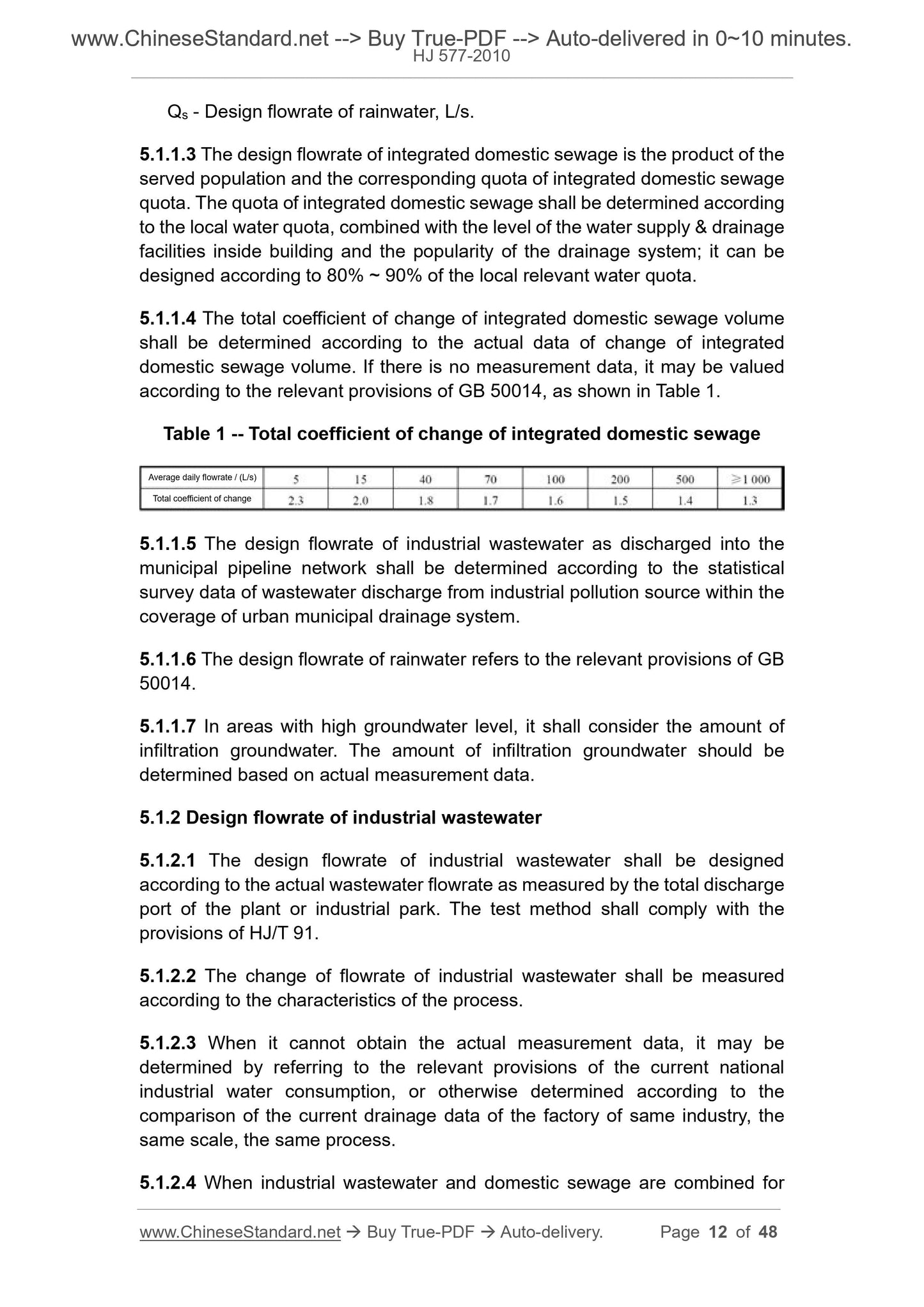

5.1.1.4 The total coefficient of change of integrated domestic sewage volume

Get QUOTATION in 1-minute: Click HJ 577-2010

Historical versions: HJ 577-2010

Preview True-PDF (Reload/Scroll if blank)

HJ 577-2010: Technical specifications for sequencing batch reactor activated sludge process

HJ 577-2010

ENVIRONMENTAL PROTECTION STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Technical specifications for sequencing

batch reactor activated sludge process

ISSUED ON: OCTOBER 12, 2010

IMPLEMENTED ON: JANUARY 01, 2011

Issued by: Ministry of Environmental Protection

Table of Contents

Foreword ... 4

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 7

4 General requirements ... 10

5 Design flowrate and design water quality ... 11

6 Process design ... 14

7 Main process equipment ... 27

8 Testing and control ... 29

9 Electrical ... 31

10 Construction and acceptance ... 31

11 Operation and maintenance ... 38

Appendix A (Informative) Other deformation processes of the sequencing

batch reactor activated sludge process ... 42

Technical specifications for sequencing

batch reactor activated sludge process

1 Scope

This standard specifies the technical requirements for the process design, main

process equipment, testing and control, construction and acceptance, operation

and maintenance of the sewage treatment projects which use the sequencing

batch reactor activated sludge method.

