1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

JB/T 7946.1-2017 English PDF (JBT7946.1-2017)

JB/T 7946.1-2017 English PDF (JBT7946.1-2017)

Regular price

$150.00 USD

Regular price

Sale price

$150.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JB/T 7946.1-2017

Historical versions: JB/T 7946.1-2017

Preview True-PDF (Reload/Scroll if blank)

JB/T 7946.1-2017: Metallograph of cast aluminium alloys - Part 1: Cast aluminium-silicon alloys modification

JB/T 7946.1-2017

JB

MECHANICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 77.120.10

J 31

Registration number: 57827-2017

Replacing JB/T 7946.1-1999

Metallograph of cast aluminum alloys -

Part 1: Cast aluminum-silicon alloys modification

ISSUED ON: JANUARY 09, 2017

IMPLEMENTED ON: JULY 01, 2017

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Cutting and preparation of specimen ... 4

4 Metallographic observation of specimen ... 5

5 Grading of cast aluminum-silicon alloy modification ... 5

Foreword

JB/T 7946 "Molded Aluminum Alloy Metallurgy" is divided into four parts:

- Part 1: Cast aluminum-silicon alloys modification;

- Part 2: Cast aluminum-silicon alloys burning;

- Part 3: Cast aluminum alloys pinhole;

- Part 4: Cast aluminum-copper alloys grain size.

This part is the part 1 JB/T 7946.

This part replaces JB/T 7946.1-1999 "Metallograph of cast aluminum alloys -

Cast aluminum-silicon alloys - Modification". As compared with JB/T 7946.1-

1999, the main technical changes are as follows:

- MODIFY part of technical content on cutting and preparation of specimen;

- MODIFY the grading instructions for phosphorus modification; REPLACE

the corresponding microscopic reference picture;

- ADD the grading instructions for strontium and antimony modification; ADD

corresponding microscopic reference pictures.

This part was drafted in accordance with the rules given in GB/T 1.1-2009.

This part was proposed by the China Machinery Industry Federation.

This part shall be under the jurisdiction of the National Foundry Standardization

Technical Committee (SAC/TC 54).

The responsible drafting organization of this part: Tianjin Lizhong Alloy Group

Co., Ltd.

Participated drafting organization of this part: Shenyang Foundry Research

Institute, Anhui Hualing West Kitchen Equipment Co., Ltd., Anhui Hengtai

Power Technology Co., Ltd., CITIC Daika Co., Ltd., Zhangzhou Jinnuo

Industrial Co., Ltd.

The main drafters of this part: Ge Sujing, Zong Fuchun, Liu Chuang, Xu

Zhenghua, Zhang Gaowei, Huo Huijuan, Bai Bangwei, Ma Zhengsong, Guo

Dong.

This standard replaces the standard previously issued as follows:

- JB/T 7946.1-1995, JB/T 7946.1-1999.

Metallograph of cast aluminum alloys -

Part 1: Cast aluminum-silicon alloys modification

1 Scope

This part of JB/T 7946 specifies the cutting and preparation of metallographic

specimens of cast aluminum-silicon alloys, the observation of metallographic

structure, the grading of cast aluminum-silicon alloys.

This part applies to the evaluation of the grade of modification of cast aluminum-

silicon alloys.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 3246.1 Inspection method for structure of wrought aluminum and

aluminum alloy products - Part 1: Inspection method for microstructure

3 Cutting and preparation of specimen

3.1 Cutting of specimen

The metallographic specimens are usually cut from a single-cast tensile test bar

of the same furnace. The metallographic specimens of the important castings

shall be cut from the additional cast test bars of the castings or from the

representative parts of the castings according to the technical agreement.

3.2 Preparation of specimens

3.2.1 The metallographic specimen is coarsely ground, finely ground by

sandpaper, then coarsely polished and finely polished to obtain a flat, scratch-

free, distortion-free mirror surface, until a clear microstructure is observed.

Metallographic specimens can be finely polished or electrolytically polished if

required.

