1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

HJ/T 37-1999 English PDF (HJT37-1999)

HJ/T 37-1999 English PDF (HJT37-1999)

Regular price

$170.00 USD

Regular price

Sale price

$170.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click HJ/T 37-1999

Historical versions: HJ/T 37-1999

Preview True-PDF (Reload/Scroll if blank)

HJ/T 37-1999: Stationary source emission. Determination of acrylonitrile. Gas chromatography

HJ/T 37-1999

HJ

STANDARD OF STATE ENVIRONMENTAL

PROTECTION ADMINISTRATION

Stationary Source Emission -

Determination of Acrylonitrile - Gas Chromatography

ISSUED ON: AUGUST 18, 1999

IMPLEMENTED ON: JANUARY 01, 2000

Issued by: State Environmental Protection Administration

Table of Contents

1 Scope of Application ... 3

2 Method Principle ... 3

3 Normative References ... 3

4 Reagents and Materials ... 3

5 Instruments ... 5

6 Sample Collection and Storage ... 6

7 Analysis Procedures ... 8

8 Calculation and Representation of Result ... 9

9 Precision and Accuracy ... 12

10 Description ... 12

Appendix A (Standard) Acrylonitrile-Assisted Qualitative Chromatographic

Column Conditions ... 13

Appendix B (Standard) Preparation and Aging of Chromatographic Column . 15

Additional Instructions: ... 16

Stationary Source Emission -

Determination of Acrylonitrile - Gas Chromatography

1 Scope of Application

1.1 This standard is applicable to the determination of acrylonitrile for both intentional

and fugitive emissions from stationary pollution sources.

1.2 When the sampling volume is 30L, the detection limit of the method is 0.2 mg/m3.

The quantitative measurement concentration range of the method is 0.26~33.0mg/m3.

2 Method Principle

Acrylonitrile (CH2=CHCH2CN) is adsorbed and enriched by activated charcoal at room

temperature; and then desorbed by carbon disulfide at room temperature. The

components in the desorbed liquid are separated by the chromatographic column and

then enter the hydrogen flame ionization detector (FID). From the measured

acrylonitrile chromatogram peak height (or area), quantify the concentration of

acrylonitrile in the desorption solution; and finally calculate the concentration of

acrylonitrile in the gas sample from the volume, concentration, and sampling volume

of the desorption solution.

3 Normative References

The provisions in following documents become the provisions of this Standard through

reference in this Standard:

GB 16297-1996 Comprehensive Emission Standard of Air Pollutants

GB 16157-1996 The Determination of Particulates and Sampling Methods of

Gaseous Pollutants Emitted from Exhaust Gas of Stationary Source

4 Reagents and Materials

4.1 Acrylonitrile: Chromatographically pure (or analytically pure, but there must be no

chromatographic interference peaks for acrylonitrile).

and dilute to the mark with carbon disulfide.

5 Instruments

5.1 Gas chromatograph: Equipped with hydrogen flame ionization detector

5.2 Chromatographic column

5.2.1 Column material: Glass or PTFE.

5.2.2 Column length: 3m.

5.2.3 Column inner diameter: 3mm.

5.2.4 Column type: packed column.

5.2.5 In-column packing: GDX-502, 60~80mesh.

5.2.6 Preparation and aging of chromatographic column (see Appendix B).

5.3 Micro syringe: 1.0µL

5.4 Sampling instrument

Refer to 9.3 in GB 16157-1996 to configure the sampling instrument.

5.4.1 Sampling instrument for intentional emission monitoring

5.4.1.1 Sampling tube

It is made of stainless steel, hard glass or PTFE, with appropriate dimensions, and is

equipped with an insulation jacket that can be heated to above 120°C.

5.4.1.2 Sample collecting device

Activated charcoal adsorption tube (4.7).

5.4.1.3 Flowrate measuring device

See 9.3.6 of GB 16157-1996.

5.4.1.4 Suction pump

See 9.3.7 of GB 16157-1996.

5.4.1.5 Connecting pipe

PTFE hose or silicone rubber tube lined with PTFE film.