This standard is applicable to urban sewage and industrial wastewater

treatment projects which use the sequencing batch reactor activated sludge

process. It can be used as technical basis for environmental impact assessment,

design, construction, environmental protection acceptance, facility operation

management.

2 Normative references

The contents of this standard refer to the terms in the following documents. For

undated references, the valid version applies to this standard.

GB 3096 Environmental quality standard for noise

GB 12348 Emission standard for industrial enterprises noise at boundary

GB 12801 General principles for the requirements of safety and health in

production process

GB 18599 Standard for pollution control on the storage and disposal site for

general industrial solid wastes

GB 18918 Discharge standard of pollutants for municipal wastewater

treatment plant

GB 50014 Code for design of outdoor waste-water engineering

GB 50015 Code for design of building water supply and drainage

GB 50040 Code for design of dynamic machine foundation

GB 50053 Code for design of 10kV and under electric substation

GB 50187 Code for design of general plan of industrial enterprises

GB 50204 Code for acceptance of constructional quality of concrete

structures

GB 50222 Code for fire prevention in design of interior decoration of

buildings

GB 50231 General code for construction and acceptance of mechanical

equipment installation engineering

GB 50254 Code for construction and acceptance of cow-voltage apparatus

electric equipment installation engineering

GB 50268 Code for construction and acceptance of water and sewerage

pipeline works

GB 50334 Quality acceptance code for municipal sewage treatment plant

engineering

GB 50352 Code for design of civil buildings

GBJ 16 Code for fire protection of building design

GBJ 87 Specifications for the design of noise control system in industrial

enterprises

GB 50141 Code for construction and acceptance of water and sewerage

structures

GBZ 1 Hygienic standards for the design of industrial enterprises

GBZ 2 Occupational exposure limit for hazardous agents in the workplace

CJJ 60 Technical specification for operation, maintenance and safety of

municipal wastewater treatment plants

HJ/T 91 Technical specifications requirements for monitoring of surface

water and waste water

HJ/T 247 Specifications for environmental protection product. Vertical shaft

mechanical surface aerator

HJ/T 251 Specifications for environmental protection product. Roots blower

HJ/T 252 Specifications for environmental protection product. Middle and

fine bubble diffusers

HJ/T 260 Specifications for environmental protection product. Blast

submerged aerator

HJ/T 277 Specifications for environmental protection product - Rotary

decanter

HJ/T 278 Specifications for environmental protection product - Single stage

and high speed aeration centrifugal blower

HJ/T 279 Specifications for environmental protection product - Pusher

submersible agitator

HJ/T 353 Technical guidelines of wastewater on-line monitoring equipment

and installation (on trial)

HJ/T 354 Technical specifications for check and acceptance of wastewater

on-line monitoring system (on trial)

HJ/T 355 Technical specifications for the operation and assessment of

Wastewater on-line monitoring system (on trial)

Administrative measures for environmental protection acceptance of

completion of construction projects (State Environmental Protection

Administration, 2001)

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

Sequencing batch reactor activated sludge process

Refers to the activated sludge wastewater treatment method consisting of

five basic processes of fill, aeration, settle, drawn, idle in the same reaction

tank (reactor), abbreviated as SBR method. The main deformation

processes include a cyclic activated sludge system/technology (CASS or

CAST process), a demand aeration tank-intermittent aeration tank (DAT-IAT

process), an alternating internal circulation activated sludge process (AICS

process), etc.

3.2

Operating cycle

Refers to a cycle in which a reaction tank completes the fill, aeration, settle,

drawn, idle work procedures in sequence. The time elapsed during an

operating cycle is called the cycle time.

3.9

Reaction time

Refers to the time it takes for the aeration to stop during the fill and aeration

processes in one operating cycle.

3.10

Biological selector

Refers to the pre-reaction zone that is provided at the front end of the

reaction tank, to bring the return sludge into contact with and mix the

undiluted sewage. The types of biological selectors are aerobic, anoxic and

anaerobic.

3.11

Main reaction zone

Refers to the aerobic reaction zone downstream of the biological selector in

the CASS or CAST reaction tank.

3.12

Pretreatment

Refers to the treatment measures set in front of the SBR reaction tank when

the influent water’s quality can meet the biochemical requirements of the

SBR process, such as grilles, grit chambers, primary sinks, air floatation

tanks, grease traps, fiber and hair traps, etc.

3.13

Preprocessing

Refers to the treatment process set in front of the SBR reaction tank

according to the need to adjust the water quality when the influent water’s

quality cannot meet the biochemical requirements of the SBR process, such

as hydrolysis acidification tank, coagulation sedimentation tank,

neutralization tank, etc.

3.14

Standard state

It refers to a state where the atmospheric pressure is 101325 Pa and the

temperature is 293.15 K.

Qs - Design flowrate of rainwater, L/s.

5.1.1.3 The design flowrate of integrated domestic sewage is the product of the

served population and the corresponding quota of integrated domestic sewage

quota. The quota of integrated domestic sewage shall be determined according

to the local water quota, combined with the level of the water supply and drainage

facilities inside building and the popularity of the drainage system; it can be

designed according to 80% ~ 90% of the local relevant water quota.

5.1.1.4 The total coefficient of change of integrated domestic sewage volume

Share