3.2.2 Polished metallographic specimens are directly observed by an optical

microscope. If there is a special need, use the 0.5% (mass fraction) of

hydrofluoric acid aqueous solution to etch it according to the provisions of GB/T

3246.1.

3.2.3 During the process of cutting and preparing metallographic specimens, it

shall be ensured that the metallographic structure does not change.

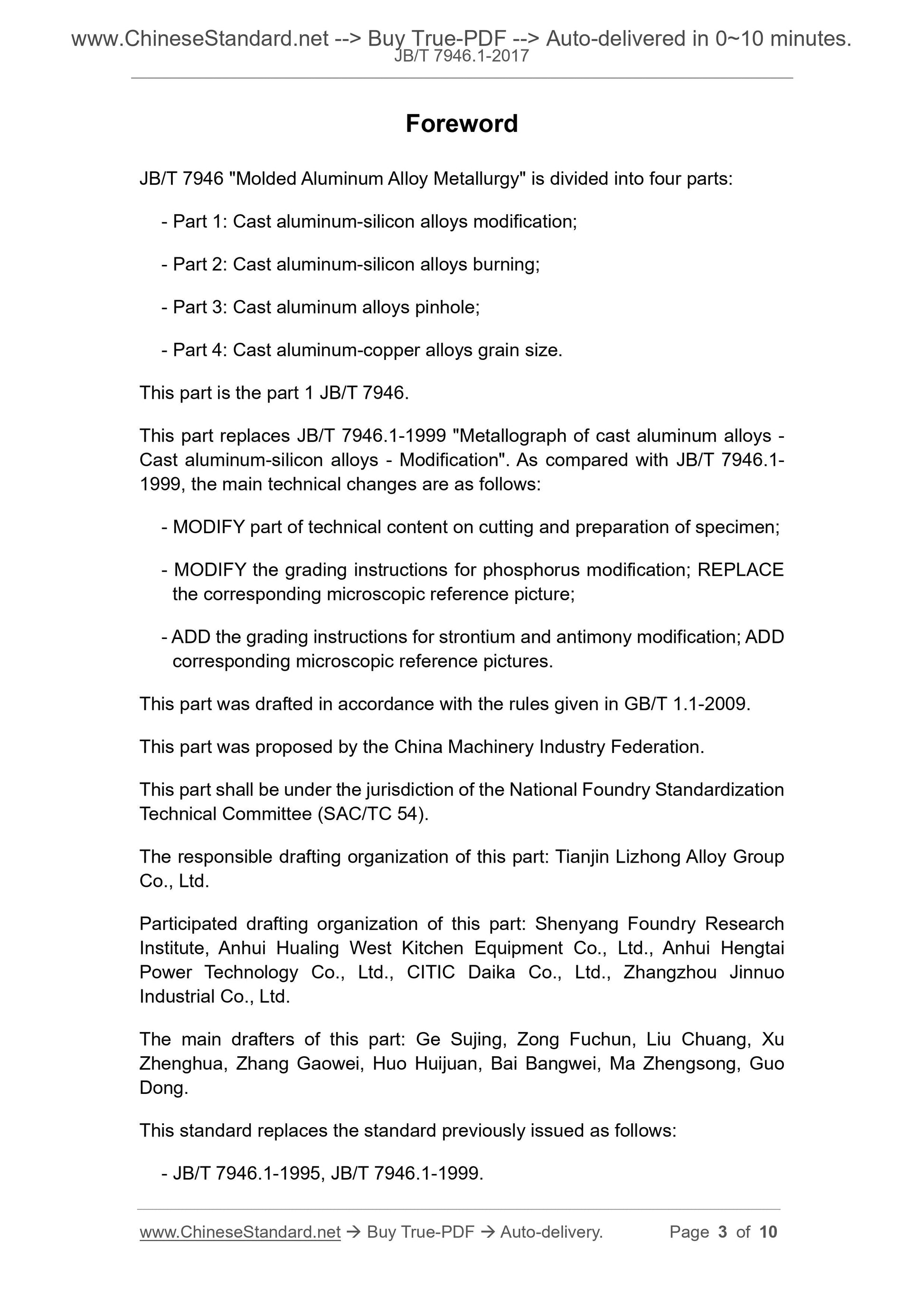