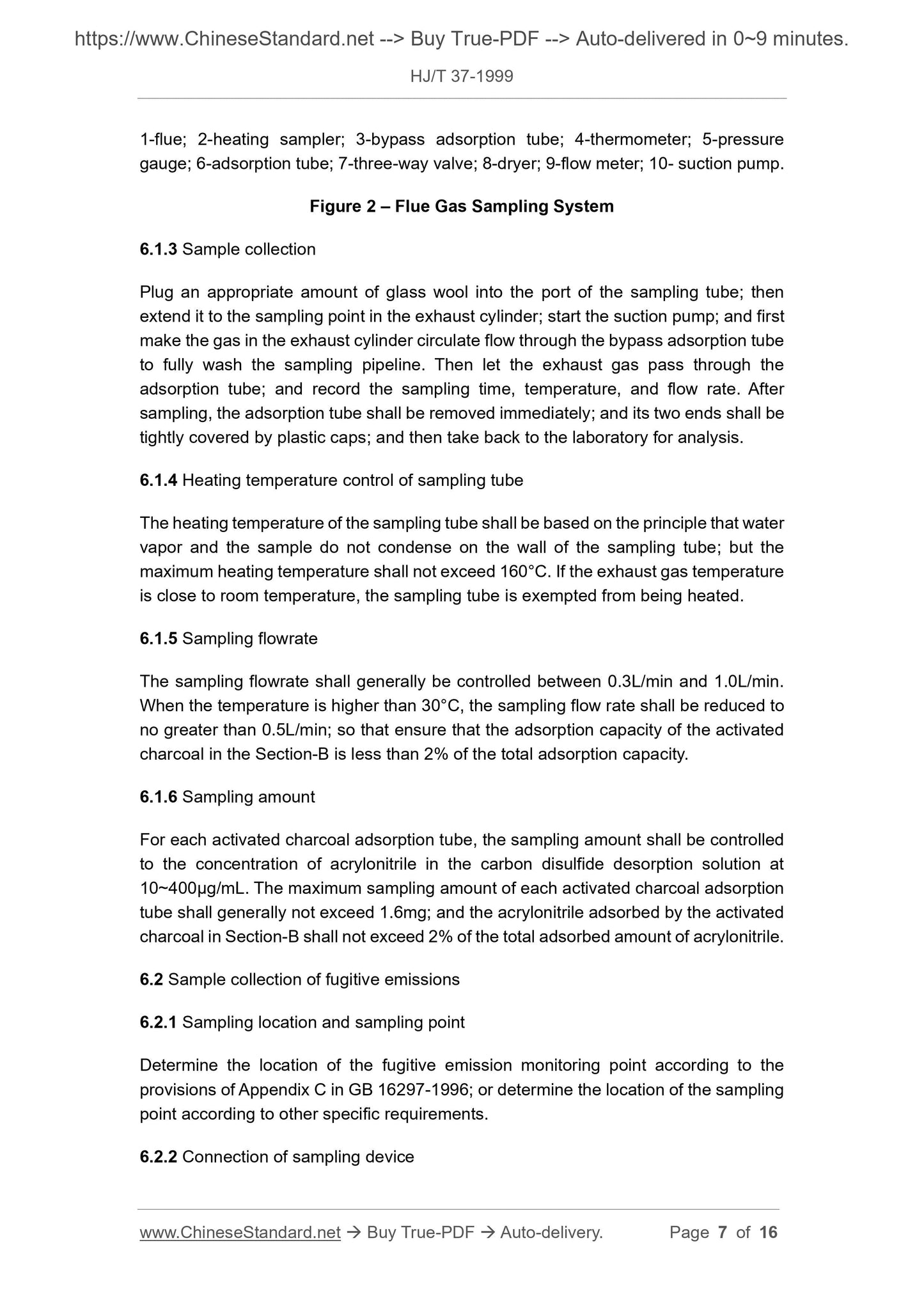

1-flue; 2-heating sampler; 3-bypass adsorption tube; 4-thermometer; 5-pressure

gauge; 6-adsorption tube; 7-three-way valve; 8-dryer; 9-flow meter; 10- suction pump.

Figure 2 – Flue Gas Sampling System

6.1.3 Sample collection

Plug an appropriate amount of glass wool into the port of the sampling tube; then

extend it to the sampling point in the exhaust cylinder; start the suction pump; and first

make the gas in the exhaust cylinder circulate flow through the bypass adsorption tube

to fully wash the sampling pipeline. Then let the exhaust gas pass through the

adsorption tube; and record the sampling time, temperature, and flow rate. After

sampling, the adsorption tube shall be removed immediately; and its two ends shall be

tightly covered by plastic caps; and then take back to the laboratory for analysis.

6.1.4 Heating temperature control of sampling tube

The heating temperature of the sampling tube shall be based on the principle that water

vapor and the sample do not condense on the wall of the sampling tube; but the

maximum heating temperature shall not exceed 160°C. If the exhaust gas temperature

is close to room temperature, the sampling tube is exempted from being heated.

6.1.5 Sampling flowrate

The sampling flowrate shall generally be controlled between 0.3L/min and 1.0L/min.

