1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JC/T 2428-2017 English PDF (JCT2428-2017)

JC/T 2428-2017 English PDF (JCT2428-2017)

Regular price

$210.00 USD

Regular price

Sale price

$210.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JC/T 2428-2017

Historical versions: JC/T 2428-2017

Preview True-PDF (Reload/Scroll if blank)

JC/T 2428-2017: Non-curable rubber modified asphalt coating for waterproofing

JC/T 2428-2017

JC

BUILDING MATERIALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 91.120.30

Q 17

File No.: 61689-2018

Non-curable rubber modified asphalt coating for

waterproofing

非固化橡胶沥青防水涂料

ISSUED ON: NOVEMBER 07, 2017

IMPLEMENTED ON: APRIL 01, 2018

Issued by: Ministry of Industry and Information Technology of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Marking ... 6

5 General requirements ... 6

6 Technical requirements ... 6

7 Test methods ... 7

8 Inspection rules ... 14

9 Marks, packaging, transportation and storage ... 16

Non-curable rubber modified asphalt coating for

waterproofing

1 Scope

This document specifies the terms and definitions, marking, general requirements,

technical requirements, test methods, inspection rules and signs, packaging,

transportation and storage of non-curable rubber modified asphalt coating for

waterproofing (hereinafter referred to as non-curable waterproof coating).

This Standard applies to non-curable rubber modified asphalt coating for waterproofing,

which is used for non-exposed waterproofing in construction engineering.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 267, Petroleum products - Determination of flash and fire points - Open cup

GB/T 3190-2008, Wrought aluminium and aluminium alloy - Chemical composition

GB 11614, Flat glass

GB/T 16777-2008, Test methods for building waterproofing coatings

JC/T 474-2008, Water-repellent admixture for mortar and concrete

JC/T 1068-2008, Waterproof materials for pitched roof - Underlayments of self-

adhering polymer modified bituminous

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 non-curable rubber modified asphalt coating for waterproofing

The waterproofing coating that takes rubber and asphalt as the main components, is

made by adding additives to keep sticky paste during the service life.

3.2 stress relaxation

After the product is melted, stir it and visually inspected.

7.4 Flash point

According to GB/T 267.

7.5 Solid content

Heat and melt the specimen in a watch glass according to the manufacturer's

instructions. Then carry out the test according to Chapter 5 of GB/T 16777-2008. The

heating temperature is (105±2)°C.

7.6 Bonding properties

7.6.1 Dry base

Carry out the test according to method B in Chapter 7 of GB/T 16777-2008. Heat and

melt the specimen on the surface of the mortar block according to the manufacturer's

requirements. After the specimen is prepared, under the standard test conditions, cure

for 24h and test. After the test, if there is no exposed part on the surface of the mortar

block, it shall be considered to be 100% cohesive failure.

7.6.2 Wet base

Soak the mortar block in water for 24h. Take it out. Use paper to wipe the water off the

surface. Prepare according to method B in Chapter 7 of GB/T 16777-2008. Heat and

melt the specimen on the surface of the mortar block according to the manufacturer's

requirements. After the specimen is prepared, under the standard test conditions, cure

for 24h and test. After the test, if there is no exposed part on the surface of the mortar

block, it shall be considered to be 100% cohesive failure.

7.7 Extensibility

7.7.1 Preparation of test piece

Butt two 120mm×50mm×(2~4)mm aluminum plates along the short side into a whole.

The gap between the two aluminum plates shall not be greater than 0.05mm. Heat and

melt the specimen to the aluminum plate as per the manufacturer's specifications. The

coating area between the two aluminum plates is 150mm×50mm. The thickness is (2.0

± 0.2) mm. Prepare 3 test pieces in total. Cure for 24h under the standard test conditions.

7.7.2 Test steps

Clamp the test piece in the center of the grip of the tensile machine. It cannot be twisted

or deformed. Record the value L0 indicated by the pointer of the extended ruler at this

time. Start the pulling machine. The pulling speed is 10mm/min. Pull the test piece until

the crack cracks or shrinks to 10mm from the edge of the test piece. Record the value

L1 indicated by the pointer of the extension ruler at this time, accurate to 1mm.

7.10.2 Extensibility

Prepare the test piece according to 7.7.1 from the processed specimen. Test according

to 7.7.2. The result is calculated according to 7.7.3.

7.10.3 Low temperature flexibility

Test the processed sample in accordance with 7.8.