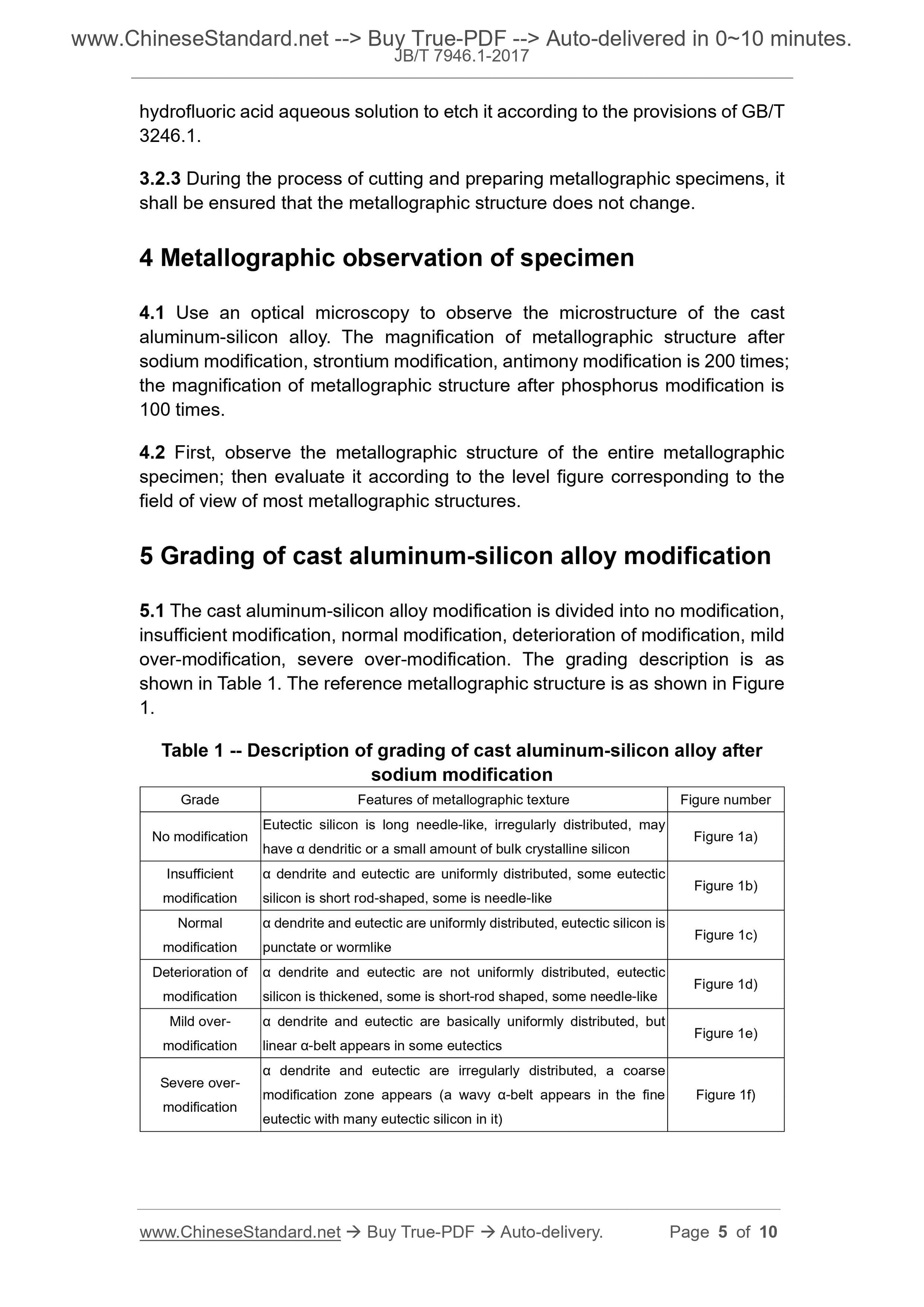

4 Metallographic observation of specimen

4.1 Use an optical microscopy to observe the microstructure of the cast

aluminum-silicon alloy. The magnification of metallographic structure after

sodium modification, strontium modification, antimony modification is 200 times;

the magnification of metallographic structure after phosphorus modification is

100 times.