When the temperature is higher than 30°C, the sampling flow rate shall be reduced to

no greater than 0.5L/min; so that ensure that the adsorption capacity of the activated

charcoal in the Section-B is less than 2% of the total adsorption capacity.

6.1.6 Sampling amount

For each activated charcoal adsorption tube, the sampling amount shall be controlled

to the concentration of acrylonitrile in the carbon disulfide desorption solution at

10~400µg/mL. The maximum sampling amount of each activated charcoal adsorption

tube shall generally not exceed 1.6mg; and the acrylonitrile adsorbed by the activated

charcoal in Section-B shall not exceed 2% of the total adsorbed amount of acrylonitrile.

6.2 Sample collection of fugitive emissions

6.2.1 Sampling location and sampling point

Determine the location of the fugitive emission monitoring point according to the

provisions of Appendix C in GB 16297-1996; or determine the location of the sampling

point according to other specific requirements.

6.2.2 Connection of sampling device

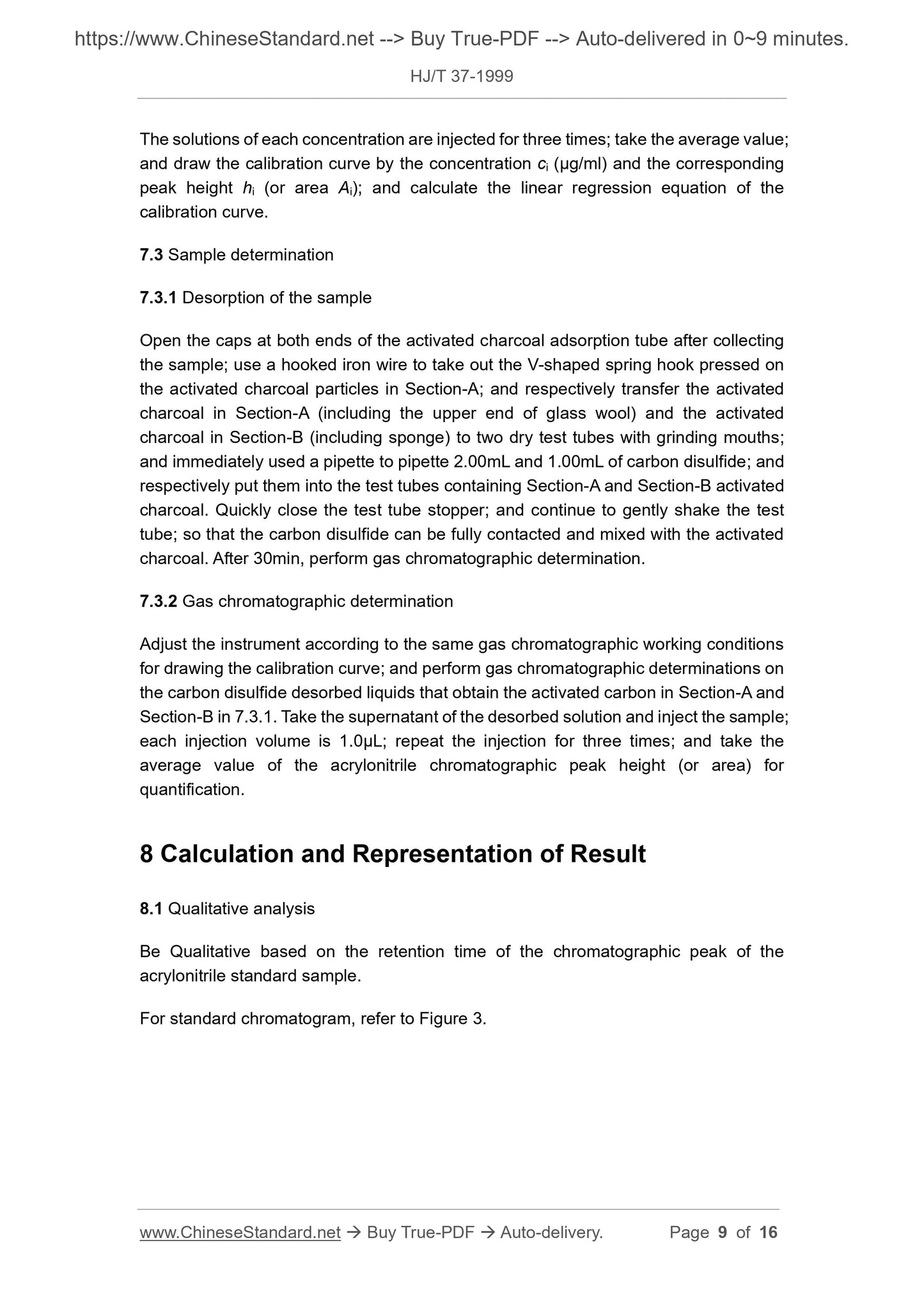

The solutions of each concentration are injected for three times; take the average value;

and draw the calibration curve by the concentration ci (µg/ml) and the corresponding

peak height hi (or area Ai); and calculate the linear regression equation of the

calibration curve.