7.11 Acid resistance

7.11.1 Extensibility

7.11.1.1 Preparation of test piece

Prepare 3 test pieces according to 7.7.1. The substrate is a 120mm×50mm×4mm glass

plate or other suitable substrate.

7.11.1.2 Test steps

Put the prepared test piece into 600ml of 2% chemically pure H2SO4 solution. The liquid

level shall be more than 10mm above the surface of the test piece. Continuously

immerse for (168±2)h. Place for 4h under the standard test conditions. Observe whether

the surface of the specimen changes. Test according to 7.7.2. Calculate the result in

accordance with 7.7.3.

7.11.2 Mass change

7.11.2.1 Test steps

Heat, melt and scrape the specimen onto a 100mm×100mm×4mm glass plate. The

coating area is 100mm×80mm. The thickness is (2.0±0.2)mm. Place for 24h under the

standard test conditions. Weigh the mass (m1). Put into 600mL of 2% chemically pure

H2SO4 solution. The liquid level shall be more than 10mm above the surface of the test

piece. Continuously immerse for (168±2)h. Take out. Control it dry. Immerse in acetone

for 5s. Take out and place for 5min. Then weigh the mass (m2).

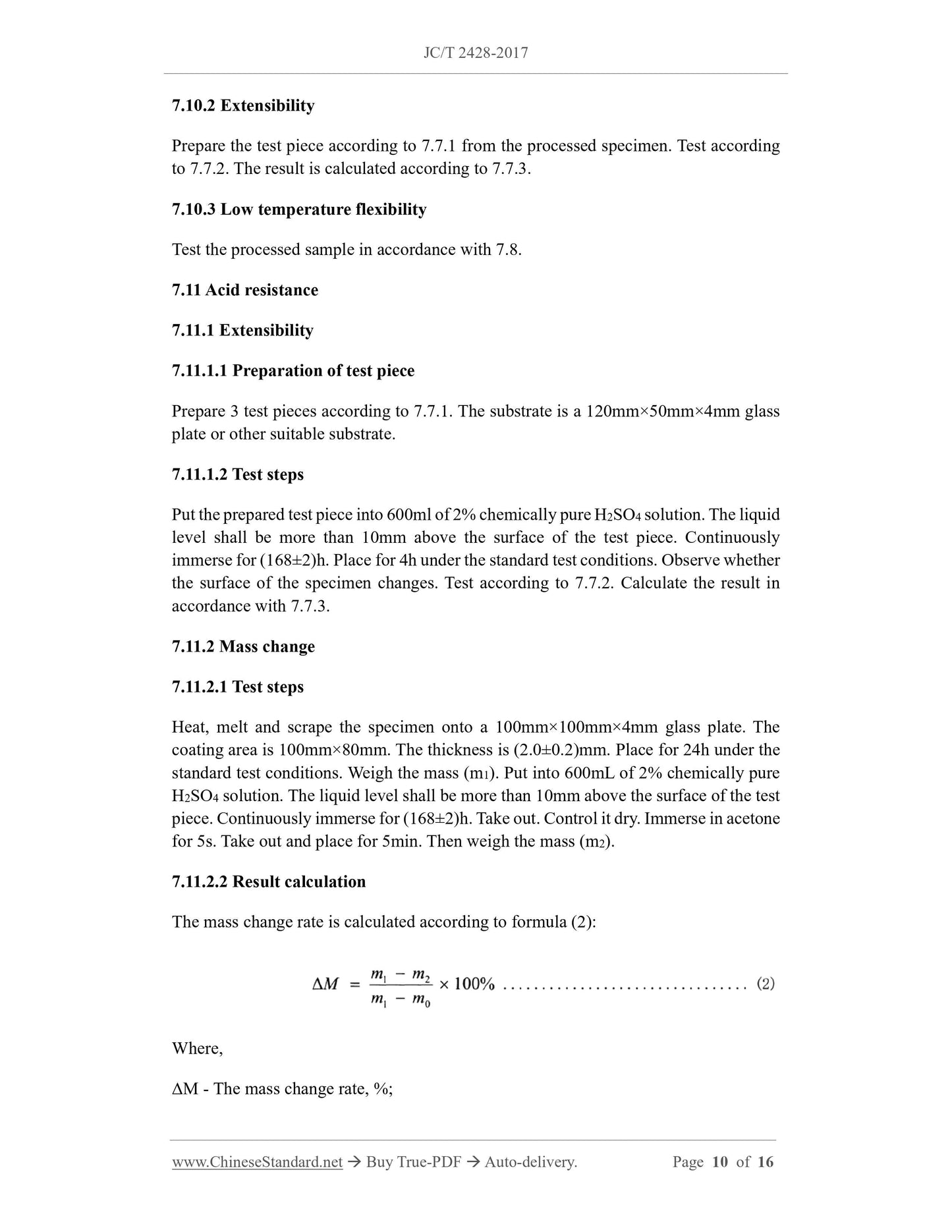

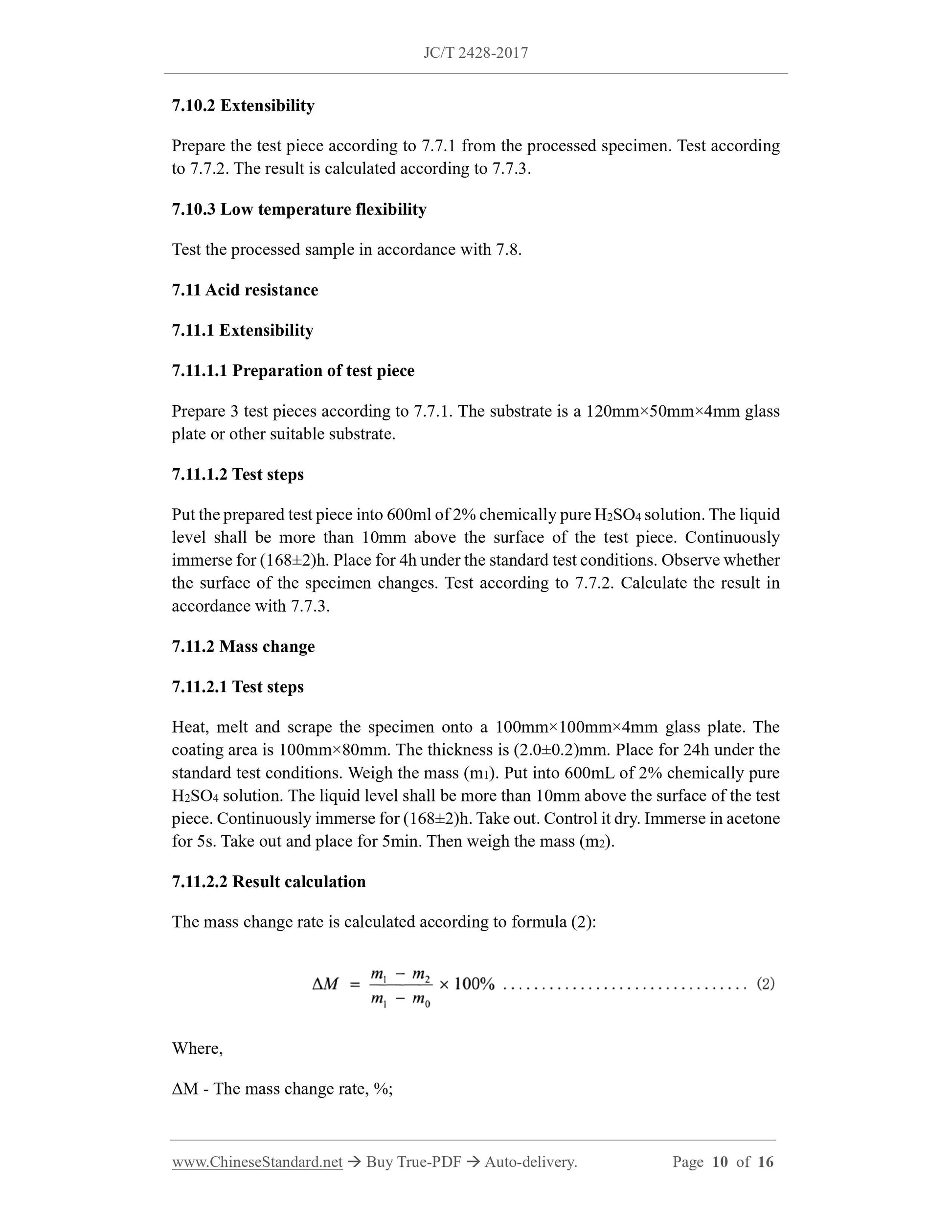

7.11.2.2 Result calculation

The mass change rate is calculated according to formula (2):

Where,

ΔM - The mass change rate, %;

m0 - The mass of the glass plate, in grams (g);

m1 - The mass of the specimen before soaking, in grams (g);

m2 - The mass of the specimen after soaking, in grams (g).