4.2 First, observe the metallographic structure of the entire metallographic

specimen; then evaluate it according to the level figure corresponding to the

field of view of most metallographic structures.

5 Grading of cast aluminum-silicon alloy modification

5.1 The cast aluminum-silicon alloy modification is divided into no modification,

insufficient modification, normal modification, deterioration of modification, mild

over-modification, severe over-modification. The grading description is as

shown in Table 1. The reference metallographic structure is as shown in Figure

1.

Table 1 -- Description of grading of cast aluminum-silicon alloy after

sodium modification

Grade Features of metallographic texture Figure number

No modification Eutectic silicon is long needle-like, irregularly distributed, may have α dendritic or a small amount of bulk crystalline silicon Figure 1a)

Insufficient

modification

α dendrite and eutectic are uniformly distributed, some eutectic

silicon is short rod-shaped, some is needle-like Figure 1b)

Normal

modification

α dendrite and eutectic are uniformly distributed, eutectic silicon is

punctate or wormlike Figure 1c)

Deterioration of

modification

α dendrite and eutectic are not uniformly distributed, eutectic

silicon is thickened, some is short-rod shaped, some needle-like Figure 1d)

Mild over-

modification

α dendrite and eutectic are basically uniformly distributed, but

linear α-belt appears in some eutectics Figure 1e)

Severe over-

modification

α dendrite and eutectic are irregularly distributed, a coarse

modification zone appears (a wavy α-belt appears in the fine

eutectic with many eutectic silicon in it)

Figure 1f)

Get QUOTATION in 1-minute: Click JB/T 7946.1-2017

Historical versions: JB/T 7946.1-2017

Preview True-PDF (Reload/Scroll if blank)

JB/T 7946.1-2017: Metallograph of cast aluminium alloys - Part 1: Cast aluminium-silicon alloys modification

JB/T 7946.1-2017

JB

MECHANICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 77.120.10

J 31

Registration number: 57827-2017

Replacing JB/T 7946.1-1999

Metallograph of cast aluminum alloys -

Part 1: Cast aluminum-silicon alloys modification

ISSUED ON: JANUARY 09, 2017

IMPLEMENTED ON: JULY 01, 2017

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Cutting and preparation of specimen ... 4

4 Metallographic observation of specimen ... 5

5 Grading of cast aluminum-silicon alloy modification ... 5

Foreword

JB/T 7946 "Molded Aluminum Alloy Metallurgy" is divided into four parts:

- Part 1: Cast aluminum-silicon alloys modification;

- Part 2: Cast aluminum-silicon alloys burning;

- Part 3: Cast aluminum alloys pinhole;

- Part 4: Cast aluminum-copper alloys grain size.

This part is the part 1 JB/T 7946.

This part replaces JB/T 7946.1-1999 "Metallograph of cast aluminum alloys -

Cast aluminum-silicon alloys - Modification". As compared with JB/T 7946.1-

1999, the main technical changes are as follows:

- MODIFY part of technical content on cutting and preparation of specimen;

- MODIFY the grading instructions for phosphorus modification; REPLACE

the corresponding microscopic reference picture;

- ADD the grading instructions for strontium and antimony modification; ADD

corresponding microscopic reference pictures.

This part was drafted in accordance with the rules given in GB/T 1.1-2009.

This part was proposed by the China Machinery Industry Federation.

This part shall be under the jurisdiction of the National Foundry Standardization

Technical Committee (SAC/TC 54).