7.3 Sample determination

7.3.1 Desorption of the sample

Open the caps at both ends of the activated charcoal adsorption tube after collecting

the sample; use a hooked iron wire to take out the V-shaped spring hook pressed on

the activated charcoal particles in Section-A; and respectively transfer the activated

charcoal in Section-A (including the upper end of glass wool) and the activated

charcoal in Section-B (including sponge) to two dry test tubes with grinding mouths;

and immediately used a pipette to pipette 2.00mL and 1.00mL of carbon disulfide; and

respectively put them into the test tubes containing Section-A and Section-B activated

charcoal. Quickly close the test tube stopper; and continue to gently shake the test

tube; so that the carbon disulfide can be fully contacted and mixed with the activated

charcoal. After 30min, perform gas chromatographic determination.

7.3.2 Gas chromatographic determination

Adjust the instrument according to the same gas chromatographic working conditions

for drawing the calibration curve; and perform gas chromatographic determinations on

the carbon disulfide desorbed liquids that obtain the activated carbon in Section-A and

Section-B in 7.3.1. Take the supernatant of the desorbed solution and inject the sample;

each injection volume is 1.0μL; repeat the injection for three times; and take the

average value of the acr...

Get QUOTATION in 1-minute: Click HJ/T 37-1999

Historical versions: HJ/T 37-1999

Preview True-PDF (Reload/Scroll if blank)

HJ/T 37-1999: Stationary source emission. Determination of acrylonitrile. Gas chromatography

HJ/T 37-1999

HJ

STANDARD OF STATE ENVIRONMENTAL

PROTECTION ADMINISTRATION

Stationary Source Emission -

Determination of Acrylonitrile - Gas Chromatography

ISSUED ON: AUGUST 18, 1999

IMPLEMENTED ON: JANUARY 01, 2000

Issued by: State Environmental Protection Administration

Table of Contents

1 Scope of Application ... 3

2 Method Principle ... 3

3 Normative References ... 3

4 Reagents and Materials ... 3

5 Instruments ... 5

6 Sample Collection and Storage ... 6

7 Analysis Procedures ... 8

8 Calculation and Representation of Result ... 9

9 Precision and Accuracy ... 12

10 Description ... 12

Appendix A (Standard) Acrylonitrile-Assisted Qualitative Chromatographic

Column Conditions ... 13

Appendix B (Standard) Preparation and Aging of Chromatographic Column . 15

Additional Instructions: ... 16

Stationary Source Emission -

Determination of Acrylonitrile - Gas Chromatography

1 Scope of Application

1.1 This standard is applicable to the determination of acrylonitrile for both intentional

and fugitive emissions from stationary pollution sources.

1.2 When the sampling volume is 30L, the detection limit of the method is 0.2 mg/m3.

The quantitative measurement concentration range of the method is 0.26~33.0mg/m3.

2 Method Principle

Acrylonitrile (CH2=CHCH2CN) is adsorbed and enriched by activated charcoal at room

temperature; and then desorbed by carbon disulfide at room temperature. The

components in the desorbed liquid are separated by the chromatographic column and

then enter the hydrogen flame ionization detector (FID). From the measured

acrylonitrile chromatogram peak height (or area), quantify the concentration of

acrylonitrile in the desorption solution; and finally calculate the concentration of

acrylonitrile in the gas sample from the volume, concentration, and sampling volume

of the desorption solution.

3 Normative References

The provisions in following documents become the provisions of this Standard through

reference in this Standard:

GB 16297-1996 Comprehensive Emission Standard of Air Pollutants

GB 16157-1996 The Determination of Particulates and Sampling Methods of

Gaseous Pollutants Emitted from Exhaust Gas of Stationary Source

4 Reagents and Materials

4.1 Acrylonitrile: Chromatographically pure (or analytically pure, but there must be no

chromatographic interference peaks for acrylonitrile).

and dilute to the mark with carbon disulfide.