Take the arithmetic mean of 2 parallel tests as the test result. The calculation result is

accurate to 0.1%.

7.12 Alkali resistance

7.12.1 Extensibility

7.12.1.1 Preparation of test piece

Prepare 3 test pieces according to 7.7.1. The substrate is a 120mm×50mm×4mm glass

plate or other suitable substrate.

7.12.1.2 Test steps

Put the prepared test piece into 600mL of 0.1% chemically pure NaOH solution. Add

Ca(OH)2 reagent. Reach supersaturation. The liquid level shall be more than 10mm

above the surface of the test piece. Continuously immerse for (168±2)h. Take out. Place

for 4h under standard test conditions. Observe whether the surface of the specimen

changes. Then test according to 7.7.2. Calculate the result in accordance with 7.7.3.

7.12.2 Mass change

Heat, melt and scrape the specimen a 100mm×100mm×4mm glass plate. The coating

area is 100mm×80mm. The thickness is (2.0±0.2)mm. Place for 24h under standard test

conditions. Weigh the mass (m1). Put in 600ml of 0.1% chemically pure NaOH solution.

Add Ca(OH)2 reagent. Reach supersaturation. The liquid level shall be more than 10mm

above the surface of the test piece. Continuously immerse for (168±2)h. Take out. Dry

it. Immerse in acetone for 5s. Take out. Place for 5min. Then weigh the mass (m2).

Cal...

Get QUOTATION in 1-minute: Click JC/T 2428-2017

Historical versions: JC/T 2428-2017

Preview True-PDF (Reload/Scroll if blank)

JC/T 2428-2017: Non-curable rubber modified asphalt coating for waterproofing

JC/T 2428-2017

JC

BUILDING MATERIALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 91.120.30

Q 17

File No.: 61689-2018

Non-curable rubber modified asphalt coating for

waterproofing

非固化橡胶沥青防水涂料

ISSUED ON: NOVEMBER 07, 2017

IMPLEMENTED ON: APRIL 01, 2018

Issued by: Ministry of Industry and Information Technology of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Marking ... 6

5 General requirements ... 6

6 Technical requirements ... 6

7 Test methods ... 7

8 Inspection rules ... 14

9 Marks, packaging, transportation and storage ... 16

Non-curable rubber modified asphalt coating for

waterproofing

1 Scope

This document specifies the terms and definitions, marking, general requirements,

technical requirements, test methods, inspection rules and signs, packaging,

transportation and storage of non-curable rubber modified asphalt coating for

waterproofing (hereinafter referred to as non-curable waterproof coating).

This Standard applies to non-curable rubber modified asphalt coating for waterproofing,

which is used for non-exposed waterproofing in construction engineering.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 267, Petroleum products - Determination of flash and fire points - Open cup

GB/T 3190-2008, Wrought aluminium and aluminium alloy - Chemical composition

GB 11614, Flat glass

GB/T 16777-2008, Test methods for building waterproofing coatings

JC/T 474-2008, Water-repellent admixture for mortar and concrete

JC/T 1068-2008, Waterproof materials for pitched roof - Underlayments of self-

adhering polymer modified bituminous

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 non-curable rubber modified asphalt coating for waterproofing

The waterproofing coating that takes rubber and asphalt as the main components, is

made by adding additives to keep sticky paste during the service life.

3.2 stress relaxation

After the product is melted, stir it and visually inspected.

7.4 Flash point

According to GB/T 267.

7.5 Solid content

Heat and melt the specimen in a watch glass according to the manufacturer's

instructions. Then carry out the test according to Chapter 5 of GB/T 16777-2008. The

heating temperature is (105±2)°C.

7.6 Bonding properties

7.6.1 Dry base

Carry out the test according to method B in Chapter 7 of GB/T 16777-2008. Heat and

melt the specimen on the surface of the mortar block according to the manufacturer's

requirements. After the specimen is prepared, under the standard test conditions, cure

for 24h and test. After the test, if there is no exposed part on the surface of the mortar

block, it shall be considered to be 100% cohesive failure.