The responsible drafting organization of this part: Tianjin Lizhong Alloy Group

Co., Ltd.

Participated drafting organization of this part: Shenyang Foundry Research

Institute, Anhui Hualing West Kitchen Equipment Co., Ltd., Anhui Hengtai

Power Technology Co., Ltd., CITIC Daika Co., Ltd., Zhangzhou Jinnuo

Industrial Co., Ltd.

The main drafters of this part: Ge Sujing, Zong Fuchun, Liu Chuang, Xu

Zhenghua, Zhang Gaowei, Huo Huijuan, Bai Bangwei, Ma Zhengsong, Guo

Dong.

This standard replaces the standard previously issued as follows:

- JB/T 7946.1-1995, JB/T 7946.1-1999.

Metallograph of cast aluminum alloys -

Part 1: Cast aluminum-silicon alloys modification

1 Scope

This part of JB/T 7946 specifies the cutting and preparation of metallographic

specimens of cast aluminum-silicon alloys, the observation of metallographic

structure, the grading of cast aluminum-silicon alloys.

This part applies to the evaluation of the grade of modification of cast aluminum-

silicon alloys.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 3246.1 Inspection method for structure of wrought aluminum and

aluminum alloy products - Part 1: Inspection method for microstructure

3 Cutting and preparation of specimen

3.1 Cutting of specimen

The metallographic specimens are usually cut from a single-cast tensile test bar

of the same furnace. The metallographic specimens of the important castings

shall be cut from the additional cast test bars of the castings or from the

representative parts of the castings according to the technical agreement.

3.2 Preparation of specimens

3.2.1 The metallographic specimen is coarsely ground, finely ground by

sandpaper, then coarsely polished and finely polished to obtain a flat, scratch-

free, distortion-free mirror surface, until a clear microstructure is observed.

Metallographic specimens can be finely polished or electrolytically polished if

required.

3.2.2 Polished metallographic specimens are directly observed by an optical

microscope. If there is a special need, use the 0.5% (mass fraction) of

hydrofluoric acid aqueous solution to etch it according to the provisions of GB/T

3246.1.

3.2.3 During the process of cutting and preparing metallographic specimens, it

shall be ensured that the metallographic structure does not change.

4 Metallographic observation of specimen

4.1 Use an optical microscopy to observe the microstructure of the cast

aluminum-silicon alloy. The magnification of metallographic structure after

sodium modification, strontium modification, antimony modification is 200 times;

the magnification of metallographic structure after phosphorus modification is

100 times.

4.2 First, observe the metallographic structure of the entire metallographic

specimen; then evaluate it according to the level figure corresponding to the

field of view of most metallographic structures.

5 Grading of cast aluminum-silicon alloy modification

5.1 The cast aluminum-silicon alloy modification is divided into no modification,

insufficient modification, normal modification, deterioration of modification, mild

over-modification, severe over-modification. The grading description is as

shown in Table 1. The reference metallographic structure is as shown in Figure

1.

Table 1 -- Description of grading of cast aluminum-silicon alloy after

sodium modification

Grade Features of metallographic texture Figure number

No modification Eutectic silicon is long needle-like, irregularly distributed, may have α dendritic or a small amount of bulk crystalline silicon Figure 1a)

Insufficient

modification

α dendrite and eutectic are uniformly distributed, some eutectic

silicon is short rod-shaped, some is needle-like Figure 1b)

Normal

modification

α dendrite and eutectic are uniformly distributed, eutectic silicon is

punctate or wormlike Figure 1c)

Deterioration of

modification

α dendrite and eutectic are not uniformly distributed, eutectic

silicon is thickened, some is short-rod shaped, some needle-like Figure 1d)

Mild over-

modification

α dendrite and eutectic are basically uniformly distributed, but

linear α-belt appears in some eutectics Figure 1e)

Severe over-

modification

α dendrite and eutectic are irregularly distributed, a coarse

modification zone appears (a wavy α-belt appears in the fine

eutectic with many eutectic silicon in it)

Figure 1f)

Share