5 Instruments

5.1 Gas chromatograph: Equipped with hydrogen flame ionization detector

5.2 Chromatographic column

5.2.1 Column material: Glass or PTFE.

5.2.2 Column length: 3m.

5.2.3 Column inner diameter: 3mm.

5.2.4 Column type: packed column.

5.2.5 In-column packing: GDX-502, 60~80mesh.

5.2.6 Preparation and aging of chromatographic column (see Appendix B).

5.3 Micro syringe: 1.0µL

5.4 Sampling instrument

Refer to 9.3 in GB 16157-1996 to configure the sampling instrument.

5.4.1 Sampling instrument for intentional emission monitoring

5.4.1.1 Sampling tube

It is made of stainless steel, hard glass or PTFE, with appropriate dimensions, and is

equipped with an insulation jacket that can be heated to above 120°C.

5.4.1.2 Sample collecting device

Activated charcoal adsorption tube (4.7).

5.4.1.3 Flowrate measuring device

See 9.3.6 of GB 16157-1996.

5.4.1.4 Suction pump

See 9.3.7 of GB 16157-1996.

5.4.1.5 Connecting pipe

PTFE hose or silicone rubber tube lined with PTFE film.

1-flue; 2-heating sampler; 3-bypass adsorption tube; 4-thermometer; 5-pressure

gauge; 6-adsorption tube; 7-three-way valve; 8-dryer; 9-flow meter; 10- suction pump.

Figure 2 – Flue Gas Sampling System

6.1.3 Sample collection

Plug an appropriate amount of glass wool into the port of the sampling tube; then

extend it to the sampling point in the exhaust cylinder; start the suction pump; and first

make the gas in the exhaust cylinder circulate flow through the bypass adsorption tube

to fully wash the sampling pipeline. Then let the exhaust gas pass through the

adsorption tube; and record the sampling time, temperature, and flow rate. After

sampling, the adsorption tube shall be removed immediately; and its two ends shall be

tightly covered by plastic caps; and then take back to the laboratory for analysis.

6.1.4 Heating temperature control of sampling tube

The heating temperature of the sampling tube shall be based on the principle that water

vapor and the sample do not condense on the wall of the sampling tube; but the

maximum heating temperature shall not exceed 160°C. If the exhaust gas temperature

is close to room temperature, the sampling tube is exempted from being heated.

6.1.5 Sampling flowrate

The sampling flowrate shall generally be controlled between 0.3L/min and 1.0L/min.

When the temperature is higher than 30°C, the sampling flow rate shall be reduced to

no greater than 0.5L/min; so that ensure that the adsorption capacity of the activated

charcoal in the Section-B is less than 2% of the total adsorption capacity.

6.1.6 Sampling amount

For each activated charcoal adsorption tube, the sampling amount shall be controlled

to the concentration of acrylonitrile in the carbon disulfide desorption solution at

10~400µg/mL. The maximum sampling amount of each activated charcoal adsorption

tube shall generally not exceed 1.6mg; and the acrylonitrile adsorbed by the activated

charcoal in Section-B shall not exceed 2% of the total adsorbed amount of acrylonitrile.

6.2 Sample collection of fugitive emissions

6.2.1 Sampling location and sampling point

Determine the location of the fugitive emission monitoring point according to the

provisions of Appendix C in GB 16297-1996; or determine the location of the sampling

point according to other specific requirements.

6.2.2 Connection of sampling device

The solutions of each concentration are injected for three times; take the average value;

and draw the calibration curve by the concentration ci (µg/ml) and the corresponding

peak height hi (or area Ai); and calculate the linear regression equation of the

calibration curve.

7.3 Sample determination

7.3.1 Desorption of the sample

Open the caps at both ends of the activated charcoal adsorption tube after collecting

the sample; use a hooked iron wire to take out the V-shaped spring hook pressed on

the activated charcoal particles in Section-A; and respectively transfer the activated

charcoal in Section-A (including the upper end of glass wool) and the activated

charcoal in Section-B (including sponge) to two dry test tubes with grinding mouths;

and immediately used a pipette to pipette 2.00mL and 1.00mL of carbon disulfide; and

respectively put them into the test tubes containing Section-A and Section-B activated

charcoal. Quickly close the test tube stopper; and continue to gently shake the test

tube; so that the carbon disulfide can be fully contacted and mixed with the activated

charcoal. After 30min, perform gas chromatographic determination.

7.3.2 Gas chromatographic determination

Adjust the instrument according to the same gas chromatographic working conditions

for drawing the calibration curve; and perform gas chromatographic determinations on

the carbon disulfide desorbed liquids that obtain the activated carbon in Section-A and

Section-B in 7.3.1. Take the supernatant of the desorbed solution and inject the sample;

each injection volume is 1.0μL; repeat the injection for three times; and take the

average value of the acr...

Share