7.6.2 Wet base

Soak the mortar block in water for 24h. Take it out. Use paper to wipe the water off the

surface. Prepare according to method B in Chapter 7 of GB/T 16777-2008. Heat and

melt the specimen on the surface of the mortar block according to the manufacturer's

requirements. After the specimen is prepared, under the standard test conditions, cure

for 24h and test. After the test, if there is no exposed part on the surface of the mortar

block, it shall be considered to be 100% cohesive failure.

7.7 Extensibility

7.7.1 Preparation of test piece

Butt two 120mm×50mm×(2~4)mm aluminum plates along the short side into a whole.

The gap between the two aluminum plates shall not be greater than 0.05mm. Heat and

melt the specimen to the aluminum plate as per the manufacturer's specifications. The

coating area between the two aluminum plates is 150mm×50mm. The thickness is (2.0

± 0.2) mm. Prepare 3 test pieces in total. Cure for 24h under the standard test conditions.

7.7.2 Test steps

Clamp the test piece in the center of the grip of the tensile machine. It cannot be twisted

or deformed. Record the value L0 indicated by the pointer of the extended ruler at this

time. Start the pulling machine. The pulling speed is 10mm/min. Pull the test piece until

the crack cracks or shrinks to 10mm from the edge of the test piece. Record the value

L1 indicated by the pointer of the extension ruler at this time, accurate to 1mm.

7.10.2 Extensibility

Prepare the test piece according to 7.7.1 from the processed specimen. Test according

to 7.7.2. The result is calculated according to 7.7.3.

7.10.3 Low temperature flexibility

Test the processed sample in accordance with 7.8.

7.11 Acid resistance

7.11.1 Extensibility

7.11.1.1 Preparation of test piece

Prepare 3 test pieces according to 7.7.1. The substrate is a 120mm×50mm×4mm glass

plate or other suitable substrate.

7.11.1.2 Test steps

Put the prepared test piece into 600ml of 2% chemically pure H2SO4 solution. The liquid

level shall be more than 10mm above the surface of the test piece. Continuously

immerse for (168±2)h. Place for 4h under the standard test conditions. Observe whether

the surface of the specimen changes. Test according to 7.7.2. Calculate the result in

accordance with 7.7.3.

7.11.2 Mass change

7.11.2.1 Test steps

Heat, melt and scrape the specimen onto a 100mm×100mm×4mm glass plate. The

coating area is 100mm×80mm. The thickness is (2.0±0.2)mm. Place for 24h under the

standard test conditions. Weigh the mass (m1). Put into 600mL of 2% chemically pure

H2SO4 solution. The liquid level shall be more than 10mm above the surface of the test

piece. Continuously immerse for (168±2)h. Take out. Control it dry. Immerse in acetone

for 5s. Take out and place for 5min. Then weigh the mass (m2).

7.11.2.2 Result calculation

The mass change rate is calculated according to formula (2):

Where,

ΔM - The mass change rate, %;

m0 - The mass of the glass plate, in grams (g);

m1 - The mass of the specimen before soaking, in grams (g);

m2 - The mass of the specimen after soaking, in grams (g).

Take the arithmetic mean of 2 parallel tests as the test result. The calculation result is

accurate to 0.1%.

7.12 Alkali resistance

7.12.1 Extensibility

7.12.1.1 Preparation of test piece

Prepare 3 test pieces according to 7.7.1. The substrate is a 120mm×50mm×4mm glass

plate or other suitable substrate.

7.12.1.2 Test steps

Put the prepared test piece into 600mL of 0.1% chemically pure NaOH solution. Add

Ca(OH)2 reagent. Reach supersaturation. The liquid level shall be more than 10mm

above the surface of the test piece. Continuously immerse for (168±2)h. Take out. Place

for 4h under standard test conditions. Observe whether the surface of the specimen

changes. Then test according to 7.7.2. Calculate the result in accordance with 7.7.3.

7.12.2 Mass change

Heat, melt and scrape the specimen a 100mm×100mm×4mm glass plate. The coating

area is 100mm×80mm. The thickness is (2.0±0.2)mm. Place for 24h under standard test

conditions. Weigh the mass (m1). Put in 600ml of 0.1% chemically pure NaOH solution.

Add Ca(OH)2 reagent. Reach supersaturation. The liquid level shall be more than 10mm

above the surface of the test piece. Continuously immerse for (168±2)h. Take out. Dry

it. Immerse in acetone for 5s. Take out. Place for 5min. Then weigh the mass (m2).

Cal...

Share